PowerofPaper

advertisement

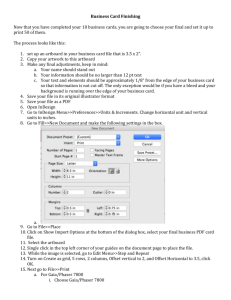

Paper Course Videos 1. www.thepowerofpaper.net 2. username: Erika 3. password: erika888 Did you make PDF slides? no What font did you use on the Power of Paper website? Found I had to turn down and turn up volume from video to video. Looking into issue. The Power of Paper Course 10.17.12 4:41 The History of PaperMaking 11.07.12 3:33 Paper Making – Pulp Fiction From the bottom up veneer / furniture, flooring/ pulp wood/ biomass 11.07.12 5:32 made from cellulose 75% Hardwood - aspen & birch shorter fibers weaker paper smoother 25% Soft wood - fir & pine longer fibers stronger rougher Ingredients - soft/hardwood, water (100 liters per 2lbs of paper), fillers (clay), binders (corn or potato starch), dye 1. Mechanical pulping (groundwood pulp) a. 90-95% of wood can be used for papermaking b. physical damage during process causes shorter, weaker fibers c. high opacity d. less brightness, yellows easily e. typically used for newsprint 2. Chemical pulping a. freesheet – lignin free b. 45-50% of wood can be used for papermaking c. chemical process leaves longer, stronger fibers d. less opacity and bulk e. higher brightness and color fastness (lignin is removed) Paper Making – The Process Most US mills do not buy their own pulp 11.08.12 6:45 wood/waste paper > debarked pulpwood > chipper > digester > bleaching plant > blend chest > paper machine > coater > super calendar > slitter winder> sheet cutter > sheets/rolls > dispatch Paper Properties – Acid Free 11.14.12 2:59 Now the industry standard. Measured on pH level 0 (acidic) -14 (alkaline) 7 pH - 25 years acid free 7pH+ - 200 years Archival paper is an especially permanent, durable acid-free paper. Used for Publications of high legal, historical, or significant value. US comply with ANSI 7.5pH, 2% carbonate Paper Properties – Basis Weight 11.13.12 Comparison sheet to download? Basic Sheet Sizes 17x22 (writing) 25x38 (text) 20x26 (cover) 500 sheets @ basic sheet size (25x38) = 50lbs text US – uses lbs. Europe – uses GSM 3:14 Paper Properties – Brightness 11.13.12 Brightness, whiteness and shade are independent paper properties. 4:42 Brightness – US measurement, wave length of blue light (RGB), 0-100 reflective light, brightening agents added – blue white Whiteness – Europe & rest of the world, reflection of light from full color spectrum (RGB) Shade – actual white color of the paper – blue white, balanced white, warm white Blue white – absorb warmer tones – make skin tones look gray Warm white – absorb blue tones Paper Properties – Caliper (Thickness) 11.13.12 4:22 3 variable in papermaking: weight, caliper (or thickness), and smoothness. Mills can only control 2 out of the 3. Weight (lbs) – mills concentrate on weight and smoothness Point (pt) – caliper and stiffness of the sheet are guaranteed No correlation between weight and point. PPI (pages per inch) 60t gloss coated @2.9pt = 668PPI vs. 60t vellum @5.2 pt = 368PPI Paper Properties – Formation 11.13.12 2:40 Can I get the contents of the binder? Bad formation – uneven, mottled vs. Good formation – spreads evenly, limits dot gain Uncoated hold up against the light, ask for a printed sample Dot gain – growth of the ink dot during the printing process Paper Properties - Grain Direction 11.13.12 4:30 8.5x11 means 11 is your grain direction all the long grains are running the 11” side Tear test: if it goes straight & tears smooth that’s the grain direction. If there’s resistance and tears ragged that is not the grain direction. Fold test: fold it and if it folds smoothly that’s the grain direction. If it cracks then that is not the grain direction. Avoid cracking – pick a good quality sheet, fold in the grain direction and score, protect the spine (with coating) Paper Properties - Opacity Or show thru. Measured on a scale of 1-100. 1. thicker is more opaque than thin 2. rough is more opaque than smooth 11.13.12 3:24 3. coated is more opaque than uncoated 4. darker shades are more opaque than whites Printed sample. Opacity test (black/white to put behind sheet) Paper Categories – Offset & Opaques 11.28.12 Offset – dimensional stability, resistance to curling. Up to 94 brightness Opaque – enhanced opacity, better formation. Up to 98 brightness 2:23 Approving color by adjusting curves (as per the press) , adding a touchplate, using UV inks Both available in smooth, vellum, digital companion sheets, comes in 60t-100DTC. Opaque also available in super smooth Overall smoother the paper – level surface, sharper image reproduction Paper Categories – Coated Papers 11.28.12 4:48 Created by using uncoated base sheet adding coating (latex pigments adhesives) seals base sheet, limiting ink absorption/dot gain, provides smoother surface. But decreases caliper. Can be