biaxial (plane) stress situation

BIAXIAL (PLANE) STRESS SITUATION

APPLYING MAXIMUM SHEAR STRESS THEORY

THE CASE OF TRI-AXIAL STRESS WHEN YIELDING OCCURS

The MAXIMUM SHEAR STRESS theory of failure states:

When Yielding occurs in any material, the maximum shear stress at the point of failure equals or exceeds the maximum shear stress when yielding occurs in the tension test specimen .

MAXIMUM SHEAR STRESS THEORY

BI-AXIAL (PLANE) STRESS SITUATION

Plane stress situation

The plane stress situation is the stress situation in which the stress elements are

x

,

y

, and

xy

, and the stresses on the z-axis are zero,

Principal stresses in biaxial stress situation

In such a plane stress situation, the principal stresses are expressed in terms of the stress elements by the expression

1

=

x

2

y

+

x

2

y

2

xy

2

(1)

2

=

x

2

y

-

x

y

2

2

xy

2

(2)

3

0 The bi-axial (plane) stress situation (3)

The three principal stresses above describe the bi-axial stress situation

PRINCIPAL STRESSES AND PLANE STRESS ELEMENTS

THE BI-AXIAL STRESS SITUATION

Maximum shear stress at a location of the element

The extreme values of shear stresses

12

,

13

,

23

, in each of the three principal planes are then given by the expressions:

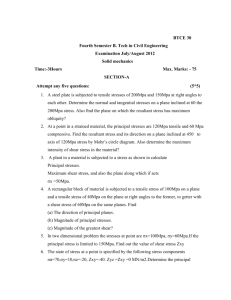

University of Nairobi Engineering design II

12

1

2

,

13

1

3

,

23

2

3

2 2 2

Expressing the principal stresses in the order of magnitude and sign

1

2

3

Then the maximum shear stress is given by

13

1

3

2

MAXIMUM SHEAR STRESS IN TERMS OF PLANE STRESS ELEMENTS

This is given by the expression

max

x

y

2

2

xy

2

PLANE STRESS SITUATION WITH

y

0

Substituting for

y

0 into the equation for maximum shear stress yields

max

x

2

0

2

xy

2

=

2 x

2

xy

2

=

4 x

2

xy

2

x

2

max

4

xy

2

1

=

2

x

2

4

xy

2

SOLID CIRCULAR SHAFT SUBJECT TO BENDING AND TORSION

COMBINED TORSION AND BENDING OF SHAFT

In the case of combined torsion and bending, the stress elements in the plane stress situation are:

x

y

normal

0 stress due to bending

32 M

d

3

xy

shear stress due to torque

16 T

d

3

Nyangasi Page 2 of 4 30 January 2005

University of Nairobi Engineering design II

APPLYING MAXIMUM SHEAR STRESS THEORY OF FAILURE

PLANE STRESS SITUATION WITH

y

0

In this situation, the equation maximum shear stress becomes

max

x

2

xy

2

4

Substituting for

x

,

y

y

0 ,

,

1

=

2

x

2

4

xy

2 and

xy

in equation for equivalent stress with

Yields

x

xy

Normal

Shear stress stress due due to to bending

32 M

d

3 torque

16 T

d

3

max

1

2

x

2

4

xy

2

1

2

32 M

d

3

2

4

16 T

d

3

2

(1)

max

16

d

3

M

2

T

2

(2)

DESIGN OF A TRANSMISSION SHAFT

SELECTION OF MATERIAL FOR PART

Material selected is medium carbon steel, to British Standard specification BS

970:080M040(H&T), whose mechanical properties are:

(a) Tensile yield strength S y

385 Mpa

(b) Ultimate tensile strength S ut

625

775 Mpa

(c) Elongation % =16%

(d) Hardness number=179-229 HB

The material is a ductile material, having an elongation % of 16 %>5%.

Nyangasi Page 3 of 4 30 January 2005

University of Nairobi Engineering design II

EXTERNAL LOAD CARRIED BY TRANSMISSION SHAFT

CONSISTS OF TORQUE LOAD T

32 .

9 N

m

32900 N

BENDING MOMENT M max

16 .

5 N

m

16500 N

mm

mm

From (2), Maximum shear stress

max

16

d

3

M

2

T

2

But the same maximum shear stress theory predicts that S sy

S

2 y

Where

S sy

Shear strength of the material

S y

Yield strength of the material in tension

Design equation then becomes

max

16

d

3

M

2

T

2

=

S sy f .

s .

2 *

S y f .

s .

OR d

3

16

M

2

T

2

*

2 *

S y f .

s .

Substituting for working (design, allowable) stress

w

S y f .

s .

d

3

16

M

2

T

2

*

2 *

S y f .

s .

; OR d

3

32

w

M

2

T

2

Where

Substituting the TORQUE and BENDING MOMENT loads into design equation d

3

32

16500

32900

2

* f .

s .

S y

Substituting for yield strength of chosen material and the factor of safety

Factor of safety =2.5 and Tensile yield strength S y

385 Mpa d

3

32

d

13 .

45

16500

32900

2 mm .

2 .

5

*

385

Nyangasi Page 4 of 4 30 January 2005