Shell and Tube Exchanger

advertisement

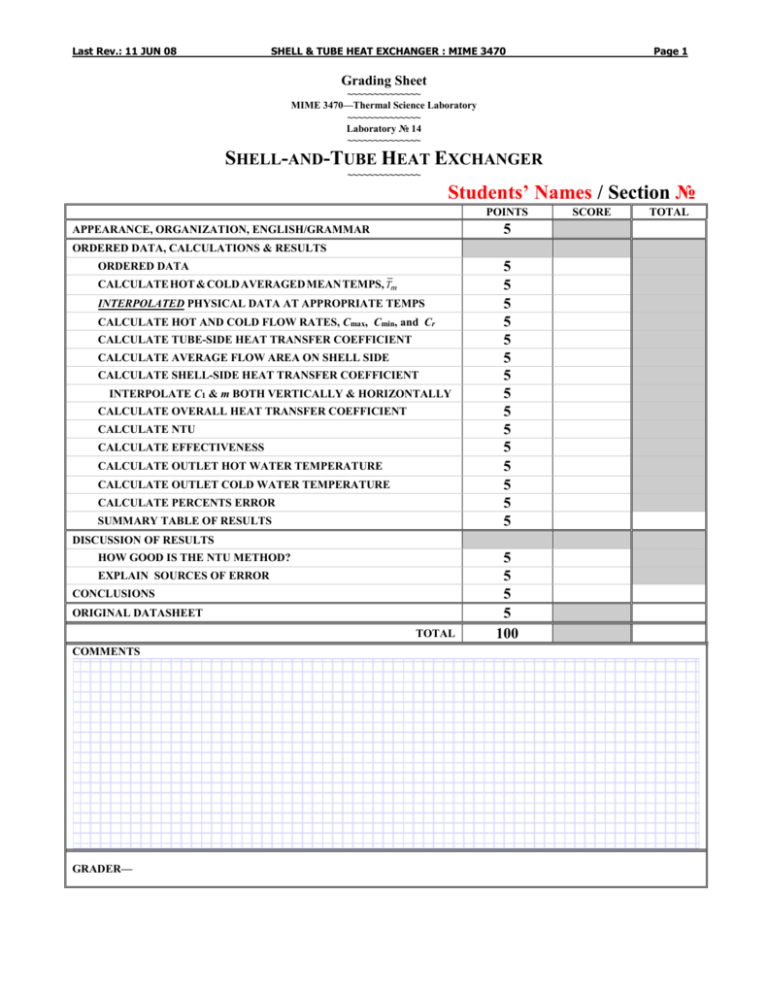

Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 Page 1 Grading Sheet ~~~~~~~~~~~~~~ MIME 3470—Thermal Science Laboratory ~~~~~~~~~~~~~~ Laboratory № 14 ~~~~~~~~~~~~~~ SHELL-AND-TUBE HEAT EXCHANGER ~~~~~~~~~~~~~~ Students’ Names / Section № POINTS 5 APPEARANCE, ORGANIZATION, ENGLISH/GRAMMAR ORDERED DATA, CALCULATIONS & RESULTS ORDERED DATA CALCULATE HOT & COLD AVERAGED MEAN TEMPS, Tm INTERPOLATED PHYSICAL DATA AT APPROPRIATE TEMPS CALCULATE HOT AND COLD FLOW RATES, Cmax, Cmin, and Cr CALCULATE TUBE-SIDE HEAT TRANSFER COEFFICIENT CALCULATE AVERAGE FLOW AREA ON SHELL SIDE CALCULATE SHELL-SIDE HEAT TRANSFER COEFFICIENT INTERPOLATE C1 & m BOTH VERTICALLY & HORIZONTALLY CALCULATE OVERALL HEAT TRANSFER COEFFICIENT CALCULATE NTU CALCULATE EFFECTIVENESS CALCULATE OUTLET HOT WATER TEMPERATURE CALCULATE OUTLET COLD WATER TEMPERATURE CALCULATE PERCENTS ERROR SUMMARY TABLE OF RESULTS 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 DISCUSSION OF RESULTS HOW GOOD IS THE NTU METHOD? EXPLAIN SOURCES OF ERROR CONCLUSIONS ORIGINAL DATASHEET TOTAL COMMENTS d GRADER— 5 5 5 5 100 SCORE TOTAL Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 MIME 3470—Thermal Science Laboratory ~~~~~~~~~~~~~~ Laboratory №. 14 SHELL-AND-TUBE HEAT EXCHANGER ~~~~~~~~~~~~~~ LAB PARTNERS: NAME NAME NAME SECTION № EXPERIMENT TIME/DATE: NAME NAME NAME TIME, DATE IMPORTANT—When using the Heat Exchanger Performance Test Bench, there are some important items to remember for your safety and the safety of others. they make many passes. This experiment employs a shell-and-tube heat exchanger consisting of two tube passes and one shell pass. THEORY: HEAT EXCHANGER ANALYSIS Thermodynamics and the First Law dictate the overall energy transfer in a heat exchanger. There are two widely used methods of heat exchanger analysis, the NTU-Effectiveness method and the Log-Mean-Temperature-Difference (LMTD) method. These are briefly discussed below. Log-Mean-Temperature-Difference (LMTD) Method For a heat exchanger between two fluids with given inlet and outlet temperatures, there are three equations for the rate of heat transfer, Q, Q = Rate of heat transfer, W = m 1c p T1,i T1,o 1. Make sure the proper inlet and outlet valves are open before the heat exchanger is operated. Failure to do this will pressurize the system and rupture the heat exchanger seams. As a rule of thumb, do not close any of the outlet ball valves more than half way. In particular, make sure the outlet valves that allow the water to go to the drain are open prior to turning on water. m 2c p T2,i T2,o 2 T1,i T2,o T1,o T2,i UA 1 = = T1,i T2,o ln T1,o T2,i 2. For meaningful data, bleed taps will need to be opened and closed to allow air to escape while the experiment is going on. Outlet valves may be closed SLIGHTLY to help keep the heat exchanger full. OBJECTIVE of this experiment is to measure the two inlet temperatures and the mass flows through the shell and tubes, in order to predict the two outlet temperatures using the NTU method and compare these predicted values with actual measured outlet temperatures. INTRODUCTION—Many engineering applications involve a process of heat exchange between two fluids. Heat exchangers are devices used to promote the heat transferred between two fluids; e.g., a car radiator and the condenser units on air conditioning systems. Space heating, air conditioning, power production, and chemical processing are typical areas of application. There are many heat exchanger designs. The laboratory setup for this