Animal Identification and Record Maintenance

advertisement

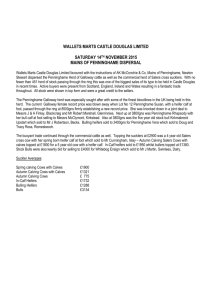

DFA Gold Standard Program Follow up Resources Technical services provided by Disclaimer Dairy Farmers of America, Inc. (DFA) is pleased to make the enclosed Gold Standard Dairy Standard Operating Procedures (SOPs) templates available for your use and benefit. These templates are to be used as a guide while developing local standard operating procedures in conformance with applicable rules and regulations which may vary from state to state. By using these SOPs, you warrant that you understand that the enclosed SOPs are only to be used as a guide. Use of the enclosed SOPs is strictly voluntary. SOPs should be reviewed on an annual basis to address any changes that have occurred that might impact individual practices. DFA expressly disclaims any and all representations and warranties concerning the SOPs and the accuracy of the information and content of the same. DFA disclaims any representation or warranty that any information included in the SOPs satisfies the requirements of any government agency, association, or other organization; or complies with any state, federal, local, or agency laws, rules, ordinances, or regulations. The SOP guide may be changed without notice. Technical services provided by Tips for modifying Standard Operating Procedures Save the document to your desktop Find and replace text You can automatically replace a word or phrase with another — for example, you can replace Acme with Apex. The replacement text uses the same capitalization as the text that it replaces unless you select the Match case check box. For example, if you search for AKA and replace it with Also known as, the result is ALSO KNOWN AS. If the Match case check box is selected, Office Word 2007 searches only for words that match the case of the word or phrase that you typed in the Find what box. For example, if you search for AKA, the result includes AKA but not aka. Note: If you don't see the Match case check box on the Replace tab, click More. On the Home tab, in the Editing group, click Replace. 1. Click the Replace tab. 2. In the Find what box, type the text that you want to search for. 3. In the Replace with box, type the replacement text. 4. Do one of the following: a. To find the next occurrence of the text, click Find Next. b. To replace an occurrence of the text, click Replace. After you click Replace, Office Word 2007 moves to the next occurrence of the text. c. To replace all occurrences of the text, click Replace All. Note: To cancel a replacement in progress, press ESC. Technical services provided by Table of Contents 1. Animal Care and Wellness Policy 2. Camera and Recording Devices Policy 3. Animal Identification and Record Maintenance 4. Calf and Heifer Management Procedures 5. Calving Management Procedures 6. Emergency Action Procedures 7. Employee Orientation and Training Procedures 8. Facility Upkeep 9. Herd Health Plan 10. Parlor Management Procedures 11. Special Needs Management 12. Best Management Check List to Avoid Antibiotic Residues 13. Biosecurity Procedures Technical services provided by 14. Expectations of the Herd Manager 15. Manure and Wastewater Handling Procedures 16. Pesticide Handling and Storage Procedures 17. Equipment, Machinery, Vehicle and Tool Use Procedures Technical services provided by Animal Care and Wellness Policy It is this dairy farm’s policy to ensure that all animals are treated humanely, and that all employees who work with animals comply with the guidelines for the proper care and handling of livestock as set forth in this farms training programs and/or in Dairy Farmers of America, Inc.’s Gold Standard Dairy program. Prompt disciplinary action will be taken against any employee who has abused animals, including but not limited to overdriving; overloading; torturing; cruelly beating; unjustifiably injuring, maiming, mutilating, whether wild or tame; depriving any animal of necessary sustenance, food or drink; or in any way furthers any act of cruelty to any animal. Any employee who witnesses actions in violation of this policy must immediately report such actions to management. I acknowledge that I have read and understand this dairy farm’s Animal Care and Wellness Policy statement and will adhere to this policy. I also understand that failure to adhere to this policy will result in disciplinary action, up to, and including dismissal. Employee signature: Printed Name: Date: Farm Name: Animal Care and Wellness Policy 6 Technical services provided by Camera and Recording Devices Policy Employees are not permitted to use cameras and audio/video recording devices or take pictures at any time for any reason while on this dairy farm’s property without prior approval and/or direction from farm management. Prompt disciplinary action will be taken against any employee who violates this policy. I acknowledge that I have read and understand this dairy farm’s Camera and Recording Devices Policy and will adhere to this policy. I also understand that failure to adhere to this policy, may result in disciplinary action, up to, and including dismissal. Employee signature: Printed Name: Date: Farm Name: Camera and Recording Devices Policy 7 Technical services provided by Animal Identification and Record Maintenance ABC Dairy Utopia, USA Date Issued: 10/19/2010 Date Revised: 11/01/2010 Page 1 of 2 Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To outline the procedures for animal identification, both newborn and purchased animals, and to establish the system for record maintenance Principles: 1. All livestock on ABC Dairy will have current, legible identification. 2. Records involving animal identification and production will show compliance with training, inventory control of medications and health record compliance. 3. Records will be maintained in computer form for the life of the animals and one year thereafter. _________________________________________________________________________ Animal Identification and Record Maintenance 8 Technical services provided by I. Animal Identification 1. Newborns a. Before initial processing, update the calving record. b. Heifers are to be ear tagged within six hours of birth. i. Heifer calves will be ear tagged with __________________________________ c. Record the birth date, ID number, and vaccinations in ___________________________ 2. Purchased animals a. All purchased animals entering ABC Dairy are to be identified _____________ _________________________________________________________________ 3. Identification maintenance a. When animals are locked up each morning, ear tag identification is to be evaluated. If a tag is lost or illegible, the tag is to be replaced immediately. II. Records Maintenance 1. All records for an animal must be kept for one year after the animal’s leave ABC Dairy 2. A copy of all health records (includes pesticide application records, medication and vaccination records, and medicated feed additives’ records) will move with all animals 3. Records will be kept in both computer and written form and be easily accessible by ABC Dairy managers or designated employees Animal Identification and Record Maintenance 9 Technical services provided by Calf and Heifer Management Procedures ABC Dairy Utopia, USA Date Issued: 10/20/2010 Date Revised: 11/01/2010 Page 1 of 3 ____________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To provide healthy animals for replacements in the lactating herd. Principles: 1. To grow live, healthy calves and heifers through daily and weekly procedures. 