Effect of Relative Humidity and Temperature on PVC

advertisement

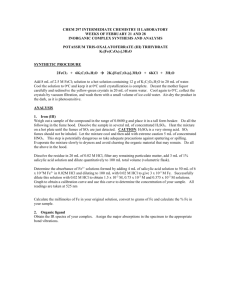

Effect of Relative Humidity and Temperature on PVC Degradation under Gamma Irradiation: Evolution of HCl Production Yields V. Labeda*, H. Obeidb, K. Ressayrea a b CEA DEN/DTCD/SPDE/L2ED, BP 17171, 30207 Bagnols-sur-Cèze Cedex, France Present adress: Lebanese International University, Al Mouseitbeh, Beirut, Lebanon Abstract The separate and combined effects of the relative humidity and temperature were investigated on the HCl production yields arising from two types of PVC subjected to gamma irradiation (pure PVC and PVC formulated with plasticizing additives). The test procedure developed included experiments performed at different dose rates (400 Gy·h-1 and 4 kGy·h-1), temperatures (room temperature and 70°C) and relative humidity values (<10%, 70−75%, and 100%), for irradiation doses ranging from 0.1 to 4 MGy. These operating conditions are representative of applications in a nuclear environment. For the plasticized PVC at low dose rates, raising the temperature increases the HCl production by a factor of about 1.3, with either low or high relative humidity. For pure PVC, depending on the humidity and dose rate, G(HCl) varies differently with the temperature: at low humidity and low dose rates, G(HCl) increases by a factor of 1.7 for a 45°C temperature increase; at high humidity, the same temperature increase does not result in a significant increase of G(HCl). The influence of the relative humidity on HCl production has not been clearly identified and interpreted. The relative humidity appears to be a factor limiting the effects of temperature on the formation of HCl from pure PVC at high dose rates. The G values remain constant and even diminish under some experimental conditions. For plasticized PVC, the relative humidity has no influence on the HCl production yields. Keywords: PVC; gamma irradiation; HCl production yields; temperature; relative humidity 1. Introduction Polyvinyl chloride (PVC) has been widely used in numerous applications (medical, food packaging, chemical and nuclear industries) for many years because of its excellent properties and low cost. Since the 1950s, numerous studies have been performed on the behavior of PVC under ionizing radiation at low doses, generally under 50 kGy, and sometimes up to 500 kGy. The purpose of these studies was to characterize the behavior of this polymer and especially the production of evolved gases in presence of γ irradiation representative of radiation sterilization conditions. PVC is widely used as packaging for medical equipment, drugs or food and γ irradiation at low doses is often used as a bactericidal treatment. Polymers such as PVC are also used for various applications in the nuclear industry. During use and especially in storage after use, the PVC may be exposed to gamma irradiation but also to temperatures up 70°C and relative humidity that can reach 70%. A preliminary study examined the behavior of pure PVC and PVC formulated with plasticizing additives at doses and dose rates expected for nuclear waste containing PVC (Colombani, 2006; Colombani, Raffi et al., 2006; Colombani, Labed et al., 2007). * Corresponding author: CEA DEN/DTCD/SPDE/L2ED, BP 17171, 30207 Bagnols-sur-Cèze Cedex, France E-mail: veronique.labed@cea.fr Tel: +33 4 66 39 78 28 Fax :+33 4 66 39 78 71 2 An experimental approach was developed to supplement this study and take into account the influence of external parameters related to the repository site conditions, such as the temperature and relative humidity. The purpose of this study is to identify the influence of the temperature and relative humidity (or even a possible coupling of these parameters) on G(HCl). 2. Material and method 2.1 Samples The “pure PVC” used in these experiments was in fact a 50:50 mixture of two types of PVC manufactured by Solvay: Solvin® 266SF (made by suspension polymerization) and Solvin® 372LD (made by emulsion polymerization). The pure PVC was procured in white powder form with a particle size below 100 µm. The plasticized PVC was a Plastisol® flexible plate one centimeter thick. The experiments were carried out on massive cubic PVC samples. The plasticized material comprised only 27% pure PVC, the remainder being organic and inorganic additives, mainly plasticizers: di-isononyl phthalate, di-n-butyl phthalate, and 2-ethylhexyl diphenyl phosphate. 