experiment contains three heat exchanger types: a shell-and-tube exchanger, a concentric tube exchanger, and a tube bank exchanger in cross flow. This particular experiment employs the shell-and-tube type heat exchanger (see Figure 1). A shell-and-tube heat exchanger is constructed of tubes that are attached on each end by a plate, called the tube sheet, through which the tubes pass. One fluid streams into the inlet of the heat exchanger, flows through the tubes, and exits through the tube sheet at the opposite end of the heat exchanger. Page 2 Tlm where, m j = mass flow rate of fluid j, kg/s cp j = specific heat of fluid j, J/(kgK) T = temperature, C i inlet o outlet U = overall heat transfer coefficient, W/(m2K) A = area of surface across heat transfer occurs, m2 For known specific heats, U, A, and entering temperatures, the three equations above can be solved for three unknowns—T1,o, T2,o, and Q —by successive substitution of one of the equations for Q onto another. It is a simple matter to use the log-mean-temperaturedifference method of heat exchanger analysis when the fluid inlet temperatures are known and the outlet temperatures are specified or readily determined from the energy balance expressions. The value of Tlm for the exchanger may then be determined. However, if only the inlet temperatures are known, use of the LMTD method requires an iterative procedure. In such cases, it is preferable to use an alternative approach, termed the NTU-Effectiveness method. NTU-EFFECTIVENESS METHOD—Often, when working with a given heat exchanger one must predict the outlet temperatures given the inlet temperatures. As the dimensions of the exchanger are known, the NTU-effectiveness method is a popular way to perform this task. This is an easy method to calculate the overall heat transfer rate, Q. The number of (heat) transfer units, NTU, is a dimensionless parameter which precipitates form the heat exchanger analysis and is defined as: NTU Figure 1—Schematic of shell-and-tube exchanger A shell encloses the internal volume where the tubes are housed. Another, fluid flows through the shell and heat is exchanged between the tube-side fluid and the shell-side fluid. In a power plant, most heat exchangers are of the shell-and-tube design. The number of passes commonly presents a further description of a shell-and-tube heat exchanger. A single pass means the fluid flows straight through the entire heat exchanger without changing direction and so, in this design, the fluid moves past the length of the heat exchanger only a single time. In a two-pass heat exchanger the fluid in the tubes goes in one end, flows to the other end, reverses direction then flows back to the same end that the fluid entered through a second set of tubes. Thus, the fluid travels the full length of the heat exchanger twice. Similarly, multiple pass heat exchangers are so named because where UA , C min (1) U – Overall heat transfer coefficient (W/m2K) A – Area of heat transfer (m2) C cp CC = m (2a) – Cold fluid heat capacity rate H cp CH = m (2b) C H – Hot fluid heat capacity rate Cmin = min(CC, CH) – Smaller of the two heat capacity rates (W/K) Cmax = max(CC, CH) – Larger of the two heat capacity rates (W/K) Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 Note that NTU is a function of geometric and material properties, and the mass flow rates. It does not include any fluid temperatures. Using the calculated NTU, the effectiveness of the heat exchanger, , can be calculated from tables where the effectiveness formulae for different heat exchanger arrangements can be found. In such tables, another dimensionless term that precipitates from the analyses appears. This is the heat capacity rate ratio, Cr = Cmin/Cmax. For a shell-and-tube exchanger with one shell pass and some multiple of two tube passes, the effectiveness is Hot water inlet thermometer Cold water inlet thermometer Cold water outlet thermometer 1 2 1/ 2 1 / 2 1 e NTU 1 C r 21 C r 1 C r2 . 