2. To provide comfort and support to animals aiding in their recovery from injury or illness, allowing them to return to the healthy herd as soon as possible without long-term health conditions. ____________________________________________________________________________ Calf and Heifer Management Procedures 10 Technical services provided by I. Calf/Heifer Monitoring 1. Daily Procedures a. Observe all heifers for health problems, foot problems and general appearance daily i. Look for uneven or labored respiration, abdominal distension, swollen joints, lameness, diarrhea, unusual discharges from eyes, nose or reproductive tract, ears down and listlessness ii. If the calf or heifer is noted with problem(s), record animal number, date and problem(s) on the board in the calf hospital b. Observe feed presented in feed bunk i. Management monitors feed quantity and quality ii. If problems are noted, inform management c. Check water tanks in each pen for available water d. Pick up all trash and litter around pens 2. Weekly Procedures a. Clean all waterers associated with the calf/heifer pens i. ii. iii. iv. v. Before cleaning, shut water off Drain the waterer Scrub the waterer with the brush and rinse thoroughly Replace stopper and turn water on Check for leaks b. Sweep the medication room in calf hospital; discard trash accordingly (needles in labeled containers, etc.) c. Wipe down the countertops and clean the sink with water and soap d. Watch for excessive rats or other rodents; report increased rodent activity to herd manager Calf and Heifer Management Procedures 11 Technical services provided by e. Wash out the trailer used to move calves/heifers with a high-pressure washer (do not wash in extremely cold weather) II. Treatment of Sick Calves Remember: When treating an animal with an antibiotic that has a withdrawal period, put a red leg band on one of its rear legs, move to appropriate hospital pen and record all actions on daily herd log. All medications require the withholding instructions be followed. 1. Review board in calf hospital for calves on treatment or recently identified as needing treatment 2. Administer treatment noted on board or in calf log 3. General treatments to be administered: a. Scours i. When a calf is not drinking milk, the following steps need to be taken: 1) If the calf has normal manure, tube the calf with the milk normally fed 2) If the calf has runny manure, feed normal milk amount and administer ____________________________________________________________ 3) If the calf has cold ears as well as the symptoms expressed in 1 and 2, treat ____________________________________________________________ b. Pneumonia i. When a calf is found to be coughing, take the following steps: 1) If the calf is still drinking, give the calf ______________________________ 2) If the calf is not drinking, treat the calf ______________________________ 3) If coughing persists, contact the manager for further instruction Calf and Heifer Management Procedures 12 Technical services provided by Calving Management Procedures ABC Dairy Utopia, USA Date Issued: 10/20/2010 Date Revised: 11/01/2010 Page 1 of 3 __________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To support the birth of live, healthy calves and to transition cows into lactation Principles: 1. At calving time, all cows and heifers will be monitored for calving activity and progress. 2. All animals needing assistance will be given appropriate attention. 3. All newborn calves will receive immediate attention, including the feeding of colostrum. 4. Calving facility and equipment are to be cleaned after each use and prepped for the next use. _________________________________________________________________________ Calving Management Procedures 13 Technical services provided by I. Calving Procedures 1. Once heifers are springing and showing udder development, move them into the appropriate pen 2. If animal is actively pushing or straining for one hour, but shows no progress, contact the herd manager 3. If the calf must be pulled, bring the mother into the calving facility a. If the animal cannot be moved, offer the following assistance in the current pen: i. Follow the calf pulling procedures listed in the maternity area ii. After pulling the calf, put the cow and calf in a pen 4. Process calf as described in “Newborn Calf Processing” outline below 5. Do not leave the calf in the calving barn for an extended period of time; warming the calf in the barn under heat lamps is recommended when delivery has been difficult or the temperature is below 32o degrees F 6. After six hours, if it appears that the cow is in good condition, move her to the fresh cow pen II. Newborn Calf Processing 1. Before initial processing, update the calving record 2. Spray the umbilical cord with iodine 3. Administer _____________________ vaccinations 4. Heifer calves are to be tagged within six hours of birth and tagged according to animal identification standard operating procedures 5. All calves are to receive colostrum immediately within 30 minutes of birth 6. Calf should also receive two more bottles in the next 12 hours 7. Record the birth date, ID number and vaccinations in the calf log 8. Move the calf to a clean hutch after it has had the first bottle Calving Management Procedures 14 Technical services provided by III. Calving Facility Cleaning Procedures 1. Clean the calving facility and all calving equipment every three days or sooner, if needed 2. All cleaning equipment is stored in the calving facility 3. Remove all solid waste daily; dispose of material properly 4. Following calving, use the high-pressure washer to thoroughly wash down the concrete and calving chute 5. Sweep standing water down the drain 6. Use a high-pressure washer and soap to thoroughly clean all calving equipment used 7. Return the calving equipment to its proper storage location Calving Management Procedures 15 Technical services provided by Emergency Action Procedures ABC Dairy Utopia, USA Date Issued: 10/18/2010 Date Revised: 10/29/2010 Page 1 of 3 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Herd owner, herd manager, unit supervisor Purpose: To enable an immediate and organized response in the event of an emergency Principles: 1. All personnel will receive training in emergency action procedures; this includes consideration of both livestock and personnel emergencies. 2. The training will be presented in native worker language or a translator shall be involved. This document is also available in native worker language (attached). 3. For employees whose second language is English, prepared statements asking for help have been written (attached to this sheet) and taught to employees word for word. ___________________________________________________________________________ Emergency Action Procedures 16 Technical services provided by I. EMERGENCY ACTION PLAN 1. Dairy Contacts a. Contact: ____________________________ b. Contact: ____________________________ 2. Emergency Contacts a. Address of dairy: _________________________________________________ b. Directions to the dairy: _____________________________________________ c. Ambulance: _____________________________________________________ d. Sheriff: _________________________________________________________ e. Fire department: _________________________________________________ f. Herd vet: _______________________________________________________ g. Power company: _________________________________________________ h. Gas company: ___________________________________________________ i. DFA Field Representative: _________________________________________ j. Milk Hauler: _____________________________________________________ 3. Emergency Supplies on Dairy a. First aid kit location: ______________________________________________ b. Main electrical supply is located: _____________________________________ c. Materials Safety Data Sheets for all chemicals are located: ________________ _____________________________ Emergency Action Procedures 17 Technical services provided by 4. Basic Repair Service Contacts a. Refrigeration: ____________________________________________________ b. Milking equipment: _______________________________________________ c. Other (equipment): _______________________________________________ 5. Personal Injury a. In the event of someone getting hurt, _________________________________ 6. Storm Events (Tornado, Electrical Storm, etc.) a. In the event of a tornado, employees are to ____________________________ _______________________________________________________________ b. In the event of a several electrical storm, ______________________________ _______________________________________________________________ 7. Catastrophic Animal Loss a. In the event of a catastrophic animal loss, employees are to notify __________ _______________________________________________________________ _______________________________________________________________ . Emergency Action Procedures 18 Technical services provided by Employee Orientation and Training Procedures ABC Dairy Utopia, USA Date Issued: 10/18/2010 Date Revised: 11/01/2010 Page 1 of 3 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To outline the procedures for introductory training of all new personnel and ongoing training for all dairy employees Principles: 1. All personnel will receive initial orientation training in the areas of their specific job description, plus basic animal care and animal movement. New hires are to initial each training component as they are trained on it. A copy will be retained in employee’s file. 2. The training will be presented in native worker language or a translator shall be involved. 