STABILIZED TWO

advertisement

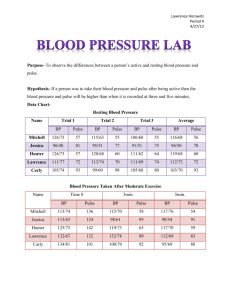

Modified version of the Minsk STABILIZED TWO-WAVELENGTHS LED-BASED PULSED AND CONSTANT LIGHT SOURCE CERN 2004 TTL levels: FREEZE: Stabilization ON/OF Constant/pulsed light mode TTL pulses: Color selection Light pulse trigger: NIM pulses Original control via the TTL levels and front panel switches is replaced by the full remote control by TTL levels and pulses only. Any regime changes can be made only is FREEZE level is “1”. FREEZE = 0 means the pulser is running according to the previously defined settings. To setup operation in pulsed mode, blue LED: 1. put FREEZE level to “1” 2. sent TTL pulse to the “blue” input of the Color selection cable 3. start to send TTL pulses to the left (“blue”) Light pulse trigger LEMO connector ( could be sent all the time, pulser become sensitive to it only is blue pulsed more is selected ) 4. choose the output signal level by “INTENSITY + - “ switch 5. press “Set” button: red LED above the button will light, it indicates that the internal output intensity procedure is started. Wait for this light get OFF 6. put “FREEZE” level to “0” 7. “high” “low” yellow lights at the right side of the box should start to blink – means putput regulation is running. If one of the lights is ON all the time – outut signal is too low or too high. Repeat the adjustment procedure. “Blue” and “Red” stabilization are logically independent. I means once defined, the stabilization level is stored in the memory and will be restored as soon as the corresponding color pulsed mode is selected. Of course all settings are lost on box power OFF. Constant light mode is selected by CONSTANT level “1” ( green indicator should light). By setting it bact to “0” you restore the previous pulsed mode, including color and output amplitude. Stabilized Light Pulse Source !!! VERY IMPORTANT. The box operates normally only if one of the output fibers is connected to the feedback input. Stabilized Light Pulse Source Appendix 1. Original text of the light source description STABILIZED TWO-WAVELENGTHS LED-BASED PULSED AND CONSTANT LIGHT SOURCE MINSK 2003 Stabilized Light Pulse Source Stabilized Two-wavelengths LED-based Light Pulsed Source Stabilized two-wavelengths LED-based pulsed light source (Light Pulser) is designed for monitoring of electromagnetic calorimeter detector cells at two wavelengths, namely 1=460 nm (BLUE channel) and 2=638 nm (RED channel). Light at the output is uniformized in the quartz cylinder of 8.0 mm diameter. General Technical Data 1 Number of photons at the . light output 2 . 3 . 4 . Light pulse duration adjustment range (typical) Non-stability of photon number per pulse (after 30 min warming-up) Repetition rate of light pulses (with external synchronization) Input signals “FREEZE”, “COLOR”, “CONSTANT” Input signal “START” 5 . 6 . 7 Output signal “MONITOR”: . amplitude shaping 8 Power requirements, min: . +6 V10% +24 V10% -6 V10% -24 V10% 9 Power consumption . BLUE channel: 500×106 photons for 20 ns optical pulse duration 5000×106 photons for 100 ns optical pulse duration RED channel: 500×106 photons for 20 ns optical pulse duration 5000×106 photons for 120 ns optical pulse duration 20 – 100 ns FWHM 0.1% 1 Hz 1 kHz TTL standard NIM standard 0 V 4.5 V (3 V in stabilization mode) quasi-Gauss 250 mA 500 mA 1000 mA 300 mA ~ 25 W Stabilized Light Pulse Source Technical description Light Pulser diagram is shown in Figure. Light Pulser contains two output channels (RED and BLUE) and one PIN diode reference unit. The description below is valid for both channels Input pulse “START” activates monostable multivibrator made of the ECL logic elements and built-in digitally controlled delay line providing electronic adjustment of pulse duration. This signal of predefined duration drives the current switch that connects digitally controlled current source to the input of fast linear current amplifier with superbright LED as a load. Short time of