POLA_24803_sm_suppinfo

advertisement

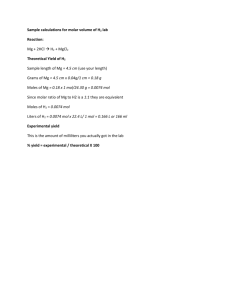

Journal of Polymer Science Part A: Polymer Chemistry Supporting information for: UCST switchable micelles based on polystyrene-blockpoly(methyl acrylate) block copolymers Aydin Can,1,2,3 Stephanie Hoeppener,1,2,3 Pierre Guillet,4,5 Jean-François Gohy,4 Richard Hoogenboom,1* Ulrich S. Schubert1,2,3* 1. Laboratory of Macromolecular Chemistry and Nanoscience, Eindhoven University of Technology, Den Dolech 2, 5612 AZ Eindhoven, The Netherlands 2. Dutch Polymer Institute (DPI), John F. Kennedylaan 2, 5612 AB Eindhoven, The Netherlands 3. Laboratory of Organic and Macromolecular Chemistry (IOMC) and Jena Center for Soft Matter (JCSM), Friedrich-Schiller-University Jena, Humboldtstrasse 10, 07743 Jena, Germany 1 4. Institute of Condensed Matter and Nanosciences (IMCN), Unité de Chimie des Matériaux Inorganiques et Organiques (CMAT), Université catholique de Louvain, Place L. Pasteur 1, B-1348 Louvain-la-Neuve, Belgium 5. Laboratoire de Chimie Bioorganique et des Systèmes Moléculaires Vectoriels (EA 932), Université d’Avignon et des Pays de Vaucluse, 33 rue Louis Pasteur, 84000 Avignon, France Instrumentation 1 H-NMR spectra were recorded on a Varian AM-400 spectrometer using deuterated chloroform (CDCl3) as solvent. Chemical shifts are reported in ppm relative to TMS or residual solvent signals. Size exclusion chromatography (SEC) was measured on a Shimadzu system equipped with a SCL-A10 system controller, a LC-10AD pump, a RID-10A refractive index detector, a SPD-10A UV detector at 254 nm, and a PLgel 5 μm Mixed-D column at 50 °C utilizing a chloroform:triethylamine:2-propanol (94:4:2) mixture as eluent at a flow rate of 1 mL/min. The molar masses and the molar mass distribution of the prepared polymers were calculated using poly(styrene) and poly(methyl methacrylate) standards. MALDI-TOF MS measurements were performed with an Ultraflex III TOF/TOF (Bruker Daltonics, Bremen, Germany) mass spectrometer equipped with a Nd:YAG laser and a collision cell. All spectra were measured in the positive ion mode. The instrument was calibrated prior to each measurement with an external PMMA standard H(CH2CCH3COOCH3)nH + Na+ (measured with sodium iodide) from PSS in the required measurement range. MS data were processed using the software FlexAnalysis, PolyTools 1.0 and an isotope pattern calculator from Bruker Daltonics and Data Explorer software. For the sample preparation, the polymers (10 mg/mL) were dissolved in THF, DCTB in chloroform (20 mg/mL) were used, and NaI dissolved in chloroform was used as the doping salt in analysis. The dried-droplet spotting technique (matrix and analyte previously mixed together) as applied. For each sample 1 µL of the mixture was spotted onto the target plate. 2 Experimental procedures for polymer synthesis General procedure for the solution ATRP of homo and block (co)polymers The reaction flasks, syringes and stirring bars were dried overnight at 105 °C and purged with argon gas while cooling to ambient temperature prior to use. The polymerization was carried out in a microwave vial using anisole as solvent. The CuBr was weighed into the vial and the reaction vial with a stirring bar was sealed with rubber cap and purged with argon for 15 minutes. Subsequently, the monomer, anisole and the PMDETA ligand were mixed in a second vial and transferred into the reaction vial by syringe. The resulting mixture was stirred and bubbled with argon for 15 minutes before the vial was immersed into a preheated oil bath. The initiator was introduced into the reaction vial by a micro-syringe. When using macroinitiators, the polymer was dissolved in solvent before addition to reaction vial. Polymerizations were conducted under argon at the desired temperature. The reaction mixtures were initially light green and turned from green to dark green in time. The overall mixtures were heterogeneous during the polymerization