2.2 Irradiation conditions 2.2.1 Dose rates and integrated doses The PVC samples (5 g) were irradiated in air in sealed glass ampoules (aerobic radiolysis). The planned integrated doses and experimental conditions were specified to take advantages of the characteristics of the two cobalt-60 irradiation systems available in the laboratory. • An experimental irradiator providing dose rates of 400 Gy·h-1 representative of repository conditions, and suitable for testing at room temperature and at 70°C and with controlled relative humidity. • An industrial irradiator providing dose rates of 4 kGy·h-1 simulating high integrated doses within a reasonable time frame, but only for room-temperature tests with controlled relative humidity. Dosimetry was performed using Perspex films (routine measurements). 2.2.2 Relative humidity Pure water or saturated salt solutions were chosen to ensure controlled relative humidity during irradiation. Based on published data (Carr and Harris, 1946; Rockland, 1960) and the results of several preliminary tests, a NaNO3 solution was selected as the most suitable for regulating the relative humidity at 70% during irradiation of the PVC samples. We first verified that radiolysis of the NaNO3 solution did not form compounds that could interfere with analysis of the HCl. A sealed double-wall ampoule was also developed to contain both the PVC sample and the solution without any contact between them other than the resulting humid atmosphere. 2.2.3 Temperature The temperature conditions in the irradiators were set to (25 5)°C for the experimental irradiator and (30 5)°C for the industrial irradiator. A temperature-controlled device was used to irradiate the samples at 70°C; it consisted of an insulated chamber installed only in the experimental irradiator, and an external control unit. The system was connected by irradiation-resistant cables. This device allows sample temperatures ranging from about −15°C to 100°C. 3 2.3 Monitoring the quantity of HCl generated by radiolysis 2.3.1 Gas phase HCl gas was determined by Gas-phase Fourier Transform InfraRed spectroscopy (FTIR-Gas). The four bands with the highest intensity in the infrared spectrum of HCl (A, B, C and D: Figure 1) are used as references. Their areas are calculated and summed to determine the number of moles of HCl initially present in the ampoule. The integration ranges for the four reference bands are the following: • Band A: between 2970.8 and 2953.0 cm-1 • Band B: between 2953.0 and 2933.6 cm-1 • Band C: between 2853.2 and 2831.0 cm-1 • Band D: between 2831.0 and 2807.8 cm-1 2.3.2 Solid phase In order to obtain an overall balance of HCl production, the analysis of the gas phase was supplemented by an analysis of water-soluble chlorides retained in the material. The chloride ions include CaCl2 formed by a reaction between HCl and loaded calcium compounds (Ca(OH)2 and CaCO3) (Colombani, 2006), as well as the residual HCl bound to PVC macromolecules via hydrogen bonds, or HCl dissolved in water formed by radiolysis of the material. The water-soluble chloride was quantified by leaching 0.5 g of PVC powder for 8 hours in a Soxhlet device in pure water under full reflux conditions. The leachate was then sampled and analyzed by ion chromatography to determine the extracted chloride ions. 2.3.3 Liquid phase Chlorides are also trapped by the aqueous phase when irradiation is performed under conditions of high relative humidity. In this case the solution is analyzed by ion chromatography as described above for the solid phase. 3. Results 3.1 Pure PVC The results are indicated in Table 1. Depending on the humidity and dose rate, G(HCl) varies differently with the temperature. At low humidity and low dose rates, G(HCl) increases with the temperature by a factor of 1.7 for a 45°C temperature increase. At high humidity, the same temperature increase does not result in a significant increase of G(HCl). At room temperature, higher relative humidity (Δ%RH 90%) results in a decrease in G(HCl) when irradiation is performed at high dose rates (reduction by a factor of 3.8). Conversely, the results obtained at low dose rates suggest that G(HCl) does not vary significantly for Δ%RH = 60%. At 70°C, a 60% variation in relative humidity at a low dose rate caused G(HCl) to diminish by a factor of 2. Moreover, the dose rate affects G(HCl), which decreases when the dose rate increases. This effect was not observed during the previous study (Colombani, 2006) but the range of dose rates was more limited (400−800 Gy/h). Some authors (Decker, 1976; Arakawa, Seguchi et al., 1986) have also reported this phenomenon. 