AN OPTIMIZATION APPROACH TO HEAT INTEGRATION WITH

advertisement

A PROPERTY-INTEGRATION APPROACH TO THE

DESIGN AND INTEGRATION OF ECO-INDUSTRIAL

PARKS

Eva M. Lovelady and Mahmoud M. El-Halwagi

Department of Chemical Engineering, Texas A&M University

College Station, TX 77843-3122, USA

Irene M.L. Chew, Denny K.S. Ng and Dominic C.Y. Foo

Department of Chemical and Environmental Engineering

University of Nottingham Malaysia, Broga Road, 43500 Semenyih, Selangor, Malaysia

Raymond R. Tan

Center for Engineering and Sustainable Development Research, De La Salle University-Manila

2401 Taft Avenue, 1004 Manila, Philippines

Abstract

An eco-industrial park (EIP) represents an infrastructure that provides integrative services to multiple

industrial processes. The primary objective is to induce integration of materials exchange, utility

sharing, waste treatment, and discharge. Because of the high level of interaction provided by the EIP, a

system integration approach must be adopted to design the common infrastructure and to make decisions

on the optimal allocation of streams. The objective of this work is to develop a systematic approach to

the design of EIPs using a property-integration framework. Interfaces among the various processing

facilities are characterized in terms of key properties. Next, property integration techniques are used to

synthesize the EIP. A structural representation is used to embed potential configurations of interest. The

representation accounts for the possibilities of direct reuse/recycle, material (waste) exchange, mixing

and segregation of different streams, separation and treatment in interception units, and allocation to

process users (sinks). A case study is solved to illustrate the applicability of the devised approach.

Keywords

Eco-industrial parks, Property integration, Process integration, Sustainability

Introduction

The concept of an eco-industrial park (EIP) is gaining

much interest as an effective organizational framework

and operating facilities involving a cluster of several

processes that share a common infrastructure that is

designed and operated primarily to induce integration of

materials exchange, waste treatment, and discharge. A

well-designed EIP provides numerous ecological and

economic benefits (Gibbs and Deutz, 2007). They also

lead to benefits for the local governments by generating

more revenues and taxes and by lowering the burden on

local treatment facilities (Lowe, 1997). Recently, there

have been many successful cases of well-functioning EIPs.

A commonly-referenced EIPs is Kalundborg Park, located

in Denmark. Other successful examples span in various

parts of the world.

Recent research contributions have been made in the

area of locating and designing EIPs. Chew et al. (2008) as

well as Lovelady and El-Halwagi (2009) developed an

integrated framework and an optimization formulation for

the design of a multi-facility EIP with composition-based

constraints. Fernandez and Ruiz (2009) developed a

mathematical model that can be used to locate EIPs.

Sendra et al. (2007) used a framework of materials flow

analysis to keep track of the various inputs and outputs of

the EIP. Zhao et al. (2007) developed a dynamic model to

simulate and retrofit an EIP in Changchun Economic and

Technological Development Zone in China. Spriggs et al.

(2004) developed a framework to characterize the

challenges associated with EIPs and grouped them into

two classes: technical/economic challenges and

organizational/commercial/political challenges.

p

p p, j p

p

max

p, j

j, p

(1)

max

where p min

p , j and p p , j are given lower and upper

bounds on permissible values of the pth property

entering the jth sink.

A set of process waste streams referred to as sources:

SOURCES = {i| i = 1,2, …, Nsources}. Each source has

a given flow rate, Fi, and properties pp,i.

The objective is to develop a systematic procedure for

the optimal design of an EIP that treats various sources

and assigns them to different sinks. The EIP requires the

installation

of

a

set

of

interception

units:

INTERCEPTORS = {k | k =1,2, …, NInt} to be used for

treating the effluents by modifying the targeted properties

to allow them to be assigned to various process sinks for

further recovery or environmental discharge. The

interceptors can be either a fixed outlet concentration or

removal types. Available for service are f th fresh (external)

resources that can be purchased to supplement the use of

process sources.

where p p,i and p p are linearized operators on the

property p of stream i and the mixture property p p ,

respectively, and xi is the fractional contribution of stream

i of the total mixture flow rate.

i=1

j=1

i=2

j=2

Plant A

Int 1

Int 2

Fresh

resource

EIP

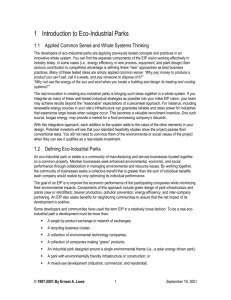

A source-interception-sink superstructure (Figure 1) is

used here, analogous to the composition-based EIP

framework developed by Chew et al. (2008) as well as

Lovelady and El-Halwagi (2009). Each source is split into

several fractions that are fed to interceptors (Int k) which

adjust properties. Intercepted streams are allowed to mix

and be allocated to process sinks or to final discharge.

j=3

i =3

j = Nsinks

i = Nsources

Figure 1. Superstructure for property-based EIP

The optimization objective is to minimize the total

annualized cost of the interception devices in the EIP and

the cost of fresh resource(s). Therefore, the objective

function is given by:

Minimize total annualized cost =

N int

F

k 1

Int

k

C kInt

N fresh

F

f 1

Fresh

f

(3)

C Fresh

f

where CkInt is the unit cost associated with the kth

interceptor (including fixed capital cost) and C Fresh

is the

f

unit cost of the fth fresh resource. FkInt is the total

intercepted flow rate at interceptor k while FfFresh is the

total amount of the fth fresh resource.

