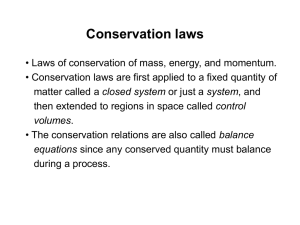

Chapter 5, Control Volume Analysis

advertisement

Chapter 5, Control Volume Analysis

1. Conservation of Mass

i) Continuity Equation

Time rate of change of the mass in a system is zero

Dmsys/Dt = 0

From Reynolds Transport Theorem

B = m = mb

b= 1

Dmsys/Dt = D/Dt ∫ ρdV = ∂/∂t ∫ ρdV + ∫ ρV∙ndA

sys

CV

CS

Continuity

∂/∂t ∫ ρdV + ∫ ρV∙ndA = 0

CV

CS

Steady flow, ∂/∂t = 0

∫ ρV∙ndA = 0

CS

or

Σmout = Σmin

Since m = ρQ = ρVA = ∫ ρV∙ndA

Define average velocity

V = (1/ρA) ∫ ρV∙ndA = m/(ρA)

ii) Fixed, Non-deforming Control Volume

∂/∂t ∫ ρdV + ∫ ρV∙ndA = 0

CV

CS

Ex. 5.1 - 5.5

iii) Moving, Non-deforming Control Volume

Absolute velocity (Fluid velocity seen by an observer in a

V = Wr + VCV

fixed coordinate system):

where Wr is the relative(to the control volume) velocity

VCV is the velocity of the control volume

∂/∂t ∫ ρdV + ∫ ρ Wr ∙ndA = 0

CV

CS

Ex. 5.6

Vplane = Wr1 = -VCV = 971 km/h

V2 = 1050 km/h (from the engine)

Wr2 = V2 - VCV = 1050 - (-971) = 2021 km/h

Steady state, conservation of mass

∫ ρ Wr ∙ndA = 0

CS

ρ2Wr2A2 - ρ1Wr1A1 - m fuel in = 0

Ex 5.7

VCV = -U = -Rω

V2 = Wr2 + VCV

Steady state, conservation of mass

∫ ρ Wr ∙ndA = 0

CS

Σmout - Σmin = 0

2ρWr2A2 - ρQ = 0

Wr2 = Q/(2A2)

iv) Deforming Control Volume

∂/∂t ∫ ρdV + ∫ ρ Wr ∙ndA = 0

CV

∂/∂t ∫ ρdV ≠ 0

CV

CS

V = Wr + VCS

where VCS is the velocity of the control surface seen by a fixed observer

Ex. 5.8 Syringe

∫ ρdV = ρ(ℓA1 + Vneedle)

CV

∂/∂t ∫ ρdV = ρA1(dℓ/dt)

CV

The plunger velocity, Vp = -dℓ/dt

Conservation of mass

∂/∂t ∫ ρdV + mout - min = 0

CV

mout = ρQ2 + ρQleak

min = 0

-ρA1Vp + ρQ2 + ρQleak = 0

Vp = (Q2 + Qleak)/A1

Ex. 5.9 Filling a bath tub

∂/∂t ∫ ρdV + ∫ ρ Wr ∙n dA = 0

CV

CS

C.V. Water in the tub

mout = 0

min = ρ(Vj + dh/dt)Aj

∂/∂t [ρhA] + 0 - ρ(Vj + dh/dt)Aj = 0

ρAdh/dt - ρ Aj dh/dt - ρVj Aj = 0

dh/dt = Vj Aj /(A - Aj ) = Q/(A - Aj )

