Agriculture and Environmental Biotechnology Nisreen Y. Badr

advertisement

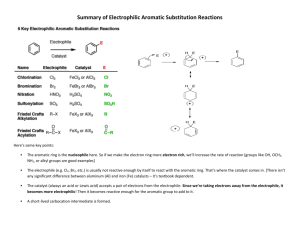

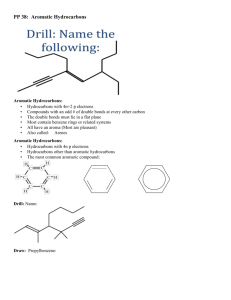

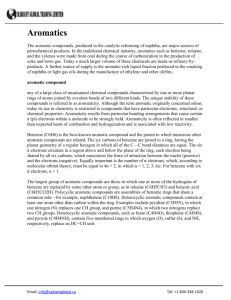

Agriculture and Environmental Biotechnology Nisreen Y. Badr Objectives Be able to biodegrade of xenobiotic (Petroleum). I. Introduction Environmental pollution caused by the release of a wide range of compounds as a consequence of industrial progress. Thousands of hazardous waste sites have been generated worldwide resulting from the accumulation of xenobiotics in soil and water over the years. Nitroaromatic compounds (NACs), polycyclic aromatics and other hydrocarbons (PAHs) that are constituents of crude oil, and halogenated organic compounds together constitute a large and diverse group of chemicals that are responsible for causing widespread environmental pollution. I.1 Properties of xenobiotics Rare in nature: substitutions of Cl, Br, NO2 and SO3H. Position and number of substituents influences biodegradability: - Ortho, meta, para p-most degradable. - Number of Cl in biphenyls or dioxins. Bioremediation, a biodegradation process in which sites contaminated with xenobiotics are cleaned up by means of bacterial bio-geochemical processes, exploits the ability of microorganisms to reduce the concentration and/or toxicity of a large number of pollutants. Bioremediation utilizes the microbial ability to degrade and/or detoxify chemical substances such as petroleum products, aliphatic and aromatic hydrocarbons (including polycyclic aromatic hydrocarbons and polychlorinated biphenyls), industrial solvents, pesticides and their metabolites, and metals. I.2 Basic requirements for biodegradation Biodegradation is a redox process this mean. This mean that energy for biodegradation arises from electron transfer reactions. I.2.1 Suitable degrading organism, generally bacteria or fungi. I.2.2 Substrate biodegradability Straight chair aliphatic: easily degraded; branching: strictly hindered configuration resistant to degradation; unsaturated aliphatic: less readily transformed than saturated analogues. Simple aromatics: degradable by several mechanisms of ring cleaving; substituted by halogens decreases degradability; even highly chlorinated aromatics. 1 Agriculture and Environmental Biotechnology Nisreen Y. Badr Nitrogen and sulfur compounds are linked to their uses as nutrients; branched are difficult. Polymeric materials are the most difficult. I.2.3 Electron donors that are the energy source (food) for the organisms. The electron donors are generally organic carbon compounds, which are mostly converted to CO2, water and mineral salts in the redox reactions that comprise the metabolism of the organisms. I.2.4 Electron acceptors generally O2, NO3, SO4, Fe and CO2. I.2.5 Carbon for cell growth, which comes from organic carbon. About 50% of bacterial dry mass is carbon. I.2.6 Nutrients, including nitrogen, phosphorous, calcium, magnesium, iron and trace elements. Of these, nitrogen and phosphorus are needed in the largest quantities Bacterial dry mass is about 12% nitrogen and about 2- 3% phosphorous. I.2.7 Acceptable environmental condition; pH, salinity, hydrostatic pressure, solar radiation, toxic substance, moisture, oxygen, etc., must be all within acceptable limits for the particular bioprocess. Microbes capable of degrading petroleum hydrocarbons generally prefer a ph between 6 and 8, and the temperatures between 5ºC and 25ºC. Temperatures lower than 5ºC tend to inhibit biodegradation in general. I.2.7.1 Moisture Biodegradation requires moisture for two reasons: 1. For cellular growth because cellular tissue is 75- 80% moisture. 2. As a medium for movement of the microorganism to the substrate for non- motile species. I.2.7.2 Oxygen Requirements The level of dissolved oxygen may control biodegradation. Dissolved oxygen should be maintained above the critical concentration for the promotion of aerobic activity, which ranges from 0.2 to 2.0 mg/l, with the most common being 0.5 mg/l. Many methods have been developed for aerating fluid and semisolid systems above the ground. These includes pumps, stirrers, spargers and sprayers. Example: the oxygen required to completely mineralize one milligram of alkene is calculated as follow: C7H12 + 10 O2 7CO2 + 6H2O 10 (2 Х 16) = 3.33 mg O2/ mg alkene (7 Х 12) + (12 Х 1) 2 Agriculture and Environmental Biotechnology Air inlet well Air extraction well Nisreen Y. Badr Air inlet well Unsaturated zone Contaminated zone Water table Groundwater Fig. 5.1 II. Crude oil constituents Crude oil is a complex mixture of hydrocarbons, basically composed of aliphatic, aromatic and asphaltene fractions along with nitrogen, sulfur and oxygen-containing compounds. These compounds have been reported to be carcinogenic, mutagenic and have immunomodulatory effects on humans, animals and plant life. The sites contaminated with hydrocarbons are ecologically important locations as one may encounter microbial flora of diverse nature, which may be potential candidates for important industrial processes. II.1 Aliphatic hydrocarbon Saturated and unsaturated hydrocarbons occur naturally and thus it is relatively easy to isolate microorganisms capable of biodegrading them. The aliphatic fraction is the major constituent of crude oil. II.2 Aromatic hydrocarbon degradation The aromatic hydrocarbon compounds basically contain benzene ring in their structure and are ubiquitous in the environment. Aromatic hydrocarbons being derivatives of benzene are very stable. In order to overcome this stability certain microorganisms have evolved which capable of dihydroxylation the aromatic ring and then bringing about ring cleavage. Aerobically the dihydroxylation step involves a dioxygenase enzyme which catalyses the input of both atoms of molecular oxygen onto the aromatic ring as shown in (fig. 5.2). Benzene Cis-benzene glycol Catechol Fig.5.2: The initial oxidation reaction of aromatic ring cleavage: dihydroxylation. 