nwu6

advertisement

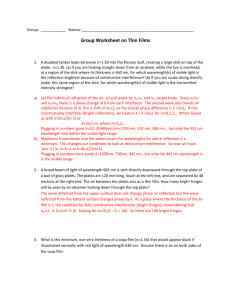

Measurements of surface roughness in cold metal rolling in the mixed lubrication regime MPF Sutcliffe and HR Le Cambridge University Engineering Department, Trumpington Street, Cambridge, CB2 1PZ, U.K. Abstract This paper describes measurements of the change in surface roughness of aluminium strip due to cold rolling. Rolling is in the mixed lubrication regime, where there is both asperity contact and hydrodynamic action. The strip is in the as-received condition before rolling, with a continuous spectrum of roughness wavelengths. The spectra of roughness for both the initial and rolled surfaces are used to extract amplitudes for long and short wavelength components, with an arbitrary division between these components at a wavelength of 14 m. It is found that the short wavelength components persist more than the long wavelength components, and that flattening of the strip increases with increasing reduction in strip thickness. The qualitative effect of wavelength on flattening is similar to that observed with unlubricated rolling, and is in line with theoretical models of mixed lubrication. The effect of reduction is not predicted by existing theories, but is in agreement with measured variations of friction with reduction. Keywords: Asperity, Friction, Lubrication, Metal Rolling, Tribology, Roughness. To be submitted to ASME Journal of Tribology, Sept. 1988 1 Nomenclature A Fraction of nominal area in contact between roll and strip h Film thickness separating strip and roll hs Theoretical film thickness in the bite for smooth rolls and strip h* Film thickness corresponding to zero pressure gradient Characteristic hydrodynamic inlet length L Length of the bite q Reduced hydrodynamic pressure; q 1 exp( pv ) r Reduction in strip thickness R Roll radius t0 Initial strip thickness U Mean entraining velocity x Y Co-ordinate in rolling direction Pressure viscosity coefficient of lubricant Temperature viscosity coefficient of lubricant (0) Viscosity of lubricant (at ambient pressure) s hs t 0 Ratio of the theoretical smooth film thickness to the initial combined strip and roll roughness Average friction coefficient µp Friction coefficient on the plateaux v Friction coefficient in the valleys 0 Angle between roll and strip at the inlet to the bite , (0) (Initial) r.m.s. amplitude of the short wavelength components of strip roughness t0 Initial combined r.m.s amplitude of the strip and roll including both short and long wavelengths rr r.m.s amplitudes of the short and long wavelength components of the roll roughness , ( 0 ) (Initial) r.m.s. amplitude of the long wavelength components of strip roughness Plane strain yield strength of the strip 2 1. Introduction Accurate models of metal rolling are needed by industry to increase productivity and improve quality. For cold strip rolling, the key areas where industry needs more reliable and accurate models are in friction and surface finish. Lubrication is applied to reduce frictional forces, to protect the roll and strip surfaces, and to act as a coolant. To meet surface finish requirements on the strip, it is essential that the asperities on the roll come into contact with the strip, so that the smooth ground finish of the rolls is imprinted onto the strip. To meet the needs both of low friction and good surface finish, most cold rolling operates in the 'mixed' regime, where there is some hydrodynamic action drawing lubricant into the bite, but also some contact between the asperities on the roll and strip. During the last three decades, many tribological models of cold rolling have been proposed. In the early models (Cheng, 1966, Wilson and Walowit, 1972), surface roughness was ignored and the one-dimensional Reynolds’ equation was integrated in the inlet zone. The lubricant film thickness at the end of the inlet is determined by the lubricant rheological properties, the rolling speed and the roll geometry. Wilson and Walowit derive an expression for the 'smooth' film thickness hs as hs 6 0U 0 1 exp Y (1) where U is the average entraining velocity, 0 is the inlet angle between the strip and roll, Y is the plain strain yield strength of the strip and 0 is the viscosity of the lubricant at ambient pressure. is the pressure viscosity coefficient in the Barus equation 0 exp(p) used to describe the variation of viscosity with pressure p. The ratio s hs t 0 of the smooth film thickness hs to the combined roll and initial strip roughness t0 is used to characterise the lubrication regime. For large the surfaces are kept apart by a continuous film of oil. The mixed lubrication regime, with some asperity contact, occurs when s falls below about 3. A simple picture