Nienke Lindebooma

advertisement

Nienke Lindebooma

Peter R. Changb

Robert T. Tylera

a

Department of Applied

Microbiology and Food Science,

University of Saskatchewan,

Saskatoon, Canada

b

Agriculture and Agri-Food

Canada, Saskatoon, Canada

Analytical, Biochemical and Physicochemical Aspects of Starch Granule Size, with Emphasis

on Small Granule Starches: A Review

Granule size, size distribution and shape are among the most important morphologically

distinguishing factors of starches from different origins. This article provides an overview of

aspects related to starch granule size, including procedures for determining the size, the impact of

granule size on the physicochemical characteristics of starch, and biosynthetic and environmental

determinants of granule size. The focus is on small granule starches, including their isolation and

current and potential utilization.

Keywords: Starch granule; Small granule starch; Granule size determination; Starch isolation

Contents

1

Introduction............................ 89

2

Granule Size and Morphology.............. 89

2.1 Granule size............................ 89

2.2 Granule morphology..................... 90

3

Techniques for the Determination

of Granule Size.......................... 90

3.1

Microscopy.......................r..... 91

3.2 Sieving................................ 91

3.3 Electrical resistance...................... 91

3.4 Laser light scattering..................... 91

3.5 Field flow fractionation.................... 91

4

Granule Size Distribution Models........... 92

4.1 Aggregates............................. 92

4.2 Mono- and bimodal granule size

distributions............................ 92

5

Compositional, Structural and Functional Differences between Small and Large

Granules............................... 92

5.1 Amylose and amylopectin content and structure............................... 92

5.2 Gelatinization behavior.................... 93

5.3 Amylose-lipid interactions................. 93

5.4 Solubility and swelling power.............. 93

5.5 Acid and enzymatic hydrolysis............. 93

6

Determinants of Granule Size.............. 94

6.1

Environment............................ 94

6.2 Biosynthesis............................ 94

6.3 Genetics............................... 95

7

Starch Isolation......................... 95

Correspondence: Peter Chang, Research Scientist of Bioprod-ucts and Bioprocesses National

Science Program, Agriculture and Agri-Food Canada, 107 Science Place, Saskatoon, SK, S7N 0X2,

Canada. Phone: +306-956-7637, Fax: +306-956-7247, e-mail: Changp@agr.gc.ca.

7.1

Problems encountered in the isolation

of small granule starches.................. 95

7.2 Potential solutions....................... 95

8

Current and Potential Uses of Small

Granule Starch.......................... 96

8.1

Fat replacement......................... 96

8.2 Biodegradable films...................... 96

8.3 Carrier materials......................... 96

9

Conclusions............................ 97

1 Introduction

Starch is composed of two types of molecules, amylose and amylopectin, which are arranged in a

relatively water-insoluble granule of a particular size. Granule size influences the physicochemical

characteristics of starch, as well as the procedures employed in starch refining. Amylose/amylopectin ratio, molecular weight and molecular fine structure also influence the

physicochemical properties of starch. This review presents a summary of literature available in the

area of starch granule size and size determination. The focus is on starch from storage organs and

primarily the specific characteristics of small granule starches, which offer both unique

functionality and unique challenges with respect to commercial-scale refining.

2 Granule Size and Morphology

2.1 Granule size

Granule size and shape are related to the biological source from which the starch is isolated. In

general, granule size may vary from less than 1 μn to more than 100 μm. Generally, granule size

refers to the average diameter of the starch granules. For this, spherical granules

are assumed, which is seldom correct. Granule size may also be expressed as the average length of

the major and minor axes, mean maximum diameter, mean granule volume or mean surface area. In

this article, granule size is expressed as the average spherical equivalent diameter. No precise

categorization of granule size was found in the literature. For this reason, the following classes are

defined: large (>25 μm), medium (10-25 μrn), small (5-10 μm) and very small (<5 μn) granules.

This article focuses on small and very small granule starches. For convenience, the term small

granule starch will be used in reference to both. Tab. 1 is a compilation of granule size data on

small granule starches and starches exhibiting a bimodal size distribution from various sources [113]. Commercial sources of small granule starch include rice, wheat and oat. Other potential

sources of small granule starch include amaranth (Ama-ranthus cruentus L.), quinoa (Chenopodium

quinoa Willd.), taro (Alocasia macrorrhiza L), pigweed (Amaranthus ret-roflexus L), cow cockle

(Saponaria vaccaria L), canary grass (Phalaris canariensis L), cattail (Typha latifolia L), dasheen

(Colocasia esculenta L), grain tef (Eragrostis tef (Zucc.) Trotter) and dropwort (Filipendula

vulgaris Moench), all having granule sizes ranging from 0.5 to

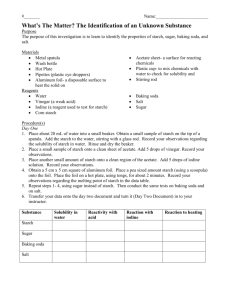

Tab. 1. Granule sizes of starches from different origins.

10 μm. Cow cockle starch has the smallest granule size of any starch studied to date [2]. Small

granule starch may also be obtained by selective fractionation of the small granules from some

cereal starches. Starches of wheat, barley, rye, and triticale (wheat-rye hybrid) are noted for their

bimodal granule size distributions, with differentiation being made between granule fractions with

diameters smaller than and larger than 10 μn. Fractionation is achieved by air classification or

sedimentation [14]. Starch granule size distribution will be discussed in more detail later.

