Leesupp - AIP FTP Server

advertisement

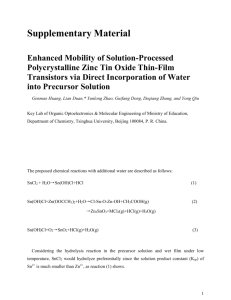

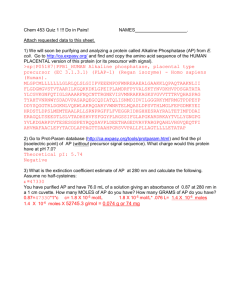

Materials and Methods Solution-processed ZTO TFTs were fabricated on a glass substrate (SCHOTT Glass, AF32eco). A bottom-gate and top-contact device structure is employed, as shown in the inset of Fig. 1b). Ti and AuPd (Au/Pd ratio = 30/70) are selected as the adhesion layer and gate electrode, respectively. A thickness of 2.5 nm (Ti) / 35 nm (AuPd) was deposited with an e-beam evaporator (CHA industries, SE-1000-RAP) on the glass substrate. The dielectric (ZrO2) and active layer (ZTO) were processed with a sol-gel method. All the processes of the solution-deposited thin films were performed in a nitrogen glove box except the annealing step. Details of the precursor synthesis and device fabrication have been reported in ref.7 and are only summarized here. The ZrO2 precursor solution was synthesized by dissolving 0.5M of zirconium chloride (ZrCl4, Sigma Aldrich) and 0.5M of zirconium isopropoxide isopropanol complex (Zr(OCH(CH3)2)4 · (CH3)2CHOH, Sigma Aldrich) in 2-methoxyethanol (CH3OCH2CH2OH, Sigma Aldrich). The ZTO precursor solution was synthesized by dissolving 0.12 M of zin chloride (ZnCl2, 99.999%, Sigma Aldrich) and 0.12 M of tin chloride (SnCl2, ≥ 99.99 %, Sigma Aldrich) in acetonitrile (CH3CN, Sigma Aldrich). The precursor solutions were mixed with spin bars overnight. Prepared ZrO2 precursor solution was filtered through a 0.2 µm PTFE (polytetrafluoroethylene) filter (Pall Corporation), spin-coated at 2000 rpm for 30 s and was kept in nitrogen box for 1 h to evaporate the residual solvent. Then, the precursor film was converted to ZrO2 by annealing on a hotplate at 500 ˚C for 1 h in ambient air. The dielectric deposition process was repeated once to achieve a thickness of ~90 nm. Prepare ZTO precursor solution was filtered through a 0.2 µm PTFE filter and spin-coated at 6000 rpm for 1 min. A pre-bake process at 100 ˚C for 30 min was performed in the nitrogen environment. The ZTO precursor film was converted to ZTO by annealing on a hotplate at 500 ˚C for 1 h in ambient air. 40 nm of Al source/drain electrodes were deposited through a shadow mask with a thermal evaporator. The channel length and the channel width are 50µm and 1mm, respectively. The capacitance value of the ZrO2 gate dielectric is ~240 nFcm-2, measured with a metal-insulator-metal structure using a LCR meter (HP 4284A). The capacitance value varies within 10 % in a wide frequency range (100 Hz to 1M Hz). Thickness for the ZrO2 dielectric layer and ZTO active layer are ~90 nm and 20 nm, measured with a profilometer (Dektak 150).The transfer curve and output characteristics shown in Fig.1 were measured in ambient air at room temperature with a semiconductor parameter analyzer (Agilent 4155C). Measurement of the temperature-dependent mobility was performed in the vacuum chamber of a cryogenic probe station (LakeShore Model CRX-4K). In order to ensure calculating the mobility in the saturation regime, the VDS is kept at a higher value than the VGS-VT for all the transfer curve measurements. The mobility values in Fig. 2a) is extracted using the usual equation valid for saturation region. The activation energy in Fig. 3 is calculated by using the slope of the linear fit of experimental data in the [ln(µeff)]-[1000/T] plot. The inset of Fig. 3 provides an example of the activation energy calculation at VG-VON=3 V. Six temperature points, ranging from 77 K to 333 K, were employed to the linear fit. The standard error of the slope calculation is usually less than 15 %, which indicates the experimental data fit very well to the MTR model. The conductivity data were extracted from the linear region of the VDID plot. The thickness of the accumulation layer is assumed to be 5 nm. Subthreshold Slope (SS) calculation SS calculation for the room temperature device operation is illustrated in the figures below. The left figure shows the forward sweep of the VGID plot. The red line is the guild line for the SS calculation at one gate voltage. The SS is derived from the slope by the following equation: SS = (V2-V1)/ log (I2/I1). The right figure shows the SS values as a function of the gate voltage in the subthreshold region. The lowest SS value is 122 meV/decade. The SS slope calculation has been included in the supplementary material. Guildline for SS calculation VDS=10V -2 0 2 4 6 VG(V) 8 Guild line for SS calculation. 10 0 SS (mV/decade) ID(A) 1 100m 10m 1m 100µ 10µ 1µ 100n 10n 1n 100p 10p 200 400 600 0.0 0.5 1.0 VG(V) 1.5 2.0 SS values as a function of gate voltage.