of the interface between the roll and strip divides the contact into areas of contact and 3 areas separated by an oil film, as illustrated schematically in Fig. 1a. The area of contact ratio A can then be used to estimate a mean friction coefficient µ by A p 1 A v (2) where the friction coefficient µp of the plateaux is frequently modelled using a boundary friction coefficient, and the coefficient of the valleys µv can be estimated knowing the oil viscosity and film thickness. In industrial practice the valley contribution is generally small. Several recent models of mixed lubrication have been published (Sheu 1985, Sutcliffe and Johnson 1990, Sheu and Wilson 1994, Lin et. al. 1998, Marsault et. al. 1998). These consider both the pressure build-up in the lubricant and the contact between the two surfaces. The more recent models include the way in which asperities deform when on a substrate which is deforming plastically (Greenwood and Rowe 1965, Sheu and Wilson 1983, Wilson and Sheu 1988, Sutcliffe 1988). This feature of the contact is peculiar to metal working tribology, and renders studies of lubrication without a deforming workpiece of very limited value. Experimental measurements of oil film thickness and surface roughness in the mixed regime have confirmed the main points of these models (Sheu 1985, Sutcliffe, 1990, Sheu and Wilson, 1994). As predicted by these models, Tabary et. al. (1996) showed a transition from hydrodynamic friction for large s, to complete conformance of the surfaces and friction typical of boundary additives for very small s. However, in the transition regime, the measured frictional traction was significantly smaller than would be predicted by the existing models. For example, Marsault (1998) showed that these results could only explained by assuming a large drop in apparent boundary friction coefficient with increasing s, which does not seem physically likely. It is the authors' hypothesis that these differences arise due to an oversimplification in the modelling of surface roughness. A weakness in all the above models is that roughness is represented by an array of asperities with a uniform height and wavelength of roughness (c.f. Fig. 1a and b, for triangular and pseudo-Gaussian roughness), while in practice the roughness is made up a spectrum of different wavelengths of roughness. Although results are sensitive to the roughness wavelength, with asperity crushing being much greater for longer wavelengths of 4 roughness,. theoretical models give no guidance as to an 'appropriate' wavelength to choose for practical rough surfaces. If small wavelength asperities persist on top of larger scale asperities, as illustrated in Fig. 1c, then models which only include the longer wavelength component could predict the film thickness with reasonable accuracy, but would still be considerably in error in estimating the area of contact ratio A and hence friction. This effect is suggested by the work of Steffensen and Wanheim (1977) for unlubricated contact. They considered roughness consisting of a series of triangular arrays of asperities of successively shorter wavelengths, superimposed on each other. Using this model they showed that the real contact area is significantly reduced by including more than one wavelength of roughness. This effect was further considered by Sutcliffe (1998), again for dry contacts. Aluminium sheet with an as-received, random surface finish, was rolled using smooth rolls. Experimental measurements of the spectrum of roughness were used to show that the short wavelength components were crushed much more slowly than the long wavelength components. Sutcliffe's model, using an idealised roughness composed of just two wavelengths, showed good agreement with measured changes in roughness amplitude. The purpose of this paper is to establish experimentally the flattening behaviour of different wavelengths of roughness for lubricated cold rolling in the mixed regime. The measurements are made using strip with a random rough surface typical of industrial practice. This work aims to confirm the above hypothesis and to provide useful data to validate theoretical models. Experimental details of the work are summarised in the following section. Section 3 presents the results and discussion and conclusions are drawn in section 4. 