The model is subject to the following constraints:

Distribution of sources for reuse/recycle,

interception devices and final waste discharge:

Fi

Optimization Model

(2)

i

Plant B

Given a set of multiple processes with the following:

A set of process sinks (units): SINKS = {j | j = 1,2, …,

Nsinks}. Each sink requires a certain flow rate, Gj and a

given constraint on inlet property for each property p:

min

p, j

p p xi p p ,i

Waste

discharge

Problem Statement

Before proceeding to the mathematical formulation, a

mixing rule is needed to define all possible mixing patterns

among individual properties. One such form for mixing is

the following expression (Shelley and El-Halwagi, 2000):

N int

N sinks

H

j 1

i, j

wi , k wiwaste

i∈{1…NSources}

to

(4)

k 1

where Hi,j is the reuse/recycle flow rate between the ith

source and jth sink, wi,k is the ith source entering the kth

interceptor and wiwaste is the waste flowrate discharged

from the ith source to the environment without interception.

Material balance for the mixed sources before

entering the kth interceptor and its property mixing rules:

Wk

N sources

w

i ,k

k ∈ {1…Nint}

(5)

k, p

(6)

i 1

N sources

w

Wk ( p p,k )

i ,k ( p p ,i )

j, p

max

Sink constraints: p min

p, j p p, j p p, j

(1)

This is a nonlinear program (NLP) that can be solved

to determine the allocation of streams and design of the

EIP. A property-based water minimization case study is

next used to illustrate the proposed method.

i 1

Water Minimization Case Study

Distribution of intercepted streams from the EIP:

Wk

N sinks

g

k

wkwaste

k, j

(7)

j 1

where Wk is the intercepted flowrate, and gk,j and wkwaste are

the flow rate of the kth source fed to the jth sink and

wastewater discharge to the environment, respectively.

Mixing of the distributed streams before the jth sink

and its property mixing rules:

Gj

N sources

H

i 1

i, j

N fresh

F

f

N int

f ,j

j

gk, j

Two industrial wafer fabrication plants that possess

similar process water characteristics, i.e. resistivity and

heavy metal content are located within an EIP. Table 1

tabulates the process sinks and sources for both plants,

adapted from Ng et al. (2009) and Gabriel et al. (2003),

respectively. Resistivity is taken as the main characteristic

in evaluating water reuse/recycle opportunity between

both plants and ultra pure water (UPW) is used to

supplement the use of process sources (with a unit cost of

$2/t). The mixing rule for resistivity is given as follows:

(El-Halwagi, 2006).

(8)

1

k 1

R

G j ( p p , j )

N sources

H

i 1

p p ,i

i, j

N fresh

F

p Fresh

p, f

f,j

(9)

f

N int

g k , j ( p int

p ,k )

j

k 1

where Ff,j is the flow rate of the fth fresh resource, while

and pint

are the properties for the fth fresh resource

p Fresh

p ,k

p, f

and the kth intercepted source, respectively.

The total flow rate of the fth fresh resource is given as:

j (10)

F Fresh F

f

R

xi

i

(11)

i

Two interceptors with fixed resistivity value and

heavy metal concentration are given for use in the EIP, to

treat process sources either for further reuse/recycle or

environmental discharge. Each of them has different

performance and unit treatment cost, as shown in Table 2.

Meanwhile, heavy metal concentration is chosen as the

main characteristic for final discharge and is given as 2

ppm.

f,j

j

Table 1. Limiting data for case study

Plant

Process

Flow rate

(t/h)

Resistivity, R (MΩ)

Lower

Upper

bound

bound

Operator, ψ( MΩ-1)

Lower

Upper

bound

bound

Heavy metal

concentration

(ppm)

(Sink)

Wet (SK1)

Litography (SK2)

CMP (SK3)

Etc (SK4)

Plant A

(Ng et al., 2009)

500

450

700

350

7

8

10

5

18

15

18

12

0.1429

0.1250

0.1000

0.2000

0.0556

0.0667

0.0556

0.0833

-

(Source)

Wet I (SR1)

Wet II (SR2)

Litography (SR3)

CMP I (SR4)

CMP II (SR5)

Etc (SR6)

250

200

350

300

200

280

1

2

3

0.1

2

0.5

1

0.5

0.3333

10

0.5

2

5

4.5

5

10

4.5

5

(Sink)

Plant B

(Gabriel et al.,

2003)

Wafer Fab (SK5)

CMP (SK6)

182

159

16

10

20

18

0.0625

0.1

0.0500

0.0556

-

(Source)

50 % spent (SR7)

100 % spent (SR8)

Ultra pure water (UPW)

227

227

?

