shipping guide - Southern Crop Production Association

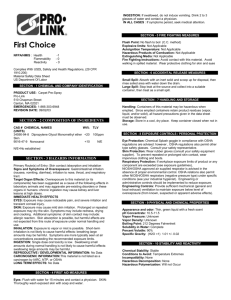

advertisement

INTERREGIONAL COORDINATING COUNCIL

TRANSPORTATION & DISTRIBUTION

COMMITTEE

HAZARDOUS MATERIALS

SHIPPING GUIDE

L/R 02/26/15

The IRCC Transportation & Distribution Committee

The Interregional Coordinating Council (IRCC) was formed in 1991 to coordinate programs of the three

regional crop protection associations -- the Southern Crop Production Association, Mid America

CropLife Association, and Western Plant Health Association - with CropLife America.

The Transportation & Distribution (T&D) Committee was formed by the IRCC Executive Board to

follow transportation issues in the crop protection industry. This committee has representatives from

major crop protection manufacturers and distributors. Membership is open to all CLA and regional

association member companies.

The Committee meets three times a year. Usually, these meetings are in conjunction with the three

regional associations’ Board or Annual Meetings.

One of the primary objectives of the T&D Committee is to interpret, summarize, and communicate the

U.S. Department of Transportation (DOT) Hazardous Materials Regulations to the crop protection

industry. The T & D Committee reviews DOT and International Regulations, comments on proposed

rules, prepares training materials, and issues informational bulletins summarizing regulatory compliance

requirements.

The T&D Committee has published several editions of the "Hazardous Materials Shipping Guide", a

booklet summarizing the DOT Regulations. These are updated as regulations change. They also publish

the Hazardous Materials Shipping Descriptions which is updated annually and have produced a training

video to accompany the two books including test and answers for training purposes.

The IRCC Transportation & Distribution Committee

Paul Derig – J. R. Simplot Co., Chair

Margaret Lewandowski – BASF Corp., Vice Chair

Becky Roark – Helena Chemical Co.

David W. Peters – Monsanto Co.

Kevin Greene – DuPont Crop Protection.

Joseph Paster – Syngenta Crop Protection

Michael Goosev – American Warehouse Co., Inc.

Mike Weingardt -- Crop Production Services

Mana House – ISK Biosciences Corp.

Greg Leyes – ISK Biosciences Corp.

Joe Matousek – BASF Corp.

Lindsey Jackson – Dow AgroSciences

Patrick McGlinchey – FMC Corp.

Gary Gold – FMC Corp.

Don Schultz – Land O'Lakes

William J. Briner – Consultant

Liaisons

Amanda Griesser – CropLife America

Edgar W. Duskin – SCPA

Bonnie McCarvel – MACA

Renee Pinel – WPHA

1

DOT HAZARDOUS MATERIALS

SHIPPING GUIDE

NOTICE

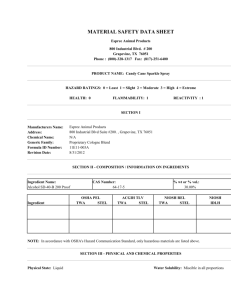

This booklet, compiled and published by the regional crop protection products associations’

Transportation and Distribution Committee, contains a summary of the hazardous materials

transportation regulations.

Every effort has been made to be accurate and clear, and to incorporate a summary of the U.S.

Department of Transportation’s Hazardous Materials Regulations into this booklet. Due to the constantly

changing nature of government regulations, it is impossible to guarantee absolute accuracy of the

material contained herein. Those responsible for complying with the provisions of Title 49 CFR and

other applicable laws & regulations should be advised that the authors of this booklet, their companies

and associations accept no legal responsibility for statements or errors which might be in this booklet.

To ensure compliance, the Transportation and Distribution Committee further advises those responsible

for compliance to read and to follow the official publications of the applicable regulations and laws

dealing with the transportation of hazardous materials.

Interpretations concerning the Hazardous Materials Regulations can be obtained directly from the U.S.

Department of Transportation, Research and Special Programs Administration, 400 Seventh Street, SW,

Washington, D.C. 20590-0001, telephone number (800) 467-4922, internet web site

http://www.phmsa.dot.gov/hazmat.

This booklet may be duplicated but only for non-commercial purposes. Any other use of this booklet

requires the express written consent of the Interregional Coordinating Council.

©2015 - Interregional Coordinating Council

SCPA, P.O. Box 7000, Dawson, Georgia 39842

2

TABLE OF CONTENTS

Introduction

4

Penalties

4

Registration and Fee Assessment

4

Training

6

Transportation Security

6

Definitions

10

Hazardous Materials Classification

12

The Hazardous Materials Table

12

DOT Hazard Classes

15

Precedence of Hazards

22

General Packaging Requirements

23

Marking Requirements

25

Labeling Requirements

32

Shipping Paper Requirements

35

Placarding Requirements

39

Intermodal Certification

41

Loading and Unloading Requirements

42

Customer Pickup, Loading and Bracing Recommendations

44

Leaking Containers

45

Emergency Response Information

45

Hazardous Materials Insurance Requirements

47

Materials of Trade Exceptions

47

Intrastate Agricultural Operations

49

Transportation and Unloading of Liquefied Compressed Gases

49

Federal Motor Carrier Safety Regulations

50

Safety Performance History of New Drivers

54

Minimum Training Requirements for Entry Level of CMV Driver

57

Protection Against Shifting and Falling Cargo

58

DOT Hazardous Materials Regulations Index

61

Miscellaneous Conversion Factors

67

3

INTRODUCTION

The Hazardous Materials regulations are intended to protect against the risk to life and property inherent

in the transportation (including loading, unloading, and temporary storage) of such commodities in

commerce. The regulations are published in Title 49 of the Code of Federal Regulations, Parts 100-180,

and are quite extensive. Regulations governing the shipment of hazardous materials by air are found in

the current editions of the International Civil Aviation Organization (ICAO) Technical Instructions For

The Safe Transport of Dangerous Goods By Air and the International Air Transport Association (IATA)

Dangerous Goods Regulations. Regulations governing the shipment of hazardous materials by ocean are

found in the current edition of the IMDG Code.

All persons involved with the shipment of hazardous materials must be knowledgeable of those

regulations as they apply to their position or function. Such persons are subject to the training and

testing requirements discussed in the Training section of this booklet.

This Hazardous Materials shipping guide summarizes key requirements for the transport of agricultural

chemicals. Refer to Title 49 of the Code of Federal Regulations or seek further clarification from

knowledgeable sources for any questions not answered by this booklet.

PENALTIES

No person may offer or accept a hazardous material for transportation in commerce unless they are

trained and the material is properly classed, described, packaged, marked, labeled, placarded and in

proper condition for shipment. Certain shippers and carriers are also subject to the registration and fee

assessment requirements discussed in the Registration and Fee Assessment section of this booklet.

Civil penalties range from $450 to $75,000 for each violation. If a violation results in death, serious

illness, severe injury or substantial destruction of property, the maximum penalty increases to $175,000.

When a violation is a continuing one, each day of the violation constitutes a separate offense. Criminal

penalties may be assessed in the form of fines up to $500,000, or imprisonment for up to five years, or

both, except that the maximum amount of imprisonment shall be 10 years in any case in which the

violation involves the release of a hazardous material which results in death or bodily injury to any

person.

Following are several examples of DOT baseline assessment guidelines used in making initial penalty

determinations: (1) $600 for failure to include a required technical name in parentheses for a listed

generic or "n.o.s." material; (2) $3200 for failure to include an emergency response telephone number on

a shipping paper; and (3) $6200 for offering a Packing Group III hazardous material for transportation in

an unauthorized non-UN standard or non-specification packaging.