2. Experimental details 2.1 Rolling details Most of the experimental details are as for the unlubricated rolling experiments of Sutcliffe (Sutcliffe, 1998). The only significant change in methodology is in the inclusion of a lubricant. Cold-rolled 5052 work-hardened aluminium strips of thickness 0.82 mm, length 200 mm and width 50 mm were rolled in a two-high mill with roll diameters of 51 mm at roll speeds between 0.003 and 1.0 m/s. Before rolling, the strips had a micro-Vickers hardness Hv of 550 MPa, giving an estimated yield 5 strength Y (= Hv/2.57) of 214 MPa ??. The reduction is strip thickness was measured with a micrometer, taking the average of a number of readings for each specimen before and after rolling. Nominal reductions of 25 and 50%, were used; actual reductions were within 1% of these values. Three naphthenic base oils were liberally applied to both sides of the strip (except were film thickness measurements were made as described below). These oils had nominal viscosities of 100, 500 and 2000 SUS at 39°C and the actual viscosities were determined at temperatures of 30 and 50 °C using a capillary viscometer. These measurements were fitted by the exponential equation 0 exp t t r , where t and tr are actual and reference temperatures, to extract values for the temperature viscosity coefficient and the viscosity at a typical rolling temperature of 25°C. These are detailed in Table 1. Room temperature was recorded to estimate values for in each set of tests. Oil type (Pas, 25C) (C–1) (m2/N) 100 SUS 0.041 0.0419 (2.010–8) 500 SUS 0.271 0.0647 2.010–8 2000 SUS 1.44 0.0896 3.010–8 Table 1 Properties of lubricants The pressure viscosity coefficient was estimated from measurements of the film thickness, using the oil drop method described by Azushima (1978). Results of these film thickness measurements are given in Fig. 2 (a correction ?? has been applied to the measured film thickness, to allow for thinning of oil in the bite). A value of equal to 3.0×10–8 m2/N was chosen for the most viscous 2000 SUS oil so as to match the measured film thickness with the theoretical smooth film thickness value hs, equation 1, for film thicknesses much greater than the combined surface roughness t0 of the roll and strip (here t0 = 0.38 µm). The measured film thickness equals the theoretical film thickness along the dashed line in Fig. 2. For the 500 SUS oil, a value of equal to 2.0×10–8 m2/N was chosen to produce a smooth transition between results for this oil and the 2000 SUS oil. These values for are in good agreement with published figures (Evans and Johnson, 1986). For the thinnest 100 SUS oil, 6 where it was not possible to make accurate film thickness measurements due to the thinness of the films, a value of equal to that for the 500 SUS oil was assumed. Thermal effects and the effects of roll curvature on the calculation of smooth film thickness were found to be negligible (Wilson and Murch 1976, Tsao and Wilson 1981). A comparison between roughness measurements made with the oil drop and fully lubricated rolling experiments showed insignificant differences for the smaller reduction of 25%. With the larger reduction of 50%, however, the strip roughness was flattened significantly more in the oil drop tests than when oil was applied to both sides of the strip. This was attributed to deflection of the strip in the inlet due to the unsymmetrical rolling conditions (c.f. Sutcliffe 1990). Results presented in this paper apart from those of Fig. 2 are for symmetrical lubrication conditions. 2.2 Surface roughness details The roughness of the strips was measured with a standard diamond-stylus profilometer at a traverse speed of 0.3 mm/s. Roll roughness was measured from an acetate impression of the roll. A profile of length 3mm was sampled at an interval of 0.3 m and the digitised profile transferred to a computer to estimate the roughness parameters. An average of three measurements was used for each specimen. Since the experiments are designed to investigate the behaviour of different wavelengths, some way is needed of representing the continuous spectrum of wavelengths in a digestible form. Here we follow the method described in detail by Sutcliffe (1998) to divide the spectrum into long and short wavelength components. Contributions for wavelengths below an arbitrary wavelength are summed up to give the amplitude of a short wavelength components , while wavelengths between this arbitrary breakpoint wavelength and an upper cut-off are summed to estimate a long wavelength amplitude . In this case we choose to divide the spectrum between short and long wavelengths at 14 m, with an upper cut-off wavelength of 250m. The initial r.m.s. contributions from the short and long wavelength components 0 and 0 for the initial strip surface were 0.12 and 0.36 m and the corresponding values r and r for the roll were 0.024 and 0.048 µm. The total combined roughness t 0 02 02 r2 2r for the initial strip and roll surfaces equalled 0.38 m. 3 Experimental results 7 Measurements of surface roughness of the strip were made and split into long and short wavelength components and at an arbitrary wavelength of 14 m, as described in the previous section. Results for the effect of film thickness ratio s , roughness wavelength and strip reduction ratio on the flattening behaviour are presented in this section. 