Lesson 4.2

advertisement

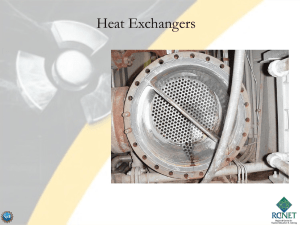

Lesson 4.2 Heat Exchangers content 1 words 2 Expressions and Technical Terms 3 Text Words 热交换 refrigerant [ri`friʤərənt] n. 冷却剂,冷冻剂,致冷剂 insulation [͵insju`leiʃən] n. 【物理学】绝缘,绝热 linearly [`liniəli] adv. .线地,直线地;线性地 expand[ik`spænd] vt/vi. 扩大(范围等);使增加;扩张;使膨胀 radiator [͵reidi`eitə] n. 辐射体,辐射器,放热物;散热器,暖气管 agitator [`æʤiteitə] n. 搅拌器 其他 independent [͵indi`pendənt] adj. 独立的 simultaneously [͵siməl`teiniəsli] adv. 同时发生地,同时做地,同时 地 transmit [trænz`mit] vt. 送达,传达(命令、话等);透射(光),传导(热 等),传声 reflect [ri`flekt] vt/vi. 【物,计】反射(光、热、声音等 Expressions and Technical Terms thermal conductivity 热传导系数 electrical conductivity 导电性 buoyancy force 浮力 in turn 反过来 natural convection 自然对流 forced convection 强制对流 electromagnetic wave 电磁波 transform…into 把…转化成 text Heat exchangers are so important and so widely used in the process industries that their design has been highly developed. Standards devised and accepted by the TEMA (the Tubular Exchanger Manufacture Association) are available covering in detail materials, methods of construction, technique of design, and dimensions for exchanger. Most exchangers are liquid-to-liquid, but gases and noncondensable vapors can be treated in them. 加工工业中,热交换器是如此的重要,如此的使用广泛.以至 于热交换器的设计发展的很成熟.由管式热交换器制造协 会制定并认可的标准,是很有用的关于热交换器的资料手 册.在手册中详细记录其制造原料.方法结构,技术及尺寸, 大多数热器是液体对液体,但气体和未冷凝的蒸气也可使 text The simple double-pipe exchanger is inadequate for flow rates that cannot readily be handled in a few tubes. If several double pipes are used in parallel, the weight of metal required for the outer tubes becomes so large that the shell-and-tube construction, such as that shown in Fig 13, where one shell serves for many tubes, is more economical. This exchanger, because it has one shellside pass and one tube-side pass, is a 1-1 exchanger. 套管式换热器不适宜处理在管子中流体流速不易控制的流 体的换热.如果几个套管同时平行使用,那么外面的管子所 需要的金属就会变得很重,这样就会使列管式结构的换热 器变得更经济,就像图13所示的,一个壳管里面有很多内管, 这种换热器因为它有一个壳层和一个管层,称为1-1换热器. Fig13 single-pass 1-1 counter-flow heat exchanger text In an exchanger the shell-side pass and tube-side heat-transfer coefficient is of comparable importance, and both must be large if a satisfactory overall coefficient is to be attained. The velocity and turbulence of the shell-side liquid are as important as those of the tube-side liquid. 在热交换器里管程和壳程的热交换系数同等重要,但如果 要使热交换系数大的话,管程和壳程的热交换系数都得很 大.在壳层里液体的速度和湍流状况与管程中液体的速度 和湍流状况一样重要 text To promote cross-flow and raise the average velocity of the shell-side fluid, baffles are installed in the shell. In the construction shown in Fig 13 the baffles A consist of circular disk of sheet metal with one side cut away. Common practice is to cut away a segment having a height equal to one-fourth the diameter of the shell. Such baffles are called 25 percent baffles. 为了改进壳程中错流的程度和速度,在壳层中必须安装挡 板,在图13所示结构中挡板A是由一边被切掉的环形盘式金 属层所组成,常用的方法就是切换高度=壳层直径的1/4环 片.这样的挡板称为25%挡板, text The baffles are perforated to receive the tubes, to minimize leakage, the clearances between baffles and shell and tubes should be small. The baffles are supported by one or more guide rods C, which are fastened between the tube sheets D and D’ by setscrews. 挡板要穿洞以接收管子,为了降低泄露量,挡板,壳体,管子之 间的间隙要很小才行,挡板由一个或多个导杆C所组成,这 个导杆C在管杆D,D间由螺丝钉固定 text To fix the baffles in place short sections of tube E are slipped over the rod C between the baffles. In assembling such an exchanger it is necessary to do the tube sheets, support rods, spacers, and baffles first and then to install the tubes. 为了在定间管中固定这个挡板,管翼的一小部分插到介于 挡板间的导杆C中,在安装这样的换热器时,首先将管板,支 撑导杆,定间距,挡板做好后再安装内管. text Standard lengths of tubes for heat-exchanger construction are 8, 12, 16, and 20 ft. (1ft. = 0.3048m). Tubes are arranged on triangular pitch or square pitch. Unless the shell side tends to foul badly, triangular pitch is used, because more heat-transfer area can be packed into a shell of given diameter than in square pitch. 热交换器的管子标准长度为8,12,16和20英寸,管子排列为 三角形或正方形排列.三角形排列常使用,除非壳层易结垢 时不用,因为对于一定直径的壳管而言,三角形排列的换热 面积为正方形的更大. text TMEA standards specify a minimum center-to-center distance 1.25 times the outside diameter of the tubes for triangular pitch and a minimum cleaning lane of 1/4 in. (1in. = 0.0254m the same below) for square pitch. 管式换热器制造协会标准规定,对于三角形排列而言最小 的中心距是管子外径的1.25倍.关于正方形而言最小的是 清洁路径的1/4英寸. text The distance between baffles (center to center) is the baffle pitch, or baffle spacing. It should not be less than one-fifth the diameter of the shell or more than the inside diameter of the shell. 挡板间的距离称为板间距,板间距不应该小于壳层直径1/5 或不应大于壳层内径. text Using multi-pass construction with two, four, or more tube passes, permits the use of standard tube lengths while ensuring a high velocity and a high tube-side coefficient. 如果用由2,4或更多管层的多管层换热器结构,那么就能确 保使用标准长度的内管,而同时又能确保很高的流速和很 高的管层的热交换系数. text The disadvantage are that (1) the construction of the exchanger is slightly more complicated, (2) some sections in the exchanger have parallel flow, which limits the temperature approach, and (3) the friction loss is greatly increased. A common construction is the 1-2 parallel-counter-flow exchanger, in which the shellside liquid in two passes. 缺点:①热交换器结构较复杂②在换热器中有时会出现并 流,会使换热器内温度受到限制③摩擦损失高,普通换热器 是对流式1-2换热器,在这种对流换热器中,壳层流量服务 于两个管层. text The 1-1 exchanger has limitations, because when the tube-side flow is divided evenly among all the tubes, the velocity may be quite low, giving a low heat-transfer coefficient. If the number of tubes is reduced and the length increased so that the velocity is sufficiently high, the tube length required may be impractical. 1-1式换热器在使用时有限制,因为当管程中的流体流动平 均分散于所有管子时,速度就很低,因为热交换系数会很小, 如果管子数减少,长度增加,使管内流体速度很大,那么所需 管子长度是不切实际的. text 附录 text 附录 作业 1、查找关于热交换方面的英文资料,并翻译其中一段 2、课后练习