2.2 Granule morphology

Starch granules from different botanical origins differ in morphology. Granules of tuber and root

starches, for example, are oval, although round, spherical, polygonal, and irregular shaped granules

also exist [15]. Taro, dasheen and parsnip (Pastinaca sativa L.) starches consist of very small

granules compared to other root and tuber starches [4]. The small granule size fractions of wheat,

barley, rye and triticale have a different morphology than their larger counterparts. Granules of bean

and pea starches are characterized as thick disks with a 'cut' around the middle or at the ends and an

indentation at one end. Starch granules from fruits and nuts vary in shape. Some nut starches have

unusual granule morphology of half-spheres, although most are round in shape. Granules of small

granule starches are characterized by their very irregular, polygonal shape [4].

3 Techniques for Determination of Granule Size

Generation of granule size distribution data makes it possible to compare starches from different

botanical origins and to assess starch-processing parameters, especially the efficiency of centrifugal

operations [17]. The accuracy of the granule size distribution obtained is dependent on both the size

determination technique and the starch isolation method employed. A satisfactory size determination technique evaluates all granules without missing the small granule fraction, maintains the

granules in an unag-gregated form, and is able to distinguish between starch granules and nonstarch particles. It is also important that the technique incorporates an intrinsic allowance for

granule shape [18]. Furthermore it is a prerequisite that the granules that are analyzed are not

aggregated. Granule size analysis can be performed both in situ as well as in a recovered starch

fraction. Isolation of starch, however, may result in an incorrect granule size distribution

due to the loss of certain granule fractions, particularly the smaller granules, or to granule damage

experienced during isolation.

3.1 Microscopy

Light microscopy is suitable for use in situ by staining a small slice of sample tissue with iodine, as

well as for analysis of an isolated starch fraction [19]. However, this method is laborious and can

not be expected to provide the detailed information that can be obtained with methods such as light

scattering and field flow fractionation. The light microscope method has been developed into what

is called image analysis of optical microscopy (IA0M). Image analysis involves the processing (i.e.

the quantitative evaluation of several features) of an image of an object and enables detailed

manipulation and presentation of the data. A prerequisite to successful image analysis is that the

granules are not damaged during isolation of the starch, and samples must be homogenous [19].

Image analysis is much faster than the traditional microscopic method. However, differentiation

between starch granules and non-starch particles may be difficult. Scanning electron microscopy

(SEM) is frequently used because of the short wavelength of the electron beam, which makes it

possible to determine granule size more accurately than is the case with light microscopy. The resolution possible with SEM also provides a more detailed perspective on granule surface

characteristics and granule morphology [19].

3.2 Sieving

Granule size determination by micro-sieving is a non-microscopic technique whereby granules of

different sizes are separated in a specially-designed sieving apparatus. The relative weights of starch

granules above and below one or more aperture sizes are thereby determined. A shortcoming of this

method is that larger granules tend to be ellipsoidal in shape, hence their size tends to be

understated [20]. In addition, errors resulting from granule aggregation are of particular concern in

sieving methods. Although fractions of small granules (<10 μm) were found to be essentially free of

larger granules, the other sieved fractions were inevitably heterogeneous [20].

3.3 Electrical resistance

The electrical resistance method using the Coulter counter discriminates among particles by how

they affect the electrical resistance of an electrically conductive liquid.

The liquid, with suspended particles, is forced to flow through an orifice having an immersed

electrode on each side [18]. This procedure is not affected by either granule shape or density, and it

is claimed by many workers that the results can be more accurate than those obtained by other

techniques [18]. However, the Coulter counter was shown to be incapable of accurately measuring

granules with diameters less than 3 μrn [21]. Furthermore, the technique appears to over-size when

most of the granules are smaller than 20 μm [18].

3.4 Laser light scattering

With lower angle laser light scattering (LALLS), the light of a parallel-laser beam is deflected at an

angle dependent on the diameter and optical properties of the granules. Small granules scatter the

laser beam of electromagnetic waves at larger angles than do larger granules. This method is fast

and objective because the number of granules measured is greater than 100,000 [19]. It is possible

to evaluate granules as small as 0.1 μm in diameter [21]. A prerequisite for successful analysis

using this technique, however, is that the granules are not damaged [19]. Because most starch

granules are not truly spherical, the granule diameters determined tend to be smaller than those

measured by image analysis techniques [21].

3.5 Field flow fractionation

Field flow fractionation (FFF) techniques are a group of analytical elution methods suitable for

both size determination and fractionation of macromolecules and particles [22]. Suspended particles

are separated in a thin flow channel by the action of a gravitational or centrifugal field directed at

right angles to the channel. This process forces particles of different sizes into different streamlines

which elute at different times [22, 23]. Like LALLS, FFF techniques are able to measure large

numbers of starch granules in a relatively short period of time. The advantage of FFF over other

techniques is its ability to fractionate the sample according to granule size [19]. Furthermore, it is

fast and offers high resolution [18]. A disadvantage of sedimentation techniques is that the

assumption is made that all particles are spherical and of uniform density [18]. In addition, the

instrumentation for field flow fractionation is rather complex and expensive [19]. A prerequisite to

successful analysis using FFF techniques is that the granules are not damaged during isolation of

the starch. Field flow fractionation techniques are useful for the investigation of degradation (e.g.

enzymatic digestion) of starch granules when

digestion takes place mainly inside the starch granule. Under these circumstances, the density of the

particles is changed before any measurable change in size occurs. These density changes can be

measured by sedimentation [19].

Tab. 2 summarizes the advantages and disadvantages of the various granule size determination

methods.

Tab. 2. Advantages and disadvantages of different granule size determination techniques.

4 Granule Size Distribution Models

4.1 Aggregates

There are two aspects to the distribution of starch granule size. One is the impact of aggregation of

the granules in a starch sample on the apparent granule size distribution. The other is the actual size

distribution of individual granules. Aggregated starch granules are typical of most starch raw

materials that consist of small granules, such as quinoa, amaranth and cow cockle [24]. Large

spherical particles, 30-80 μm in diameter, can be observed in spray-dried samples, where the small

granules cluster together to minimize surface area. Clustering can also

occur in situ immediately after biosynthesis via hydropho-bic interactions among residual adhering

membrane constituents derived from the amyloplast [25], Aggregate formation complicates

obtaining an accurate perspective on the granule size distribution.