having some visible small copper particles close to the glass. During the polymerization, samples were taken in order to analyze by GC and SEC. The final products were precipitated into ice-cold methanol. For the catalyst removal, the products were dissolved in dichloromethane and passed through a basic aluminum oxide column prepared with the same solvent. The product that eluted over the column was reprecipitated into ice-cold methanol and dried under reduced pressure at 40 ºC overnight. For the characterization; all polymers were dissolved in chloroform and analyzed by SEC, 1H-NMR spectroscopy and MALDI-TOF MS. PS50: Styrene (26 g, 0.25 mol), 25 mL anisole (0.1 M), CuBr (359 mg, 2.5 mmol) and PMDETA (523 µL, 2.5 mmol) and EBIB (367 µL, 2.5 mmol) were used according to the general procedure. The polymerization was conducted at 110 °C for 16.5 hours. 9.2 g polymer (93% yield) was obtained after column purification. Conversion = 38%; Mn = 5,400 g/mol; Mw = 5,700 g/mol; PDI = 1.05. PS100: Styrene (26 g, 0.25 mol), 25 mL anisole (0.1 M), CuBr (179 mg, 1.25 mmol) and PMDETA (261 µL, 1.25 mmol) and EBIB (183 µL, 1.25 mmol) were used according to the general procedure. The polymerization was conducted at 110 °C for 41 hours. 12.4 g polymer (91% yield) was obtained after column purification. Conversion = 53%; Mn = 9,600 g/mol; Mw = 10,400 g/mol; PDI = 1.08. PMA60: Methyl acrylate (17.22 g, 0.2 mol), 15 mL anisole (0.1 M), CuBr (286 mg, 2 mmol) and PMDETA (418 µL, 2 mmol) and EBIB (294 µL, 2 mmol) were used 3 according to the general procedure. The polymerization was conducted at 90 °C for 5.5 hours. 8.3 g polymer (94% yield) was obtained after column purification. Conversion = 51%; Mn =5,000 g/mol; Mw = 5,400 g/mol; PDI = 1.07. PMA120: Methyl acrylate (17.22 g, 0.2 mol), 15 mL anisole (0.1 M), CuBr (143 mg, 1 mmol) and PMDETA (209 µL, 1 mmol) and EBIB (147 µL, 1 mmol) were used according to the general procedure. The polymerization was conducted at 90 °C for 9 hours. 9.1 g polymer (93% yield) was obtained after column purification. Conversion = 57%; Mn =10,500 g/mol; Mw = 11,200 g/mol; PDI= 1.07. PMA60-b-PS50: Styrene (2.6 g, 0.025 mol), 5 mL anisole, CuBr (14 mg, 0.1 mmol) and PMDETA (21 L, 0.1 mmol) and poly(methyl acrylate) (PMA60) (500 mg, 0.1 mmol) were used according to the general procedure. The polymerization was conducted at 110 °C for 8 hours. 1.1 g block polymer was obtained after column purification. Mn = 9,600 g/mol; Mw = 10,600 g/mol; PDI= 1.09. Mn (NMR) = 8,600 g/mol; ratio of PMA to PS is 66:41. PMA120-b-PS100: Styrene (4.17 g, 0.04 mol), 5 mL anisole, CuBr (29 mg, 0.2 mmol) and PMDETA (42 L, 0.2 mmol) and poly(methyl acrylate) (PMA120) (2.0 g, 0.2 mmol) were used according to the general procedure. The polymerization was conducted at 110 °C for 22 hours. 2.8 g (88% yield) block polymer was obtained after column purification. Conversion= 28%; Mn =20,000 g/mol; Mw= 22,000 g/mol; PDI= 1.11. Mn (NMR) = 20,000 g/mol; ratio of PMA to PS is 117:91. PS50-b-PMA120: Methyl acrylate (6.89 g, 0.08 mol), 5 mL anisole, CuBr (57 mg, 0.4 mmol) and PMDETA (84 L, 0.4 mmol) and polystyrene (PS50) (1.0 g, 0.4 mmol) were used according to the general procedure. The polymerization was conducted at 90 °C for 27 hours. 3.2 g (92% yield) block polymer was obtained after column purification. Conversion = 36%; Mn = 13,800 g/mol; Mw = 16,500 g/mol; PDI = 1.19. Mn (NMR) = 12,300 g/mol; ratio of PS to PMA is 59:88. PS100-b-PMA60: Methyl acrylate (3.44 g, 0.04 mol), 5 mL anisole, CuBr (29 mg, 0.2 mmol) and PMDETA (42 L, 0.2 mmol) and (PS100) (2.0 g, 0.1 mmol) were used according to the general procedure. The polymerization was conducted at 90 °C for 12 hours. 2.5 g (90% yield) block polymer was obtained after column purification. Conversion = 23%; Mn = 15,000 g/mol; Mw = 17,000 g/mol; PDI= 1.12. Mn (NMR) = 13,700 g/mol; ratio of PS to PMA is 100:50. 4 Figure S1 SEC traces of the investigated block copolymers. 5