8

2

18

0.1250

0.5000

0.0556

5

11

-

Table 2. Performance and unit cost for interceptor

Outlet

concentration of

Interceptor

heavy metal

(ppm)

I

2

II

2

References

Resistivity Interception

(MΩ)

cost ($/t)

5

8

0.9

1.5

It is further assumed that the EIP is operated for 8760

hours per annum. The CPLEX linear solver of GAMS v2.5

was used to solve the optimization model. Minimum total

annualized cost is determined at $ 28.69 million/year,

associated with a total UPW flow rate of 473 t/h and

discharge effluent of 166 t/h.

Fig. 2 shows the optimized EIP design for the case

study. It is observed that, while both interceptors

regenerate water for further reuse/recycle in Plant A and

B, interceptor I also treat wastewater for final discharge.

Note that there is one cross-plant pipeline that connects

between SR7 of Plant B and SK1 of Plant A.

Conclusion

This paper has presented a structural representation

and optimization formulation for the design of EIPs with

property-based constraints. Plants are allowed to exchange

streams, intercept them, and discharge unused portions. It

is observed that processes participating in an EIP are likely

to gain savings in the forms of cost reduction for fresh

resource(s) and overall reduction in waste discharge as

well as treatment through material exchange and common

infrastructure for interception and treatment. A case study

was solved to illustrate these points.

Chew, I. M. L., Ng, D. K. S., Foo, D. C. Y., Tan, R. R., Majozi,

T., Gouws, J. (2008). Synthesis of Inter-Plant Water

Network. Ind. Eng. Chem. Res., 47 (23), 9485-9496.

El-Halwagi, M.M. (2006). Process Integration, Amsterdam:

Elsevier.

Fernandez, I., Ruiz, M. C. (2009). Descriptive Model and

Evalutaion System to Locate Sustainable Industrial

Areas. J. Clean. Prod., 12, 87-100.

Gabriel, F. B., Harell, D. A., Dozal, E., El-Halwagi, M. M.

(2003). Pollution Targeting via Functionality Tracking,

AICHE Spring Meeting. New Orleans.

Gibbs, D., Deutz, P. (2007). Reflections on Implementing

Industrial Ecology through Eco-Industrial Park

Development. J. Clean. Prod., 15, 1685-1695.

Lovelady, E. M., El-Halwagi, M. M. (2009). Design and

Integration of Eco-Industrial Parks for Managing Water

Resources. Env. Prog. (article in press)

Lowe, E. A. (1997). Creating By-Product Resource Exchanges:

Strategies for Eco-Industrial Parks. J. Clean. Prod., 5

(1-2), 57-65.

Ng, D. K. S., Foo, D. C. Y., Tan, R. R., Tan, Y. L., Pau, C. H.

(2009). Automated Targeting for Conventional and

Bilateral Property-Based Resource Conservation

Network.

Chem.

Eng.

J.

(doi:

10.1016/j.cej.2008.10.003).

Sendra, C., Gabarrell, X., Vincent, T. (2007). Material Flow

Analysis Adapted to an Industrial Area. J. Clean.

Prod., 15, 1706 – 1715.

Shelley, M. D., El-Halwagi, M. M. (2000). Componentless

Design of Recovery and Allocation Systems: A

Functionality-Based Clustering Approach. Comput.

Chem. Eng., 24, 2081–2091.

Spriggs, H. D., Lowe, E. A., Watz, J., Lovelady, E. M., ElHalwagi, M. M. (2004). Design and Development of

Eco-Industrial Parks. AIChE Spring Meeting. New

Orleans.

Zhao, Y., Shang, J. C., Chen C., Wu, H. (2007). Simulation and

Evaluation of the Eco-Industrial System of Changchun

Economic and Technological Development Zone,

China. Environ Monit Assess. 139, 339-349.

252

163.8

SK3

SK2

450

448

SR1

85.4

SR2

200

SR3

350

SR4

300

SK1

UPW

SK4

255.4

469.3

635.4

200

SR6

280

Interceptor I

k =1

SK6

166.1 t/h

101.8

125.2

SR7

18.2

1153.4

Interceptor II

k=2

164.6

SR5

SK5

Discharge

effluent

350

119.3

57.2

227

944.6

Plant A

EIP

Figure 2. EIP design for case study

Plant B

SR8