4.2 Mono- and bimodal granule size distributions

Granule size distributions are usually classified as mono-modal or bimodal. A bimodal size

distribution of large and small granules is characteristic of wheat starches as well as those from rye

and barley. The two populations are classified as A-granules (>10 μm) and B-granules (<10 μm)

and differ somewhat in their physicochemical characteristics and end-use potential [26-31]. The

proportion of small and large granules differs among genotypes [32]. Raeker et al. [21] reported that

wheat starch actually showed a trimodal rather than a bimodal granule distribution. An intermediate

(underdeveloped A-type) granule was mentioned as constituting the third group. However, most of

the time wheat endosperm is said to contain just two types of starch granules. A-type granules are

10-35 μm in diameter and account for more than 70% of the total starch weight but less than 10% of

the granules by number. B-type granules account for over 90% of the granules by number, but less

than 30% of the total starch by weight in wheat endosperm [21, 30, 33, 34].

5 Compositional, Structural and Functional Differences between Small and Large Granules

Starch composition, gelatinization and pasting properties, enzyme susceptibility, crystallinity,

swelling and solubility are all affected by granule size. However, several other factors, including

amylose/amylopectin ratio and molecular weight and granule fine structure, are also influential.

Most of the research done in this area has been on wheat and barley starches.

5.1 Amylose and amylopectin content and structure

Some reports claim that the amylose concentration is higher in the large granules of bimodal

starches [32, 34, 35], whereas others have found the same amylose concentration in both small and

large granules [36,37]. A variety of procedures have been used to determine the amylose content of

starch [38-41]. These methods all have their particular limitations, which has resulted in discrep-

ancies in the amylose contents reported for various starches. Variation in the molecular structure of

amylose and amylopectin appears to explain many of the apparent contradictions in the literature

[41, 42]. The molecular structure of the amylose and amylopectin fractions varies between granules

of different size. For barley, it was found that the number-average degree of polymerization of

amylopectin decreased with decreasing granule size, and that amylose polymerization was the same

for small and large granules [1]. Takeda [35] concluded that in barley, large granules contained

smaller, less branched amylose polymers. The branch chain length of amylopectin is also correlated

with granule size and granule size distribution. The amylopectin of large granules contained a

greater number of long amylopectin B chains and had a lower fraction infraction II ratio, one of the

structural characteristics of amylopectin, than did small granules from the same cultivar [43].

5.2 Gelatinization behavior

The gelatinization properties of starch are related to a variety of factors including the size,

proportion and kind of crystalline organization, and ultra-structure of the starch granule. Goering

and DeHaas [13] reported that small granule starch had, in general, a lower pasting temperature

than large granule starch. However, small granule size is not necessarily associated with a low

pasting temperature, as dasheen starch has a pasting temperature 20°C higher than that of most

other small granule starches. The low amylose content of dasheen and the fact that it is a tuber

starch made this gelatinization temperature totally unexpected [13]. Lorenz [24] showed that

monomodal small granule starches had higher pasting temperatures than did large granule starches.

In wheat and barley starches, the smaller B-granules paste at a higher temperature and over a wider

temperature range than do the larger A-granules [33, 37, 44, 45]. According to Eliasson and

Larsson [33], the gelatinization enthalpy of wheat starch is independent of the granule size distribution. However, others have found higher gelatinization enthalpies for A-type than for B-type starch

granules in wheat [34, 44]. This lower enthalpy value for the gelatinization of B-type granules

suggests a lower proportion of organized structures in B-granules than in A-type, or a lower

stability of the crystalline regions. Chiotelli and Le Meste [44] showed, with X-ray diffraction, that

A-type granules are indeed somewhat more crystalline than B-type granules. A difficulty in the

interpretation of such data is that differences in the apparent crystallinity of starch, as determined by

X-ray diffraction, can be attributed to differences in water content among the starch types [46, 47].

5.3 Amylose-lipid interactions

The dissociation enthalpy of the amylose-lipid complexes of small granules is higher than that of

large granules [33, 37, 44]. Soulaka and Morisson [48] and Raeker et al. [21] explained this on the

basis of the higher lipid content in B-type wheat granules. Moreover, as the gelatinization

endotherm represents essentially the difference between the endothermic energy (associated with

melting of crystallites, granule swelling and denaturation) and the exothermic energy (associated

with hydration of starch and formation of amylose-lipid complexes [49]), the greater amount of

internal lipid in B-granules (as well as better hydration) may generate a lower endothermic energy

(enthalpy underestimation) [44].

5.4 Solubility and swelling power

At similar amylose contents, small granule starches tend to have a lower pasting temperature and

more amylose leakage out of the intact granule, than do their larger granule counterparts at

temperatures of 55°C and higher [6]. According to Zheng and Sosulski [6], the swelling power of

starch is associated more with granule structure and chemical composition, particularly amylose and

lipid content, than with granule size. Higher amounts of lipid-com-plexed amylose would inhibit

swelling and gelatinization [6]. However, B-granules are associated with a higher rate of water

absorption, earlier hydration and more swelling than are A-granules [44]. The reason for this is the

less crystallized arrangement of the polysaccharide chains in B-granules (a higher proportion of

amorphous zones more accessible to water). Greater specific surface area may also contribute to the

higher water absorption of B-granules [44], though other factors like starch ageing and sorption

time might have a larger influence than surface area [50, 51]. Hellmann and Melvin [52] even concluded that the surface area of starch does not give a quantitative explanation of the water

absorption capacity of starches at 25°C from different botanical origin with varied granule sizes.