3. Task-specific training documentation includes participant content and documentation that standard operating procedures have been read (when applicable). 4. ABC Dairy will maintain training records that document each employee's initial and ongoing training. Records will be maintained in employee file and by training date. __________________________________________________________________________ Employee Orientation and Training Procedures 19 Technical services provided by I. New Hire Orientation (initials) _____ _____ _____ _____ _____ 1. Farm orientation a. Each new employee of ABC Dairy will be given a tour of the facility by the herdsman (or a designee), with an in-depth tour of the facility specific to his or her job description (hospital, parlor, feeding, etc.) and other places for employees (breakroom, lunchroom, lockers, etc.) b. Information about employment policies and procedures will be given regarding: i. Keys or key cards (if applicable) ii. Parking policies and permits iii. Issue of dairy uniforms, boots, gloves, lockers, etc. and expectation of how these items are to be maintained (cleaned by dairy; not to be taken off dairy, cleaned at home, etc.) 8. Safety a. Each new employee of ABC Dairy will be trained in the dairy’s emergency plan (injury, fire, storm event, etc.). The trainer (owner, herdsperson, or other designated employee) will review the chain of command and emergency plan for employees facing such events. b. Each new employee of ABC Dairy will be trained in the basic care, observation and handling of animals per the Herd Health Plan (animal handling and movement). The trainer (owner, herdsperson, or other designated employee) will review safety principles in working with animals with all new employees so they are aware of potential hazards associated with their work and have knowledge of safe work practices around livestock. Additional critical points to train on include: i. Animal flight zones and using them to move animals ii. Moving uncooperative, difficult, or non-ambulatory animals iii. Moving animals out of critical emergencies (cow goes down in parlor, animal is down in stall, etc.) iv. Moving newborns properly v. ABC Dairy has a “no tolerance” policy in animal abuse 9. Job description a. Each new employee (or person changing position on the dairy) will be provided with a job description. This description will outline the expectations and protocols for communicating with other key individuals on the dairy. Job-related standard operating procedures (SOP) will be discussed with the individual and referenced to SOPs can be accessed for periodic review. Employee Orientation and Training Procedures 20 Technical services provided by _____ 4. ABC Dairy work policies a. Each new employee of ABC Dairy will be trained in the dairy’s employment policies, including: i. Work schedules ii. Illness iii. Holiday/annual time off iv. Timesheets or time clock procedures II. Annual Training/Professional Development 1. On-site employee training a. All full- and part-time employees involved in animal care or handling will be provided periodic training to maintain current knowledge and expected practices on ABC Dairy. These will include: i. Popular press magazines will be provided in the breakroom/employee lounge for employees to read. ii. Videos and DVDs of specific animal care and management (animal movement, calving, hospital treatments, reproduction, etc.) will be provided to all employees as the dairy has access. Viewing of these shall be noted in employee’s file. iii. Annual training sessions and discussions will be held with all managers and employees to emphasize ABC Dairy’s expectations of animal care and management. 2. Off-site education opportunities a. All employees are encouraged to continue their education in animal care and management by attending and participating in meetings, conferences, courses and workshops with prior approval from management. These events may be sponsored by industry, universities, etc. b. Documentation of attendance and participation in these meetings, conferences, courses and workshops are to be submitted to the manager to be included in the individual’s personnel files as continuing education/training. Employee Orientation and Training Procedures 21 Technical services provided by Facility Upkeep ABC Dairy Utopia, USA Date Issued: 10/30/2010 Date Revised: 11/01/2010 Page 1 of 2 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To properly maintain the safe operation of all facilities and reduce the risk of injury to personnel and livestock Principles: 1. All facilities and equipment will be maintained in good repair to allow for efficient use when needed. 2. Facilities shall be maintained to provide the animals with healthy and clean living conditions. ___________________________________________________________________________ Facility Upkeep 22 Technical services provided by I. General Upkeep of facilities 1. All employees are responsible for viewing facilities they are working in and noting facilities or equipment in need of repair. 2. If a simple fix is possible, employees are to repair facilities or equipment as needed. 3. Report any necessary repairs in the facility upkeep log located in the employee breakroom. 4. Report any lighting that needs replaced in the facility upkeep log 5. Report any flooring area where cattle or employees have slipped in the facility upkeep log. 6. Fans are to be cleaned and maintained ___________________________________. 7. Curtains on the freestalls are to be inspected ______________________________. II. Housing Management 1. Bedding management a. Manure is to be scraped from back of stall by pusher as group is moved to parlor b. Stalls are groomed ____________________________________________ c. Additional bedding is added _____________________________________ 2. Alley management a. Alleys are to be scraped each time the group is moved to the parlor 3. Dust control a. Roadways around animal housing are to be _________________________ 4. Dry lots/pastures a. Lots are to be groomed _________________________________________ b. Mounds are to be groomed ______________________________________ c. New dirt is to be brought in ______________________________________ d. Lanes to parlor are to be groomed ________________________________ Facility Upkeep 23 Technical services provided by Herd Health Plan ABC Dairy Utopia, USA Date Issued: 10/28/2010 Date Revised: 11/01/2010 Page 1 of 13 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To ensure that all animals will be handled humanely at all times, to outline the procedures for prevention/treatment of animal disease and to provide an effective nutrition program that ensures end-product safety Principles: 1. Animals will be given preventative care in the form of vaccines, etc., as directed by the herd veterinarian, to promote health and reduce incidence of disease. 2. All livestock with a treatable disease will be treated according to protocols based upon recommendations of a veterinarian with a valid Veterinarian-Client-Patient Relationship (VCPR). 3. All standard operating procedures involving herd health will be reviewed on a periodic basis by management in consultation with the herd vet. 4. Records involving antibiotics and other substances (including anthelmintics) requiring mandatory withdrawal times will be maintained for one year. 5. All feedstuffs (including medicated) will have the proper receiving, storage, handling and feeding protocols. 6. All animals will receive clean water sources. 7. All non-ambulatory animals will receive comfort and therapeutic support. 