REGISTRATION AND FEE ASSESSMENT

(49 CFR Part 107 Subpart G)

Each company or subsidiary engaged in offering or transporting the following hazardous materials in

commerce must register and pay a fee to the U.S. Department of Transportation:

(1) Highway route-controlled quantities of radioactive materials

4

(2) More than 55 pounds of Division 1.1, 1.2 or 1.3 explosives

(3) More than 1 liter per package of Hazard Zone A poisonous liquids or gases

(4) Hazardous materials in a bulk packaging having a capacity equal to or greater than 3,500 gallons or

468 cu. Ft. (This applies whether the tank contains a residue, is partially full, or is completely full.)

(5) A shipment of 5,000 pounds or more gross weight of hazardous material in non-bulk packaging

loaded at one loading facility of a class of hazardous material for which vehicle, rail car or freight

container placarding is required.

(6) A quantity of hazardous material that requires placarding, except for the activities of a farmer that are

in direct support of the farmer’s farming operations.

Each company or subsidiary that is required to register and does not meet the criteria of a small business

or a not-for-profit organization must pay an annual fee of $2600, including the processing fee.

Each company or subsidiary that is required to register and qualifies as a small business under criteria

specified in 13 CFR Part 121 or a not-for-profit organization exempt from taxation under 26 U.S.C.

501(a) must pay an annual fee of $275, including the processing fee.

Following are some examples of businesses which meet the small business criteria:

2002 NAICS code 111110 (1987 SIC code 0116) – Soybean Farming; and 2002 NAICS code

111150 (SIC code 0115) – Corn Farming – annual receipts of $750,000 or less;

2002 NAICS code 115112 (1987 SIC code 0721) – Soil Preparation, Planting, and Cultivating –

annual receipts of $6,000,000 or less;

2002 NAICS code 325320 (1987 SIC code 2879) – Pesticide and other Agricultural Chemical

Manufacturing – 500 employees or less;

2002 NAICS code 424910 (1987 SIC code 5191) – Agricultural Chemicals Merchant

Wholesalers – 100 employees or less.

Contact the Small Business Administration 1-800-UASK-SBA (1-800-827-5722) if you have any

questions concerning the small business criteria.

Registration is required no later than June 30 of each year or prior to the first shipment of the indicated

hazardous materials.

Registrants must maintain a copy of the registration statement filed with the DOT and the Certificate of

Registration at its principal place of business for a period of three years from the date of issuance of each

Certificate of Registration.

A copy of the motor carrier’s Certificate of Registration or another document bearing the registration

number identified as “U.S. DOT Hazmat Reg. No.” must be carried on board all transport vehicles used

to transport hazardous materials subject to the registration requirements.

5

TRAINING

(49 CFR Part 172 Subpart H)

Individuals who perform functions involving the transportation of hazardous materials must receive

training concerning regulatory requirements applicable to those functions. Persons who in the course of

employment directly affect hazardous materials transportation safety must be trained.

This regulatory requirement is designed to increase hazmat employee awareness of safety considerations

involved in loading, unloading, handling, storing, shipping paper preparation, marking, labeling,

placarding, and transportation of hazardous materials, and to improve emergency preparedness for

responding to transportation incidents and accidents.

Hazmat employee training must include (1) general awareness/familiarization training; (2)

function-specific training; (3) safety training; (4) security awareness training; and (5) in-depth security

training (is a security plan is required). In addition, hazardous materials drivers must be trained on the

safe operation of the motor vehicle which they intend to operate and the applicable requirements of the

Federal Motor Carrier Safety Regulations [per 49 CFR 177.816].

New employees or those who change hazardous materials functions must complete training within 90

days after beginning their job. Prior to training, employees must work under the direct supervision of a

properly trained and knowledgeable hazmat employee. Hazmat employees must receive training at least

once every three years.

Employers are responsible for ensuring that the level of training is adequate and appropriate for each

hazmat employee.

Even employees who are not customarily involved with hazardous materials need to be taught enough not

to do something improper, such as transporting a hazardous material in an automobile without proper

packaging, marking, shipping papers, or securement, or carrying a hazardous sample in their suitcase on

an airplane.

After completion of training, each employer must certify, with appropriate documentation, that each

hazmat employee received training and was tested on appropriate areas of responsibility. A record of

each employee’s training for the prior three (3) years must be maintained for the duration of employment

in each applicable hazardous materials job function and for 90 days thereafter. The record of training

must contain the name of the person receiving the training, the training completion date, a copy of or the

location of the training material presented or a description of the training given, the name and address of

the person presenting the training, and certification that the hazmat employee has been trained and tested.

Training may be provided by a 3rd party trainer, but certification must be made by the hazmat employer.

Transportation Security Requirements

(49 CFR Part 172 Subpart I)

Shippers and carriers who offer or transport one or more of the following hazardous materials in commerce

must develop and adhere to a transportation security plan for hazardous materials (the phrase “large bulk

quantity,” as used in the following list, refers to a quantity greater than 3,000 kg (6,614 pounds) for solids or

6

3,000 liters (792 gallons) for liquids and gases in a single packaging such as a cargo tank motor vehicle,

portable tank, tank car, or other bulk container):

(1) Any quantity of a Division 1.1, 1.2, or 1.3 material;

(2) A quantity of a Division 1.4, 1.5, or 1.6 material requiring placarding

(3) A large bulk quantity of Division 2.1 material;

(4) A large bulk quantity of Division 2.2 material with a

subsidiary hazard of 5.1;

(5) Any quantity of a material poisonous by inhalation;

(6) A large bulk quantity of a Class 3 PG I and II materials;

(7) A quantity of a desensitized explosives meeting the definition of a Division 4.1 or Class 3 material

requiring placarding;

(8) A large bulk quantity of a Division 4.2 PG I and II materials;

(9) Any quantity of a Division 4.3 material;

(10) A large bulk quantity of a Division 5.1 PG I and II materials; perchlorates; or ammonium nitrate,

ammonium nitrate fertilizers, or ammonium nitrate emulsions, suspensions, or gels;

(11) Any quantity of organic peroxide, Type B, liquid or solid, temperature controlled;

(12) A large bulk quantity of Division 6.1 material (other than materials poisonous by inhalation);

(13) A select agent or toxin regulated by the Centers for Disease Control and Prevention under 42 CFR part 73

or the United States

Department of Agriculture under 9 CFR part 121;

(14) A quantity of uranium hexafluoride requiring placarding under 49 CFR 172.505(b);

(15) International Atomic Energy Agency (IAEA) Code of Conduct Category 1 and 2 materials including

Highway Route Controlled quantities as defined in 49 CFR 173.403 or known as radionuclides in forms listed as

RAM-QC by the Nuclear Regulatory Commission;

(16) A large bulk quantity of Class 8 PG I materials.

Materials shipped in accordance with an exception authorized under the HMR, such as the materials of trade

exception, small quantity exceptions limited quantity or consumer commodity exceptions, are not subject to

security planning requirements.

Transportation activities of a farmer who generates less than $500,000 annually in gross receipts from the sale

of agricultural commodities or products are not subject to the security plan requirements if such activities are

(1) conducted by highway or rail; (2) in direct support of their farming operations; and (3) conducted within a

150-mile radius of those operations.

Hazmat employers who are required to have a security plan must provide in-depth security training to their

hazmat employees in the plan’s specifics. All hazmat employees must receive training that provides an

awareness of the security issues associated with hazardous materials transportation and possible methods to

enhance transportation security. This training must also include a component covering how to recognize and

respond to possible security threats.

Hazmat employees subject to in-depth security training must receive recurrent training at least once every three

years or, if the security plan for which training is required is revised during the three-year recurrent training

cycle, within 90 days of implementation of the revised plan.

The in-depth security training requirements apply only to hazmat employees who are directly involved with

implementing security plans.

7

The requirement for developing and adhering to a security plan applies to persons who offer for transportation

or transport hazardous materials in commerce, including loading, unloading, or storage incidental to the

movement of hazardous materials.