5.5 Acid and enzymatic hydrolysis

Small barley and wheat granules hydrolyze faster with acid or enzyme than do large granules [14,

53]. This again might be due to the higher surface area per unit weight of small granule starch.

Also, the pattern of enzyme digestion differs between large and small granules [41]. It has been

reported that enzymatic hydrolysis of granular starch at temperatures below the starch gelatinization

temperature results in a pitted and porous granule surface, which is readily discernible by

microscopic exami-

nation [54]. The starch granules are reduced to a sponge-like structure due to uneven hydrolysis.

For example, an enzyme like α-amylase appears to attack at discrete points on the granule surface,

forms tunnels into the granule interior, and then hydrolyzes the granule from the inside [54].

However, no pinholes were detected in small granules after incubation with a-amylase. The surface

of small granules became rough, and the granules appeared to be hydrolyzed from the outside by

surface erosion. The rough appearance of small starch granules after enzyme incubation is quite

different from the still-smooth surface of extensively degraded, large granules [54]. It is questionable, however, whether granule size is the main factor responsible for the observed differences

in the pattern of enzyme attack on small and large granules. Fannon et al. [55] proposed that the

presence of pores as an anatomical feature of some starches, and the absence of these in other

starches, affected the pattern of attack by amylases and by at least some chemical reagents. Pores

were found along the equatorial groove of large granules of wheat, rye, and barley starches, but not

in oat and rice starch, which have small granules.

6 Determinants of Granule Size

6.1 Environment

Environment seems to affect starch granule size and size distribution. Raeker et al. [21] concluded

that for wheat, the magnitude of this effect was cultivar dependent. Oli-veira et al. [56] found that

environment had a significant effect on starch traits in barley, whereas genotype/environment

interactions were not significant. In barley, temperature-induced stress reduced both the size of Aand B-type granules and the number of B-type granules [57]. This was also found in wheat [21].

When other stresses were present, the number of A-granules was reduced by high temperatures, but

proportionally to a lesser extent than was the number of B-granules [43, 57]. Different wheat

cultivars have shown considerable variation with respect to the sensitivity of the B-granule fraction

to environmental stress [58]. Significant differences in amylose content exist among cultivars,

hence the observed negative correlation between amylose content and granule size may explain, at

least in part, the relationship between cultivar and granule size [21].

6.2 Biosynthesis

Starch morphology and granule size are genetically controlled [4]. The biosynthesis of starch occurs

in the amylo-plast and/or the chloroplast. The membranous structures

and physical characteristics of plastids can impart a particular shape or morphology to starch

granules, and can affect the arrangement and association of the amylose and amylopectin molecules

within the granule [4]. Until now, research on differences in the biosynthesis of small and large

granules has focused mainly on the granules in a bimodal distribution, such as in barley and wheat

starches. Not much is known of the determinants of granule size in monomodal, small granule

starches, nor has a satisfactory explanation yet emerged from biosynthetic studies with respect to

the origin of the dual population of A- and B-granules in some cereal starches [16]. Lange-veld et

al. hypothesized that small granules are formed in vesicles budded off from out-growth of the Atype granule-containing amyloplast. This hypothesis is supported by the demonstration of the

presence of B-type granules using transmission electron microscopy and confocal laser scanning

microscopy [59]. For a general review on starch granule structure and biosynthesis, the reader is

referred to Buleon et al. [3].

The biosynthesis of cereal starches is postulated to occur by two processes. The first of these

governs the ratio and nature of the amylose and amylopectin components, whereas granule shape

and size are controlled independently, the mode depending on the cultivar [20]. In the development

of a barley kernel, the A-granules form soon after anthesis and may continue to grow throughout

grain filling, whereas B-granules are initiated some days after anthesis and remain small [58]. The

composition of B-granules differs from that of A-granules throughout development, mainly with

respect to amylose and phosphorus content. At most stages of development, the numbers of Agranules per endosperm remained constant while granule size increased, but the numbers of B-granules per endosperm increased throughout grain development [60]. Amylose content increases with

granule size and with granule maturity [61].

Takeda et al. [35] characterized the structure of amylose and amylopectin in barley, and indicated

that the genetic regulation of starch biosynthesis may differ for granules of different sizes. It was

also suggested that the regulation of biosynthesis of small granules in amyloplasts was different

from that of large granules and that of a middle fraction of granules. One group of enzymes that is

reported to influence granule size is the starch-branching enzymes [62], which are preferentially

associated with A-type starch granules in wheat endosperm. Two isoforms of a 152-kDa starchbranching enzyme [1,4-α-glucan branching enzyme] from wheat are located in the endosperm

starch granules but are not found in the endosperm soluble fraction or in pericarp starch granules

younger than 15 days post-anthesis (DPA). Small B-granules initiated

before 15 DPA incorporate the two isoforms throughout endosperm development and grow into

full-size A-gran-ules. In contrast, small starch granules harvested after 15 DPA contained only

small amounts of the branching enzyme and developed mainly into B-granules [62]. In the barley

shrunken (shx) mutant, starch synthase I was suggested as the primary mutation site [63]. The

overall size of the A-type starch granules is reduced, and the granule size-distribution is apparently

monomodal rather than bimodal as was the case in the wild type [63-65]. No mutant with altered

starch granule size distribution, analogous to the shx in barley, has been reported in other bimodal

starches.

