Heat Transfer Problem Set: Boilers & Exchangers

advertisement

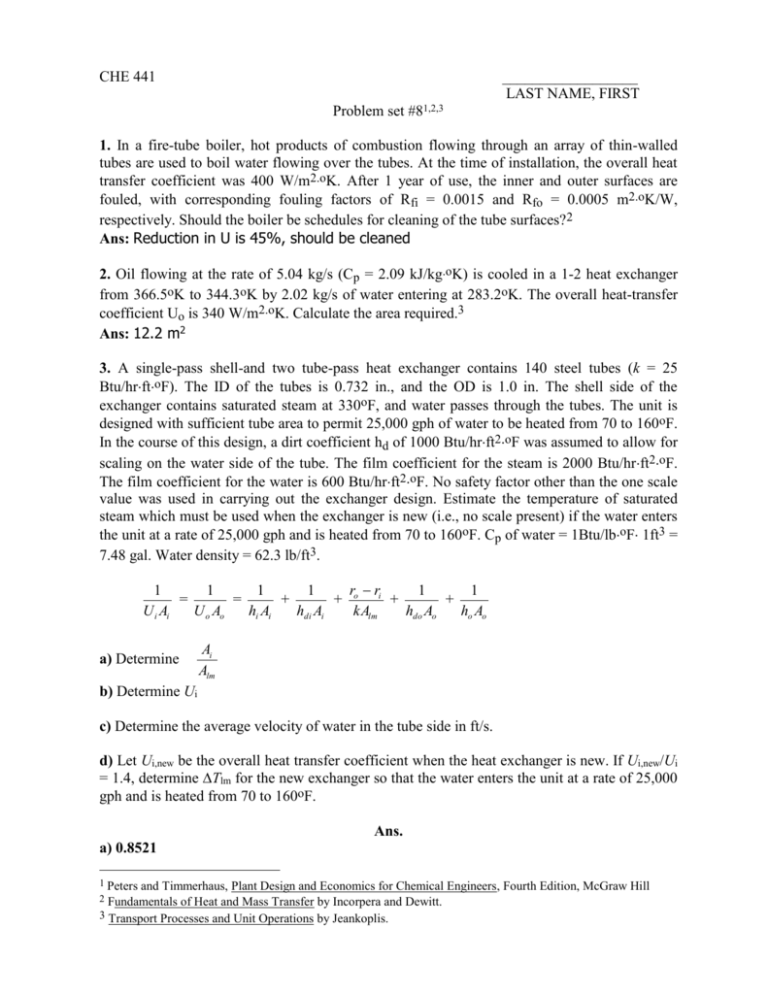

CHE 441 __________________ LAST NAME, FIRST Problem set #81,2,3 1. In a fire-tube boiler, hot products of combustion flowing through an array of thin-walled tubes are used to boil water flowing over the tubes. At the time of installation, the overall heat transfer coefficient was 400 W/m2.oK. After 1 year of use, the inner and outer surfaces are fouled, with corresponding fouling factors of Rfi = 0.0015 and Rfo = 0.0005 m2.oK/W, respectively. Should the boiler be schedules for cleaning of the tube surfaces?2 Ans: Reduction in U is 45%, should be cleaned 2. Oil flowing at the rate of 5.04 kg/s (Cp = 2.09 kJ/kg.oK) is cooled in a 1-2 heat exchanger from 366.5oK to 344.3oK by 2.02 kg/s of water entering at 283.2oK. The overall heat-transfer coefficient Uo is 340 W/m2.oK. Calculate the area required.3 Ans: 12.2 m2 3. A single-pass shell-and two tube-pass heat exchanger contains 140 steel tubes (k = 25 Btu/hrftoF). The ID of the tubes is 0.732 in., and the OD is 1.0 in. The shell side of the exchanger contains saturated steam at 330oF, and water passes through the tubes. The unit is designed with sufficient tube area to permit 25,000 gph of water to be heated from 70 to 160oF. In the course of this design, a dirt coefficient hd of 1000 Btu/hrft2oF was assumed to allow for scaling on the water side of the tube. The film coefficient for the steam is 2000 Btu/hrft2oF. The film coefficient for the water is 600 Btu/hrft2oF. No safety factor other than the one scale value was used in carrying out the exchanger design. Estimate the temperature of saturated steam which must be used when the exchanger is new (i.e., no scale present) if the water enters the unit at a rate of 25,000 gph and is heated from 70 to 160oF. Cp of water = 1Btu/lboF 1ft3 = 7.48 gal. Water density = 62.3 lb/ft3. 1 1 1 1 r r 1 1 = = + + o i + + U i Ai U o Ao hi Ai hdi Ai kAlm hdo Ao ho Ao a) Determine Ai Alm b) Determine Ui c) Determine the average velocity of water in the tube side in ft/s. d) Let Ui,new be the overall heat transfer coefficient when the heat exchanger is new. If Ui,new/Ui = 1.4, determine ∆Tlm for the new exchanger so that the water enters the unit at a rate of 25,000 gph and is heated from 70 to 160oF. Ans. a) 0.8521 1 Peters and Timmerhaus, Plant Design and Economics for Chemical Engineers, Fourth Edition, McGraw Hill Fundamentals of Heat and Mass Transfer by Incorpera and Dewitt. 3 Transport Processes and Unit Operations by Jeankoplis. 