paper on box culvert - railwayengineering.in

advertisement

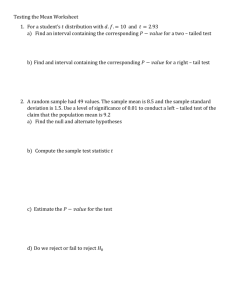

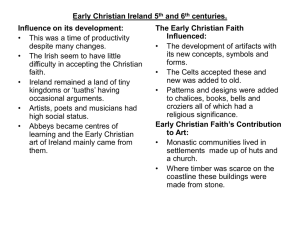

1 Sub: RCC Box Culverts for Railway Bridges* Shri K.C. Vikram, Assistant Manager, RPO-LKO RITES 1.0 For small spans, Pipes, Slabs or Box culverts are commonly used. Slabs and Box culverts are without bearings. Span is generally restricted to 12.0m. 2.0 Standard Drawings for pipe culverts were used by Railways earlier (RDSO/B-1609 R1). These Drawings were withdrawn in 2006 vide RDSO letter No. CBS/DCP dated 04.12.2006. Vide this letter; use of NP-4 pipes is permitted subject to instructions detailed in RDSO’s letter of even number dated 24.12.2003 and 22.01.2004. Standard Designs for NP-4 pipes are for diameters 80 mm to 2600 mm (IS 458:2003). Pipes of Dia 300 mm to 1800 mm are permitted for Railway use with maximum cushion of 5m and minimum cushion of 600 mm for pipes upto 600 mm dia and 900 cushion for pipes beyond 600 mm dia. 3.1 Standard designs are available for slabs up to 12.2m. These designs are not designed for any fill. Slabs of span 0.61m, 0.915m, 1.22m, 1.83m and 2.44m are pre-cast RCC slabs. Designs for these spans are for Grade M-25 and M-30. 3.2 Slabs beyond 2.44m are pre-stressed. Designs for spans 3.05m, 3.66m, 4.57m and 6.1m are with pre-tensioned. Design for 9.15m and 12.2m are with post tensioned. 3.3 RCC Slabs have also been designed for following: Sl No. Drawing No. Description 1 2 3 4.1 BA-10059 Precast Approach Slab (MBG Loading) BA-10053 to 58 Ballastless slabs upto 3.05m (approved for trial) RDSO/B-10061 Ballastless track slab For box culverts, standard designs as given in following table are available for various loadings i.e. MBG/HM, 25 Ton and DFC. These designs are for single track and with maximum fill height of 10.0m. Drawings are of Single Box and Double Box. Largest span of single box is 6.0m and of double box is 2 x 6.0m. Box type Single Double MBG/HM RDSO/M-00004 RDSO/M-00005 Drawing Ref. 25T RDSO/B-10152 - DFC RDSO/B-10151 RDSO/B-10154 The article is also available on www.railwayengineering.in Page 1 2 4.1.1 Barrel Length is decided based on fill height. It should at least be equal to formation width. At the end, small parapet of height 225mm and width 450mm is provided to prevent falling of any material. If barrel length is to be curtailed due to some reason/s then end of box can be projected up suitably as ballast retaining wall. 4.1.2 As per practice prevailing on Railways, these Boxes are being cast in-situ or precast. The precast boxes are in single unit or multiple units. In case of multiple units, segment lengths are non uniform and generally vary from 1.0m to 2.5m. 4.2 Standard drawings have also been issued for segmental box (Drawing No. B-10153 for limited height subway). These designs are for single box and are for multiple lines and for maximum span of 5.5 x 4.0 with maximum fill of 1.0m. Length of segments is 1.53m. These boxes are placed on pre-cast base slabs. Intermediate base slabs are of width 1.53 and end base slab of 2.30m. 5.0 RCC Box culverts are commonly used at locations with no appreciable scour. Floor level of boxes is generally kept same as bed level/ground level. Bed below box should be prepared in order to achieve adequate bearing capacity required to withstand foundation pressure given in drawing. However, in case sufficient bearing capacity is not available at bed/ground level then floor level can also be lowered. 6.0 Box culverts are designed for vertical loading on top due to dead and live loads and lateral loading on sides due to earth pressure. Ballast cushion of 350mm is considered for designing. These boxes are not designed for seismic forces and longitudinal forces due to tractive/braking. Thermal stresses due to restriction in movement in direction of span are also not considered. Boxes with fill will have lesser thermal stresses. Higher the fill, lesser the thermal stresses. Likewise transmission of longitudinal forces due to tractive and braking reduces with fill height. 6.1 They are designed as rigid closed frames. Design is done for unit length of the barrel with structural element spanning perpendicular to the barrel length. No side sway analysis is done for these type of boxes. 