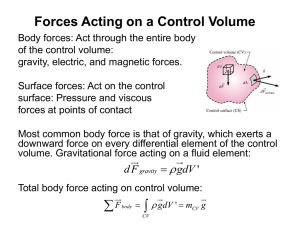

2. Newton’s Second Law

The linear momentum and moment-of-momentum

i) Linear momentum

ΣFsys = D/Dt ∫ VρdV

ΣFsys = ΣFCV

Reynolds Transport Theorem

D/Dt ∫ VρdV = ∂/∂t ∫ VρdV + ∫ V ρV∙n dA

sys

CV

CS

Linear Momentum Equation

ΣFCV = ∂/∂t ∫ VρdV + ∫ V ρV∙n dA

CV

CS

where ΣFCV = ΣFbody + ΣFsurface

ii) Application of the linear momentum equation

a. For inertial (stationary, non-deforming) control volume

Ex. 5-10

ΣFCV = FA - Wn - p1A1 - Ww + p2A2

∂/∂t ∫ VρdV = 0 (Steady state)

CV

∫ V ρV∙n dA = (mV) out - (mV) in

CS

= m(-w2 + w1)

FA - Wn - p1A1 -Ww + p2A2 = m(-w2 + w1)

FA = Wn + p1A1 + Ww - p2A2 - m(-w2 + w1)

Where

m = ρQ = ρw1A1 = ρw2A2

Wn = mg

Ww = ρVg

When FA is positive, force acts upwards in the z-direction.

Important generalities applied to the linear momentum equation

a. One-dimensional (easier to work)

b. Linear momentum is directional

c. Mass flow out is positive, flow in is negative

d. Velocity is according to the direction of the coodinate

e. Steady state

f. Select the C.V. so that the surface is perpendicular to

the fluid

g. Use gage pressure because patm on C.V. cancel each

other

h. External forces have algebraic signs

i. Only external forces acting on the content of C.V. are

considered

For example: C.V. = fluid alone, shear force between

fluid and solid surface is

external force.

C.V. = fluid and surface, shear force is internal only

anchoring force is external

j. Force required to anchoring an object exists in response to surface pressure and/or shear force

acting on C.V.

ii) For an inertial moving, non-deforming control volume

D/Dt ∫ VρdV = ∂/∂t ∫ VρdV + ∫ V ρ Wr ∙ndA

sys

CV

CS

ΣF sys = ΣFCV

Since ΣF sys = D/Dt ∫ VρdV

sys

.

ΣFCV = ∂/∂t ∫ VρdV + ∫ V ρ Wr ∙ndA

CV

CS

Since V = Wr + VCV

ΣFCV = ∂/∂t∫ (Wr+VCV) ρdV + ∫ (Wr +VCV )ρWr ∙ndA

CV

Steady flow

CS

∂/∂t∫ (Wr+VCV) ρdV = 0

CS

VCV = constant

∫ (Wr +VCV )ρWr ∙ndA

CS

= ∫ Wr ρWr ∙ndA + VCV∫ ρWr ∙ndA

CS

CS

∫ ρWr ∙ndA = 0

But

for steady flow

CS

Since

Dmsys/Dt = ∂/∂t ∫ ρdV + ∫ ρWr∙ndA = 0

CV

CS

ΣFCV = ∫ Wr ρWr ∙ndA

CS

Ex. 5-16

C.V. = moving fluid

VCV = Vo

V = W + VCV

∫ Wx ρW∙ndA = -Rx

CS

Ww = ρgA1ℓ

Momentum in the x-direction

∫ Wx ρW∙ndA = -Rx

CS

(mWx)out - (mWx)in = -Rx

m2W2cos45 - m1W1 = -Rx

Momentum in the z-direction

∫ Wz ρW∙ndA = Rz - Ww = m2W2sin45

CS

Assuming frictionless, W1 =W2 = V1 - Vo

m1 = ρW1A1 = ρW2A2 = m2

Rx =m1W1 (1 -cos45) = ρ W12 (1 - cos45)

Rz = ∫ Wz ρW∙ndA + Ww = ρW12A1 sin45 + ρgA1ℓ

CS

The resultant force

R = (Rx2 + Rz2)1/2

Angle of R from x-direction

α = tan -1 ( Rz/ Rx )

iii) Derivation of Moment-of-Momentum Equation

Newton’s second law of motion applied to particle of fluid

D/Dt (VρdV) = δFparticle

The moment-of-momentum

r x D/Dt (VρdV) = r x δFparticle

r is the position vector, Dr/Dt = V,

D/Dt (r x VρdV) = Dr/Dt x V ρdV + D/Dt (Vρ dV)