created either inline or offline. Paper Surface: Uncoated/Matte/Dull/Gloss Matte Coated – glare free, easy to read surface. Bridge between coated and uncoated paper. Less expensive and bulkier than dull coated sheets. Dull Coated – little or no gloss. Sheen rather than shine. Low light reflection. Silk Coated – silk, satin, velvet and suede variations of a dull finish. No specific differentiation. Mill determines what they want to call the sheet. Gloss Coated – shiny surface and high light reflectance. Least dot gain. Preferred surface for photographic reproductions. Cast coated – packaging, presentation folders. In its own class, does not use super-calendared process instead is pressed against a heated chromium drum then is cast surface onto paper without compressing it. Highly-polished, mirror like surface. Less ink holdout than a conventional coated sheet. Colored and metallic options avail. (by coloring coating). Paper Categories – Writing, Text and Cover 11.28.12 3:40 So many different color and so many finishes, 60t-120c, dtc, duplex sheets Suitable for offset, specialty – embossing, foil stamping, letterpress printing Paper Categories – Digital Papers 11.28.12 5:58 There is more than white. More than coated, smooth sheets to choose from. All different colors, finishes, metallic, synthetic. High-speed digital presses recently started rivaling the offset printing counter parts. Any printing process using digital technology from home printer to i-Gen. Offset (moist, ink) Digital (warm, toner). Digital production presses – indigo, nexpress, iGen. Printing full color, high quality at fast speeds (70-100 pages per minute). Digital papers – Precision mill cut to minimize debris and dust, which can damage the machine and your design. Provide superior smoothness and formation to ensure quality toner transfer. Optimized moisture levels to minimize static or curl, which keeps paper feeding consistent and jam free. Certified Digital Papers Indigo Press 156 coated / 329 uncoated options iGen/Nexpress 138 coated / 439 uncoated options Paper Categories – Specialty Papers 11.28.12 7:58 Metallic papers – base sheet, pigment, coating – uncoated sheets with mica coating. Translucent papers – fly sheets/vellum sheets. Naturally translucent: cellulose fibers heated up and pressed several times to eliminate air pockets, makes for a really firm sheet. Chemically translucent: treated to make it translucent. Makes fiber more brittle and since chemically treated not recyclable. Mineral papers – made from “stone”, calcium carbonate. Limestone. Tear and water-resistant. Slower drying time. Not compostable or recyclable. Only white. 5-20pt. Not for digital printing. Synthetic papers – made from polypropylene and inorganic fillers (plastic). Durable. Scratch resistant, water and tear resistant. Only white. 55t-144c. Offset. Limited digital. Agri-fiber papers – non-wood based crops either “left over” or specifically grown to make paper. Hemp cannot be grown in US but you can find paper made from hemp. Not readily available in commercial quantities. Made to order or imported. Paper Categories – Paper Grades 11.28.12 4:49 Based on not only brightness and opacity. But also formation, runability, marketing AF & PA Standard Grade Classifications Number 1 91.0 & greater Number 2 87.0 – 90.9 Number 3 82.0 – 86.9 Number 4 Number 5 81.9 & below NA Printed sample of one grade below the sheet you had in mind. Grade Comparison – (based on Premium sheet) 12% savings on #1, 24% savings on #2 Paper Categories – Watermark 11.29.12 3:41 85-90% water dandy roll carries a die of illustration shifts fibers to make room for watermark. Once thru drying process it’s part of the sheet. Lighter the weight the more visible the watermark. Types of watermarks – wire mark (lighter than sheet of paper), shaded mark (darker than sheet of paper), combination Watermark positions – random, localized (same spot on every sheet), paraded (horizontal or vertical), scattered (diagonally) Private watermark – minimum 100lbs, chemical or digital watermarks, sheet of your choice, 4 week turnaround Sustainability – Sustainability Intro 12.05.12 1:57 The concept of meeting the needs of the present without compromising the ability of future generations to meet their needs. Sustainability – Recycled Fiber 12.05.12 6:49 Saves approx. 60-70% energy over virgin pulp, uses 55% less water, reduces water pollution by 35%, and reduced air pollution by 74% Pre-consumer waste – mill/printer scraps, unsold magazines. Has always been recycled. Post-consumer waste – recovered material from the end user (you & me). Recycled more than 60% paper used in the last year. What does recycled have to do with sustainability? 45k tons of postconsumer fibers, saves over 15k cubic ft from landfills = 2,250 semi-truck load fulls Is recycled enough? 