8. Any animal determined not salvageable is to be humanely euthanized. ___________________________________________________________________________ Herd Health Plan 24 Technical services provided by This Herd Health Plan has been developed as a template to cover the basics of herd health. It will be the responsibility of the individual dairy facility to complete this form in conjunction with the herd veterinarian in accordance to the dairy operation. This should be reviewed on an annual basis to address any changes that have occurred that might impact individual practices. Farm name: __________________________________________________________ Consulting veterinarian: _________________________________________________ Date last reviewed: ______________________ Individuals or positions responsible for this process: _______________________________ _________________________________________________________________________ **Attach current vaccination schedule protocol, including the attending veterinarian’s name and contact information as well as any special or temporary treatment and care protocols beyond those already listed. Herd Health Plan 25 Technical services provided by I. Animal Care and Handling 1. All employees shall be trained at hire in basic animal care and handling procedures and training will be periodically reviewed annually thereafter 2. Prior to working or moving cattle, inspect the fences, chutes, corrals and working facility to ensure proper care and ease of handling; make any necessary repairs 3. Handle all animals gently and humanely at all times to minimize stress to the animals and to avoid injury to handlers 4. When working animals, do not get them excited; move them slowly and quietly 5. Before working cattle through the chute, ensure that all chains and items that might distract cattle are removed to prevent balking 6. An electric cattle prod is only to be used as cattle enter the squeeze chute, if necessary; it is not to be used to routinely move cows 7. When not in use, the hotshot is to remain on the table at the processing area, not in the hands of the workers 8. The goal is to have cattle walk through processing and walk out 9. All humane animal care and handling procedures are expected from both employees of ABC Dairy and non-employees/contractors; a copy of this page is to be signed by nonemployees/contractors and maintained on file in the dairy office II. Animal Monitoring and Flagging of Sick Animals 1. All animals will be monitored daily a. Calves will be monitored by ___________________________________________ b. Heifers will be monitored by ___________________________________________ c. Dry cows will be monitored by _________________________________________ d. Milking cows will be monitored by ______________________________________ Herd Health Plan 26 Technical services provided by e. Hospital pen will be monitored by ______________________________________ 2. Animals will be visually evaluated for: a. Normal hair coat b. Normal behavior (alert, etc.) c. Respiration (labored breathing) d. Feed and water consumption (gut fill, hydration) e. Discharges (eyes, nose, vulva, etc.) f. Manure consistency g. Locomotion (will get up when asked, moves willingly, etc.) h. Milk abnormalities (by forestripping, California Mastitis Test, etc.) 3. Any animal looking abnormal or appearing to have problems shall be flagged for further evaluation a. Calves needing attention are to be identified by _______________________________ and will be further evaluated by _________________________________________ b. Cows needing further evaluation shall be identified by _______________________ and will receive a follow up evaluation by _________________________________________ c. Dry cows and heifers will be further evaluated by ___________________________ d. Animals in the hospital pen will be further evaluated by ______________________ 4. Further evaluation shall include: a. Taking the animal’s temperature; temperature should be recorded with the animal ID in the daily health log b. Other evaluation(s) may include _________________________________________ Herd Health Plan 27 Technical services provided by 5. A plan of action shall be made and recorded on any animal deemed sick or needing medical treatment III. Treatment of Sick Animals Note: When treating an animal with an antibiotic/anthelmintic that has a milk or meat withdrawal period, identify that animal by placing a red leg band on one leg and move to the animal to an appropriate hospital pen. All antibiotic treatments are to be recorded in the health log. 1. Treatment of all sick animals shall be overseen by _____________________________ 2. Initial treatment of any sick animal must follow the ABC Dairy’s Special Needs Management – Basic Animal Treatment Plan IV. Foot Health Care Plan 1. Hoof trimming shall be done on each cow ______ times per year 2. Any animal observed to have a sore foot or leg shall be identified to the herd manager as needing further evaluation 3. The herd manager will evaluate these animals for identification of the potential problems a. Foot rot i. If condition is determined to be foot rot, then the foot is to be treated __________ ________________________________________________________________ b. Laminitis i. If condition is determined to be laminitis, then ____________________________ ________________________________________________________________ Herd Health Plan 28 Technical services provided by c. Hairy heel wart i. If condition is determined to be hairy heel wart, then _______________________ ________________________________________________________________ d. Other i. If condition is determined to be something other than those ailments listed above, then ___________________________________________________________ V. Vaccination Plan 1. Herd vaccination protocols are determined by the herd manager and the herd veterinarian and include: a. Calves on first day of life: ______________________________________________ b. Calves at four months: ____________________________________________________ c. Dry cows at dry off: ________________________________________________ e. Cows at calving: __________________________________________________ VI. Vet Recommended Medical Practices and the Use of Pain Management 1. Vet-recommended medical practices shall be done by the following age: a. Dehorning (age at dehorning = ______________________) i. Method: _________________________________________________________ ii. Anesthesia required:________________________________________________ iii. Pain management: ________________________________________________ Herd Health Plan 29 Technical services provided by b. Extra teat removal (age at removal = ______________________) i. Method: _________________________________________________________ ii. Anesthesia required:________________________________________________ iii. Pain management: ________________________________________________ c. Castration (age at castration = ________________________) i. Method: _________________________________________________________ ii. Anesthesia required:________________________________________________ iii. Pain management: ________________________________________________ 2. If beyond above age: a. Anesthetic is to be used and procedure is to be done under the supervision of the herd veterinarian VII. Parasite/Pest Control 1. Parasite control (designate drug, rotation, ages and intervals between deworming and internal parasite/external parasite treatments) a. Deworming, calves are to be treated with ________________________________ b. Deworming, cows are to be treated with _________________________________ c. Lice infestation, calves are to be treated with _______________________________ d. Lice infestation, cows are to be treated with _______________________________ 2. Pest control a. Determine pest problem (mites, flies, etc.) b. If mites, calves are to be treated with ____________________________________ c. If mites, cows are to be treated with _____________________________________ d. If flies, calves are to be treated with ____________________________________ Herd Health Plan 30 Technical services provided by e. If flies, cows are to be treated with _____________________________________ VIII. Feed Quality Management 1. Receiving a. All feed records are kept on file in the office b. No feeds containing banned ruminant-derived protein sources are to be purchased; these include meat and bone meal or any other products produced from ruminant muscle or bone tissue c. When feed or supplements are received, the source, date and description of feed are to be entered into the feed record system d. Inspect incoming feedstuffs on arrival for possible signs of contamination (discoloration, insects, mold, moisture, odor, etc.) e. Return any feedstuffs that appear to be contaminated 2. Sampling and testing a. Hay i. Upon arrival of hay, collect a core sample from every ____ bale; collect at least ___ samples from each lot, cutting, field, etc. of hay ii. Place the core samples into a pint-sized sealable plastic bag and seal bag iii. Label the bag accordingly iv. Send the samples for analysis immediately after they are collected v. Hay should be analyzed for ___________________________________________ vi. Sample analysis is to be