(Since V x V = 0)

D/Dt (r x VρdV) = r x δFparticle

For a system which is a collection of particles

∫ D/Dt (r x VρdV) = ∫ r x δFparticle = Σ(r x F)

sys

sys

sys

Since Σ(r x F)sys = Σ(r x F)CV

D/Dt ∫ (r x VρdV)

sys

= ∂/∂t ∫ (r x V)ρdV + ∫ (r x V) ρV∙n dA

CV

CS

Σ(r x F)CV = ∂/∂t ∫ (r x V)ρdV + ∫ (r x V) ρV∙n dA

CV

CS

iv) Application of the Moment-of-Momentum Equation

Simplifications:

a. One-dimensional (uniform distribution of average

b. Steady state (steady in the mean for cyclic flows)

c. Work with the component of the torque (along the axis

Consider a Rotating Sprinkler

Water exerts a torque on sprinkler

head

for the axial component

Section (1), r x V = 0

Section (2), |r x V| = r2 vθ2

where vθ2 is tangential velocity

observered from a fixed control

volume

V = vθ2, absolute velocity

W2 = (vθ2)r, relative velocity

VC.V. = -r2ω = -U2, velocity of the nozzle (C.V.)

Since

V = W2 + VC.V.

vθ2 = (vθ2)r - r2ω

To find

∫ (r x V) ρV∙n dA

CS

mass flow rate into the C.V.,

mass flow rate out of the C.V.,

right hand rule for r x V

ρV∙n dA is negative

ρV∙n dA is positive

velocity at any section)

of rotation)

r2er x vθ2eθ = -r2vθ2ez

∫ (r x V) ρV∙n dA

CS

= -r2vθ2ez(mout) - 0ez(min)

= -r2vθ2m

The torque about the axis of rotation

Tshaft = Σ(r x F)CV = ∫ (r x V) ρV∙n dA = -r2vθ2m

CS

At a shaft of rotational speed ω, the shaft power

Wshaft = Tshaftω = -r2vθ2mω

Shaft work per unit mass

wshaft = Tshaftω/m = -r2vθ2ω = - U2vθ2

Ex. 5-17 Rotating lawn spinkler

a. Stationary, ω = 0

V2 = vθ2

= Q/2A = 16.7 m/s

Tshaft = -r2vθ2m = -3.34 N-m

b. ω = constant = 500 rpm

= (500 rev/min)(2π rad/rev)/(60 s/min)

= 50 rad/s

V2 = W2 - U2

Tshaft = -r2vθ2m = -r2m(W2 - U2)

W2 = Q/2A = 16.7 m/s

U2 = r2ω = 10.5 m/s

Tshaft = -1.24 N-m

c. If no resisting torque is applied

Tshaft = -r2vθ2m = -r2m(W2 - U2) = 0

W2 - U2 = W2 - r2ω = 0

ω = W2/ r2 = 83.5 rad/s

For a General One-Dimensional Flow Through a Rotating machine

Tshaft = (+m out)(±rvθ)out + (-m in)(±rvθ)in

mass flow out is positive

mass flow in is negative

Wshaft = Tshaftω = (+mout)(±Uvθ)out + (-min)(±Uvθ)in

+ if U and vθ are in same direction

- if U and vθ are in opposite direction

+Wshaft, Tshaft and ω are in same direction, means power

Power per unit mass flow rate

wshaft = Tshaftω/m = (±Uvθ)out - (±Uvθ)in

SUMMARY

into C.V. (Ex. Pump)