66.8% of paper was recycled in 2011. Not enough recycled fiber to meet demand. NA would run out of paper in 2 months. Paper fiber can be recycled 5-7 times. Sustainability – Fiber Sources 12.06.12 10:52 Typo on slide 2:28 minutes into video PEFC says PECF FSC (Forest Stewardship Council) Founded in 1992 by environmental organizations, concerned business representatives, social groups. Sustainability managed forests to conserve biodiversity and support local communities. Worldwide certification. Controlled or Certified sourcing – not FSC certified but are screened to ensure that these sources are not contributing to any of the most destructive practices in forestry – illegal logging, liquidation of high conservation value forests, civil rights violations or genetic modification of forest species. SFI (Sustainability Forestry Initiative) Originally developed by AF&PA, now independent organization with diverse board. Promotes environmental, social, and economic forest values. US certification. SFI Average Percentage Method – Allows manufacturers to consistently label 100% of their labels. Batch has to have at least 10% certified forest content. Must show actual percent of certified forest content on label. SFI Volume Credit Method – Allows manufacturers to label only the percentage of output corresponding to the percentage of certified forest content used in the manufacturing process SFI Certified Sourcing Label – 100% of the fiber used in this product comes from well-managed forestry operations under the articles of the SFI. None of the forests have to actually be SFI certified PEFC (Program for the Endorsement of Forest Certification) Founded in 1999 as the forest orwners and forest industry’s answer to FSC. Is the umbrella organization for the national forest certification schemes. SFI functions as the US arm of the PEFC, CSA as the Canadian arm. Well-managed forests are maintained in a sustainable, ecologically and socially responsible manner: waterways are protected, wildlife habitat is maintained, natural forests can not be converted to plantations, high conservation value areas are conserved, First Nations and community rights are respected Less than 10% forests in world, less than 13% forests in US are certified. 3rd party certifications – FSC, SFI, PEFC do not certify. Independent companies test, probe and certify specific forest areas. Additional cost for certification and recertification. Sustainability – Chain of Custody Forest > paper mill > merchant > printer > consumer 12.05.12 3:36 Sustainability – Green Certifications 12.05.12 2:55 EPA (Environmental Protection Agency) guidelines for government agencies, based on minimum recycled fiber content. 30%PCW+ uncoated. 10%PCW+ coated. Green Seal is an independent non-profit organization. Safeguarding the environment. Promoting environmentally responsible products & services. EcoLogo Established in 1988 by Environment Canada. Helps consumers identify products and services less harmful to the environment (Canadian version of Green Seal). 30%PCW. Chlorine Free Products Association has no law currently for bleaching guidelines, merely suggestions. Independent non-profit organization. Sustainability – Renewable Energy 12.05.12 6:21 Typo 2:53 into video nonprofit inconsistent with prior non-profit Green-e is a non-profit organization that promotes the use of renewable energy. RECs Renewable Energy Credits are tradable, non-tangible energy commodities to offset a percentage of annual electricity use in the US, typically sold in 1 megawatt-hour units. Carbon neutral Everyone has a carbon footprint. Purchasing carbon offsets carbon footprint. VERs Verified Emission Reductions are a type of carbon offset exchanged in the voluntary or overthe-counter market of carbon credits. Side note: 98% windpower 2% solar (Palo Alto) Sustainability – Bleaching 12.05.12 2:03 ECF Elemental Chlorine Free is virgin or recycled fiber. Bleached with chlorine dioxide. TCF Totally Chlorine Free is 100% virgin fiber. Bleached with non-chlorine compounds. PCF Processed Chlorine Free is 100% recycled fiber. Bleached with non-chlorine compounds. Can be combination of recycled fiver (PCF) and virgin fiber (TCF). How to Spec’ – 1. How to Spec 12.11.12 2:43 Title is different on www (How to Spec) vs. youtube (Consider Paper Early) Most appropriate equals best – enhances your design, suitable for your printing processes, accommodates the end use, fits your budget. Preliminary design done – ask printer for suggestion – making adjustment of 1/16” may fit on press and save money. Get quotes early. Available or have to order from mill? Custom sheet sizes may help fit job better but may take 5-14 days to order. How to Spec’ – 2. Personality 12.11.12 1:07 