repair compound modified by nano particles of ferrous oxide

advertisement

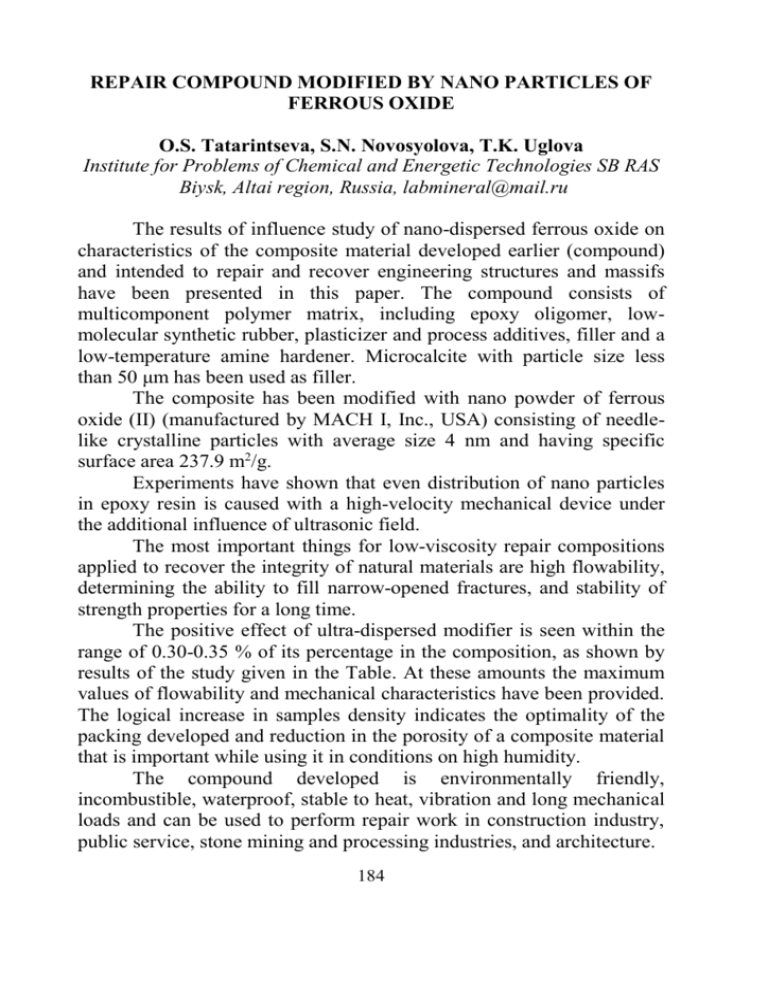

REPAIR COMPOUND MODIFIED BY NANO PARTICLES OF FERROUS OXIDE O.S. Tatarintseva, S.N. Novosyolova, T.K. Uglova Institute for Problems of Chemical and Energetic Technologies SB RAS Biysk, Altai region, Russia, labmineral@mail.ru The results of influence study of nano-dispersed ferrous oxide on characteristics of the composite material developed earlier (compound) and intended to repair and recover engineering structures and massifs have been presented in this paper. The compound consists of multicomponent polymer matrix, including epoxy oligomer, lowmolecular synthetic rubber, plasticizer and process additives, filler and a low-temperature amine hardener. Microcalcite with particle size less than 50 μm has been used as filler. The composite has been modified with nano powder of ferrous oxide (II) (manufactured by MACH I, Inc., USA) consisting of needlelike crystalline particles with average size 4 nm and having specific surface area 237.9 m2/g. Experiments have shown that even distribution of nano particles in epoxy resin is caused with a high-velocity mechanical device under the additional influence of ultrasonic field. The most important things for low-viscosity repair compositions applied to recover the integrity of natural materials are high flowability, determining the ability to fill narrow-opened fractures, and stability of strength properties for a long time. The positive effect of ultra-dispersed modifier is seen within the range of 0.30-0.35 % of its percentage in the composition, as shown by results of the study given in the Table. At these amounts the maximum values of flowability and mechanical characteristics have been provided. The logical increase in samples density indicates the optimality of the packing developed and reduction in the porosity of a composite material that is important while using it in conditions on high humidity. The compound developed is environmentally friendly, incombustible, waterproof, stable to heat, vibration and long mechanical loads and can be used to perform repair work in construction industry, public service, stone mining and processing industries, and architecture. 184 Table. Percentage influence of ferric oxide nano powder on technical characteristics of the composite material Characteristics Dynamic viscosity at T = 20 oC, Pa·s Flowability, cm 3 Density, g/m Compressive force, MPa Relative deformation, % Value at modifier percentage, % 0 0.10 0.20 0.30 0.35 0.40 21.0 21.2 22.5 26.2 26.6 28.8 4.8 4.8 4.8 5.2 5.3 4.5 1.41 1.41 1.43 1.45 1.46 1.46 79 78 79 82 86 74 0.23 0.21 0.21 0.25 0.25 0.20 185