A. Radial flow rotating machinery

Conservation of mass, m = ρVR1A1 = ρVR2A2

VR1 = Q/A1

VR2 = Q/A2

C.V. velocity, U1 = r1ω

U2 = r2ω

Velocity Triangle

V1 = W1 + U1

V1 = VR1 + Vθ1

W1 = WR1 + Wθ1

VR1 = WR1

similarly

V2 = W2 + U2

V2 = VR2 + Vθ2

W2 = WR2 + Wθ2

VR2 = WR2

Moment-of-momentum

Tshaft = (+m out)(±rvθ)out + (-m in)(±rvθ)in

Wshaft = Tshaftω = (+mout)(±Uvθ)out + (-min)(±Uvθ)in

wshaft = Tshaftω/m = (±Uvθ)out - (±Uvθ)in

+ if U and vθ are in same direction

- if U and vθ are in opposite direction

Ex. 5-18

Conservation of mass, m = ρ VR1A1 = ρ VR2A2

At inlet,

Vθ1 = 0

V1 = VR1 + Vθ1

V1 = VR1

V1 = W1 + U1

U1 = r1ω

W1 = WR1 + Wθ1

Since , V1 = VR1 = WR1

Wθ1 = -U1 = -r1ω

At exit

V2 = W2 + U2

V2 = VR2 + Vθ2

Since, VR2 = WR2

U2 = r2ω

From velocity triangle

Vθ2 = U2 - W2cosθ

VR2 = W2sinθ

W2 = VR2 / sinθ

m2 = ρQ = 2πr2 hρVR2

VR2 = m2 /(2πr2 hρ)

Wshaft = (+mout)(±Uvθ)out + (-min)(±Uvθ)in

= m2(±U2 Vθ2)

B. Axial flow rotating machinery

Conservation of mass, m = ρ Vx1A1 = ρ Vx2A2

Since A1 = A2 = 2πrm(ro - ri)

rm = (ri + ro)/2

U1 = U2 = rmω

Vx,1 = Vx,2

(for incompressible flow)

Velocity Triangle

V1 = W1 + U1

V1 = Vx1 + Vθ1

W1 = Wx1 + Wθ1

Vx1 = Wx1

similarly

V2 = W2 + U2

V2 = Vx2 + Vθ2

W2 = Wx2 + Wθ2

Vx2 = Wx2

Moment-of-momentum

Tshaft = (+m out)(±rvθ)out + (-m in)(±rvθ)in

Wshaft = Tshaftω = (+mout)(±Uvθ)out + (-min)(±Uvθ)in

wshaft = Tshaftω/m = (±Uvθ)out - (±Uvθ)in

+ if U and vθ are in same direction

- if U and vθ are in opposite direction

Ex. Problem 5-77

Axial flow water turbine

rm = 6 in

ω = 1000 rpm

Stator blabe exit angle = 70

Rotor blabe inlet angle = 45

rotor blade exit angle = 45

Find: wshaft

Consevation of mass, m = ρ Vx1A1 = ρ Vx2A2

Vx1= Vx2

C.V. Velocity

U1 = U2 = rmω

=[(6/12)(1000)(2π)/60]

= 53.2 ft/s

Velocity triangle

V1sin70 = Vθ1

(1)

V1cos70 = Vx1

W1sin45 = Vθ1 - U

(2)

(3)

W1cos45 = Vx1

(3)/(4)

(4)

tan 45 = [Vθ1 - U]/Vx1

= [V1sin70 - U]/[V1cos70]

V1 =U/[sin70 - cos70tan45]

= 86.7 ft/s

Vθ1 = V1 sin70 = 82.3 ft/s

Vx1 = V1 cos70 = 29.9 ft/s

W1 = Vx1/cos45 = 242.4 ft/s

Similarly

W2cos45 = Vx2

(5)

Vθ2 = U2 - W2 sin45 (6)

V2sinα2 = Vθ2

(7)

V2cosα2 = Vx2

(8)

From conservation of mass

Vx1 = Vx2 = 29.9 ft/s

W2 = Vx2/cos45 = 42.4 ft/s

Vθ2 = U2 - W2 sin45 = 22.4 ft/s

(7)/(8)