6.3 Genetics

Little information is available with respect to the genetic control of granule size. Borem and Mather

[66] used simple interval mapping to reveal a region of chromosome 2 (2H) containing quantitative

trait loci (QTL) which affected the overall mean starch granule volume, the proportion of large Atype granules, the mean volume of A-granules, the mean maximum diameter of A-granules, and the

mean F-shape (roundness) of small B-type granules in barley starch. Composite interval mapping

revealed further QTL affecting starch granule traits on chromosomes 4 (4H; mean F-shape of Bgranules) and 7 (5H; mean maximum diameter of A-granules). Mutations in the genes affecting

amylose and amylopectin content show some effects on the granule size distribution. The presence

of the 'waxy' loci of several species results in a low amylose content of starch. Relatively low

amylopectin contents compared to non-mutant lines can occur in gene mutations that affect

amylopectin synthesis, for example at the amylose extender locus [67]. Starch from waxy barley

was reported to have a greater number of starch granules per endosperm, but the average granule

size was smaller than that of wild-type starches. In contrast, the gene that causes a relatively high

amylose content in barley starch was associated with a reduction in the mean volume of A-granules

and an increase in the mean volume of B-granules. The relative quantities (numbers) of A- and Bgranules were unaffected by either mutation [67].

7 Starch Isolation

The industrial process of starch isolation from commercial sources consists mainly of the separation

of starch from protein and fiber. Important considerations in starch isolation include avoidance of

amylolytic or mechanical damage to the starch granules during the initial isolation steps,

effective deproteinization of the starch, and minimizing the loss of small granules [68]. Commercial

production and use of small granule starch is still of relatively minor importance due to difficulties

experienced in the isolation and purification of small granule starch and the associated costs.

Processing experience on a laboratory scale has also been problematic. As a result, small granule

starch often has a high protein content and a portion of the small granule starch fraction is lost

during isolation.

7.1 Problems encountered in the isolation of small granule starches

A problem encountered in protein-starch separations is the entrapment of small granules in the

protein and fine fiber sediments generated during centrifugation [57, 68-71]. In batch

centrifugation, a dark-colored layer is generally observed on top of the white starch cake, which

contains mainly large starch granules. The interface consists of protein, non-starch polysaccharides

and smaller starch granules. When the upper layer is scraped off and discarded, which is common in

laboratory purification methods and in some industrial processes, a severe loss of small granules

occurs [72]. This affects starch yield as well as the ratio of small to large granules in starches having a bimodal starch granule size distribution.

In contemporary industrial starch refining processes, hydrocyclones are often used in lieu of

centrifuges. The advantage of hydrocyclones is that they are low in cost, contain no moving parts,

and result in a faster separation. However, important disadvantages include their relatively low

capacities and their relatively low efficiency in recovering small granules from both bimodal and

monomodal sources [73]. Granule size is a primary determinant of the efficiency of hydrocyclones

for the recovery of starch, as the sedimentation velocity of particles of similar density in a

centrifugal field is proportional to particle mass [73]. In the wheat processing industry, it is well

known that smaller granules do not sediment from aqueous suspension as rapidly as larger granules

and are partially lost in the supernatant [58].

7.2 Potential solutions

To overcome problems associated with deproteination and entrapment of small granules in the

protein layer, researchers have degraded the protein enzymatically, followed by separation of the

peptides and starch by centrifugation [74, 75]. However, the process required chroma-tography to

purify the protease so that it would not contain any amylase activity [63].

McDonald and Stark [76] suggested that instead of discarding the brown starch-protein layer, starch

in the layer should be purified separately and then added back to the white starch layer to provide a

representative starch granule preparation. Recovery of 45% of the starch from the proteinacious

brown layer was achieved by enzymatic processing of tailings with protease.

To remove β-glucans and other viscous non-starch poly-saccharides that can entrap the starch,

Wilhelm et al. [77] and Zheng and Bhatty [78] used enzyme preparations containing predominantly

β-glucanase, cellulase and arabi-noxylase activity. Subsequently, centrifugation separated the starch

slurry into well-defined phases (protein, compound starch granules, fine fiber). Wilhelm [25]

combined these non-starch-polysaccharide-degrading enzymes with proteases to effect better

purification of the starch. Another effective method for eliminating protein contaminants is the

centrifugation of the starch granules through a cesium chloride gradient. However, the cost of this

method restricts it to small-scale laboratory isolation [68], Zhao and Whistler [79] used low-gravity

centrifugation to separate a major proportion of the protein, such that when the supernatant was

centrifuged at higher gravity, starch settled with only mild contamination of the starch cake surface.

Although enhanced recovery of small granule starches is technically feasible, the extent to which

enzyme technology or alternative centrifugation regimes, for example, are adapted in commercial

practice will depend on economic factors.

8 Current and Potential Uses of Small Granule Starches

There is increasing interest in starches manufactured from novel materials for use in special

products. Starches having small granules and narrow granule size distributions can be used in fine

printing paper and plastic sheets [4, 77], as a binder with orally active ingredients, and as a carrier

material in cosmetics [80]. Microgranular starches are also suitable for one-layer-thick honeycomb

coatings and in this way can be used in the cosmetic, paper, textile and photographic industries [12].

A well-established use of small granule starch, mainly rice starch, is as a cold-water laundrystiffening agent. The small granule size affords superior penetration of starch into the fabric. The

stiffness of textiles and fabrics so treated is less affected by humidity than those treated with other

starches [81].

8.1 Fat replacement

Aqueous dispersions of small starch granules are known to produce a creamy, smooth texture that

exhibits fat-mimetic properties [4, 12, 82]. With the growing demand

for carbohydrate-based fat replacers, starch from cow cockle, for example, may find commercial

applications. In food applications, microgranular and uniform granule size starches produce a

creamy mouth feel, a desirable attribute in frozen desserts, cookies, cheesecakes and other low-fat

and fat-free food formulations. For example, rice starches, because of their uniformly small granule

size (2-8 μm, the smallest among commercially available starches), are well known to produce a

smooth creamy texture [4, 12]. Whistler [83] patented a process in which small granule starch (an

average granule size of 5 μm or less, preferably less than 3 μm, is preferred) is subjected to partial

hydrolysis with a-amylase or glucoamylase to produce a novel, granular starch composition having

an enzymatically hydrolyzed surface appearing diffuse and substantially non-porous under

microscopic examination, and exhibiting crystallinity characteristic of the corresponding native

starch granules. The partially hydrolyzed granular starch exhibited fat-like characteristics for use in

reduced-calorie processed foods.