Personality and lifespan of the piece. Non-profit – lower brightness, uncoated. How to Spec’ – 3. Finish 12.11.12 1:35 Image reproduction/color commonly use coated. Uncoated used more nowadays with high end. Eddie Bauer sample – felt cover, looks like a sketchbook. How to Spec’ – 4. Color and Brightness 12.11.12 2:02 Blue white makes color pop. Warm white easier tends to be easier on the eyes, extended reading Skin tones shouldn’t be printed on blue white. Color papers great with 1-color jobs. Colored with blind embossing. Options are endless. How to Spec’ – 5. Weight 12.11.12 2:57 Printed on both sides or heavy ink coverage – opacity is crucial – make sure the paper you choose doesn’t allow for any show-thru and when it doubt select a paper one weight heavier Projects that are mailed – weight is a major consideration – watch out for postal costs – make a dummy, weigh it and know that ink weighs as well Bulk & Weight: an uncoated sheet is always thicker than a coated sheet of the same weight How to Spec’ – 6. Sustainability 12.11.12 2:26 Misconceptions – 1. it’s going to be recycled anyway; 2. limited choices; 3. cause trouble on press How to Spec’ – 7. Printing Process 12.11.12 1:52 Specialty printing (foil stamping, embossing, letterpress printing) check out mills swatchbook or printed samples or ask printer/rep for samples Digital printing: make sure to not spec an offset sheet or vice versa. Digital papers are made specifically to run well in the dry, heat environment. While offset are made to run in the moist, cool ink environment. How to Spec’ – 8. End Use 12.12.12 2:19 Does not have a number in title on youtube Mailing rates – watch for weight. Reply or Postcards – make sure it is a bit more than the minimum caliper for the USPS Letterheads – will be run in a laser/inkjet printer, select weight appropriately Education – durability, synthetic recommended (or if exposed to weather) Write notes on piece? – watch out for varnishes used Heavy handling – laminate & coat piece How to Spec’ – 9. Price 12.12.12 1:50 Paper is 30% of overall cost of print budget Ways to Cut Paper Costs – merchant paper programs, seconds (outlet/leftovers), close out list, broken cartons, reduce page count, special sheet size if it will fit better If you can’t afford the premium sheet you requested ask printer for one grade below and a printed sample How to Spec’ – 10. Availability 12.11.12 1:38 Overall 80% of all printed projects are printed on coated/uncoated white paper If your project requires a large amount of paper, contact mill as soon as possible. In a rush, consider printers’ house sheet. Q&A Call 1 11.14.12 29:20 Seems the questions are answered in the videos (as I watched them all before viewing the Q&A sessions. Power of Paper voted to be delivered weekly I can’t seem to get papers in quantities of less than 5,000 sheets in some cases 1. Sold in cartons. Mill may sell broken cartons. 2. Specialty usually available in small quantities 3. Specialized in Broken Cartons (Glodan, ThePaperMillStore.com, Limited PaperSpecs) …find a better way to find the specialty papers that my clients are looking for… 1. Magazines, newsletters to subscribe to 2. Sign up for PS newsletter 3. Talks about CRUSH from Italy 4. PS Pro Database How do finishes of a stock affect printing? (not effect) Flint Group Colour Quiz. All reds are the same but different sheets. What are my stock options for digital printing? 1. Stocks for Digital Printing (576=iGen, Nexpress, etc; 484= Indigo) How do I read a swatchbook? Example: Neenah Classic Linen 1. Calls out digital/offset/envelope options 2. Print & service guarantee 3. General information about green options 4. Cost of swatch book (average $15-25) 5. Printed samples 6. Marketing descriptions 7. Guaranteed always available up to 10,000 lbs. or you get a discount 8. Waterfall – mills give every color and every weight samples a. Digital sizes available, matching label stock, 30pcw, fsc, green-e, pcf, carbon neutral b. Color, weight, gsm, w, t, c, dtc, fsc, brightness, digital, label 9. Stock chart a. Weight, size, mm, mwt, sheets per carton, colors 10. Duplex covers (l2 different papers glued together) example 120DC are (2) 60lb What is M Weight and why should I care? 1. Weight of 1,000 sheets of paper of a given size 2. Why do you need this? Paper is sold by the lb 3. Cost per 100lbs (CWT) x m weight / 100 = cost per 1,000 sheets a. $125.50 x 103/100=$129.26=60lbs text b. $125.50 x 119/100=$149.34=70lbs text Q&A Call 2 11.28.12 29:42 The merchant is out of a specific paper? 1. Call mill directly 2. Merchant or printer may tell you discontinued if they don’t have it How do you best determine the shade of a paper? 1. Color name 2. Life samples 3. View it in the light it will be used in Do you have basic guidelines for the range of thickness? 