The Theory and Practice of Logistics Infrastructure Capability

advertisement

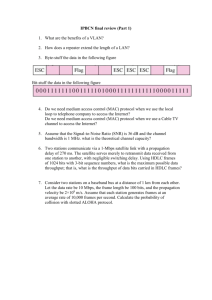

Optimized Forms of Bracket Frames Tseng-Hsing Hsu1*, Chi-Chie Chang2, and Chen-Hua Lin1 1 Department of Civil Engineering and Engineering Informatics, Chung Hua University 707, Sec.2, WuFu Rd., Hsinchu, Taiwan 30012, R.O.C. E-mail: thsu@chu.edu.tw Tel.: +886-3-5186720 Fax.: +886-3-5372188 2 Institute of Occupational Safety and Health No. 99, Lane 407, Hengke Rd., Sijhih City, Taipei County 22143, Taiwan (R.O.C.) E-mail: chngc@mail.iosh.gov.tw Abstract The safety performance and stability of the scaffolds are highly dependent on the strength of the bracket frames they erected on. If these bracket frames lack sufficient strength, it is possible to cause the collapse of the scaffolds. There are various factors that can affect the strength of the bracket frames. The cross sections, internal stress, distribution of these stresses, and the anchorages can all have effects on the strengths. The construction industries in Taiwan usually use the cheapest frames and ignore the possible consequence. The current research performed finite element analysis on various types of bracket frames. These results are then used to explore the optimized designs of the bracket frames. These designs can then be used by the industry to manufacture better products. Keywords: Loading capacity, bracket frame, finite element analysis, optimized form. 1. Introduction In densely populated urban area, the space for construction work is severely limited. It is very important for the industry to utilize a measure that requires less space without affecting the progress and safety of the project. One way to circumvent the problem is to use bracket frames and erect scaffold system from the second floor up [1]. It can reduce the space required and shorten the work period which in turns save time and budget. As a result, the bracket frames are one of the most often used equipments on construction sites [2, 3]. Because the bracket frames of appropriate bracket frame strength may cause possible collapse of the scaffold system [7, 8]. Most researches explore the strength of the scaffold system [9, 10, 11, 12]. The inspection and test focus on the scaffold systems as well [13, 14]. In light of this, this research will optimization study of the the loading bracket capacity frame. and Numerical simulations were utilized to analyze the mechanical behaviors of the bracket frames. Tests were also performed on the bracket frames to verify the numerical model. The optimized form for the frame was explored based on results of numerical simulation. provide platforms for the scaffold systems, the safety and stability of the scaffold systems depend on the 2. Finite Element Model loading capacities of the frames. Safety of working Numerical simulation was used to explore the crews demands reliable bracket frames [4, 5, 6]. Lack optimized form of the bracket frame. This approach can save time and expense for manufacturing the the industry is to weld two single frames together to experiment specimen and actually perform the tests. For form a more robust bracket frame. This research also this research, the program ANSYS was used. The considered these types of frames (type E, F, G, H). The dimension of the reference bracket frame is shown in results in this section are all obtained through numerical fig. 1. The dimension used here is the same as the frame simulations. To simplify the modeling process, the bracket used in actual test. The element used was 3D dimension of the basic configuration is slightly different solid element (Solid92). The material used is CNS- from that in fig. 1. The dimensions and configurations SS400 steel. The Poisson ratio is 0.3 ( 0.3 ) and the for types A, B, C, and D single frames are shown in fig. Young’s modulus is set to be 2.03×106 kgf/cm2 2 to fig. 5. Type E, F, G, and H double-frames combine ( E 2.03 106 kgf/cm 2 ). The frame was assumed to be two type A, B, C, and D single frames respectively. fixed at two elliptical holes shown in the figure. The point loads were applied equally at 30cm and 106cm from the left side. A linear elastic buckling analysis was performed on this numerical model. The total load at buckling is approximately 1.07 ton. To verify the numerical model, a actual test was performed on a frame with the same dimension and loading condition. The test results showed that the ultimate load of the bracket frame is approximately 1.2 ton. There was difference between simulation and test results because the simulation gave the load at first yielding while the test result was the ultimate load. This result indicated that the finite element analysis can reasonably predict the loading capacity of the bracket frame. In the finite element analysis, Solid92 elements were used in all cases. The material used was CNSSS400 steel. All frames were fixed at the two intermediate points on the left side as shown in figures. The results of the linear elastic buckling analysis were shown in table 1. From these results, it is clear that the type of reinforcement will affect the loading capacities of the bracket frames. The loading capacity of type A is the best among the four single frames while type D is the worst. The loading capacities for double frames (type E, F, G, and H) have the same trend. Other than the type of the bracket frame, the results indicate other factors to be considered. The first thing to take into consideration is the effect of combining two single frames into one double-frame bracket. At first thought, the loading capacity should be doubled because there are two frames to support the 3. Analysis of Optimized Form of Bracket Frame After verifying the validity of the finite element analysis, different types of bracket frames were analyzed to find out the best form of the frame. In order to compare the effects among various types of reinforcements, all frames used the same basic frame. Different kinds of reinforcements were then added to the basic frame (type A, B, C, D). A usual practice in load. The results of finite element analysis indicate that the effect is