2 1/ 2 NTU 1 C r 1 e Heat Exchanger Effectiveness—is defined as Q Actual rate of heat transfer actual Qmax Maximum possible rate of heat transfer that an exchanger of infinite heat transfer area would have if it had the same inlettemps, flow rates, & specific heats as actual case The maximum heat transfer occurs in the fluid with the least capacity to absorb or give off heat. This is the fluid with the minimum value of m C p = Cmin. If this fluid is the cold fluid, its Page 3 Distance between Tube Sheets, 16-1/8 (inside face to inside face) 5 Baffles, 1.2 thick. Equally spaced to form 6 chamber. 23 tube penetrations per baffle. 30 Tubes, each 0.25 diameter neglect wall thickness Hot water Shell: 5 OD outlet thermometer 4.5 ID The width of the flow course varies & thus the average velocity temperature cannot rise above the hot-side, inlet temperature. Alternately, if the fluid is the hot fluid, it cannot be cooled below the cold-side, inlet temperature. Thus, Q Qactual . actual Qmax m c p Thot,in Tcold,in min As the actual heat transfer is the same for both fluids—one gaining thermal energy and the other loosing an equal amount— the actual heat transfer rate is defined by both Qactual m c p TC,o TC,i and C Qactual m c p TH ,i TH ,o . H These last two relations yield the outlet temperatures desired. LABORATORY PROCEDURE 1. Verify the dimensions and features of Figure 2. 2. Generally, small flow rates will generate better results but may take longer to reach steady state. Also, do not let the air that comes out of entrainment accumulate in shell. Use bleed taps as needed. 3. For a hot water flow of about 15% of the maximum rotameter reading and a cold water flow of about 30%, take inlet and outlet temperatures of both flows until no further changes in temperature are noted. This is the steady-state condition—use only the associated flow rates and temperatures for calculations. DETAILED COMPUTATIONAL PROCEDURE The NTU method will be described using just one tube; but that single tube could represent an entire tube bundle. The NTU method calculation procedure for a shell-and-tube heat exchanger follows: 1. a. Determine cold and hot water flow rates, m H and m C (from rotameter readings), and their specific heats, c p and c p (look H C up values based on the average of the inlet and outlet temperatures). The units of mass flow, m , are kg/s and those of specific heat, cp, are J/(kgK). [NOTE: Some tables list specific heat as kJ/(kgK)—so always check units!!] ST SL = 0.475 ST = 0.548 SD = 0.548 SL SD Figure 2— Experimental apparatus with dimensional data b. Calculate a temperature specific energy flow known as the heat capacity rate, C, for both the cold and hot flows C cold m cold c pcold The larger of these is C max . C hot m hot c phot and the smaller C min c. Calculate the heat capacity rate ratio, Cr = Cmin/Cmax. 2. Calculate the heat transfer coefficients at the inside and outside surfaces of the tubes, hinside and houtside. These are used to compute the overall heat transfer coefficient, U. (See Figure 3) houtside hinside Figure 3—Heat transfer coefficients at inside and outside tube surfaces a. Flow Inside Tubes: Even though there are many tubes in the bundle and there are parallel and counter flows in this two-pass exchanger, the calculation may be performed by considering the flow in just one of the tubes WITH THE CAVEAT THAT one must account for the direction of the flow. That is, half of the tubes are associated with parallel flow and half the tubes are associated with counterflow. Thus, the mass flow in the equivalent tubes is m total tube- side flow m inside1 tube N 2 where, N = total number of tubes. Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 From simple flow relations, it is known that the velocity inside a single tube is m Vinside inside A where, A = cross sectional area of one tube. Given this velocity, a Reynolds number ( Re VinsideD ) can be computed to indicate whether the inside flow is laminar or turbulent. This will most likely be fullydeveloped, laminar flow. For such with constant surface temperature, Ts, and Pr ~ 0.6 : Nu D 3.66 where fluid properties are based on the mean (or bulk) temperature across a cross section, Tm. If the flow is fully developed, turbulent (Re 10,000), n 0.4, Ts Tm . Nu D 0.023 Re 4D/ 5 Pr n n 0.3, Ts Tm Tube-side fluid properties should be evaluated at the average of the mean temperatures, Tm Tm,i Tm,o 2 . b. Shell Flow Outside of Tubes: For the staggered tube arrangement of the experiment shown in Figure 4, use the following expression for the average Nusselt number 1/ 3 . Nu D 1.13C1 Re m D,max Pr (3) Use Table 1 to determine m and C1. Note in the report which values of m and C1 were used. This relation applies when there are more than 10 tubes in a bundle (NL 10), 2000 < ReD,max < 40,000 where ReD,max is defined below, and Pr 0.7. average mean temperature of the fluid, Tm , as defined above. the fluid moving form the A1 to the A2 planes. In this case, Vmax ST 2S D D Vavg , otherwise it occurs at A1 and Vmax ST ST DVavg . Note: The average velocity of flow over the tube is not constant as the shell is not wall-sided but circular. Thus, one needs to use some average value of area. To use the relations for staggered tube arrangements, a free-stream, shellside, fluid velocity must be determined. As the sides of the shell are circular, this free-stream velocity varies. Thus, an average free-stream velocity must be determined based on an average width of the shell, wavg. This can be obtained from simple integration as r 1 2 2 2 2 r x dx r 1 w av g 1.25 C1 m — — — — — — — — 0.518 0.556 0.451 0.568 0.404 0.572 0.310 0.592 1.5 C1 — — 0.497 — 0.505 0.460 0.416 0.356 2.0 m — — 0.558 — 0.554 0.562 0.568 0.580 C1 — 0.446 — 0.478 0.519 0.452 0.482 0.440 r 1 dx 0 A t this point, wav g is determined and an answer could be listed as w av g 1.571 A llternately , the expression abov e could be selected and then choose SYMBOLIC S: EVA LUA TE : SYMBOLIC A LLY from the menu to y ield w av g C1 0.213 0.401 — 0.518 0.522 0.488 0.449 0.428 m 0.636 0.518 — 0.560 0.562 0.568 0.570 0.574 Table 1—Constants of for airflow over a staggered tube bank SD SL D ST Vavg, T A2 A1 Figure 4—Staggered tube arrangement Re D ,max Vmax D / is defined for the maximum velocity occurring within the tube bank, Vmax, which occurs at one of two locations—either in way of A1 or A2 (see Figure 4). The maximum velocity will occur at A2 if 2S D D ST D . The factor of 2 results from the bifurcation experienced by 1 2 r Multiplying this with the distance between baffles gives an average cross-sectional area, Aavg, for the flow and the average velocity, Vavg, can be determined from V = AavgVavg. 