shared with the nutritionist at next meeting; copies are to be filed in the office for one year Herd Health Plan 31 Technical services provided by b. Sampling and testing silage i. Collect grab samples of fresh silage from at least 10 sites across face of bunker or from silo unloader in a gallon-sized sealable bag on the first of each month ii. Make sure the bag is properly sealed and the air is pressed out iii. Freeze the sample and send the sample for analysis within a day of collection iv. Silage should be analyzed for _________________________________________ v. Analysis is to be shared with nutritionist at next meeting; copies are to be filed in the office for one year c. Storage and feeding i. Feed storage facilities are to be kept dry, clean and free of medications, pesticides, herbicides, fertilizer, solvents, rodents, birds, manure, etc. to minimize possibility of contamination ii. All feed equipment, including scales, mixers, bins, trucks, feed bunks and feeders are to be visually inspected every ______________________________________ iii. Clean and repair all feed equipment when necessary iv. Diet formulations and changes are updated and kept on file; changes are to be communicated to ___________________________________________________ 3. Medicated feed additives a. Purchase and receiving i. Purchase only medicated feed additives that are FDA approved ii. Upon arrival, record the source, amount, date and description of the medicated feed in the medicated feed additive inventory and use record in the office iii. Place one label of each kind of medicated feed additive purchased in the medicated feed additive labels’ binder b. Storage i. Store all medicated feed additives separate from all other feeds Herd Health Plan 32 Technical services provided by c. Use and record keeping i. Use all medicated feed additives in accordance with the FDA approved label ii. After use of medicated feed additive, record amount IX. Water Quality Management 1. Sampling and testing a. All water is to be tested for __________________________________ each _________________ b. Waterers are to be kept clean with scheduled cleaning every _________________ or sooner, if needed c. Waterers are to be scrubbed every _______________________________________ X. Non-ambulatory Management 1. Movement and handling a. When a non-ambulatory animal is identified, the herd manager is to be notified b. Non-ambulatory animals that are deemed unsalvageable are to be euthanized immediately c. If deemed treatable, a person trained to operate the sled or loader for moving nonambulatory animals is notified to remove the non-ambulatory animal from an ambulatory animal group within two hours of being identified i. Picking up a non-ambulatory animal requires three people: one person operating the loader and two ground assistants ii. Never scoop the animal up by the loader; gently roll the animal into the loader bucket by the people on the ground while the loader operator rolls the bucket back d. The non-ambulatory animal is to be carried gently in the loader bucket or on the sled to an area specified for special needs’ animals Herd Health Plan 33 Technical services provided by e. This designated area should be located away from other healthy animals that can cause harm to the non-ambulatory animal and is to provide protection from predators i. Body parts of the non-ambulatory animal shall not be touching the ground while being moved ii. The loader should never be driven recklessly or at a speed that would cause additional harm to the animal; the loader must be able to stop quickly enough in case the animal attempts to get out of the loader f. The non-ambulatory animal must be gently rolled out of the loader bucket or off the sled into soft bedding where it will immediately be given clean water and food within easy reach 2. Husbandr /nursing care of non-ambulatory animals a. The non-ambulatory animal will receive treatment by (designated person or position) each morning and evening b. General treatment protocols will depend on stage of lactation and diagnosis i. Non-ambulatory animals judged to be irreparable by herd manager, due to traumatic injury, will be euthanized promptly (see euthanasia section) ii. Non-ambulatory animals judged to be treatable by herd manager will be treated according to general treatment protocols c. Treatment of non-ambulatory animals should consider anti-inflammatory and analgesic medication (individual cases to be determined by herd manager in conjunction with the herd veterinarian) d. All non-ambulatory animals will be rolled from side to side every two to three hours to prevent further damage to their muscles and nerves Herd Health Plan 34 Technical services provided by e. Non-ambulatory animals can be assisted to stand with a sling that is placed around their belly; the sling needs to be wide enough to support the animal’s weight over a broad area f. The animal should never be left in the sling unattended; the amount of time an animal is allowed to stand in the sling will be dependent on the animal g. Hip lifts are only to be used by the herd manager to temporarily lift the hind end; the animal is not to be left in lifts more than 10 minutes h. When a non-ambulatory animal that has been receiving treatment is judged to be non-responsive and unsalvageable by the herd manager, the animal is to be euthanized by _________________________ according to the euthanasia procedure outlined below i. Employees are to notify the herd manager of non-ambulatory animals in rehabilitation longer than three days ii. If the animal’s health is deemed to be improving and the animal is able to sit upright and appears alert, then rehabilitation may continue as stated in the health plan or by the veterinarian XI. Euthanasia 1. All downer animals must have access to food and water (until euthanized) 2. Animals are to be checked no less than every three to four hours and rolled accordingly 3. Euthanasia will only be conducted by the herd manager, herd vet, or another designated, trained employee 4. All euthanasia will be conducted by _______________ in accordance to the American Veterinary Medical Association approved practices Herd Health Plan 35 Technical services provided by 5. All animals are to be checked for death by confirming lack of an eye reflex after three minutes and inducing pneumothorax (if trained by veterinarian for this procedure) 6. Euthanasia incidents are to be recorded _____________________________________ XII. Mortality Disposal 1. Upon discovery of a mortality, it is to be removed from the area within 12 hours; if it can’t be removed by hand, use the loader, taking care to avoid damage to the hide 2. Take the animal to the ___________________________________________________ 3. Contact herd manager to consider autopsy by herd vet as part of herd health maintenance and disease risk prevention plan 4. Do not place mortalities near any feedstuffs 5. Avoid placing mortalities in an area that can be viewed by the public 6. Contact herd manager for proper disposal procedures 7. After moving the mortality, immediately wash and disinfect the bucket of the loader before using it again on the facility 8. If using a private farm trailer, immediately wash and disinfect the trailer upon returning to the dairy (same procedures as with the loader) 9. Record animal tag number, date of deathand cause of death Herd Health Plan 36 Technical services provided by Parlor Management Procedures ABC Dairy Utopia, USA Date Issued: 10/20/2010 Date Revised: 11/15/2010 Page 1 of 4 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, parlor supervisor Purpose: To promote the production and harvest of high quality milk while preventing mastitis and teat end injuries Principles: 1. All milkers will be routinely oversighted to ensure proper milking techniques. 2. All animals shall be handled in such a manner that they are calm throughout the entire milking process. 3. Milking equipment and milk cooling and storage equipment shall be routinely evaluated for performance. ___________________________________________________________________________ Parlor Management Procedures 37 Technical services provided by I. Parlor Set Up 1. Make sure the automatic sanitizer cycle circulated through the machines. 2. Put in milk filters. 3. Connect milk line to tank. 4. Prepare each milking unit. a. Remove jetter cups and slide all four cups into slots of the storage unit. b. Connect clip of the automatic take-off to the top of the milking unit. 5. Load parlor with individual towels. 