more than that. It can be seen in table 1 that the effects are always more than double the capacities. One possible explanation can be seen in figure 6 and figure 7. Figure 6 and 7 are the top views of the deformations of two bracket frames. In figure 6, the single frame deformed sideway because of the torsion effect of the loading. The frame in figure 7 does not have this effect due to the symmetric configuration of the double frame setup. This torsion reduces the capacity of the single frame bracket. It suggests that the 2. For single frame bracket, type A has the industry practice of combining two single frames into a highest loading capacity, followed by type C larger double-frame bracket has its merit. But the and type B. Type D (without reinforcement) configuration of the two frames in the double-frame has the lowest loading capacity. Type E, F, G, configuration should be such that the effect of torsion and H combine two type A, B, C, and D frames can cancel out. respectively. The order of their capacities is the The other thing worth noting is the effect of loading on the anchoring point of the bracket frame. same as that of their components. 3. Double-frame brackets have more than twice Usually the frames are installed using screws. As a the capacities than those of single frames due result, the stress around the anchoring point is very to the asymmetric nature of single frames. The large. The results of finite element analysis clearly show torsion effect reduces the loading capacity of this effect. Figure 8 is the stress distribution of a bracket the single frame bracket. The manufacturers frame under loading. The maximum stress (in red circle) should use double-frame design if possible. occurs at the anchoring point. Figure 9 shows the 4. The anchoring point sustains very large stress. deformation around the anchoring point. To study this Use of double-frame bracket can alleviate the effect, another set of simulations are performed by situation. Reduce the distance between the varying the distance between the edge of the frame and anchoring point and the edge of the frame can the anchoring point (distance reduce the stress as well. d in figure 10). The results showed that the loading capacity of the bracket frame will change when distance d varied. Figure 11 is the figure of the relationship between loading capacities of frame type A, B, C, and D and the distance 5. Based on the results of this research, the users should choose double-frame bracket with vertical reinforcements if possible. d . The figure shows that the capacities increase as the distance 5. Acknowledgement decreases. This work is supported by the Institute of Occupational Safety and Health under grant IOSH94-S304. 4. Conclusions From the results of this research, the following conclusions can be drawn: 1. References [1]. Chang, Chi-Chang (2004), “Practice of the Even with the same material, bracket frames Structural Calculation of the Scaffold System.”, with different designs will have different Workshop on Safety of Scaffold Operation, loading capacities. The manufacturers and Institute of Occupational Safety and Health.. users should take this into consideration and [2]. Institute of Occupational Safety and Health use bracket frames best suited the projects in (2000), ”An Evaluation of the Current Condition order to .raise the safety performance of the of the Scaffold Usage in Construction Industries temporary structures. in Taiwan”, Project Report. [3]. Gao, Jian-Chang et al. (1983), “Study on the [12]. Huang, Wen-Duo (2003), ”Evaluation of the current Usage and Safety of Steel Tube Scaffolds Loading Capacity of the Frame Scaffolds”, in Taiwan”,Project Report, Taiwan Construction Master Thesis, Institute of Applied Mechanics, Research Institute. National Taiwan University. [4]. El-Shahhat, A. M., Rosowsky, D. V. and Chen, [13]. Chinese National Standard (1996), “Standard W. F. (1993), “Construction Safety of Multistory Test on the Steel Tube Scaffold”, CNS 4751 Concrete Buildings”, ACI Structural Journal, A3079. pp.335-341, July-August. [14]. Lin, Yin (1999), “A Study on the Testing [5]. Mosallam, K.H. and Chen, W.F. (1990), “Design Technique and Evaluation System of Falsework Considerations for Formwork in Multistory (Frame Scaffold) in Taiwan”, Master Thesis, Concrete Buildings”, Engineering Structures, July, National Chun-Hsing University. pp.163-172 [6]. Peng, J.L. (1994), “Analysis Models and Design Guidelines for High Clearance Scaffold System”, Ph.D. dissertation, Purdue University. [7]. National Center for Research on Earthquake Engineering, “Investigation Data of the 331 Earthquake in Taiwan”, http://www.ncree.gov.tw/eq0331/zhongshan1.htm [8]. Chen, Ying-Chou (1991), “Study on the Characteristics of Occupational Incidents of the Construction Industries in Taiwan based on Incident Reports and on-site Inestigations.”, Master Thesis, National Chung-Hsing University. [9]. Lu, Liang-Cheng, et al. (1997), ”A Study on the Loading Capacity of the Steel Tube Scaffold and the Measurement of its Response Frequency”, Journal of Occupational Safety and Health, December, Vol. 5, Iss. 2 [10]. Ji, Ren-Chao (1994), Master Thesis, National; Chung-Hsing Unversity. [11]. Fang, Ching-Sun (1995), “Investigation on the Model Testing of Loading Capacity of the Scaffolds”, Master Thesis, National Chung-Hsing University. Unit: cm Figure 1: Dimension of the Reference frame Figure 2: Type A Bracket Frame Figure 3: Type B Bracket Frame Figure 4: Type C Bracket Frame Figure 5: Type D Bracket Frame Figure 6: Top View of the Deformation of a Single Frame Bracket Figure 7: Top View of the Deformation of a Double-Frame Bracket Figure 8: Stress Distribution for a Bracket Frame under Loading Figure 9: Deformation around the Anchoring Point for a Bracket Frame under Loading Figure 10: Definition of the Distance d Loading Capacity ( kgf) 1900 1700 1500 Type D Type C 1300 Type B 1100 Type A 900 700 500 4 6 8 10 d ( cm ) Figure 11: Relationship between Loading Capacity and Distance d Table 1: Loading Capacities of Bracket frames Type Illustration Loading Capacity (kgf) A 1050 B 780 C 880 D 640 E 2862 F 1727 G 1696 H 1083