Security plans should focus not only on the potential threats posed by the material being transported, but also

on personnel, facility, and en route security issues. A company should implement a plan that is appropriate to

its individual circumstances, considering the types and amounts of hazardous materials shipped and the modes

of transportation.

The requirements permit a shipper or carrier to develop a security plan that assesses the specific security risks

of the materials to be transported and put into place measures that are commensurate with the assessed risks.

If a shipper or carrier determines that the security risks of the materials it handles are relatively small, then its

security plan may be limited in scope and complexity.

Security plan components. A security plan must address risks related to the transportation of hazardous materials

in commerce. Persons subject to the security plan requirement must perform an assessment of the transportation

security risks associated with the materials they handle, including site-specific or location-specific risks

associated with facilities at which these hazardous materials are prepared for transportation, stored, or unloaded

incidental to movement, and appropriate measures to address the assessed risks. PHMSA has developed a

security template to illustrate how risk management methodology can be used to identify points in the

transportation process where security procedures should be enhanced within the context of an overall risk

management strategy. This template is posted on http://hazmat.dot.gov/riskmgmt/rmsef.htm. Other risk

assessment tools may also be used. Each security plan will differ because it will be based on an offeror's or a

carrier's individualized assessment of the security risks associated with the specific hazardous materials it ships

or transports and its unique circumstances and operational environment. Specific measures put into place by the

plan may vary commensurate with the level of threat at a particular time.

At a minimum, a security plan must include the following elements:

1. A method or methods for confirming information provided by applicants for jobs that involve access to

or handling of the hazardous materials covered by the plan. Employers should make an effort to check

information related to an applicant's recent employment history, references, and citizenship status.

2. Methods to address the possibility that unauthorized persons may attempt to gain access to hazardous

materials or transport vehicles being prepared for transportation.

3. A method or methods to address en route security risks. A hazardous materials transporter's security

plan will address en route security issues in some detail. However, shippers also need to address this aspect

of transportation security since it is the shipper who controls carrier selection; order entry; loading; time and

method of dispatch; and the destination. A security plan should include a system for verifying that a carrier

has an on-going transportation security program. At a minimum, a shipper should satisfy itself that the

carrier that will be transporting its material has a security plan in place that adequately addresses the

assessed security risks of the material to be transported, including risks related to storage of the material

during transportation.

The security plan must also include the following:

(1) Identification by job title of the senior management official responsible for overall development and

implementation of the security plan;

(2) Security duties for each position or department that is responsible for implementing the plan or a portion

of the plan and the process of notifying employees when specific elements of the security

plan must be implemented; and

8

(3) A plan for training hazmat employees in accordance with 49 CFR 172.704(a)(4) and (a)(5).

The security plan, including the transportation security risk assessment, must be in writing and must be retained

for as long as it remains in effect. The security plan must be reviewed at least annually and updated as

necessary to reflect changing circumstances. The most recent version of the security plan, or portions thereof,

must be available to the employees who are responsible for implementing it, consistent with personnel security

clearance or background investigation restrictions and a demonstrated need to know. When the security plan is

updated or revised, all employees responsible for implementing it must be notified and all copies of the plan must

be maintained as of the date of the most recent revision.

Each person required to develop and implement a security plan in accordance with this subpart must maintain a

copy of the security plan (or an electronic file thereof) that is accessible at, or through, its principal place of

business and must make the security plan available upon request, at a reasonable time and location, to an

authorized official of the Department of Transportation or the Department of Homeland Security.

Security awareness training. Each hazmat employee must receive training that provides an awareness of

security risks associated with hazardous materials transportation and methods designed to enhance

transportation security. This training must also include a component covering how to recognize and respond to

possible security threats. New hazmat employees must receive the security awareness training within 90 days

after employment.

In-depth security training. Each hazmat employee of a person required to have a security plan must be

trained concerning the security plan and its implementation. Security training must include company security

objectives, specific security procedures, employee responsibilities, actions to take in the event of a

security breach, and the organizational security structure.

Transportation Security Awareness

(49 CFR Part 172.704(a)(4))

Approximately 800,000 hazardous materials shipments are made per day in the United States. Hazardous

materials are essential to the economy of the U.S. and to the wellbeing of its people. They are used as

fuel for vehicles, to heat and cool homes and businesses, and they are essential in farming, health care,

manufacturing, mining and many other industrial processes.

Hazardous materials also have the potential to be used in terrorist attacks. The 1993 terrorist attack on

the World Trade Center and the 1995 attack on the Oklahoma City Federal Building used ammonium

nitrate, urea and nitric acid to produce deadly explosions. In 1993, the FBI arrested four members of a

terrorist cell planning to hijack a gasoline tank truck and igniting it in the Hudson River tunnel. A

planned attack on a 24 million gallon liquid propane storage facility in Elk Grove, California in 1999 was

discovered and prevented. Fully loaded fuel tanks in hijacked planes were an integral part of the terrorist

attacks on September 11, 2001.

Bridges, dams, tunnels, historic monuments, high density population centers and chemical plants are

potential terrorist targets.

Hazardous materials shippers, carriers and receivers should conduct vulnerability assessments for the

hazardous materials which they handle. They should conduct background checks for prospective

employees. They should conduct security reviews, including a review of access control systems,

9

reporting procedures, employee training, regular inspections of storage areas, proper identification and

enroute security.

A facility security evaluation should include:

Nature of the area surrounding the facility

Nature and quantity of hazmat present at the facility

Physical barriers to entry

Means of detecting intrusion attempts

History of unauthorized entries

Regulatory requirements

The following guidelines are recommended for security of hazardous materials:

Keep storage areas locked

Keep updated and accurate inventories

Conduct regular inspections of storage areas

Conduct security spot checks of personnel and vehicles

Lock all equipment

Be alert for unusual purchases or odd behavior

Restrict access of non-employees

In planning a trip with hazardous materials, the following items should be considered:

Know your customer

Plan the safest route

Avoid high population areas

Conduct a vehicle pre-trip inspection

Select rest stops with good lighting

Follow the regulatory attendance and parking rules

Be aware of your surroundings

Make sure your company knows your route; report any delays immediately

Report suspicious activity

Do not pick up hitchhikers

Do not talk about your cargo or destination in casual conversations

A secure transportation system is vital for our nation. It ensures our economic growth, protects our

citizens and calms the fear that we might be vulnerable to violent criminal acts. Through a better

understanding of potential targets, threats and protective measures that can be taken, we can greatly

reduce the risk of a catastrophic event. Be educated, be aware and be secure.

DEFINITIONS

The hazardous materials definitions and abbreviations are listed in 49 CFR 171.8. Several of these

definitions are included below.

Hazardous Material

A hazardous material, as defined by the U.S. Department of Transportation (DOT), is any substance or

material, including a hazardous substance, hazardous waste, marine pollutant, or elevated temperature

material, which has been determined by the Secretary of Transportation to be capable of posing an

unreasonable risk to health, safety, and property when transported in commerce.

10

Hazardous Substance

A hazardous substance is a material, including its mixtures and solutions, that (1) is listed in Appendix A

to 49 CFR 172.101; (2) is in a quantity, in one package, which equals or exceeds the reportable quantity

(RQ) for that material; and (3) for non-radioactive materials, when in mixture or solution, equals or

exceeds the concentration listed in the RQ Percentage Table [49 CFR 171.8] corresponding to the RQ for

the material.

Hazardous Waste

Any material that is subject to the hazardous waste manifesting requirements of the EPA specified in 40

CFR Part 262.

Bulk Packaging

Bulk packaging is defined as having a maximum capacity greater than 450 liters (119 gallons) for liquids;

a maximum net mass greater than 400 kilograms (882 pounds) and a maximum capacity greater than 450

liters (119 gallons) for solids; or a water capacity greater than 454 kilograms (1000 pounds) for gases.