6. Press the "Start" button on each milking unit (this will bring the milking unit up). 7. Put on milking gloves. II. Milking Procedures (to be done in groups of ____ on a side) 1. Cows are to be brought in from the holding area with calm use of the crowd gate. a. At no time are animals to be pushed to the point of being trapped in the gate. 2. Once a side is full, gates are to be closed. 3. Cows are to be processed in a soothing manner to keep the cow calm, as well. 4. Dip all four teats; make sure to cover the entire teat. 5. Strip each quarter. 6. Look for abnormal milk. Mark mastitis cows on board at end of parlor. 7. Dip teats again. 8. Use clean cloth to clean/dry teats. Attempt to remove all manure from the teat area. 9. Press the start button on the milk meter. Attach the milking unit, making sure it is positioned correctly with the udder. Place a milker on each teat, making sure each milker is parallel to each teat and that the unit is hanging correctly. Adjust hoses as needed to allow the unit to hang properly and not pinch off or limit the amount of milk removed from each teat. Fold back short milk tubes on individual quarters not milked. Parlor Management Procedures 38 Technical services provided by 10. If the milker falls off before completion, reset the milker. If the milker continues to fall off or if cow appears to be done, check the udder for any hard quarters, or for a soft, pliable bag, which would indicate the cow is completely milked out. Hard quarters will require mastitis treatment and this cow should be cut out into the holding pen when group is released. Completely milked out cows may be turned out with the rest of the healthy herd. 11. Upon completion, remove the units. Completely dip each teat into the teat dip. Mastitis and lame cows will be separated upon group exit. 12. Cow pusher will help move and segregate cows out of the parlor. III. Milking Sick Cows 1. All sick cows are to the treated, banded for identification and moved into the hospital pen. 2. Animal identification and treatments are to be recorded in the hospital log. 3. This group is to be milked together and all milk discarded. IV. Post-Milking Procedures 1. Shut off milking units. 2. Pick up all dirty towels. 3. Empty and rinse the teat cups. 4. In the parlor, wash the platform and butt plates. 5. Prepare the milking unit for the wash cycle. a. After cleaning the milking unit, replace the jetter cups. b. Rehang the entire unit, ensuring the lines are not crimped (these lines will run the washing process through the milking unit and remove any bacteria and contaminants from the unit). Parlor Management Procedures 39 Technical services provided by c. While cleaning the rest of the parlor, watch for any disconnected hoses. Reattach, if necessary. 6. Flush the holding pen with potable water. 7. Shut off water and rehang hoses tolet any remaining water drain out. 8. Lead milker should add any pertinent notes and treatments to the production record. V. Milking Equipment Maintenance 1. All milking units are to be evaluated for adequate pulsation every ______ weeks. 2. All inflations are to be changed every _________ weeks. 3. Milk cooling system is to have a routine evaluation every ______ weeks. Parlor Management Procedures 40 Technical services provided by Special Needs Management Basic Animal Treatment Plan and Records ABC Dairy Utopia, USA Date Issued: 10/29/2010 Date Revised: 11/01/2010 Page 1 of 5 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Dairy owner, herd manager, unit supervisor Purpose: To outline initial procedures for the treatment of animal disease Principles: 1. All animals requiring medical treatment will be treated according to these procedures. 2. If initial procedures are not effective after three days or as determined by the herd manager or herd veterinarian, treatment shall be adjusted as needed and logged in the daily health log. 3. All records must be transferred to the individual animal’s health record within 36 hours. _________________________________________________________________________ Note: When treating an animal with an antibiotic or other drug with a milk or meat withdrawal period, place a red leg band on one leg, move to appropriate pen and record all actions on the daily health log. Special Needs Management 41 Technical services provided by I. Basic Treatment Plans 1. Mastitis a. Determine whether the mastitis requires immediate treatment or not. Do this by performing the following actions: i. Take temperature (normal is 103 degrees F) ii. Palpate quarter (hard versus soft, cold versus warm) and evaluate milk (watery, color, etc.) iii. Check to see if the ears are cold iv. Check manure v. Use a California Mastitis Test paddle to look at the consistency of the milk and somatic cell count level vi. Consider obtaining aseptic milk sample for later culture if needed b. Mastitis treatment i. If temperature is more than ____degrees F, give _____________________________ ii. If quarter is hard, give ________________________________________ iii. Administer oral fluids _________________________________________ iv. If ears are cold or the cow is down due to mastitis, __________________ v. If the cow only has flakes and no hardness or related ailments, consult with the herd manager to decide whether or not to treat her Special Needs Management 42 Technical services provided by 2. Dystocia a. If a cow has been in hard labor more than one hour and does not appear to be making progress, the following treatments should be applied immediately: i. Wash vulva with antiseptic and dry; wearing gloves, determine position of calf ii. ________________________________________________________________ 3. Milk fever a. In the case of finding a cow that is down, or up but wobbly, use the following actions: i. If fresh in the past 80 hours, rule out toxemia from mastitis ii. If longer than 80 hours, rule out toxemia from retained placenta, mastitis, or uterine infection b. Milk fever treatment i. Give her ______________________________________________________ 4. Retained placenta a. If the cow’s reproductive tract smells fetid or the cow is lethargic and the placenta is still hanging out, perform the following actions: i. Take her temperature (normal is 103degrees F) ii. Rectally palpate her to check for fluid by massaging from the horns back (watch out for fluid) b. Retained placenta treatment i. If her temperature is below 101degrees F, evaluate cow for milk fever or severe toxemia, gangrene, etc. Special Needs Management 43 Technical services provided by ii. If her temperature is 101 to 103degrees F, identify cow to be watched at end of parlor iii. If her temperature is more than 103degrees F, give her: ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ Notes: Be sure to put a band on one rear leg, move to sick pen, and record on day sheet all information. 5. Metritis a. If you find a cow during routine post-partum reproductive check at ____ days in milk, and she has cloudy vaginal discharge, perform the following: i. Observe cow daily for metritis by examining for vaginal discharge ii. ________________________________________________________________ b. Metritis treatment i. If temperature is normal (103 degrees F), _____________________________________ ii. If temperature is more than 103 degrees F , administer _________________________ Special Needs Management 44 Technical services provided by II. Record Keeping 1. All health records are to be recorded in the daily health log at time of administration 2. All health records are to be transferred to the individual animal health record within 36 hours 3. All health records are to be maintained for the life of the animal on ABC Dairy Special Needs Management 45 Technical services provided by Best Management Check List to Avoid Antibiotic Residues 1. Establish a Valid Veterinarian-Client-Patient Relationship (VCPR) _____ a. A veterinarian has assumed the responsibility for making medical judgments regarding the health of the animals. _____ b. A veterinarian has made routine and timely visits to the dairy to gain sufficient knowledge of the animals to initiate general or preliminary diagnosis of the medical condition of the animals. _____ c. A veterinarian is readily available for follow-up in case of adverse reactions or failure of treatment. _____ d. Employees are aware that it is policy to follow the instructions of a veterinarian. _____ e. The veterinarian and producer have established an approved drug list. _____ f. All drugs on the dairy have proper labeling. 