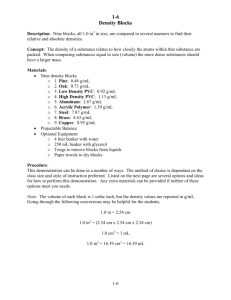

PVC Connection: Pressure Test

advertisement

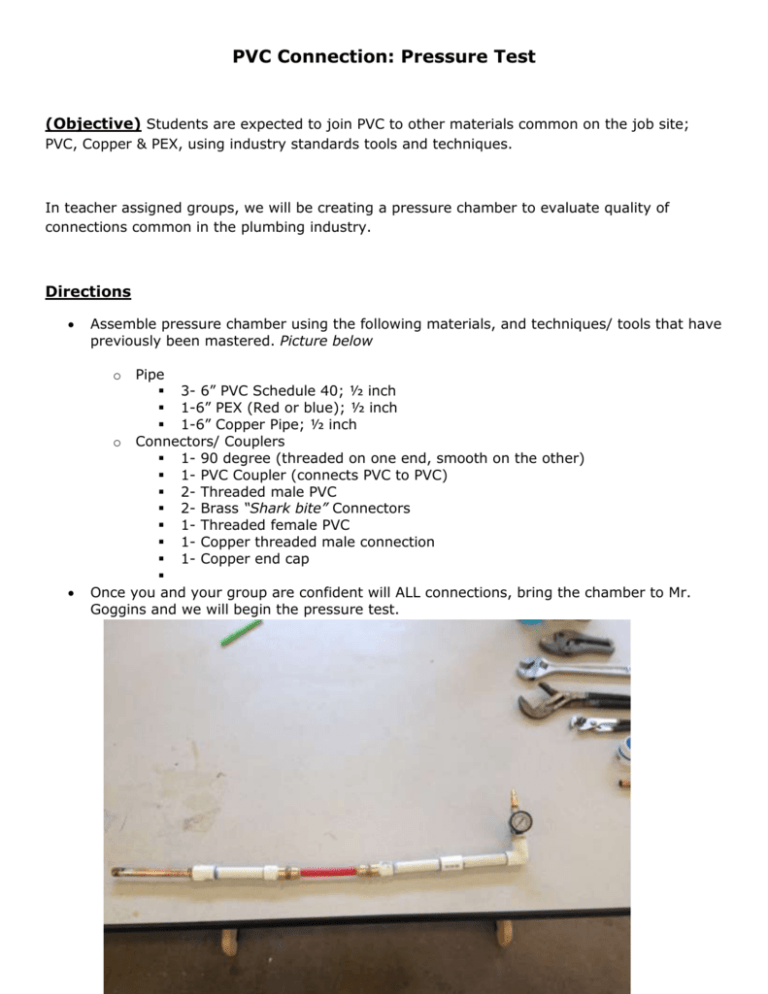

PVC Connection: Pressure Test (Objective) Students are expected to join PVC to other materials common on the job site; PVC, Copper & PEX, using industry standards tools and techniques. In teacher assigned groups, we will be creating a pressure chamber to evaluate quality of connections common in the plumbing industry. Directions Assemble pressure chamber using the following materials, and techniques/ tools that have previously been mastered. Picture below Pipe 3- 6” PVC Schedule 40; ½ inch 1-6” PEX (Red or blue); ½ inch 1-6” Copper Pipe; ½ inch o Connectors/ Couplers 1- 90 degree (threaded on one end, smooth on the other) 1- PVC Coupler (connects PVC to PVC) 2- Threaded male PVC 2- Brass “Shark bite” Connectors 1- Threaded female PVC 1- Copper threaded male connection 1- Copper end cap Once you and your group are confident will ALL connections, bring the chamber to Mr. Goggins and we will begin the pressure test. o Reminder(s) Use both PRIMER AND CEMENT on ALL PVC Connections (both the pipe and the coupler) Use pipe thread/ tape on ALL threads. Soldering: CLEAN, CLEAN, CLEAN! o Use emery cloth o Flux Misc. Upon completion and approval, take apart chamber; keep the shark bite connections and the copper portion of the chamber, all PVC components can be thrown away.