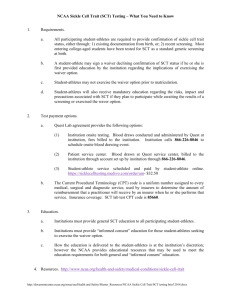

Version 2

advertisement