8.2 Biodegradable films

Small granule size substantially increases the level of starch that can be incorporated into

biodegradable films while maintaining film quality [84]. Commercial application of biodegradable

films includes garbage bags, composting yard-waste bags, grocery bags and agricultural mulches.

Commercial biodegradable films are generally manufactured from low-density polyethylene

containing degradative additives such as starch and pro-oxidants. The use of starch as a

biodegradable filler satisfies thermal stability requirements and interferes minimally with the meltflow properties required of most manufacturing applications. Starch incorporation produces a

plastic film with a porous structure, which enhances the accessibility of the plastic molecules to

oxygen and microorganisms [84, 85].

8.3 Carrier materials

Small starch granules are able to combine into interesting and potentially useful porous spheres

when spray dried with small amounts of bonding agents. A variety of bonding agents can be used

including protein, gelatin, carbox-ymethyl cellulose, guar gum, locust bean gum, starch dextrin,

pectin and alginate [86]. The spherical aggregates contain open spaces in the form of

interconnecting cavities that provide extensive porosity capable of being filled and used to transport

material within the spheres. The orifice size of the spheres is dependent on the particular spray

nozzle used. A need exists in the food industry for containment of flavor essences and other

components

in a manner that will provide for oxidative protection and for controlled release over a defined

period of time [86]. Examples would be the prolonged release of chewing gum flavor or the

containment of certain components in dry mixes until placed in water or heated to a specified

temperature. The encapsulation method using spheres of bound starch granules offers a low-cost,

food-grade package that can be produced by normal processing methods [86].

9 Conclusions

A wide range of small granule starches is available in nature. However, such starches do not see

significant commercial application. A major reason for this is the difficulty experienced in

commercial-scale purification of these starches. The development of improved methods for the

refining of small granule starches could greatly facilitate the development of new applications and

new markets for such starches.

References

[1] H. Tang, H. Ando, K. Watanaba, Y. Takeda, T. Mitsunaga: Physicochemical properties and

structure of large, medium and small granule starches in fractions of normal barley endosperm.

Carbohydr. Res. 2001, 330, 241-248.

[2] J. L. Jane, L Shen, L. Wang, C. C. Maningat: Preparation

and properties of small-particle cornstarch. Cereal Chem.

1992, 69, 280-283. [3] A. Buleon, P. Colonna, V. Planchot, S. Ball: Mini review.

Starch granules, structure and biosynthesis. Internal J.

Biol. Macromol. 1998, 23, 85-112.

[4] J. L. Jane, T. Kasemsuwan, S. Leas, A. la, H. Zobel, D. II, J. F. Robyt: Anthology of starch

granule morphology by scanning electron microscopy. Starch/Starke 1994, 46,121-129.

[5] A. D. Evers: The size distribution among starch granules in wheat endosperm. Starke 1973, 25,

303-304.

[6] G. H. Zheng, F. W. Sosulski: Physicochemical properties of small granule starches. AACC

Annual Meeting, San Diego, 1997.

[7] C. G. Oates, A. D. Powell: Bioavailability of carbohydrate material stored in tropical fruit seeds.

Food Chem. 1996, 56,405-414.

[8] G. Bultosa, A. N. Hall, J. R. N. Taylor: Physico-chemical

characterization of grain tef [Eragrostis tef (Zucc.) Trotter]

starch. Starch/Starke 2002, 54, 461-468. [9] S. K. Kumari, B. Thayumanavan:

Characterization of

starches of proso, foxtail, barnyard, kodo, and little millets.

Plant Foods for Human Nutr. 1998, 53, 47-56.

[10] L Wang, Y. J. Wang, R. Porter: Structures and physico-chemical properties of six wild rice

starches. J. Agric. Food Chem. 2002, 50, 2695-2699.

[11] E. S. M. Abdel Aal, P. J. Hucl, F. W. Sosulski: Structural and compositional characteristics of

canaryseed {Phalaris canariensis L). J. Agric. Food Chem. 1997, 45, 3049-3055.

[12] C. G. Biliaderis, G. Mazza, R. Przybylski: Composition and physico-chemical properties of

starch from cow cockle

{Saponaria vaccaha L.) seeds. Starch/Starke 1993, 45,121-127.

[13] K. J. Goering, B. DeHaas: New starches. VIII. Properties of the small granule-starch from

Colocasia esculenta. AACC 1972,712-719.

[14] K. Kulp: Characteristics of small-granule starch of flour and wheat. Cereal Chem. 1973, 50,

666-679.

[15] R. Hoover: Composition, molecular structure, and physico-chemical properties of tuber and

root starches: a review. Carbohydr. Polym. 2001, 45, 253-267.

[16] J. P. Davis, N. Supatcharee, R. L. Khandelwal, R. N. Chibbar: Synthesis of novel starches in

Planta: opportunities and challenges. Starch/Starke 2003, 55,107-120.

[17] H. J. Cornell, A. W. Hoveling, A. Chryss, M. Rogers: Particle size distribution in wheat starch

and its importance in processing. Starch/Starke 1994, 46, 203-207.

[18] V. Rasper: Investigation of starches from major crops grown in Canada on particle size and

size distribution. J. Sci. Food Agric. 1971,22,572-580.

[19] J. Chmelik: Comparison of size characterization of barley starch granules determined by

electron and optical microscopy, low angle laser light scattering and gravitational field-flow

fractionation. J. Inst. Brewing 2001, 707,11-17.