3.1 Effect of film thickness parameter and wavelength Figures 3 and 4 show changes in strip roughness amplitude with film thickness parameter s , for reductions in strip thickness of 25% and 50 %, respectively. The roughness is split into short and long wavelength components and , which are normalised by the original strip roughness amplitudes 0 and 0 . Note that s is based on the initial combined roughness t0, which includes short and long wavelengths. The wide range of s was achieved in the experiments by varying the speed and by using the three different oils. The range of s covered by each oil is indicated at the bottom of the figures. The corresponding roll roughness amplitudes r 0 and r 0 are indicated by arrows at the left hand side of the figures. For s greater than about 2, the long wavelength component increases in amplitude due to hydrodynamic roughening (Schey, 1983). There is little change in short wavelength component. It seems that this roughening occurs on the scale of the grain size of the order of a few tens of micrometres. For s less than 2, both long and short wavelengths are flattened, although the relative amplitude of the long wavelength component is always significantly smaller than for the short wavelength component, as expected from theoretical models of asperity crushing. For very small s both components of roughness approach the corresponding roughness amplitudes for the roll. To help compare the way in which the two wavelengths behave, Fig. 5 shows the ratio of the amplitudes of the short and long wavelength components. When the speed parameter is greater than about 2, the ratio falls below the corresponding value of 0.33 for the initial strip roughness due to the roughening of the long wavelength component. For s between about 0.5 and 2, increases with decreasing s as the long wavelength components flattens faster than the short wavelength components. For s below 0.5, falls off again with decreasing s as 8 the long wavelength component is by now effectively equal to the roll roughness, while there is further flattening of the short wavelength component. At the smallest values of s approaches the value of 0.5 corresponding to the roll roughness. 3.3 Effect of reduction To compare the effect of reduction on flattening behaviour, Fig. 6 shows the change in the short wavelength component of roughness for the two reductions of 25% and 50%, as a function of s . The amount of asperity flattening and the conformity of the strip surface to the roll surface is significantly greater, at the same values of s , for the higher reduction. Existing theoretical models suggest two reasons why reduction might affect the flattening behaviour. Firstly there is a relative minor effect due to thinning of the oil film as the strip surface elongates. Secondly, where asperity flattening extends through the bite, then the reduction ratio could become important. In the Appendix, however, it is shown that the transition region is short compared with the bite length in these experiments, so that the theoretical models cannot explain the difference between results at the two reductions satisfactorily. However, the experimental results of Tabary et. al. (1996) showed that, at the same value of s friction was significantly greater at a higher reduction. This is in accordance with the greater conformance between roll and strip observed here. 3.4 Height probability density functions Height probability density functions for typical tests with 500 SUS oil at a 25% reduction are shown in Fig.7. These are constructed from the original profiles, eliminating long wavelengths using an eighth order digital filter with a cut-off of 250µm. A smooth curve has been drawn through the average of histograms from 3 roughness profiles. The speed parameter s and smooth film thickness hs corresponding to each curve are included in the figure. As s decreases, the strip surfaces are flattened. This is reflected in a narrowing of the probability density function. These results are similar to those found by Tabary et. al. (1996). Theoretical predictions using a single wavelength and amplitude and assuming an unchanged valley shape would fail to predict the shape observed. In particular the right hand side of the peak is significantly shallower than would be expected. 