light flash is achieved by using the active quenching circuit. Light from LED goes through the optical system with light splitter to the input of optical feedback circuits. Thermo-stabilized PIN photodiode is used as the photo detector there. Signal from the photodiode, amplified by the charge-sensitive preamplifier and the precise adjustable shaping amplifier, goes to analog comparator, which compares the amplitude of the PIN photodiode signal with the reference voltage U REF. Comparator generates the signal proportional to the PIN diode to UREF difference, which is processed by 12-bit digital-to-analog integrator and goes to LED current control circuit. Controls located on the Light Pulser front panel: push-button “SET” with LED indicator for gain adjustment of the shaping amplifier; stabilization circuit on/off: LEMO connector “FREEZE” with LED indicator; constant blue light on/off: LEMO connector “CONST.” with LED indicator; “START BLUE”: LEMO input; “START RED”: LEMO input; “Color”: LEMO input; “Intensity” indicator; “ Intensity” switch; “UDAC” DAC output; “MONITOR” shaping amplifier output; stabilization mode LED indicators : “HOLD”, “LOW”, “HIGH”; “POWER”: power supply connector. Optical connectors located on the rear panel: “LIGHT OUTPUT”: flange type connector (diameter of the output light beam is defined by output quartz cylinder and is equal to 8.0 mm) PIN-diode connector of DNP-type for 1mm plastic optical fiber. Stabilized Light Pulse Source Operation manual 1. Installation Connect power cable to the “POWER” connector on the rear panel. Power pins specification is given in Appendix 1. Connect fiber bunch to the “LIGHT OUTPUT” optical connector on the rear panel. Design of the connector flange is shown in Appendix 2. NOTE: for the optimal light transmission the fiber bunch should be in direct optical contact with the output quartz cylinder Connect one fiber of fiber bunch to the PIN-diode optical connector located on the rear panel. Device requires warm-up time at least 30 minutes. Connect NIM Pulse Generator output to the “START BLUE” or “START RED” input. Connect TTL level high to connector “FREEZE”. The “FREEZE” LED indicator will light on. Send TTL pulse to the desired “COLOR” input. The corresponding LED indicator should light on. NOTE: Change of color possible only in “FREEZE” ON state. Only ONE color output can be active at a time. Adjust intensity of the light flash by “Intensity” push buttons, checking amplitude of the signal on a detector output via oscilloscope or pulse-height analyzer. Press push-button switch of shaping amplifier gain adjustment “SET”. Corresponding LED indicator will light on during automatic gain adjustment. Repetition rate of the “START” pulses of 200-300 Hz is recommended for installation. NOTE: time of gain adjustment will depend on frequency of start pulses; at 1 kHz start rate this gain adjustment will take several seconds. After “SET” LED switch off, start stabilization system by removing TTL level from the “FREEZE” inlut. 2. Operation “HOLD” LED on the front panel should light, “LOW” and “HIGH” LEDs should blink in the stabilization mode. If only “LOW” or “HIGH” LED lights, it means that the device is out of the adjustment range. It may happen due to wrong order of installation. In this case repeat the device installation sequence. Stabilized Light Pulse Source "HOLD" THERMOSTAT THERMO STABILIZER "MONITOR" “SET” "LOW” COMPARATOR PIN LED To DC source = PIN PREAMP "HIGH” LED CURRENT CONTROL "UDAC " SHAPER "UREF " LED “FREEZE” UREF "INTENSITY” To the second channel LED QUENCHING STAGE "START” PULSE GENERATOR POWER STAGE Light Pulser diagram Stabilized Light Pulse Source Appendix 1 Power supply connector wiring diagram 1 2 3 4 5 6 7 8 9 10 11 12 +24 V - 24 V Reserved +6 V Ground Reserved Reserved Reserved -6V Reserved Reserved Ground Connector type: “BURNDY” Appendix 2 Design of flange for optical output connector (dimensions in millimeters) Stabilized Light Pulse Source