3. a. Calculate the overall heat transfer coefficient, U 1 U 1 1 t hinner k h tubes outer 0 Assumetubes are thin- walled & very conductive 3.0 m — 0.571 — 0.565 0.556 0.568 0.556 0.562 0 ST/D SL/D 0.600 0.900 1.000 1.125 1.250 1.500 2.000 3.000 Page 4 where, t = the tubing thickness Then NTU is This value NTU should be Cmin dimensionl ess Now, the heat exchanger effectiveness, , can be determined. For one shell pass and two tube passes the effectiveness is UAtube surface 1/ 2 NTU 1 C r2 2 1/ 2 1 e 21 C r 1 C r 2 1/ 2 1 e NTU 1 C r 1 . PHYSICAL PROPERTIES—As the liquid (water) is moving, it must be under a slight pressure. This experiment is interested in the properties of liquid water density and specific heat which are both functions of temperature and pressure. However, at low pressures, one may assume that density and internal energy are approximately equal to their saturated liquid values at the same temperature; i.e., (T, p) f(T) and u(T, p) uf(T). Thus, density can be defined. Enthalpy is, h(T, p) hf(T) + [p – psat(T)]/f(T). At a room temperature of, say, 70F (~21C), psat = 0.02487bar. Compared to atmospheric pressure of 1.01325bar, this is small and negligible. Thus, h(T, p) hf(T) + p/f(T). At the temperature assumed, the density of water is 998kg/m3. At small pressures, say 2atm = 2.02bar, p/f(T) = 0.202 kJ/kg while hf(T) = 88.14 kJ/kg. Thus, a fair approximation of enthalpy is h(T, p) hf(T). Finally, the definition of specific heat is h = c(T) T; thus, C (T, p) C f(T). Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 FOR THE REPORT 1. Be sure to clearly state/show the calculations along with any assumptions made on the Mathcad worksheet in the order appearing on the grading sheet. Of course, you may have other intermediate calculations. Page 5 2. Indicate sources of error in equations as they apply to the shelland-tube heat exchanger in the lab, as well as sources of error in the measurements. 3. Discuss how good is the NTU method. Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 Page 6 ORDERED DATA, CALCULATIONS, and RESULTS The object below is reduced to 70% of full size. MATHCAD OBJECT--DOUBLE CLICK TO OPEN DA TA Look Up (& Interpolate) Phy sical Properties For The 2 Mean Temperatures C alculated A t The Right 1a. Determine Flow Rates Of Hot A nd C old Fluids 1b. C alculate Heat C apacity Rates, The MA X & MIN Heat C apacity Rates, & The Heat C apacity Rate Ratio 2a. C alculate Heat Transfer C oefficient For Tube Side 2b. C alculate Heat Transfer C oefficient For Shell Side 3a. C alculate Heat Exchanger Effectiv eness 3b. C alculate Outlet Temperatures The Measured Outlet Temperatures Were Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 DISCUSSION OF RESULTS Discuss how good is the NTU method. Indicate sources of error in equations as they apply to the shelland-tube heat exchanger in the lab, as well as sources of error in the measurements CONCLUSIONS Page 7 Last Rev.: 11 JUN 08 SHELL & TUBE HEAT EXCHANGER : MIME 3470 Page 8 APPENDICES APPENDIX A—DATA SHEET FOR SHELL-AND-TUBE HEAT EXCHANGER LAB Time/Date: ___________________________ Lab Partners: ___________________________ ___________________________ ___________________________ ___________________________ Verify supplied dimensions given in Figure 2. Is anything else needed? Is the hot flow on the tube side or shell side? ______________ Rotameter max flow rate: ________________ Run Cold Volumetric Flow Rate, VC Hot Volumetric Flow Rate, VH ( % of max rotameter rating) ( % of max rotameter rating) Hot Outlet Temperature, T H ,o Hot Inlet Temperature, TH ,i Cold Outlet Temperature, TC ,o Cold Inlet Temperature, TC ,i (C) (C) (C) (C) 1 2 3 4 5 APPENDIX B—PHYSICAL PROPERTIES TABLE