1. Postcards a. USPS 7pt/9pt is minimum requirement b. Recommendation 10-12pt minimum c. Flimsy test (paper dummy cut to size) d. Shows image samples of 8pt, 11pt, 14pt e. Heavier the sheet the more the paper will cost 2. Presentation folders a. 14pt minimum b. The thicker the more trustworthy 19-20pt 3. Brochure Covers a. b. c. d. Depends on your design Will it be mailed i.e. is weight an issue The thicker the more trustworthy Fake the thickness (French fold), sample images shown What is the difference between Cover and Index? 1. Bristol a. Vellum, rougher surface b. Made to caliper c. Offset only d. Card stocks, cards, covers, folders, signage/POP, tab/divider pages e. Lower in quality, lower in price 2. Index a. Like Bristol but with a smooth surface b. Made to caliper c. Offset only d. Card stock, cards, covers, folders, signage/POP, tab/divider pages e. Lower in quality, lower in price 3. Cover (WTC) a. Higher quality sheet, various finishes b. Made to weight c. Offset, digital, specialty finishing techniques d. Marketing materials, cards, direct mail…everything Rule of thumb is – higher the grade the more likely the better the opacity. However, you really have to look at the swatch book. Call mill, tech services, ask for pH. Most likely acid free as it is a much more cost efficient for the paper mill to make it acid free, unless you were buying newsprint or a lower quality type of paper. Writing vs. text stock – writing is fairly lighter sheet. Quality is the same. Mweight question – just confirmed cost per 1,000 Text vs. cover stock – basis weights overlap so not necessarily Is there Universal weight for postcards or direct mail pieces? No, just minimum requirement 7pt/9pt Requests reference link for USPS minimum requirements? SL will post on website Does the 14pt conform to the USPS guidelines? Can go up to 16pt for letter size mail piece. US weight vs. GSM – Basis Sheet Sizes are all over the place Archival vs. acid free – Acid free pH of 7 or more 200-500 years. Archival has added chemicals to last longer 500+ years. Q&A Call 3 11.28.12 Same date as Call 2? Notes it is the incorrect date on the call What is the difference between the different weights (pt vs lbs)? 1. Mill only able to control 2 of 3 (weights, caliper, smoothness) 14:44 2. Point is made to thickness and lb is made to weight 3. No correlation between the two Can I use any texture for digital printing? Not ANY finish but there are papers made specifically for digital, an incredible amount is available in different finishes. When scoring a sheet for an optimum fold, do you find that you get better scoring results from an inline score or a die score? We always prefer a letterpress channel score (with matrix) as it will yield the cleanest fold of any scoring option. Did you want me to redraw diagram? What should I look for in a paper if I want to emboss/foil stamp & other specialty effects? Depends on what you want to do. Letterpress – softer the sheet. Many mills provide samples in their swatch book so you can see how their paper will react to specialty printing processes. What is the difference between US and European coated sheets? US: 2/3 of a base sheet, 1/3 coating then coated on one or both sides. Europe: 50/50, less of a base sheet, more coating, higher surface gloss but less Are all triple coated sheets from Europe? Not all but 99% probably Q&A Call 4 12.12.12 22.:18 You mention that mills might mention whether papers are suitable for digital printing. I have first-hand experience when I liked a particular paper, but in my printer it smeared and wouldn’t dry. What makes the papers suitable for digital versus not and why does there have to be a difference? Mainly it’s weight, then finishes. Mills call out if suitable or guaranteed. Sometimes has slighter emboss not as deep so can run easier on home printer. In the paper binder that was provided there are two samples 23 and 24, that are labeled “finish.” I’m a little confused as to what is meant by this. It does seem like there’s a coating on there. FiberMark Touché and Suedetex – not coated, more of a specialty, the finish is created in the making of the pulp and how it is calendared. If Mica is colorless, how do they get a paper that’s specked with silver or gold? Is that maybe related to that tone on tone coating? Mica is colorless but picks up the shine and sheen of the paper it is printed on. Might include color to enhance the color of the paper. May add color pigments. For grading – what is runnability? How would it affect your paper choice and is there a way to find this information? Less trouble free on the press, the better the grading of runnability. Top 3 – 1. consistent technical quality, 2. precision cutting, 3. dimensional stability I