[20] A. D. Evers, C. T. Greenwood, D. D. Muir, C. Venables: Studies on the biosynthesis of starch

granules. Starke 1973, 26, 42-46.

[21] M. O. Raeker, C. S. Gaines, P. L. Finney, T. Donelson: Granule size distribution and chemical

composition of starches from 12 soft wheat cultivars. Cereal Chem. 1998, 75, 721-728.

[22] J. Chmelik: Different elution modes and field programming in gravitational field-flow

fractionation. A theoretical approach. J. Chromatogr. 1999, 845, 285-291.

[23] M. H. Moon, J. C. Giddings: Rapid separation and measurement of particle size distribution of

starch granules by sedi-mentation/steric field/flow fractionation. J. Food Sci. 1993, 58,1166-1171.

[24] K. Lorenz: Quinoa (Chenopodium quinoa) starch: Physico-chemical properties and functional

characteristics. Starch/ Starke 1990, 42, 81-86.

[25] E. Wilhelm: Peculiarities of aqueous amaranth starch suspensions. Biomacromol. 2002, 3, 1726.

[26] F. M. Anjum, C. E. Walker: Review on the significance of starch and protein to wheat kernel

hardness. J. Sci. Food Agric. 1991,56, 1-13.

[27] R. L Whistler, J. N. BeMiller, E. F. Paschall: Fractionation of starch, in Starch: Chemistry and

Technology, Academic Press, Orlando, 1987.

[28] T. Galliard: Starch: Properties and Potential. John Wiley, Chi-chester, 1987.

[29] J. A. Radley: The microscopy of starch, in Examination and Analysis of Starch and Starch

Products, 9. Applied Science Publishers, London, 1976.

[30] W. R. Morrison, D. C. Scott: Measurement of the dimensions of wheat starch granule

populations using a Coulter counter with 100-channel analyzer. J. Cereal Sci. 1986, 4,13-21.

[31] H. Dengate, P. Meredith: Variation in size distribution of starch granules from wheat grain. J.

Cereal Sci. 1984, 2, 83-90.

[32] J. H. Li, T. Vasanthan, B. Rossnagel, R. Hoover: Starch from hull-less barley; I. Granule

morphology, composition and amylopectin structure. Food Chem. 2001, 74, 395-405.

[33] A. C. Eliasson, K. Larsson: Physicochemical behavior of the components of wheat flour, in

Cereals in Breadmaking a Mo-

lecular Colloid Approach. (Ed. O. R. Fennema) Marcel Dek-ker, New York, 1983.

[34] M. Peng, M. Gao, E. S. M. Abdel Aal, P. Hucl, R. N. Chibbar: Separation and characterization

of A- and B-type starch granules in wheat endosperm. Cereal Chem. 1999, 76, 375-379.

[35] Y. Takeda, C. Takeda, H. Mizukami, I. Hanashiro: Structures of large, medium and small

starch granules of barley grain. Carbohydr. Polym. 1999, 38, 109-114.

[36] A. D. Evers, C. T. Greenwood, D. D. Muir, C. Venables: Studies on the biosynthesis of starch

granules. 8. A comparison of the properties of the small and large granules in mature cereal

starches. Starke 1974, 26, 42-46.

[37] P. Myllarinen, K. Autio, A. H. Schulman, K. Poutanen: Heat-induced structural changes of

small and large barley starch granules. J. Inst. Brewing 1998, 104, 343-349.

[38] T. J. Schoch: lodimetric determination of amylose, in Methods in Carbohydrate Chemistry

(Eds. R. L. Whistler, R. J. Smith, J. N. BeMiller, M. L. Wolfram) Academic Press, New York,

1964.

[39] L. A. Grant, N. Vignaux, D. C. Doehlert, M. S. McMullen, E. M. Elias, S. Kianian: Starch

characteristics of waxy and non-waxy tetraploid (Triticum turgidum L. var. durum) wheats. Cereal

Chem. 2001, 78, 590-595.

[40] T. S. Gibson, V. A. Solah, B. V. McCleary: A procedure to measure amylose in cereal starches

and flours with Conca-navalin A. J. Cereal Sci. 1997,25,111-119.

[41] A. C. Eliasson: Carbohydrates in food, Marcel Dekker Inc., New York, 1996.

[42] K. Radhika Reddy, R. Subramanian, Z. Zakiuddin AN, K. R. Bhattacharya: Viscoelastic

properties of rice-flour pastes and their relationship to amylose content and rice quality. Cereal

Chem. 1994, 71, 548-552.

[43] M. Naka, Y. Sugimoto, S. Sakamoto, H. Fuwa: Some properties of large and small granules of

waxy barley Hordeum-Vulgare endosperm starch. J. Nutr. Sci. and Vitaminology 1985,37,423-430.

[44] E. Chiotelli, M. Le Meste: Effect of small and large wheat starch granules on thermomechanical behavior of starch. Cereal Chem. 2002, 79, 286-293.

[45] A. W. MacGregor, R. S. Bhatty: Barley; Chemistry and Technology. American Association of

Cereal Chemists Inc., St. Paul, MN, 1996.

[46] J. Da Cruz Fransisco, J. Silverio, A. C. Eliasson, K. Larsson: A comparative study of

gelatinization of cassava and potato starch in an aqueous lipid phase (L2) compared to water. Food

Hydrocoll. 1996, 10, 317-322.

[47] T. Y. Bogracheva, Y. L. Wang, T. L. Wang, C. L. Hedley: Structural studies of starches with

different water contents. Biopolymers 2002, 64, 268-281.

[48] A. B. Soulaka, W. R. Morrisson: The amylose and lipid contents, dimensions, and

gelatinization characteristics of some wheat starches and their A- and B-granule fractions. J. Sci.