Non-Bulk Packaging

Non-bulk packaging is defined as having a maximum capacity of 450 liters (119 gallons) or less for

liquids; a maximum net mass of 400 kilograms (882 pounds) or less and a maximum capacity of 450

liters (119 gallons) or less for solids; a water capacity of 454 kilograms (1000 pounds) or less for gases;

or a non-bulk specification bag or a box conforming to the maximum net mass limitations provided in 49

CFR Part 178, Subpart L.

Intermediate Bulk Container

An intermediate bulk container (IBC) is a rigid or flexible portable packaging, other than a cylinder or

portable tank, with a volumetric capacity of not more than 3000 liters (793 gallons) and not less than 450

liters (119 gallons) or a maximum net mass of not less than 400 kilograms (882 pounds), which is

designed for mechanical handling.

Marine Pollutant

A marine pollutant is a material, including its mixtures and solutions, which is listed in Appendix B to 49

CFR 172.101 and is in a concentration greater than or equal to (1) ten percent by weight; or (2) one

percent by weight for materials identified as severe marine pollutants. Materials not listed in the List of

Marine Pollutants that meet the criteria for a marine pollutant in the General Introduction of the IMDG

Code, Guidelines for the Identification of Harmful Substances in Packaged Form (bioaccumulation

criteria; tainting of seafood criteria; or an aquatic life 96 hour LC50 less than 1 ppm), may be transported

as marine pollutants. Non-bulk packagings transported by motor vehicles, rail cars or aircraft are not

subject to the marine pollutant requirements [per 49 CFR 171.4(c)].

Flash Point

11

The minimum temperature at which a liquid gives off vapors which will ignite upon contact with a spark

or flame, using the Tag, Seta-flash, or Pensky-Martens Closed Tester methods.

Liquid

A material, other than an elevated temperature material, with a melting point or an initial melting point of

20C (68F) or lower. A viscous material for which a specific melting point cannot be determined is

heated to 38C (100F); if the material flows more than 2" from an inverted quart can after 3 minutes, it

is classified as a liquid.

Overpack

An enclosure that is used to provide protection or convenience in handling of a package or to consolidate

two or more packages, including packages placed or stacked on a pallet and secured by strapping or

stretch wrap. Overpacks must be marked with the proper shipping name and identification number and

labeled as required for the hazardous materials contained therein unless markings and labels are visible.

The overpack must be marked "OVERPACK" when specification packages are required and

specification markings on the inside packages are not visible.

HAZARDOUS MATERIALS CLASSIFICATION

In preparing a hazardous material for transportation, the shipper is responsible for classifying the

material according to criteria established by the Department of Transportation.

The properties and composition of the material are compared to the hazardous materials definitions. In

addition, it must be determined whether any component is a hazardous substance or a marine pollutant.

After determining the hazard class, packing group, and subsidiary risk, if any, the most appropriate

proper shipping name is selected from the DOT Hazardous Materials Table.

THE HAZARDOUS MATERIALS TABLE

The DOT Hazardous Materials Table in 49 CFR 172.101 designates hazardous materials for the purpose

of transportation. For each listed material, the Table identifies the hazard class or specifies that the

material is forbidden in transportation. The Table lists the proper shipping name, identification number,

and packing group, if any, and specifies or references requirements pertaining to labeling, packaging,

quantity limits aboard aircraft and stowage of hazardous materials aboard vessels.

If the material is not identified by name in the Table, which is commonly the case for mixtures or

solutions, then the shipper must assign a generic or N.O.S. (Not Otherwise Specified) name, which most

appropriately describes the material. Also, a material may meet the definition of more than one hazard

class. In this case the material will be described in accordance with the precedence of hazard list and

table established by the DOT in 49 CFR 173.2a.

In order to fully evaluate and properly classify a material, the List of Hazardous Substances and

Reportable Quantities (Appendix A to §172.101) and the List of Marine Pollutants (Appendix B to

§172.101) must also be reviewed to determine if any component of the material being shipped is a

hazardous substance or a marine pollutant.

12

Column 1 of the Hazardous Materials Table contains the following five symbols:

- the plus sign (+) fixes the proper shipping name, hazard class, and packing group for an entry

regardless whether the material meets the definition of that class or packing group;

- the letter "A" restricts the applicability of an entry to transport by aircraft, unless the material is a

hazardous substance or a hazardous waste;

- the letter "D" identifies proper shipping names which are appropriate for domestic transportation

but may be inappropriate for international transportation;

- the letter “G” identifies proper shipping names for which one or more technical names of the

hazardous material must be entered in parentheses, in association with the basic description [see 49

CFR 172.203(k)]

- the letter "I" identifies proper shipping names which are appropriate for international transportation

(an alternate proper shipping name may be selected when only domestic transportation is

involved);

- the letter "W" restricts the applicability of an entry to transport by vessel, unless the material is a

hazardous substance or a hazardous waste.

Column 2 lists the DOT proper shipping names (including generic or n.o.s. proper shipping names for

hazardous materials not specifically listed by name);

Column 3 indicates the DOT hazard class or division;

Column 4 indicates the identification number, where UN stands for United Nations and NA stands for

North American;

Column 5 indicates the packing group of the material;

Column 6 indicates the DOT hazard labels required on the outside of the package;

Column 7 references special provisions listed in 49 CFR 172.102;

Column 8A indicates the 49 CFR Part 173 Section, if any, where packaging exceptions are authorized

(including limited quantities);

Column 8B indicates the 49 CFR Part 173 Section where non-bulk packaging requirements are

authorized;

Column 8C indicates the 49 CFR Part 173 Section where bulk packaging requirements are authorized;

Column 9A specifies the maximum quantity for transport by passenger carrying aircraft or passenger rail

car;

Column 9B specifies maximum quantity for transport by cargo aircraft only;

Column 10A and 10B specify vessel stowage requirements for hazardous materials on board cargo and

passenger vessels.

13

14

DOT HAZARD CLASSES

The DOT hazard classes are as follows:

CLASS 1, EXPLOSIVES (49 CFR 173.50)

Explosives are materials which can detonate or are subject to very rapid combustion. Class 1 is divided

into six Divisions: 1.1, 1.2, 1.3, 1.4, 1.5, and 1.6.

CLASS 2, COMPRESSED GASES (49 CFR 173.115)

Class 2 is divided into three divisions, as follows:

Division 2.1 - Flammable gases

Flammable gases are materials which are gases at ambient conditions and are ignitable in a mixture of 13

percent or less by volume with air or have a flammable range with air of 12 percent or more.

Division 2.2 - Non-flammable gases

Non-flammable gases are materials with a pressure of 40.6 psia or more at 20oC (68oF) which do not

meet the definition of Division 2.1 or 2.3. The non-flammable gas definition includes asphyxiant and

oxidizing gases.

Division 2.3 - Poisonous gases

Poisonous gases are materials which are gases at ambient conditions which are known to be so toxic to

humans as to pose a hazard to health during transportation, or in the absence of adequate data on human

toxicity, is presumed to be toxic to humans because a concentration of 5000 ppm or less produces death

within 14 days in half of the laboratory animals tested when inhaled continuously for a period of one

hour.

CLASS 3, FLAMMABLE and COMBUSTIBLE LIQUIDS (49 CFR 173.120)

Flammable Liquid

A flammable liquid is any liquid having a flash point of not more than 60oC (140oF), or any material in a

liquid phase with a flash point at or above 37.8oC (100oF) that is intentionally heated and offered for

transportation or transported at or above its flash point in a bulk packaging.

Combustible Liquid

A combustible liquid is any liquid that does not meet the definition of any other hazard class, and has a

flash point above 60oC (140oF) and below 93oC (200oF).

A flammable liquid with a flash point at or above 38oC (100oF) that does not meet the definition of any

other hazard class may be reclassed as a combustible liquid for transportation by rail or highway [per 49

CFR 173.150(f)(1)]. An elevated temperature material that meets the definition of a Class 3 material

15

because it is intentionally heated and offered for transportation or transported at or above its flash point

may not be reclassed as a combustible liquid.