3 Agriculture and Environmental Biotechnology Nisreen Y. Badr Catechols: The products of the initial metabolism of aromatic hydrocarbons are commonly catechols (or substituted catechols if the initial ring had substituent groups replacing the hydrogens on it). Ring cleavage occurs by one of two pathways depending in the species and the initial compounds. These pathways are shown in (fig. 5.3). One of these pathways called the ortho ring cleavage pathway and meta ring cleavage pathway. Ortho: It can be seen that the ortho pathway involves cleavage of the ring between the two adjacent hydroxyl groups and this step is catalysed by a 1,2-dioxygenase. Meta: whereas the meta pathway involves cleavage of the ring between the carbon-atom containing a hydroxyl group and an adjacent carbon-atom without an hydroxyl group and this step is catalysed by a 2,3-dioxygenase. Fig.5.3. Microbial metabolism of catechols. 4 Agriculture and Environmental Biotechnology Nisreen Y. Badr Not. Both ortho and meta pathways are involved in the aromatic hydrocarbon degradation but substituted catechols are generally degraded via the meta pathway. Benzene itself is degraded via meta ring cleavage. II.3 Polycyclic aromatic hydrocarbons These compound, with two or more ring structures, (for example naphthalene, phenanthrene and petroleum). As the molecular weight of these compounds increases, solubility in lipids increases and resistance to oxidation and reduction decreases. Therefore, PAHs will vary in their behavior in the environment and in their biological effects. Low molecular weight PAHs such as naphthalene and phenanthrene are highly mobile in the aquatic environment and present significant acute toxicity to many organisms. Fig. 5.4 II.3.1 Petroleum Petroleum is a viscous liquid mixture that contains thousands of compounds mainly consisting of carbon and hydrogen. Petroleum-based products are the major source of energy for industry and daily life. Petroleum is also the raw material for many chemical products such as plastics, paints, and cosmetics. III. Experimental set- up: Soil III. A A B BH media + petroleum NA Fig. 5.5 5 Agriculture and Environmental Biotechnology Nisreen Y. Badr III. B Fig. 5.6 Materials: Equipments Cylinder 500 ml Erlenmeyer flask Petri dish Shaker Incubator stoppers Burette Chemicals BH media 0.2 g/L MgSO4.7H2O 1 g/L K2HPO4 1 g/L KH2PO4 0.05g/L FeCl3.6H2O 1.0g/L NH4NO3 0.02g/L CaCl2 Nutrient agar Petroleum or Benzene Seawater 0.1N KOH 0.05N HCl BaCl2 ph.ph. Not. For BH media adjust pH to (7- 7.2) Procedures: For experimental A: 1. Wet unsieved soil (2-5 g) sample from the upper 10 cm of soil will be taken from the agricultural site and will be kept in plastic bag at ambient temperature until processing. The bag will be kept open to prevent the increase of their temperature and subsequently death of bacteria. 6 Agriculture and Environmental Biotechnology Nisreen Y. Badr 2. The samples will be inoculated into 250 ml of wastewater in 500 ml Erlenmeyer flask containing 10 ml of benzene. 3. The flask will be incubated on a shaker operating at 120 r.p.m for several days at ambient temperature (25 ◦C). 4. At daily interval one loop full of enrichment culture from the flask will be streaked onto nutrient agar plates and BH media supplemented with benzene and incubated at 35◦C for 24 h. 5. Individual colonies will be subculture into BH plates containing benzene until pure cultures will be isolated. 6. Bacterial isolates that can handle relatively high concentration of benzene were subjected to morphological, cultural and biochemical tests. For experimental B: 1. Add 100 ml of seawater into the flask then add 1 ml of petroleum. 2. Put into the upper surface of the bottle a device for prevent CO2 interring the flask. 3. With needle insert 10 cm of KOH in the lateral arm of the system. 4. Incubate at room temperature. 5. At daily and for one week open the tap of preventing CO2 device and the rubber stopper then with needle take the products from the lateral arm. 6. Add 10 ml of KOH then close the tap of preventing CO2 device and the rubber stopper. 7. For calculate the amount of CO2 production follow these steps: Add 1 cm of BaCl2 + 0.1N ph.ph. for every sample collected. Result:----------------------------------------------------------------------------------------------. By using titration methods: Titrate the pervious product with 0.05N HCl for deletion the color of the product. Record the amount of HCl that needed for every titration. Graph the correlation ship between the amount of CO2 with time of degradation. 7