2. Use Only FDA-Approved Over-the-Counter (OTC) or Prescription (Rx) Drugs with Veterinarian’s Guidance _____ a. Only FDA-Approved drugs are used to treat animals. _____ b. Copies of drug inserts and/or product labeling are available for all drugs used on the dairy. _____ c. Only a veterinarian can prescribe drugs in an “extra-label” manner. _____ d. A list of current over-the-counter and prescription drugs has been developed that can be used with the dairy cows. _____ e. Any Veterinary Feed Directive (VFD) feeds (i.e. Pulmotil in a swine feed) on the dairy are stored in such a way that an accidental use cannot occur. Best Management Check List to Avoid Antibiotic Residues 46 Technical services provided by 3. Administer All Drugs Properly and Identify All Treated Animals _____ a. Two or more methods are used to identify treated animals. _____ b. The label and the package insert information is read and followed. _____ c. Package inserts for drugs the veterinarian and the producer have put on the approved drug list are reviewed. _____ d. A proper facility to segregate treated animals from untreated animals is available. 4. Maintain and Use Proper Treatment Records on All Treated Animals _____ a. A record system is maintained for all treated animals. _____ b. Treatment records are reviewed with the consulting veterinarian. _____ c. Records are used to improve management of potential hazards and to reduce risk to milk quality. _____ d. Record use is reviewed with family members and/or employees. 5. Use Drug Residue Screening Tests _____ a. Withholding times are never decreased for meat or milk from treated animals. _____ b. Milk is never marketed from a treated animal even if only one quarter was treated. _____ c. Milk from treated dry-cows that freshen early is always tested for residues prior to marketing. _____ d. Milk from newly purchased animals is always tested before adding their milk to the bulk tank. _____ e. When a cow is treated in an extra-label manner, the milk gets tested. (When using bulk tank tests on individual cow milk, consult your veterinarian.) Best Management Check List to Avoid Antibiotic Residues 47 Technical services provided by _____ f. The veterinarian and/or co-op field staff are consulted on how to pull samples of milk for residue testing. 6. Implement Employee/Family Awareness of Proper Drug Use to Avoid Marketing Adulterated Milk Products _____ a. Awareness exists that milk contamination often occurs when the normal pattern of milking changes (vacation, children home from college, sickness, etc.). _____ b. Treatment records are checked before marketing animals. _____ c. Employees and/or family members understand the cost of marketing adulterated meat or milk. _____ d. Recommendations from the veterinarian are reviewed with employees and/or family members. _____ e. Family members and/or employees understand the instructions found on the drug label. _____ f. Family members and/or employees understand that all treated animals are milked last and/or their milk is diverted from saleable milk to prevent violative residues. _____ g. Employees and/or family members receive regular training on the prevention of milk and meat residues. Best Management Check List to Avoid Antibiotic Residues 48 Technical services provided by Biosecurity Procedures ABC Dairy Utopia, USA Date Issued: 12/10/2010 Date Revised: 12/10/2010 Page 1 of 4 Scope: All dairy personnel Responsibility: Herd owner, herd manager Purpose: To minimize the chances of infectious disease being carried onto ABC Dairy by people and animals, and to reduce the spread of these diseases if they are present on the farm Principles: 1. All personnel working on ABC Dairy will be trained in biosecurity procedures as it relates to their job. 2. All personnel working with incoming animals will be trained in testing and handling new animals prior to herd entry. 3. All traffic shall be directed through the main office. Visitors are required to sign the visitor log. 4. All animals will be housed and managed in clean, healthy facilities to encourage strong immune systems. 5. All sick animals shall receive the necessary attention and treatments to encourage quick recovery or removal from the herd. Biosecurity Procedures 49 Technical services provided by I. Personnel Training in Biosecurity Issues 1. Employees will be trained in: a. Disease recognition b. Reporting abnormal cattle conditions c. Handling sick animals contagious to them (crypto, salmonella, etc.) d. Biocontainment procedures (taking a potential disease off the farm, limiting the risk of carrying a disease off the farm and to their family, etc.) e. Emergency plan for disease outbreaks, including reporting (farm contact point, veterinarian, etc.), contact information, timing, etc. II. Managing Incoming Risks 1. Preventing the introduction of infected animals a. Only bring in animals from herds from approved suppliers; approved suppliers will provide basic health records for animals purchased b. New animals are to be processed (dewormed, vaccinated, etc.) prior to herd entry, unless supplier provides records of such events that allow exception c. Only purchase virgin breeding animals d. Avoid purchasing animals that have been co-mingled with animals of another herd e. Test all incoming animals for infectious diseases (i.e. Bovine Virus Diarrhea, Bovine Leukemia Virus, and Johnes) as determined by the herd management before introducing them to the herd f. Milk shall be cultured from each quarter of purchased animals prior to the milk entering the bulk tank Biosecurity Procedures 50 Technical services provided by g. A Breeding Soundness Exam (vibrio, trich, etc.) shall be conducted on all purchased bulls prior to herd entry h. When possible, transport purchased animals in ABC Dairy trailers i. Only use animal transporting services approved by ABC Dairy management j. For hired transporters, ensure that they start out with a clean truck k. Outside truck cleaning is only allowed on ABC Dairy premises in designated areas 2. Preventing the introduction of infectious diseases a. A sign is posted at the farm entrance to inform visitors to report to the office before entering any unit on the dairy b. All visitors must sign the visitor log at the office c. Visitors are not allowed in barns and pens without an ABC Dairy employee present d. Visitors should wear clean boots and coveralls when entering animal facilities e. Dead stock storage and removal is maintained at a distance (at least 100 feet) from the home herd f. Market animals are loaded at a location remote from the common entry point for primary animals g. Areas around all trash bins shall be maintained in a clean manner h. ABC Dairy shall manage control access of large wildlife (coyotes, wild dogs, etc.) to the herd by __________________________________________________________ i. ABC Dairy shall manage vermin (birds, skunks, raccoons, rats, etc.) by __________________________________________________________________ j. ABC Dairy shall manage external parasites (flies, lice, etc.) by __________________________________________________________________ Biosecurity Procedures 51 Technical services provided by III. Managing Internal Risks 1. Increasing the resistance of animals to infectious diseases a. Animals will be managed to minimize stress i. Diseases will be treated promptly and animals cared for in such a manner to minimize sick time ii. Good nutrition will be provided through the feeding program b. Facilities will be managed to provide clean, comfortable living areas for all animals on ABC Dairy c. Regular administration of vaccinations and boosters will be given as recommended by the herd veterinarian in the Herd Health Plan 2. Minimizing the exposure to infectious diseases a. Isolate sick animals, especially animals with unfamiliar symptoms or those that don’t respond to standard treatment b. Remove dead animals from pens quickly and dispose of them properly c. Minimize manure contamination of hair coat, feed and water by keeping pens, feeders and waterers cleaned IV. Managing Outgoing Risks 1. Pick up location for cull cows will be maintained at a remote site or at the edge of the dairy to avoid truck traffic through the immediate housing areas 2. Pick up location for bull calves (calves removed from home site and to be co-mingled with others) will be at edge of dairy unless dairy provides transportation 3. Diagnostics (tissue, blood samples) will be completed for any unusual deaths 4. Equipment used to move dead animals will be maintained separate from equipment