The DOT Hazardous Materials Regulations do not apply to materials classed as combustible liquids in

non-bulk packaging unless the combustible liquid is a hazardous substance, a hazardous waste, or a

marine pollutant [per 49 CFR 173.150(f)(2)].

Assignment of Packing Group, Class 3 (49 CFR 173.121)

When the 172.101 Hazardous Materials Table provides more than one Packing Group for a hazardous

material, or indicates that the Packing Group is to be determined on the basis of the grouping criteria for

Class 3, the Packing Group shall be determined by applying the following criteria:

Packing

Group

I

II

III

Flash point (closed-cup)

o

o

<23 C (73 F)

>23oC, <60oC (140oF)

Initial boiling point

< 35oC (95oF)

> 35oC (95oF)

> 35oC (95oF)

The definition of a flammable liquid does not include any liquid with a flash point greater than 35C

(95F) which:

does not sustain combustion when the external source of flame is removed (per the testing

method in new Appendix H); or

is in a water-miscible solution with a water content of more than 90% by mass.

CLASS 4, FLAMMABLE SOLIDS SPONTANEOUSLY, COMBUSTIBLE MATERIALS, and

DANGEROUS WHEN WET MATERIALS (49 CFR 173.124)

Class 4 is divided into Divisions 4.1, 4.2 & 4.3 as follows:

Division 4.1 - Flammable Solids

Desensitized explosives are flammable solids that, when dry, are Explosives of Class 1 other than those

of compatibility group A, which are wetted with sufficient water, alcohol, or plasticizer to suppress

explosive properties; and are specifically authorized by name either in the 172.101 Table or have been

assigned a shipping name and hazard class by the Associate Administrator for Hazardous Materials

Safety under the provisions of an exemption issued under 49 CFR Part 107 or an approval issued under

173.56(i) of the Hazardous Materials Regulations.

Self-reactive materials are flammable solids that are liable to undergo, at normal or elevated

temperatures, a strong exothermic decomposition caused by excessively high transport temperatures or

by contamination.

Readily combustible solids are flammable solids which may cause a fire through friction, such as

matches; or show a burning rate faster than 2.2 mm (0.087 inches) per second; or any metal powders that

can be ignited and react over the whole length of a sample in 10 minutes or less, when tested in

accordance with the "UN Manual of Tests and Criteria".

16

Division 4.2 - Spontaneously Combustible Materials

A pyrophoric material is a liquid or solid that, even in small quantities and without an external ignition

source, can ignite within five (5) minutes after coming in contact with air when tested in accordance with

the "UN Manual of Tests and Criteria".

A self-heating material is a material that, when in contact with air and without an energy supply, is liable

to self-heat. A material of this type exhibits spontaneous ignition, or the temperature of the sample

exceeds 200oC (392oF) during the 24-hour test period, when tested in accordance with the "UN Manual

of Tests and Criteria".

Division 4.3 - Dangerous When Wet Material

A dangerous when wet material is a material that, by contact with water, is liable to become

spontaneously flammable or to give off flammable or toxic gas at a rate greater than 1 liter per kilogram

of the material, per hour, when tested in accordance with the "UN Manual of Tests and Criteria".

CLASS 5, OXIDIZERS and ORGANIC PEROXIDES (49 CFR 173.127 & 128)

Class 5 is divided into Divisions 5.1 and 5.2, as follows:

Division 5.1 - Oxidizers

An oxidizer is a material that may, generally by yielding oxygen, cause or enhance the combustion of

other materials.

A solid material is classed as a Division 5.1 material if, when tested in accordance with the UN Manual

of Tests and Criteria, its mean burning time is less than or equal to the burning time of a 3:7 potassium

bromate/cellulose mixture.

A liquid material is classed as a Division 5.1 material if, when tested in accordance with the UN Manual

of Tests and Criteria, it spontaneously ignites or its mean time for a pressure rise from 690 kPa to 2070

kPa gauge is less than the time of a 1:1 nitric acid (65 percent) /cellulose mixture.

Division 5.2 - Organic Peroxides

An organic peroxide is any organic compound containing oxygen in the bivalent -O-O- structure and

which may be considered a derivative of hydrogen peroxide, where one or more of the hydrogen atoms

have been replaced by organic radicals [unless the material meets the definition of an explosive; the

material is forbidden from being offered for transportation according to 49 CFR 172.101 or 173.21; the

Department of Transportation has determined that the material does not present a hazard associated with

a Division 5.2 material; or the available oxygen is below the level indicated in 49 CFR 173.128(a)(4)].

CLASS 6, POISONOUS MATERIALS and INFECTIOUS SUBSTANCES (49 CFR 173.132 &

173.134)

Class 6 is divided into Divisions 6.1 and 6.2, as follows:

17

Division 6.1 - Poisonous Materials

A poisonous material is a material, other than a gas, known to be so toxic to humans as to afford a hazard

to health during transportation, or which, in the absence of adequate data on human toxicity, is presumed

to be toxic to humans because it falls within any one of the following categories when tested on

laboratory animals:

(1) Oral Toxicity: Produces death within 14 days in half the animals tested at a single dose

(LD50) of 300 mg/kg body weight when administered orally.

(2) Inhalation Toxicity: Produce death within 14 days in half the animals tested when inhaled

continuously for a period of one hour or less (LD50) at a concentration of 4 milligrams or less per

liter for dusts or mists, or a concentration of 5000 ppm or less and a saturated vapor

concentration of more than one-fifth the lethal concentration for vapors. If the material is

administered to the animals as a dust or mist, more than 90 percent of the particles available for

inhalation in the test must have a diameter of 10 microns or less if it is reasonably foreseeable

that such concentrations could be encountered by a human during transport (including dust

generated during handling and shipping).

A solid substance should be tested if at least 10 percent of its total mass is likely to be dust in a

respirable range, e.g. the aerodynamic diameter of that particle-fraction is 10 microns or less. A

liquid substance should be tested if a mist is likely to be generated in a leakage of the transport

containment. In carrying out the test both for solid and liquid substances, more than 90% (by

mass) of a specimen prepared for inhalation toxicity testing must be in the respirable range.

(3) Dermal Toxicity: Produce death within 14 days in half the animals tested when administered

by continuous contact with the skin (dermal LD50) for 24 hours or less at a dosage of 1000

mg/kg.

For purposes of classifying and assigning packing groups to mixtures possessing oral or dermal

toxicity hazards, it is necessary to determine the acute LD50 of the mixture. If a mixture contains

more than one active constituent, one of the following methods may be used to determine the oral

or dermal LD50 of the mixture: (1) Obtain reliable acute oral and dermal toxicity data on the

actual mixture to be transported; (2) If reliable, accurate data is not available, classify the

formulation according to the most hazardous constituent of the mixture as if that constituent were

present in the same concentration as the total concentration of all active constituents; or (3) If

reliable, accurate data is not available, apply the formula in 49 CFR 173.132(c)(3).

(4) Poison-Inhalation Hazard Material: (a) Any gas with an LC50 for acute toxicity on

inhalation of vapors of 5000 ppm or less; (b) any liquid with a saturated vapor concentration at

68oF equal to or greater than ten times the LC50 for acute toxicity on inhalation of vapors and an

LC50 for acute toxicity on inhalation of vapors of 1000 ppm or less. These materials have special

shipping paper, packaging, marking, labeling and placarding requirements.

18

Division 6.1, Assignment of Packing Group, (49 CFR 173.133)

The packing group of Division 6.1 materials for routes of administration other than inhalation of vapors

shall be in accordance with the following table:

Packing

Group

Oral toxicity

LD50 (mg/kg)

Dermal toxicity

LD50 (mg/kg)

Inhalation toxicity

by dusts and mists

LC50 (mg/L)

I

II

III

<5

> 5 and < 50

> 50 and < 300

< 50

> 50 and < 200

> 200 and < 1000

< 0.2

> 0.2 and < 2

> 2 and < 4

The packing group and hazard zone assignments for liquids based on inhalation of vapors shall be in

accordance with the following Table:

Packing group

Vapor concentration and toxicity

I (Hazard Zone A).