α2 = tan -1(Vθ2/Vx2) = 37o

V2 = Vθ2/sinα2 = 37.2 ft/s

wshaft = Tshaftω/m = (±Uvθ)out - (±Uvθ)in

= (±U2mvθ,2)out - (±U1mvθ,1)in

= -3130 ft-lb/slug

3. First Law of Thermodynamics

- The Energy Equation

i) Derivation of Energy Equation

D/Dt ∫ eρdV = [(Qnet)in + (Wnet)in]

sys

sys

Total stored energy

= internal energy + kinetic energy + potential energy

or,

e= u + V2/2 + gz

take the control volume that is coinside with the system

[(Qnet)in + (Wnet)in] sys= [(Qnet)in + (Wnet)in]C.V.

Reynolds Transport Theorem

B = me

b=e

(Qnet)in , rate of heat transfer into the C.V. by conduction, convection and/or radiation,

(Qnet)in = 0, for an adiabatic process

(Wnet)in, power into the C.V.

(Wnet)in = Wshaft + Wnormal stress + Wtangential stress

Wshaft = Tshaft ω

Wnormal stress = ∫ σ V∙n dA = ∫ -p V∙n dA

= ∫ (-p/ρ)ρV∙n dA

Since the normal stress,

σ = -p

Wtangential stress = ∫ τ V∙n dA = 0

Since tangential stess, τ, is between the fluid and the

=0

∂/∂t ∫ eρdV + ∫ eρV∙n dA

CV

CS

=[(Qnet)in + (Wshaft net)in]C.V. + ∫ (-p/ρ)ρV∙n dA

CS

∂/∂t ∫ eρdV + ∫ (u + p/ρ + V2/2 + gz)ρV∙n dA

CV

CS

= [(Qnet)in + (Wshaft net)in]C.V.

ii) Application

Steady flow

∂/∂t = 0,

ehthalpy,

h = u + p/ρ

min = mout = m

m[(hout - hin) + (Vout2 - Vin2)/2 + g(zout - zin)]

= [(Qnet)in + (Wshaft net)in]C.V.

Ex. 5-20

iii) Comparison of Energy Equation with Bernoulli Equation

One-dimensional, incompressible, steady flow

m[(uout - uin) + (pout - pin)/ρ + (Vout2 - Vin2)/2 + g(zout - zin)]

solid surface where V

= [(Qnet)in + (Wshaft net)in]C.V.

Without shaft work, (wshaft net)in = 0

pout/ρ + Vout2/2 + gzout = pin/ρ + Vin2/2 + gzin

- [(uout - uin) - (qnet)in]C.V.

Bernoulli equation along a streamline

pout/ρ + Vout2 /2 + gzout = pin/ρ + Vin2/2 + gzin

Define:

Loss = (uout - uin) - (qnet)in

For flow in pipes, modified Bernoulli equation

pout/ρ + Vout2/2 + gzout = pin/ρ + Vin2/2 + gzin - Loss

Ex. 5.23

Consider friction and shaft work

pout/ρ + Vout2/2 + gzout

= pin/ρ + Vin2/2 + gzin + (wshaft net)in - Loss

Stagnation pressure, po = p + ρV2/2

(pout + ρVout2 /2)/ρ+ gzout

= (pin + ρVin2/2)/ρ + gzin + (wshaft net)in - Loss

or,

(po)out/ρ+ gzout

= (po)in/ρ + gzin + (wshaft net)in - Loss

Mechanical Efficiency:

For fan , blower, or pump

(po)out/ρ+ gzout

= (po)in/ρ + gzin + (wshaft net)in - Loss

ηFan = [(wshaft net)in - Loss]/(wshaft net)in

= {[(po)out - (po)in]/ρ+ g[zout - zin]}/(wshaft net)in

For turbine

pout/ρ + Vout2/2 + gzout + (wshaft net)out

= pin/ρ + Vin2/2 + gzin - Loss

ηturbine = (wshaft net)out/[ (wshaft net)out + Loss]

= (wshaft net)out/{[(po)in - (po)out]/ρ+ g[zin - zout]}