7.0 It is general practice that Live Load is taken from EUDL tables given at appendix XXIII & XXVI of Bridge Rules. EUDL(load per unit length) decreases with increase in The article is also available on www.railwayengineering.in Page 2 3 span. Considering EUDL for Box Culverts seems to be at variance with provision at S.N. 6 of table under Para 2.3.4 of Bridge Rules. 8.0 For earth pressure on walls of the box generally active earth pressure is considered. In case of box, due to rigidity of the structure, it is unlikely that walls will yield to earth pressure. The deflected shape of wall at top and bottom is outward. It may be more logical to take passive earth pressure or at least earth pressure at rest. 9.0 Live load is distributed on the barrel top through ballast/fill. Para 2.3.4.2 of Bridge Rules provided for it. Distribution of live load for Broad Gauge without fill is shown in Fig 1. Box is designed for the calculated load intensity (both live load and dead load) acting uniformly all along the span length of the structural element. Fig 1 9.1 Bridge Rules provide for dispersion through RC Slabs provided there is effective lateral transmission of force. As these boxes are used for segmental construction also, it is presumed that effective width is limited to load dispersion width only and no dispersion through slab is considered. 10.0 A typical box culvert arrangement for single track is shown in Fig 2. Generally, flared wing walls are provided. In case of erode-able soils, flooring is enclosed by suitably designed curtain walls and drop walls tied to the wing walls with a minimum depth below floor level of 2.0 m for curtain wall and 2.5 m for drop wall. Bottom slab is also keyed to the ground at least one foot. The article is also available on www.railwayengineering.in Page 3 4 Fig. 2 & 3 11.0 It is also quite common to extend the barrel length to function as wing walls (Fig 3). Hydraulic efficiency of such arrangement is not as good as flared wing walls. However, it eliminates need for designing of wing walls and obtaining fresh approvals from Railway authorities. It is also very advantageous in situation where additional line is contemplated or likely to come in near future. Added advantage is that vertical loads are dispersed on longer area thereby reducing bearing pressure. 12.0 The common query in regard to box culverts is regarding the use of standard RDSO section for skew crossings. Fig 4 shows the two cases of square loading and skew loading. In both the cases, bearing pressure under ballast/fill and on top of slab remains same. The barrel length, loaded area and effective area of slab are different in both the cases. There is a general misconception that direction of loading alters the direction of span. Slab spans in the direction perpendicular to the supports irrespective of the direction of loading. The article is also available on www.railwayengineering.in Page 4 5 13.0 Arrangement in case of skew is structurally sound though not efficient. In case of skew, few units of structural element on the sides of loaded area are not fully loaded and thereby leading to structural inefficiency. Length of barrel required is also more in case of skew. However, additional barrel length has few advantages. It reduces the length of wing wall on two sides, as shown in Fig 4. It also distributes the load better on bearing strata. The article is also available on www.railwayengineering.in Page 5 6 14.0 Standard Box can be used for skew crossings in another way also as shown in Fig 5 below: In this case, box is square to the loading. Instead of increase in barrel length, there is increase in span of box. This is most suitable for small drains where in any case longer span is required to be provided to allow entry and maintenance. The article is also available on www.railwayengineering.in Page 6 7 15.0 Instead of orthogonal boxes, skew boxes can also be used (Fig 6). They may be economical when skew angle is large. In this arrangement, entry to the box is skewed which is particularly not desirable for road underpass. Design of these boxes can be same as that of orthogonal boxes with span equalling perpendicular distance between supports, except that free edges of the slab to be designed on beam supporting one end of the strips in triangular portion. The article is also available on www.railwayengineering.in Page 7