V 500 LC50 200 mL/m3.

I (Hazard Zone B).

V 10 LC50; LC50 1000 mL/m3; and the criteria

for Packing Group I, Hazard Zone A are not met.

II

V LC50 ; LC50 3000mL/m3; and the criteria for

Packing Group I, are not met.

III

V .2LC50; LC50 5000 mL/m3; and the criteria

for Packing Groups I and II, are not met.

Note 1: V is the saturated vapor concentration in air of the material in mL/m3 at

20C and standard atmospheric pressure.

Note 2: A liquid in Division 6.1 meeting criteria for Packing Group I, Hazard Zones

A or B stated in paragraph (a)(2) of this section is a material poisonous by inhalation

subject to the additional hazard communication requirements in §§172.230(m)(3),

172.313 and Table 1 of §172.504(e) of this subchapter.

Division 6.2 - Infectious Substances (49 CFR 173.134)

Infectious substances are materials which may cause disease in humans or animals.

CLASS 7, RADIOACTIVE MATERIALS (49 CFR 173.403)

Radioactive materials are any materials containing radionuclides with an activity concentration and total

activity exceeding the criteria specified in 49 CFR 173.433 or 173.436. Radioactive materials can cause

burns and other injuries.

19

CLASS 8, CORROSIVE MATER1ALS (49 CFR 73.136)

A corrosive material is a liquid or solid that causes full thickness destruction of skin tissue at the site of

contact within a specified period of time, or a material that has a severe corrosion rate on steel or

aluminum.

Assignment of Packing Group, Class 8 (49 CFR 173.137)

Packing Group I. Materials that cause full thickness destruction of intact skin tissue within an

observation period of up to 60 minutes starting after the exposure time of three minutes or less.

Packing Group II. Materials that cause full thickness destruction of intact skin tissue within an

observation period of up to 14 days starting after the exposure time of more than three minutes

but not more than 60 minutes.

Packing Group III. Materials, other than those meeting Packing Group I or II criteria that cause

full thickness destruction of intact skin tissue within an observation period of up to 14 days

starting after the exposure time of more than 60 minutes but not more than 4 hours; or which

have a corrosion rate on steel or aluminum surfaces exceeding 6.25 mm (0.246 inch) a year at a

test temperature of 55oC (131oF).

Retesting of materials classified under the previous test method is not required.

Exception for materials corrosive to aluminum or steel only: Except for a hazardous substance, a

hazardous waste, or a marine pollutant, a material classed as a Class 8, Packing Group III, material solely

because of its corrosive effect on aluminum or steel is not subject to any other requirements of the

Hazardous Materials Regulations when transported by highway or rail in a bulk packaging constructed of

materials that will not react dangerously with or be degraded by the corrosive material. This exception

applies to both bulk and non-bulk packaging for materials corrosive to aluminum, but it only applies to

bulk packaging for materials corrosive to steel.

CLASS 9, MISCELLANEOUS HAZARDOUS MATERIALS (49 CFR 173.140)

Miscellaneous hazardous materials are hazardous materials which do not meet the definition of any other

hazard class (1) which have an anesthetic, noxious, or similar property which could cause extreme

annoyance or discomfort to a flight crew member so as to prevent the correct performance of assigned

duties; (2) are hazardous substances or hazardous wastes; (3) are marine pollutants; or (4) are elevated

temperature materials.

ORM-D, OTHER REGULATED MATERIAL (49 CFR 173.144)

An ORM-D material is a material such as a consumer commodity which presents a limited hazard during

transportation due to its form, quantity and packaging. Only those materials for which exceptions are

permitted in column 8A of the Hazardous Materials Table are eligible to be classified as ORM-D

materials.

A consumer commodity is a limited quantity of a hazardous material which is packaged and distributed in

a form intended or suitable for retail sale for consumption by individuals for purposes of personal or

20

household use.

The proper shipping name changes to “consumer commodity” and the hazard class changes to “ORM-D”

for materials shipped under the consumer commodity exception. A consumer commodity does not have

an Identification Number or Packing Group number, is not subject to specification packaging

requirements, and shipping papers are not required for consumer commodity shipments, unless the

material is a hazardous substance, a hazardous waste, a marine pollutant, or is offered or intended for

transportation by air.

Consumer commodities must be shipped in strong outside packagings, marked "Consumer commodity"

followed by the ORM-D designation in a rectangle, and are subject to a 66 pound (30 kg) package weight

limitation except when (i)

(ii)

Unitized in cages, carts, boxes or similar overpacks;

Offered for transportation or transported by:

(A) Rail;

(B) Private or contract motor carrier; or

(C) Common carrier in a vehicle under exclusive use for such service; and

(iii)

Transported to or from a manufacturer, a distribution center, or a retail

outlet, or transported to a disposal facility from one offeror.

In addition, display ready units, merchandisers, etc., with a maximum net quantity of 250 kg (550

pounds) containing inner packagings which conform to the consumer commodity quantity limitations

may be offered for transportation, or transported, by highway or rail between a manufacturer, a

distribution center, and a retail outlet by any type of carrier, including LTL. Display pack inner

receptacles are packed into corrugated fiberboard trays to prevent them from moving freely. The trays

are placed in a fiberboard box which is banded and secured to a wooden pallet by metal, fabric, or plastic

straps, to form a single palletized unit. The palletized unit must conform to the general packaging

requirements, and it must be marked "Consumer commodity" followed by the ORM-D designation in a

rectangle, as required in 49 CFR 172.316.

The ORM-D classification and the “consumer commodity” proper shipping name are in the process of

being eliminated from the DOT Hazardous Materials Regulations. They will no longer be authorized as

of January 1, 2021. Materials previously meeting the definition of a consumer commodity will be

required to be shipped as limited quantities.

As part of these changes, shipping papers will no longer be required for ground shipments of limited

quantities, unless they are also a hazardous substance, a hazardous waste or a marine pollutant. Shipping

papers continue to be required for air and vessel shipments.

Prior to January 1, 2021, either the new limited quantity requirements or the old limited quantity and

ORM-D requirements may be used.

A “limited quantity” or “LTD QTY” notation is still required for ocean shipments, but this notation is no

longer required for air shipments. Packages shipped by air are no longer required to be marked with the

words “Limited Quantity” or “Ltd Qty”.

Also as part of these changes, a new limited quantity marking (100 mm x 100 mm) will be required for

all modes of transportation. For limited quantity shipments by ground or water, a diamond with black

21

triangles in the top and bottom corners will be required. Ground and water shipments are not required to

be marked with the proper shipping name, identification number or to display hazard labels (except if

toxic).

For limited quantity shipments by air, a diamond with black triangles in the top and bottom corners plus

the letter “Y” in the center is required. Limited quantity shipments by air must display hazard labels, be

marked with the proper shipping name and identification number in addition to the new limited quantity

marking.

Cargo transport units containing dangerous goods in only limited quantities must be marked with large

(250 mm x 250 mm) limited quantity marks on all four sides.

PRECEDENCE OF HAZARDS

(49 CFR 173.2a(b))

A material that is not specifically listed in Table 172.101 that meets the definition of more than one

hazard class or division, shall be classed according to the highest applicable hazard class of the following

hazard classes.

The following Hazard Classes are listed in descending order of hazard.

- CLASS 1

(explosive); Division 5.2 (organic peroxide); Division 6.2 (infections substance); or

Division 4.1 (wetted explosive)

- CLASS 7

Radioactive Materials (other than limited quantity)

- Division 2.3 Poisonous Gases

- Division 2.1 Flammable Gases

- Division 2.2 Non-Flammable Gases

- Division 6.1 Poisonous Liquids, Poison-Inhalation Hazard materials only

- Division 4.2 Pyrophoric Material

- Division 4.1 Self Reactive Material

- The precedence of hazards for a material meeting more than one of the following hazards - Classes 3 or

8, Divisions 4.1, 4.2, 4.3, 5.1, or 6.1 (other than Packing Group I, poisonous-by-inhalation) - shall be

determined using the 49 CFR 173.2a Precedence of Hazard Table below.