4 3.2 Formulated PVC The results are indicated in Table 2. At low humidity and low dose rates, G(HCl) increases with the temperature by a factor of 1.2 for ΔT = 45°C. At high humidity, the same phenomenon is observed: increasing the temperature by 45°C also increases G(HCl) by a factor of 1.3. Higher temperatures increase the production of HCl at low dose rates, regardless of the relative humidity. At room temperature, higher relative humidity (Δ%RH 60%) does not significantly affect G(HCl) when irradiation is performed at a high dose rate. Similarly, the results obtained at low dose rates suggest that G(HCl) decreases only slightly for Δ%RH = 60%. At 70°C and a low dose rate, a 60% variation in relative humidity did not significantly affect G(HCl). At both 25°C and 70°C for low or high dose rates, the relative humidity does not appear to have a significant influence on HCl production in the case of plasticized PVC. However, as for pure PVC, the dose rate does have an effect on G(HCl), which diminishes as the dose rate increases. 4. Discussion The influence of the temperature the radiolysis of PVC was investigated by Miller (Miller, 1959) on PVC powder (Geon 101) irradiated by a high-energy electron beam. G(HCl) measurements revealed an increase by a factor of 4 in HCl production from 5.6 to 23 molecules/100 eV over a temperature variation range from −90 to +70°C (ΔT=160°C). Similarly, Reed (Reed, Hoh et al., 1992) observed an increase in the radiolytic yield of HCl with the temperature for PVC panels irradiated with an α source (241Am). G(HCl) increased by a factor of 36.7 from 0.3 to 11 molecules/100 eV as the temperature rose from 30 to 100°C (ΔT=70°C) The low radiolytic yields observed at low temperatures can be explained by the fact that the radical process is inhibited at the outset (Yang, Liutkus et al., 1980). The primary radicals can form but the subsequent propagation reactions do not necessarily occur because of the low system temperature. When irradiation occurs at high temperature, the radiolytic yield of hydrogen chloride increases. This phenomenon can be attributed to the fact that the temperature increase favors the propagation reactions mentioned above, but also the occurrence of thermal degradation of PVC in addition to radiolysis, which also results in the formation of HCl by similar mechanisms (Chapiro, 1962; Palma and Carenza, 1970). In this study, we also observed an increase in HCl production of lesser magnitude (by a factor of 1.2 to 1.3 for a 45°C temperature variation) irrespective of the relative humidity with formulated PVC. In the case of pure PVC, the temperature-dependent increase in G(HCl) was observed only at low relative humidity (a factor of 1.7 for ΔT = 45°C). The influence of the relative humidity was not clearly established. For pure PVC at room temperature, a 60% increase in relative humidity causes G(HCl) to diminish by a factor of 3 at high dose rates, whereas at low dose rate the observed variations are not significant. At 70°C with a low dose rate, a 50% drop in G(HCl) is again observed. In the case of plasticized PVC, at both 25°C and 70°C for low or high dose rates, the relative humidity does not appear to have a major influence on HCl production. We have no explanation for this phenomenon. The fact that HCl evolves in gaseous form (pure PVC) or remains trapped in the material (plasticized PVC) may result in different sensitivity to external parameters such as the relative humidity. It is also possible that coupling phenomena (temperature/relative humidity; dose rate/relative humidity) complicate the processes involved, requiring additional tests based on experiment plan methodology, taking into account all the potentially influential factors. 5 To the best of our knowledge, no published work is available in the literature concerning the influence of humidity on the radiolytic behavior of polymers in general, and of PVC in particular. 