As known, process of oxidation of cyclohexane at application cobalt

advertisement

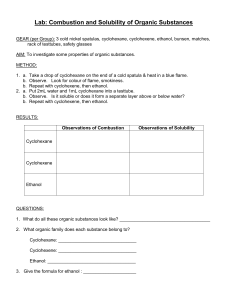

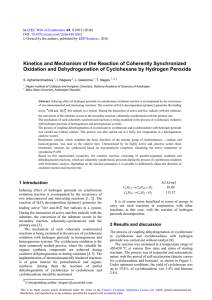

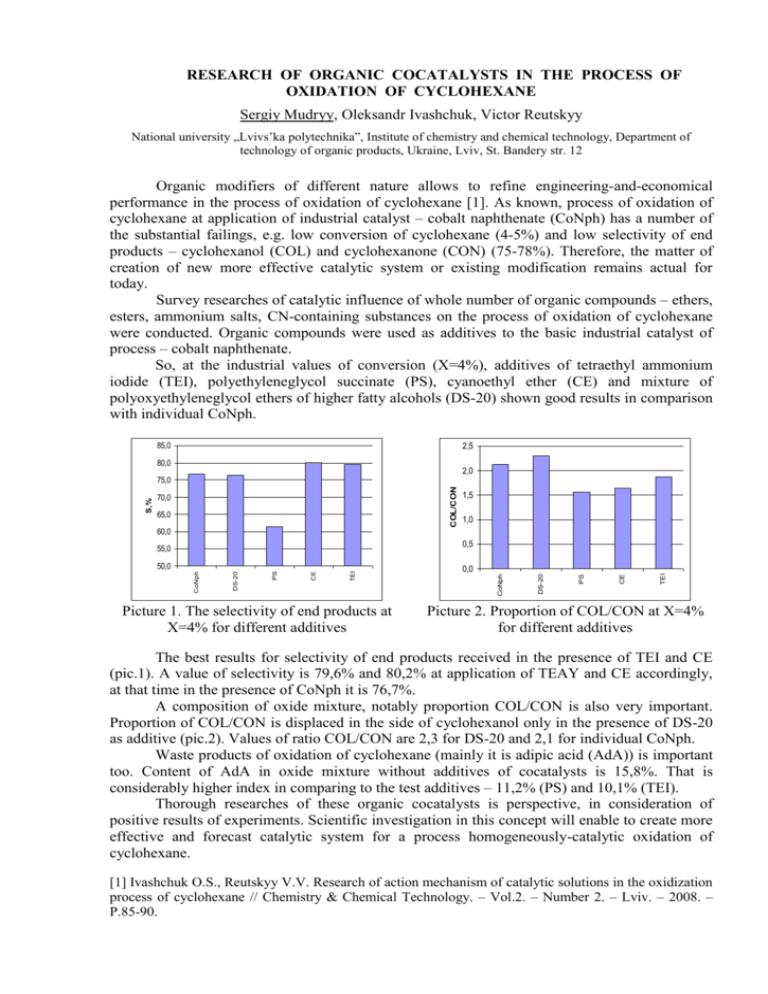

RESEARCH OF ORGANIC COCATALYSTS IN THE PROCESS OF OXIDATION OF CYCLOHEXANE Sergiy Mudryy, Oleksandr Ivashchuk, Victor Reutskyy National university „Lvivs’ka polytechnika”, Institute of chemistry and chemical technology, Department of technology of organic products, Ukraine, Lviv, St. Bandery str. 12 Organic modifiers of different nature allows to refine engineering-and-economical performance in the process of oxidation of cyclohexane [1]. As known, process of oxidation of cyclohexane at application of industrial catalyst – cobalt naphthenate (CoNph) has a number of the substantial failings, e.g. low conversion of cyclohexane (4-5%) and low selectivity of end products – cyclohexanol (COL) and cyclohexanone (CON) (75-78%). Therefore, the matter of creation of new more effective catalytic system or existing modification remains actual for today. Survey researches of catalytic influence of whole number of organic compounds – ethers, esters, ammonium salts, CN-containing substances on the process of oxidation of cyclohexane were conducted. Organic compounds were used as additives to the basic industrial catalyst of process – cobalt naphthenate. So, at the industrial values of conversion (X=4%), additives of tetraethyl ammonium iodide (TEI), polyethyleneglycol succinate (PS), cyanoethyl ether (CE) and mixture of polyoxyethyleneglycol ethers of higher fatty alcohols (DS-20) shown good results in comparison with individual CoNph. 85,0 2,5 80,0 2,0 COL/CON 70,0 65,0 60,0 1,5 1,0 Picture 1. The selectivity of end products at X=4% for different additives CE PS 0,0 DS-20 TEI CE PS DS-20 CoNph 50,0 TEI 0,5 55,0 CoNph S,% 75,0 Picture 2. Proportion of COL/CON at X=4% for different additives The best results for selectivity of end products received in the presence of TEI and CE (pic.1). A value of selectivity is 79,6% and 80,2% at application of TEAY and CE accordingly, at that time in the presence of CoNph it is 76,7%. A composition of oxide mixture, notably proportion COL/CON is also very important. Proportion of COL/CON is displaced in the side of cyclohexanol only in the presence of DS-20 as additive (pic.2). Values of ratio COL/CON are 2,3 for DS-20 and 2,1 for individual CoNph. Waste products of oxidation of cyclohexane (mainly it is adipic acid (AdA)) is important too. Content of AdA in oxide mixture without additives of cocatalysts is 15,8%. That is considerably higher index in comparing to the test additives – 11,2% (PS) and 10,1% (TEI). Thorough researches of these organic cocatalysts is perspective, in consideration of positive results of experiments. Scientific investigation in this concept will enable to create more effective and forecast catalytic system for a process homogeneously-catalytic oxidation of cyclohexane. [1] Ivashchuk O.S., Reutskyy V.V. Research of action mechanism of catalytic solutions in the oxidization process of cyclohexane // Chemistry & Chemical Technology. – Vol.2. – Number 2. – Lviv. – 2008. – P.85-90.