- Combustible Liquids

- CLASS 9

Miscellaneous Hazardous Material

22

Precedence of Hazard Table

[Hazard class or division and packing group]

4.2

3 I2

3 II2

3 III2

4.2

4.1 II2

4.2

4.1 III2

4.2 II

4.2 III

4.3 I

4.3 II

4.3 III

5.1 I1

5.1 II1

5.1 III1

6.1 I, Dermal

6.1 I, Oral

6.1, II Inhalation

6.1 II, Dermal

6.1 II, Oral

6.I, III

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

5.1 I1 5.1 II1 5.1

III1

5.1

5.1

5.1

5.1

5.1

5.1

5.1

4.1

4.1

4.2

5.1

4.3

4.3

5.1

4.1

4.1

4.2

4.2

4.3

4.3

4.3

6.1, I

6.1, I

dermal oral

3

3

3

3

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

4.3

6.1

4.3

6.1

6.1

5.1

5.1

6.1

5.1

6.1

6.1

6.1 II 6.1 III 8, I

liquid

3

3

3

3

3

8

6.1

34 8

4.1

4.1 (3)

6.1

4.1 (3)

4.2

4.2 8

6.1

4.2 8

4.3

4.3 4.3

4.3

4.3 8

6.1

4.3 8

5.1

5.1 5.1

5.1

5.1 8

6.1

5.1 8

8

8

8

8

8

8

8, I 8, II

solid liquid

(3)

3

(3)

3

(3)

8

8

(3)

8

(3)

8

4.2

8

8

4.3

4.3

8

8

8

8

5.1

5.1

8

8

8

8

6.1

6.1

6.1

6.1

6.1

6.1

6.1

8

8

8

8

8

8, II

solid

(3)

(3)

(3)

4.1

8

4.2

8

4.3

4.3

8

5.1

5.1

8

6.1

6.1

6.1

6.1

6.1

8

8, III 8, III

liquid solid

3

(3)

3

(3)

3

(3)

(3)

4.1

(3)

4.1

4.2

4.2

4.2

4.2

4.3

4.3

4.3

4.3

4.3

4.3

5.1

5.1

5.1

5.1

5.1

5.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

6.1

8

8

1

See 49 CFR 173.127(b)

Materials of Division 4.1 other than self-reactive substances and solid desensitized explosives, and materials of Class 3 other

than liquid desensitized explosives.

3

Denotes an impossible combination.

4

For pesticides only, where a material has the hazards of Class 3, Packing Group III, and Division 6.1, Packing Group III, the

primary hazard is Division 6.1, Packing Group III.

Note 1: The most stringent packing group assigned to a hazard of the material takes precedence over other packing groups; for

example, a material meeting Class 3 PG II and Division 6.1 PG I (oral toxicity) is classified as Class 3 PG I.

Note 2: A material which meets the definition of Class 8 and has an inhalation toxicity by dusts and mists which meets criteria

for Packing Group I specified in §173.133(a)(1) must be classed as Division 6.1 if the oral or dermal toxicity meets criteria for

Packing Group I or II. If the oral or dermal toxicity meets criteria for Packing Group III or less, the material must be classed as

Class 8.

2

GENERAL PACKAGING REQUIREMENTS

(49 CFR Part 173)

After hazardous materials are correctly classified and described, that information is used to select

appropriate packaging. The Hazardous Materials Table lists packaging references for each hazardous

material. The proper packaging of hazardous materials is essential for the safety of everyone involved in

handling and transportation. Each package used for hazardous materials must be designed, manufactured,

and tested so that when it is properly filled, closed and shipped there will be no unintentional release of

material under normal transportation conditions.

Non-bulk packaging is defined as having a maximum capacity of 450 liters (119 gallons) or less for

liquids; a maximum net mass of 400 kilograms (882 pounds) or less and a maximum capacity of 450

liters (119 gallons) or less for solids; or a water capacity of 454 kilograms (1000 pounds) or less for

gases [49 CFR 171.8].

23

Bulk packaging is defined as having a maximum capacity greater than 450 liters (119 gallons) for liquids;

a maximum net mass greater than 400 kilograms (882 pounds) and a maximum capacity greater than 450

liters (119 gallons) for solids; or a water capacity greater than 454 kilograms (1000 pounds) for gases [49

CFR 171.8].

An intermediate bulk container (IBC) is a rigid or flexible portable packaging, other than a cylinder or

portable tank, with a volumetric capacity of not more than 3000 liters (793 gallons) and not less than 450

liters (119 gallons) or a maximum net mass of not less than 400 kilograms (882 pounds), which is

designed for mechanical handling [49 CFR 178.700(c)(1)].

United Nations performance oriented packaging is referenced in the Hazardous Materials Table for

non-bulk and intermediate bulk container packaging.

For most bulk packaging (including tank trucks, tank cars, and certain portable tanks), DOT specification

standards, rather than UN Specifications, apply. For intermediate bulk containers, UN Specifications

apply.

Package specification markings must be shown on the container.

a) Metal drums with a capacity greater than 100 liters must have markings in a

"durable" manner (e.g. printed label) on the top or side, and markings in a permanent form

(e.g. embossed), on the bottom of the drum.

b) Metal drums with a capacity of 100 liters or less are usually embossed on the bottom.

c) Plastic drums are usually embossed on the side.

d) Boxes are imprinted on the side or the bottom flap.

e) Bags are imprinted on the back.

f) Rigid plastic or metal bulk containers have name plates.

For packages with a gross weight greater than 66 lbs., UN Specification markings or a duplicate thereof

must appear on the top or side of the packaging [per 49 CFR 178.3(a)(5)].

The product must be compatible with the packaging. The package must be able to withstand the rigors of

transportation.

Each non-bulk package containing liquids in inner packagings must be packed with closures upward.

The inner container must not be filled to capacity. Allow a minimum of 1% void for product expansion

(5% for Poison-Inhalation Hazard materials).

All packages must be properly closed to prevent leaking, sifting or rupture. Packagings must conform in

all respects with the method of packaging and size and type of inner packagings specified in the

packaging test report. Packagings must be closed for transportation in the same manner as they were

closed for UN testing. The manufacturer and each subsequent distributor of a packaging must notify

each person to whom that packaging is transferred in writing instructions for closing the packaging in the

same manner as it was closed for testing.

Nails, staples and other metal fasteners must not protrude into the package interior so as to damage the

inner container.

24

Plastic drums may be reused without undergoing leakproofness testing for five years from the date of

manufacture as long as they show no evidence of reduced integrity, are refilled with the same or similar

contents, and are transported by a private carrier, contract carrier, or common carrier in a transport

vehicle or freight container used exclusively for such service, within a distribution chain controlled by

the offeror.

During transportation

• no hazardous material may remain on the outside of the IBC

• each IBC must be securely fastened to or contained within the transport unit

• IBCs containing liquids must be resistant to an increase of internal pressure likely to

develop due to heat or an increase in elevation

Each metal IBC must be internally inspected at least every five years.

Additional carrier requirements:

Certain carriers have established their own packaging requirements, which, in some cases, are more

stringent than those in 49 CFR. These additional requirements, though not required for regulatory

compliance, must be met in order to ship hazardous materials with these carriers.

MARKING REQUIREMENTS

Shipper Package Markings: (49 CFR Part 172 Subpart D)

Each person who offers a hazardous material for transportation must mark each package, freight

container, and transport vehicle containing the hazardous material as required by the Hazardous

Materials Regulations.