4. Conclusions 9 The object of this paper was to test the hypothesis that short and long wavelengths would flatten at different rates in strip rolling in the mixed lubrication regime. Results clearly confirm this hypothesis, with short wavelength asperities persisting more than those with long wavelengths. This behaviour is similar to that observed for unlubricated strip rolling (Sutcliffe, 1998). Other surface roughness changes confirm previous observations. For example a good conformance between roll and strip is observed at small values of s, (the ratio of the smooth film thickness to the combined surface roughness), and hydrodynamic roughening occurs for s greater than about 1. Flattening of both short and long wavelengths was significantly greater, for the same value of s, at higher strip reductions. Although this effect is not be predicted by existing theories, this observation is in line with experimental observations of friction (Tabary et. al., 1996). As well as providing a quantitative measure of the difference in behaviour between different wavelengths, these experiments also provide useful data of roughness amplitude and height distribution for validating any theoretical model. It is expected, as suggested by Fig. 1 and existing experimental measurements, that it will be important to include more than one wavelength of roughness in order to determine the area of contact ratio accurately. Errors in predicting the contact ratio and hence friction will become increasingly significant as thinner strip is considered. It is unlikely that a foil model for the mixed lubrication regime that does not take this effect into account will be accurate. Acknowledgements The authors wish to thank Prof. Bill Wilson and Mr. Heng-Sheng Lin at Northwestern University, USA for their assistance and Mr Chris Pargeter at Alcan Int. Ltd. for his measurements of oil viscosity. The financial support of the Centre for Surface Engineering and Tribology at Northwestern University, the Fulbright Commission, the Engineering and Physical Sciences Research Council, Alcan Int. Ltd. and Cegelec Projects Ltd. is gratefully acknowledged. 10 References Azushima, A. 1978, “Characteristics of lubrication in cold sheet rolling”, Proc. 1st Int Conf. On Lubrication Challenges in Metalworking and Processing, (IITRI, Chicago). Cheng, H. S., 1966, “Plasto-hydrodynamic Lubrication”, ASME, Friction and Lubrication in Metals Processing, New York, pp 69-89. Evans, C.R. and Johnson, K.L. 1986, The rheological properties of elastohydrodynamic lubricants. Proc. Instn. Mech. Engrs., Part C 200(C5), 313-324 Greenwood, J.A. and Rowe, G.W., 1965, Deformation of surface asperities during bulk plastic flow, Wear, 38, 201-209 Hooke, C.J. 1977, The elastohydrodynamic lubrication of heavily loaded contacts. J. Mech. Engrg. Sci. 19, 149-156. Lin, H. S., Marsault, N. and Wilson, W. R. D., 1998, “ A Mixed Lubrication Model for Cold Strip Rolling Part I: Theoretical”, Submitted to Tribology Transaction. Marsault, N., Montmitonnet, P., Deneuville, P. and Gratacos, P., 1998, “ A Model of Mixed Lubrication for Cold Rolling of Strip”. Submitted to Tribology Transaction. Marsault, N. 1998, Modélisation du régime de lubrification mixte en laminage à froid. PhD Thesis, L'Ecole National Superieur des Mines de Paris, France. Schey, J. A., 1983, “Surface Roughness Effects in Metalworking Lubrication”, Lubrication Engineering, Vol. 39, pp 376-382. Sheu, S. 1985. Mixed lubrication in bulk metal forming. PhD Thesis, Northwestern Univ., Illinois, USA. Sheu, S. and Wilson, W. R. D., 1983, “Flattening of workpiece surface asperities in metalforming”, Proc. NAMRC XI, 172-178. Sheu, S. and Wilson, W. R. D., 1994, “Mixed Lubrication of Strip Rolling”, STLE Trib. Trans., Vol. 37, pp 483-493. Steffensen, H., and Wanheim, T., 1977, “Asperities on Asperities”, Wear, Vol.48, pp 89-98. Sutcliffe, M. P. F., 1988, “Surface asperity deformation in metal forming processes”, Int. J. of Mech. Sciences, 30, 847-868 Sutcliffe, M. P. F., 1998, “Flattening of Random Rough Surfaces in Metal Forming”, To appear in A.S.M.E. J. Tribology. Sutcliffe, M. P. F. and Johnson, K. L., 1990, “Lubrication in Cold Strip Rolling in the ‘Mixed’ Regime”, Proc. Instn. Mech. Engrs., Vol. 204, pp 249-261. Sutcliffe, M. P. F.., 1990, “Experimental measurements of lubricant film thickness in cold strip rollling”, Proc. Instn. Mech. Engrs., Vol. 204, pp 263-273. Tabary, P. T., Sutcliffe, M. P. F., Porral, F. and Deneuville, P., 1996, “Measurements of friction in Cold Metal Rolling”, ASME J. Tribology, Vol. 118, pp 629-636. Tsao, P. and Wilson, W.R.D., 1981, Entrainment of lubricant in the cold rolling of steel and aluminium, Proc. Int. Conf. On Steel Rolling, The Iron and Steel Institute of Japan, 49-64 Wilson, W.R.D. and Chang D.F. 1994, Low speed mixed lubrication of bulk metal forming processes, ASME J Tribology ?? Wilson, W. R. D. and Walowit, J. A., 