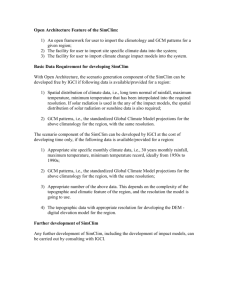

Ultracut – Autocut Sequence of Operartion

advertisement

Ultracut – Autocut Sequence of Operation Preset Gas Control GCM 2000-2010 Mode SW = RUN; Gas SW to desired gas process; Plasma Power Supply Switch to ENABLE; Shield Gas Switch to FLOW or Pressure as indicated by cut charts. Turn on wall power (FP off) Neon indicators on rear panel and inside, above inverters ON Turn on front panel ON/OFF First 3-4 seconds inverters check for correct voltage and charge up input capacitors (inrush). Input contactors come on, inverter fans start, AC LED on, other FP LEDS blink CCM firmware version. If gas control is GCM 2010 firmware versions before 2.1 display shows the following one after the other: Thermadyne, GCM 2010; GCM 2010, Soft Ver 1.xx; Waiting for Communication; If gas control is GCM 2010 firmware versions 2.1 or later display show the following one after the other: Thermadyne, GCM 2010; GCM 2010, Ver 2.x ; Welcome, Initializing; Communicating, Current __A; Waiting for Comm Connection. Once communications is established system enters purging state: Pump & coolant fan start, Power Supply front panel Gas LED blinks indicating Purging. If Autocut with GCM 1000: Plasma & Shield solenoids on for 20 seconds to purge gas lines & torch. If Autocut with GCM 2000 or 2010: Purge starts with N2 (if connected) to clear previous gas from lines Following N2 purge there are two cycles of purge with the cutting gasses then a final purge of the preflow or pilot gas. GCM 2010 will display purging sequence, if firmware prior to 2.1 sequence is Starting Purge, Gas (plasma-shield); Purging, Gas N2; Purging GAS: (plasma-shield); Purge Complete Firmware 2.1 and later: Purging Lines, Gas: (Plasma-Shield); Purging, GAS: (Plasma-Shield); Purge Complete Purge ends, GCM 2010 displays: RUN MODE & Cutting current setting. GCM 2000 LED (if present) on steady. GCM 1000 Gas Settings Set RUN/SET switch to SET, adjust Plasma & Shield pressures per cut charts. If using H2O Mist instead of shield gas set the flow per cut chart. Return switch to RUN GCM 2000/2010 Gas Settings--Mode SW SW to Set Preflow, Plasma Preflow (piloting) gas only, adj Preflow pressure per cut chart 2010 displays “SET PREFLOW” , 2000 blinks LED (if present) Switch to Set Plasma & Shield, Flows both Plasma Cutflow and Shield gasses. GCM 2010 displays “SET CUTFLOW” Set plasma pressure to 120 PSI (8.3 bar). Adjust Plasma flow meter ball per cut chart. For all processes except H2) Mist: If shield SW set to flow, set shield pressure to 120 PSI (8.3 bar). Adjust Shield flow meter ball per cut chart. If Shield SW set to pressure set pressure per cut chart. If process is N2-H2O adj. H2O Mist flowmeter per cut chart. Test – flows Plasma & Shield, displays plasma outlet pressure. Return to RUN mode. Gas SW – if changed will initiate purge with new gasses. Amperage Set-up If GCM 2000 set desired cutting current with thumbwheel switch. Settings above or below system range will give max or min current. Ex. Ultracut 100 set to 150A, output is 100A; set to 5A, output is 10A, Ready To Cut GCM 2010 Displays “RUN MODE, CURRENT: xxA Shield), READY xxA or GAS: (plasma- CNC applies START Gas control start preflow (separate pilot gas except GCM 1000) GCM 2010 displays Gas process, PLT FLOW & AMPS PS front panel Gas & DC LEDs on Preflow and Shield (except GCM 2000 & 2010 when using H2O Mist) flow for preflow time (default 2 sec). GCM 2000 & GCM 2010 H2O Mist does not flow during Preflow time to avoid coating the plate with water. Inverters & pilot circuit are enabled, pilot contactor on, system checks for unwanted current during preflow. At end of preflow, Arcstarter is enabled, HF fires, pilot starts. If no transfer, pilot is on for pilot time, 85 ms. (default) or 3 sec. If transfer, Pilot circuit disabled, Gas control (except GCM 1000) switches to Cutflow gasses. 2010 displays GAS: (plasma –shield), CUT FLOW; ____AMPS Cutting current starts at initial level, approximately same as pilot peak then ramps up to set cut level over about 100 ms. Ramp times may be longer for 200 & 300A. CNC STOP If cutting 150A and below or CCM code is version 2.2 or lower: Cut continues until CNC STOP (removal of START), then current ramps down for about 100ms. and arc goes out. As soon as arc is out, gas control (except GCM 1000) changes to preflow (piloting) gas unless Postflow time set to zero in which case it just shuts off. During postflow time GCM 2010 display shows “PLT FLOW” Gas continues for postflow time then off. If cutting above 150A and CCM is version 2.3 or later: Cut continues until CNC STOP (removal of START) Plasma and Shield are shut off. Current ramps down (time may vary with amps, up to 500 ms.) and arc goes out. If Postflow time DIP switch setting is not zero, Preflow (pilot) gas and Shield come back on for postflow time. CNC START during POSTFLOW If CNC START is applied during postflow time (if postflow time not zero) process skips the preflow state going directly to piloting state without delay.