Except for shipments made in accordance with the 49 CFR 171.14(d)(2) intermixing provision,

hazardous materials proper shipping names, technical names and identification numbers marked on

packages must agree with the hazardous materials descriptions entered on shipping papers.

Non-bulk Packaging:

Non-bulk packaging must be marked with the proper shipping name and identification number (preceded

by “UN” or “NA” as appropriate) assigned to the material in the Hazardous Materials Table [49 CFR

172.101]. Identification numbers are not required on packages which contain only limited quantities or

ORM-D materials [per 172.301(a)(1)].

The identification number marking preceded by “UN”, “NA”, or “ID” as appropriate must be marked in

characters at least 12 mm (0.47 inches) high. Packages with a maximum capacity of 30 liters (8 gallons)

or less, 30 kg (66 pounds) maximum net mass, or cylinders with a water capacity of 60 liters (16 gallons)

or less must be marked with characters at least 6 mm (0.24 inches) high. Packages with a maximum

capacity of 5 liters (1.32 gallons) or 5 kg (11 pounds) or less must be marked in a size appropriate for the

size of the package.

For domestic transportation, until January 1, 2017, the identification number markings are not subject to

the minimum size requirements.

For domestic transportation, a packaging manufactured prior to January 1, 2017 and permanently marked

25

with the appropriate identification number marking may continue in service until the end of its useful life

and are not subject to the minimum size requirements.

Marking must be durable, in English and printed on or affixed to the surface of a package or on a label,

tag, or sign. It must be displayed on a background of sharply contrasting color. It must be unobscured by

labels or attachments and located away from any other marking that could substantially reduce its

effectiveness. It must be located near the DOT label.

If non-bulk packaging containing a hazardous material will be transferred from one motor carrier to

another, and it is not part of full load being tendered from one consignor to one consignee, then it must

be marked with the name and address of the consignor or the consignee.

Each non-bulk package containing hazardous liquids in inner packaging must have orientation markings

affixed or preprinted on two opposite vertical sides with arrows indicating the upward direction of

closures. (See illustration below.)

Each non-bulk packaging containing a hazardous material described with a generic or N.O.S. proper

shipping name must be marked with the technical name(s) in parentheses in association with the proper

shipping name [per 49 CFR 172.301(b)].

If the proper shipping name for a material that is a hazardous substance does not identify the constituents

making it a hazardous substance, the name of the hazardous substance must be marked on non-bulk

packages, in parentheses, near the proper shipping name. If the material contains two or more hazardous

substances, at least the two hazardous substances with the lowest reportable quantities must be identified.

The letters “RQ” must also be marked in association with the proper shipping name on non-bulk

packages which contain a hazardous substance [per 49 CFR 172.324].

For materials poisonous by inhalation, the package must be marked "Inhalation Hazard" in association

with the required label(s) and shipping name. When the words "Inhalation Hazard" appear on the

POISON GAS or POISON-INHALATION HAZARD label, the "Inhalation Hazard" marking is not

required on the package.

A transport vehicle or freight container loaded with more than 2205 pounds (1000 kg) aggregate gross

weight of packages containing a material poisonous by inhalation must be marked on all four sides with

the identification number for the material. If the transport vehicle contains more than one material

poisonous by inhalation which requires the display of an identification number, then the transport vehicle

must be marked with the identification number of the Zone A material if one of the materials is in Zone

A and the others are in Zone B, or with the identification number of the material with the greatest

aggregate gross weight for different materials in the same hazard zone [172.313(c)(3)].

A transport vehicle or freight container that is loaded at one loading facility with 4,000 kg (8,820 lbs.) or

more of hazardous materials in non-bulk packagings must be marked on all four sides with the

26

identification number specified for the hazardous material when all of the hazardous materials have the

same proper shipping name and identification number and the transport vehicle contains no other

material, hazardous or non-hazardous.

A placard bearing an identification number may not be used to satisfy the placarding requirements unless

it is the correct identification number for all hazardous materials of the same class in the transport vehicle

or freight container. When different hazardous materials within a hazard class are present in a transport

vehicle or freight container, and the identification number of one of the materials must be displayed (e.g.,

a PIH material), the transport vehicle must bear placards for that hazard class without an identification

number plus either (1) a separate set of placards with the identification number or (2) the separate orange

panels or white square-on-point display configurations.

Each non-bulk packaging containing a material classed ORM-D must be marked on at least one side or

end with the ORM-D designation immediately following or below the proper shipping name of the

material. If the non-bulk ORM-D packaging is prepared for air shipment it must be marked ORM-D-AIR

[per 172.316(a)(1)]. The ORM-D designation must be placed with a rectangle that is approximately 0.25

inches larger than the designation in accordance with 49 CFR 172.316. The ORM-D marking is not

required for materials classed as ORM-D when they are unitized in cages, carts, boxes, or similar

overpacks and offered for transportation, or transported, by a private or contract motor carrier or a

common carrier vehicle under exclusive use for such service, from a manufacturer or a distribution center

to a retail outlet, or return.

The ORM-D classification and the “consumer commodity” proper shipping name are in the process of

being eliminated from the DOT Hazardous Materials Regulations. They will no longer be authorized as

of January 1, 2021. Materials previously meeting the definition of a consumer commodity will be

required to be shipped as limited quantities.

Shipping papers are no longer required for ground shipments of limited quantities, unless they are also a

hazardous substance, a hazardous waste or a marine pollutant. Shipping papers continue to be required

for air and vessel shipments.

Prior to January 1, 2021, either the limited quantity requirements or the ORM-D requirements may be

used.

A “limited quantity” or “LTD QTY” notation is still required for ocean shipments, but this notation is no

longer required for air shipments. Packages shipped by air are no longer required to be marked with the

words “Limited Quantity” or “Ltd Qty”.

The limited quantity marking is required for all modes of transportation. For limited quantity shipments

by ground or water, a diamond with black triangles in the top and bottom corners will be required

(minimum dimensions - 100 mm x 100 mm; minimum width of line forming diamond - 2 mm). Ground

and water shipments are not required to be marked with the proper shipping name, identification number

or to display hazard labels (except if toxic).

For limited quantity shipments by air, a diamond with black triangles in the top and bottom corners plus

the letter “Y” in the center is required. Limited quantity shipments by air must display hazard labels, be

marked with the proper shipping name and identification number in addition to the new limited quantity

marking.

27

Cargo transport units containing dangerous goods in only limited quantities must be marked with large

(250 mm x 250 mm) limited quantity marks on all four sides.

Limited quantity mark for ground & vessel shipments:

Limited quantity mark for air shipments:

Bulk Packaging:

Specifications and test dates must be verified by visual inspection of stencils on the ends and sides of

tank cars and on the specification plate of cargo tanks and portable tanks.

For bulk shipments, the four digit UN/NA identification number must be (a) incorporated into the

placards corresponding to the primary hazard class of a material (except radioactive or explosive

placards); (b) displayed on rectangular orange panels; or (c) displayed on plain white square-on-point

display configurations having the same outside dimensions as a placard [per 49 CFR 172.336(b)]. The

identification number must be marked on two opposite sides of bulk packaging with a capacity of less

than 1000 gallons and on each side and each end of packaging with a capacity of 1000 gallons or more

[per 49 CFR 172.302(a)(2)]. As indicated in 49 CFR 172.328(a), unless a cargo tank is already marked

with the required identification numbers, the shipper must provide the motor carrier with the

28

identification numbers on placards or must affix the required identification numbers to the cargo tank on

panels or placards prior to or at the time the hazardous material is offered for transportation.

Identification numbers must be displayed on each side and each end of transport vehicles or freight

containers from which the identification numbers on portable tanks or intermediate bulk containers are

not visible [per 49 CFR 172.326(c)(1) and 172.331(c)].

Portable tanks with a capacity of less than 1000 gallons must be marked on two opposing sides with the

proper shipping name of the material in letters measuring at least one inch high. Portable tanks with a