1972, “An Isothermal Hydrodynamic Lubrication Theory for Strip Rolling With Front and Back Tension”, Proc. 1971 Tribology Convention, I. Mech. E., London, pp 164-172. Wilson, W.R.D. and Murch, L.E., 1976, A refined model for the hydrodynamic lubrication of strip rolling, J. Lubrication Tech., 98, 426-432 Wilson, W.R.D. and Sheu, S., 1988, Real area of contact and boundary friction in metal forming, Int. J. Mech. Sciences., 30, 475-489 11 Appendix To evaluate the relative lengths of the inlet region and the bite, we adapt Hooke's (1977) analysis for elastohydrodynamic contacts. Consider Reynolds' equation for the variation in reduced oil pressure q 1 exp p for smooth surfaces dq 120U h h* dx h3 (3) where x is a co-ordinate in the rolling direction, h is the separation between the roll and strip and h* is the value of h at zero pressure gradient. The reduced pressure gradient is zero far from the roll, and returns to zero at h = h*, which we can assume occurs as the end of the inlet when the strip starts to deform plastically. The variation in q with position x has a point of inflection some distance ahead of the inlet; this distance can be taken as a typical hydrodynamic inlet length. The position of this inflection is given by the condition d 2q dx 2 0 h 32 h * (4) Putting h* equal to the smooth film thickness hs (equation 1), and taking the bite length L and the inlet angle 0 from the rigid roll geometry as L rRt 0 ; 0 rt0 R (5) where r is the strip reduction, R is the roll radius and t0 is the inlet strip thickness, we deduce that the ratio of a typical hydrodynamic inlet length to the length of the bite is equal to h 3 0U s s t0 L 2 0 L 2rt 0 rt 0 1 exp Y (6) For a typical value of s equal to 0.1, and a reduction of 25%, the corresponding value of /L is 10–3 in the present experiments. This suggests that changes in hydrodynamic pressure are confined to a short inlet region. Similar conclusions can be drawn using the non-dimensional speed groups defined by Wilson and co-workers (e.g. Wilson and Chang, 1994). 12 Figures Fig. 1. Schematic of surface roughness idealisations (a) triangular asperities, (b) pseudo-Gaussian roughness (c) two superimposed wavelengths of roughness. Fig. 2. Variation of experimental oil film thickness with smooth film thickness parameter hs. Fig. 3. Variation of short and long wavelength roughness amplitudes with s. Strip reduction r = 25%. Fig. 4. Variation of short and long wavelength roughness amplitudes with s. Strip reduction r = 50%. Fig. 5 Variation in the ratio / of the amplitudes of short and long wavelengths with s. Fig. 6. The effect of reduction on the crushing of short wavelength asperities. Fig. 7 The effect of s on the probability density function for the strip roughness (r = 25%). 13 Area of contact (a) Valley (b) (c) Fig. 1. Schematic of surface roughness idealisations (a) triangular asperities, (b) pseudo-Gaussian roughness (c) two superimposed wavelengths of roughness. 14 Huirong 1. Could you please fill in the question marks in the paper. 2. Figure Changes Fig 1 Correct this fig, the text and associated values of and the other figures if necessary to allow for thinning in the bite. Change the axes - x axis change hw for hs, y axis delete ht New fig 2 and new fig 3. Add bars to give the range of each of the oils. Add arrow heads to the roll roughness points X axis - delete speed parameter, leaving just Ls Y axis - add amplitudes (i.e. surface roughness amplitudes S/S etc) Figs 4 and 5 x axis - delete speed parameter, y axis add amplitude. Add arrow heads to the roll roughness points New Fig 6 needed. Fig 7. Add arrows from labels to histogram plots. 3. Could you send a draft (with token figures but not necessarily all the changes) to Keith Waterson and Peter Reeve(s) (could you check his name! and title) with a letter with a Cambridge return address and the following text, putting my name at the bottom and signing it yourself (adding after the signature (Huirong Le for Michael Sutcliffe) Dear Keith/Peter (as appropriate) Friction in cold rolling project Please could you look over the enclosed draft paper and confirm that it is OK for publication, as per our agreement re publications in the friction modelling project. In fact, in this case I believe that there should be no problem, as the work was essentially done by myself in Northwestern, with writing-up help from Huirong. Please could you write to the above address in confirmation. Thanks, and looking forward to seeing you presently for further discussion of the project. Michael Sutcliffe (Signed by Huirong Le for M Sutcliffe) Once we have heard back from Alcan and Cegelec, plus any further comments from yourself, then this is ready to go. michael 15 16