understand the difference in how cast and gloss coated papers are made, but aside from the color options, are there benefits to using one over the other? Coated are made to weight; Cast coated are made to caliper (C1S or C2S) Main difference is thickness of the sheet. Cast coated 8-20point What does C1S and C2S mean? Generally thicker than paper (usually starting at 0.25 mm / 8pt) Fully bleached board as base sheet Lightweight, but strong (packaging, postcards) C1S – packaging; C2S – magazine cover If you found a paper is right, why ask for a sample of one grade below? If you have the budget by all means, but in many cases budgets are tight and paper usually costs 30% of printing job. You may save 12% by going one grade below. Why does it take so long to develop a digital sheet? Takes 2-4 weeks to make suitable for Indigo. What takes the longest is getting the certifications and guarantees. What is the main different between digital and offset papers? Regular offset will not run thru Indigo they need a special surface treatment. Used to have Sapphire coating. Now treatment can be done inline during paper making process. Main thing is RIT certifies these papers, not necessarily saying the offset won’t run in various digital presses but most likely the digital printer won’t be comfortable running it. Confirm all videos open in a new window so not kicked out of Power Of Paper website. Q&A Call 5 12.19.12 26:04 I understand the difference between the FSC and SFI, but why choose one over the other, if given the choice? Everyone has a personal preference (example Coke or Pepsi). Both organizations want to manageably sustain forests. FSC is recognized worldwide. SFI is a North American. What is the basic process to become certified as either the mill making the paper, or the printer using, the paper? Chain of Custody: Forest – Paper Mill – Merchant – Printer – Consumer 1. Contact a certification body 2. Application and agreement 3. Complete on on-site audit 4. Certification approval 5. Annual audit If you’re using and FSC or and SFI certified paper, do you have to include the corresponding logo in the final product, or is including this a matter of choice? No you don’t. It’s perfectly voluntary. Many like to flaunt it but sometimes there isn’t room in the design. But to HAVE TO put it, it must be approved by FSC or SFI – each piece individually. Is there a basic list of standards available for what qualifies a forest as certified? Well-managed Forests are maintained in a sustainable, ecologically and socially responsible manner. (see Sustainability – Fiber Sources video for the rest of the verbage) FSC 10 Principles: http://us.fsc.org/mission-and-vision.187.htm SFI Standards: http://www.sfiprogram.org You mention that knowing the paper size the printer uses, will allow for adjustments, ultimately reducing the cost. You mention there are 3 standard sizes of paper. (I don’t recall you saying that either) Web rolls, offset sheet sizes, digital sheet sizes, cut sheet sizes …but you mention checking on the size the PRINTER uses. Printer makes the final decision. Depending on the press size, that’s the sheet size they can run. For example, 40” press can run 26x40”, 28”x40”, etc. Some printers have one press and will try to fit it on that. Example: 11x17 can fit 4-up of 28x40 but there’s a lot of white space/waste. So it would fit more snug on a 25x38 sheet. Different presses run different sizes 40” press runs 26x40, 28x40 28 press runs Press tolerance (caliper) Custom sheet sizes mix and match presses Is it a possibility to add a finish/varnish to a textured sheet? You want the smoothness/gloss of a gloss sheet, but the look of a textured sheet. You will not get a gloss like a gloss sheet on an uncoated sheet because the uncoated sheet will absorb the varnish. So you won’t get the gloss look and feel. FiberMark has some coated, textured sheets. What about smaller runs or a job with a printer you don’t have a relationship with? If printers only offer certain types of paper, will some or all allow you to send them different paper? The printer, in general, likes to use their own paper as they already have the quantity, correct sheet size. Make sure you know how many sheets the printer needs and what the exact size. Even when you provide your own paper there might be a handling fee. However, when it is smaller print jobs, printer may be keen on it. What is Triple Certification? FSC, SFI, and PEFC certified. Printers in beginning wanted one or the other but recently the paper merchants and printers are now able to get triple certified. Allows them to put whatever logo matches the paper on the end piece. If you have a small print run and need smaller quantities? There’s companies that specialize in small quantities and broken cartons.