5. Conclusion The separate and combined effects of the relative humidity and temperature were investigated on the HCl production yields arising from two types of PVC subjected to gamma irradiation (pure PVC and plasticized PVC). On the basis of the available data, we developed an experimental strategy. Irradiation sequences were defined using two irradiators with different characteristics. Variable temperature and relative humidity values were provided by a temperature-controlled device and saturated salt solutions. The G(HCl) values for the irradiated PVC samples were monitored using clearly identified analytical techniques. Increased production of HCl was observed as the temperature increased, but to a lesser extent than reported in the literature (by a factor of 1.2 to 1.3 for a 45°C temperature variation). This trend was independent of the relative humidity in the case of formulated PVC. In the case of pure PVC, the temperature-dependent increase in G(HCl) was observed only at low relative humidity (a factor of 1.7 for a 45°C temperature increase). The influence of the relative humidity on HCl production has not been clearly identified and interpreted. For pure PVC at room temperature at high dose rates, G(HCl) diminishes by a factor of 3 when the relative humidity increases, whereas at low dose rate the observed variations are not significant. At 70°C with a low dose rate, a 50% drop in G(HCl) is again observed. In the case of plasticized PVC, at both 25°C and 70°C for low or high dose rates, the relative humidity does not appear to have a major influence on HCl production. Further tests implementing distance-based experimental design principles should be considered to refine the initial results. Aknowledgements We are thankful to AREVA for the financial support. References Arakawa, K., T. Seguchi, et al. (1986). “Radiation-induced gas evolution in chlorine-containing polymer. Poly(vinyl chloride), chloroprene rubber, and chlorosulfonated-polyethylene.” Radiation Physics and Chemistry 27(2): 157-163. Carr, D. S. and B. L. Harris (1946). Ind. Eng. Chem. 41: 2014-2015. Chapiro, A. (1962). “Radiation chemistry of polymeric systems. High polymers “Interscience Publishers XV: 464-494. Colombani, J. (2006). Étude de la radiolyse gamma du poly(chlorure de vinyle) - Application à l’étude de la dégradation par irradiation et par lixiviation du PVC industriel. PhD thesis, Université Paul Cézanne Faculté des Sciences et Techniques de Marseille - Saint-Jérôme, France. 6 Colombani, J., V. Labed, et al. (2007). “High dose gamma radiolysis of PVC: Mechanisms of degradation.” Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms 265(1): 238-244. Colombani, J., J. Raffi, et al. (2006). “ESR studies on poly(vinyl chloride) irradiated at medium and high doses.” Polymer Degradation and Stability 91(7): 1619-1628. Decker, C. (1976). “Oxidative degradation of poly(vinyl chloride).” Journal of Applied Polymer Science 20: 3321-3336. Miller, A. A. (1959). “Radiation chemistry of polyvinyl chloride.” Journal of Physical Chemistry 63: 1755-1759. Palma, G. and M. Carenza (1970). “Degradation of poly(vinyl chloride). I. Kinetics of thermal and radiation-induced dehydrochlorination reactions at low temperatures.” Journal of Applied Polymer Science 14(7): 1737-1754. Reed, D. T., J. Hoh, et al. (1992). “Radiolytic gas production in the alpha particle degradation of plastics.” Waste Management, Tucson, Arizona, United States. Rockland, L. B. (1960). Analytical Chemistry 32(10): 1375-1376. Yang, N. L., J. Liutkus, et al. (1980). “An ESR study of initially formed intermediates in the photo degradation of PVC.” Polymer Characterization by ESR and NMR: 35-48. 7 Figures Bande B Bande D Bande C 0,2 Bande A Absorbance 0,15 0,1 0,05 0 2600 2700 2800 2900 3000 3100 Nombre d'onde (cm-1) Figure 1. Gaseous HCl reference spectrum showing the bands with the highest intensity Tables Table 1. G(HCl) values obtained for pure PVC under the experimental conditions G(HCl): molecules/100 eV Irradiation conditions Room temperature 70°C Low RH 70% 100% High dose rate (4 kGy/h) 0.5−4 MGy 6.8 — 1.8 Low dose rate (0.4 kGy/h) 0.2−1.5 MGy 0.5−1.5 MGy 9.6 — 10.5 8.5 — — Low RH 70% 100% — — 16.5 — 8.5 — — Table 2. G(HCl) values obtained for plasticized PVC under the experimental conditions G(HCl): molecules/100 eV Irradiation conditions Room temperature Low RH 70% High dose rate (4 kGy/h) 0.5−4 MGy 11.2 10.5 Low dose rate (0.4 kGy/h) 0.5−1.5 MGy 0.2−1.3 MGy 15.1 — — 13.5 70°C Low RH 70% — 17.9 — — 18.3