2 b) Ui = 294.12 Btu/hrft2oF c) 4.5382 ft/s d) 151.3oF 4. A finned-tube, cross-flow heat exchanger is to use the exhaust of a gas turbine to heat pressurized water. Laboratory measurements are performed on a prototype version of the exchanger, which has a surface area of 10 m2, to determine the overall heat transfer coefficient as a function of operating conditions. Measurements made under particular conditions, for which mh= 2 kg/s, Thi = 325oC, mc = 0.5 kg/s, and Tci = 25oC, reveal a water outlet temperature of Tco = 150oC. What is the overall heat transfer coefficient of the exchanger?2 Ans: 160 W/m2oK 5. Run the program Microplant as an Established Troubleshooter and turn in the last display of the program. 6. At an average film temperature of 350oK, what are the individual heat-transfer coefficients when the fluid flowing in a 0.0254-m inside diameter tube is air, water, or oil? Each fluid in the comparison exhibits a Reynolds number of 5×104. How would the pressure drop vary for each fluid (specify the ratio of pressure drop of water and air over pressure drop of oil)? The properties of the three fluids at 350oK are as follows: Air Water Oil 3 Density, kg/m 0.955 973 854 Viscosity, Pa∙s 2×10-5 3.72×10-4 3.56×10-2 Thermal conductivity, W/m∙K 0.030 0.668 0.138 Heat capacity, J/kg∙K 1050 4190 2116 2 o Ans: Heat transfer coefficients: Air: 138.5 W/m K, Water: 4608 W/m2oK, Oil: 54876 W/m2oK P ~ 0.5V2 (because of constant Re) Relative magnitude of P Air: 811 N/m2, Water: 276 N/m2, Oil: 2.88106 N/m2 Pair Pwater = 2.8216×10-4, = 9.594×10-5 Poil Poil 7. A counter flow, concentric tube heat exchanger is designed to heat water from 20 to 80oC using hot oil, which is supplied to the annulus at 180oC and discharged at 140oC. The thin-wall tube has a diameter of Di = 20 mm, and the overall heat transfer coefficient is 500 W/m2K. The design condition calls for a total heat transfer rate of 3000 W. (a) What is the length of the heat exchanger? (b) After 3 years of operation, performance is degraded by fouling on the water side of the exchanger, and the water outlet temperature is only 65oC for the same fluid flow rates and inlet temperatures. What are the corresponding values of the heat transfer rate, the outlet temperature of the oil, and the overall heat transfer coefficient Ans: (a) 0.871 m (b) 336 W/m2K 8. A heat exchanger with two tube passes has been recommended for cooling 25 kg/s distilled water from 33.9 to 29.4oC. The proposed unit contains 160 copper tubes, each with a 0.0191-m outside diameter, 18 BWG, and 4.876-m length. The tubes are laid out on a 0.0238-m triangular pitch within a 0.387-m inside diameter shell. Twenty-five percent cut segmental baffles, spaced 0.3 m apart, are located within the shell. Cooling water at a temperature of 24oC and a flow rate of 2.0 m/s will be used in the tubes to provide the cooling. The shell-side heat transfer coefficient might be estimated from k a ho = f o Do Fs DoGs s 0.6 Cp k f 1/ 3 (Eq. 8-1) a) Determine Gs. b) If the viscosity of distilled water is 7.82×10-4 kg/m∙s, determine the Reynold number in Eq. 8-1. c) Determine the number of tube row across which shell fluid flow. Ans a) 1091.7 kg/m2∙s b) 2.6664×104 c) 8.13