used in feed handling Biosecurity Procedures 52 Technical services provided by Expectations of the Herd Manager ABC Dairy Utopia, USA Date Issued: 12/10/2010 Date Revised: 12/10/2010 Page 1 of 3 Scope: All dairy personnel Responsibility: Herd owner, herd manager Purpose: To outline responsibilities of the herd manager and provide direction as to the expectations of this position Expectations of the Herd Manager 53 Technical services provided by I. Basic Animal Care Responsibilities of the Herd Manager 1. Daily oversight a. Check on maternity pens and dry cows for new calves; move and treat newborn calves, as necessary b. Check on sick cows i. Treat any sick cows as necessary, and note on the record c. Check in with the milkers d. Check that the milk tank is at 38 to 42 degrees F e. Check on springers, if applicable f. Check in with the feeder g. Check in with calf care person h. Make sure manure is being cleaned out of stalls and bedding leveled i. Check all cows prior to leaving for the day, particularly the sick cows and maternity cows j. Note any conditions regarding the herd on the bottom of the day sheet k. Note any particular details about any calving assistance given 2. Night-check procedures a. Check in with the night milkers b. Check that the milk tank is at 38to 42 degrees F c. Check on dry cows and mat pens; move and treat calves accordingly if the calf feeder has gone home II. Manure/Wastewater Handling and Storage 1. The herd manager is to visually inspect the lagoon and all diversion berms each week for potential breeches and leaks Expectations of the Herd Manager 54 Technical services provided by 2. Any significant odors are to be noted and investigated immediately 3. During daily oversight of animals, the herd manager will visually evaluate drainage sites from animal housing for correct drainage 4. During rainfall events and periods of melting snow, the herd manager will drive around the perimeter of the animal housing sites and assess drainage from lots for correct flow to lagoon area Expectations of the Herd Manager 55 Technical services provided by Manure and Wastewater Handling Procedures ABC Dairy Utopia, USA Date Issued: 12/08/2010 Date Revised: 12/08/2010 Page 1 of 3 ___________________________________________________________________________ Scope: All dairy personnel Responsibility: Herd owner, herd manager Purpose: To ensure the proper storage, handling and application of manure and wastewater Principles: 1. All manure and wastewater will be handled according to _________________ State Guidelines. 2. All manure and wastewater storage areas will be maintained in a hygienic manner. ___________________________________________________________________________ Manure and Wastewater Handling Procedures 56 Technical services provided by I. Manure Management Plan 1. The ABC Dairy manure management plan is on file in the dairy office. 2. Daily activities of the plan include: a. Keep the lagoon and surrounding area free of trash b. ___________________________________________ c. ___________________________________________ 3. Weekly activities of the plan include: a. Mow around lagoon to keep weeds down b. ___________________________________________ c. ___________________________________________ 4. Monthly activities of the plan include: a. ___________________________________________ b. ___________________________________________ c. ___________________________________________ 5. Activities required as-needed: a. Maintain records of rainfall events b. Maintain records of manure application to fields c. Maintain records of lagoon pumping d. ___________________________________________ 6. Annual activities of the plan include: a. Soil tests of all fields where manure applied (if required by plan) b. Annual review of manure management plan by approved third-party c. ___________________________________________ Manure and Wastewater Handling Procedures 57 Technical services provided by II. Periods of Rainfall or Melting Snow 1. During periods of rainfall or melting snow, the herd manager will visually evaluate a. Lagoon, berms and drainage routes from animal housing for breeches or incorrect drainage b. Mortality storage areas for containment of leachate Manure and Wastewater Handling Procedures 58 Technical services provided by Pesticide Handling and Storage Procedures ABC Dairy Utopia, USA Date Issued: 12/10/2010 Date Revised: 12/10/2010 Page 1 of 3 Scope: All dairy personnel Responsibility: Herd owner, herd manager Purpose: To ensure the proper storage, handling and application of pesticides. Principles: 1. All pesticides and similar chemicals will be handled by employees trained in safety and proper use. 2. All pesticides and similar chemicals to be used on or administered to livestock will be conducted by trained personnel. 3. Employees will ensure proper disposal of all pesticide containers. ___________________________________________________________________________ Pesticide Handling and Storage Procedures 59 Technical services provided by I. Receiving 1. Purchase only pesticides that are EPA approved 2. When pesticides are received, update the office records II. Storage 1. Store all pesticides on designated pallets for short-term storage 2. For long-term storage, store all pesticides in the long-term designated area 3. Ensure that storage facilities are kept clean, dry and well-ventilated 4. Keep all pesticides dry and out of the way of activities that might knock over a jug or rip open a bag 5. Keep all pesticides and fertilizer away from feedstuffs at all times 6. Evaluate liquid pesticides for freezing and all containers for cracks or rupture 7. Clean up all spills immediately III. Mixing, Use and Record Keeping 1. All mixing and loading of pesticides is to take place on the concrete pad for control of spills 2. When mixing, take care to prevent pesticides from being back siphoned from the sprayer tank into the well and the ground water a. Keep the end of the fill hose well above the water level in the spray tank b. Use an anti-backflow device on the fill hose 3. Keep current records of past field application rates and their effectiveness 4. Record information such as the manufacturer's name and address, pesticides types and handling precautions 5. Use oldest products first to keep inventory current and effective 6. Only use pesticides on animals that are labeled for animal use Pesticide Handling and Storage Procedures 60 Technical services provided by 7. When applying pesticides to animals, follow label directions carefully 8. Before pesticides are used on animals, record the treatment in the animal health log IV. Disposal of Containers 1. Dispose of all pesticide containers ______________________________________ Pesticide Handling and Storage Procedures 61 Technical services provided by Equipment, Machinery, Vehicle and Tool Use Procedures ABC Dairy Utopia, USA Date Issued: 12/10/2010 Date Revised: 12/10/2010 Page 1 of 2 Scope: All dairy personnel Responsibility: Herd owner, herd manager Purpose: To ensure the proper access and function of all equipment, machinery, vehicles and tools when needed ___________________________________________________________________________ Equipment, Machinery, Vehicle and Tool Use Procedures 62 Technical services provided by I. General Operating Procedures 1. Anyone using ABC Dairy equipment, machinery, or tools is required to have authorization from management and proper training before use 2. Keep all vehicles, equipment and machinery clean and free of trash 3. Operate and maintain all vehicles, equipment and machinery according to their respective operating procedures 4. If any defective function is noticed on vehicles, equipment, machinery, or tools, it is to be reported to _____________________________ 5. After use, return all tools, vehicles, equipment and machinery to their original place of storage 6. After use, return all keys to the office, or designated site, at the end of the day II. Fueling Procedures 1. Check the fuel and oil prior to operating any equipment or machinery 2. Every time a vehicle is refueled, record the date, vehicle identification and amount of fuel dispensed in the fuel log located in each vehicle 3. All heavy equipment requires diesel fuel only 4. All other pickups and all-terrain-vehicles require unleaded gasoline only III. Maintenance 1. All tractors and machinery will be maintained or repaired in the dairy shop by _______________________________________ Equipment, Machinery, Vehicle and Tool Use Procedures 63 Technical services provided by