FoodAgric. 1985, 36, 709-718.

[49] M. Kugimiya, J. W. Donovan, R. Y. Wong: Phase transition of amylose-lipid complexes in

starches: a calorimetric study. Starch/Starke 1980, 32, 265-270.

[50] H. J. Von Hennig, H. Lechert, W. Goemann: Untersuchung des Quellverhaltens von Starke mit

Hilfe der Kernresonanz-Impuls-Spektroskopie. Starch/Starke 1997, 49,10-13.

[51] N. W. Taylor, H. F. Zobel, M. White, F. R. Senti: Deuterium exchange in starches and

amylase. J. Phys. Chem. 1961, 65,1816-1820.

[52] N. N. Hellman, E. H. Melvin: Surface area of starch and its role in water sorption. J. Am.

Chem. Soc. 1950, 72, 5186-5188.

[53] T. Vasanthan, R. S. Bhatty: Physicochemical properties of small- and large-granule starches of

waxy, regular, and high-amylose barley. Cereal Chem. 1996, 73,199-207.

[54] A. W. MacGregor, D. L. Balance: Hydrolysis of large and small starch granules from normal

and waxy barley cultivars by alpha-amylases from barley malt. Cereal Chem. 1980,57, 397-402.

[55] J. E. Fannon, R. J. Hauber, J. N. BeMiller: Surface pores of starch granules. Cereal Chem.

1992, 69, 284-288.

[56] A. B. Oliveira, D. C. Rasmusson, R. G. Fulcher: Genetic aspects of starch granule traits in

barley. Crop Sci. 1994, 34,1176-1180.

[57] R. F. Tester: Influence of growth conditions on barley starch properties. Int. J. Biol. Macromol.

1997, 21, 37-45.

[58] F. L. Stoddard: Survey of starch particle-size distribution in wheat and related species. Cereal

Chem. 1999, 76, 145-149.

[59] S. M. J. Langeveld, R. van Wijk, N. Stuurman, J. W. Kijne, S. dePater: B-type granule

containing profusions and interconnections between amyloplasts in developing wheat endosperm

revealed by transmission electron and GFP expression. J. Exp. Bot. 2000, 51, 1357-1361.

[60] A. M. L McDonald, J. R. Stark, W. R. Morrison, R. P. Ellis: The composition of starch

granules from developing barley genotypes. J. Cereal Sci. 1991, 13, 93-112.

[61] W. R. Morrison, H. Gadan: The amylose and lipid contents of starch granules in developing

wheat endosperm. J. Cereal Sci. 1987, 5, 263-276.

[62] M. S. Peng, M. Gao, M. Baga, P. Hucl, R. N. Chibbar: Starch-branching enzymes

preferentially associated with A-type starch granules in wheat endosperm. Plant Physiol. 2000, 724,

265-272.

[63] A. H. Schulman, H. Ahokas: A novel shrunken endosperm mutant of barley. Plant Physiol.

1990, 78, 583-589.

[64] J. Tyynela, A. H. Schulman: An analysis of soluble starch synthase isozymes from the

developing grain of normal and shx c. Bomi barley (Hordeum vulgare). Plant Physiol. 1993, 89,

835-841.

[65] J. Tyynela, M. Stitt, A. Lonneborg, S. Smeekens, A. H. Schulman: Metabolism of starch

synthesis in developing grains of the shx shrunken mutant of barley {Hordeum vulgare). Plant

Physiol. 1995, 93, 77-84.

[66] A. Borem, D. E. Mather: Mapping quantitative trait loci for starch granule traits in barley. J.

Cereal Sci. 1999, 29, 153-160.

[67] J. S. Swanston, R. P. Ellis, I. M. Morrison, G. R. Mackay, M. F. B. Dale, A. Cooper, S. A.

Tiller, C. M. Duffus, M. P. Cochrane, R. D. M. Prentice, L. Paterson, A. Lynn: Combining highamylose and waxy starch mutations in barley. J. Sci. Food Agric. 2001,87,594-603.

[68] A. H. Schulman, K. Kammiovirta: Purification of barley starch by protein extraction.

Starch/Starke 1991, 43, 387-389.

[69] A. A. M. Andersson, R. Andersson, P. Aman: Starch and byproducts from a laboratory-scale

barley starch isolation procedure. Cereal Chem. 2001, 78, 507-513.

[70] S. T. Lim, J. H. Lee, D. H. Shin, H. S. Lim: Comparison of protein extraction solutions for rice

starch isolation and effects on residual protein content on starch pasting properties. Starch/Starke

1999, 57,120-125.

[71] X. J. Xie, P. A. Seib: Laboratory wet-milling of grain sorghum with abbreviated steeping to

give two products. Starch/ Starke 2002, 54, 169-178.

[72] J. Szczodrak, Y. Pomeranz. Starch and enzyme-resistant starch from high-amylose barley.

Cereal Chem. 1991, 68, 589-596.

[73] F. van Esch: The efficiency of hydrocyclones for the separation of different starches.

Starch/Starke 1991,43, 427-431.

[74] M. Radosavljevic, J. Jane, L. A. Johnson: Isolation of amaranth starch by diluted alkalineprotease treatment. Cereal Chem. 1998, 75,212-216.

[75] L. Wang, Y. Wang: Comparison of protease digestion at neutral pH with alkaline steeping

method for rice starch isolation. Cereal Chem. 2001, 78, 690-692.

[76] A. M. L. McDonald, J. R. Stark: A critical examination of procedures for the isolation of

barley starch. J. Inst. Brewing 1988,94,125-132.

[77] E. Wilhelm, H. W. Themeier, M. G. Lindhauer: Small granule starches and hydrophilic

polymers as components for novel biodegradable two-phase compounds for special applications. 1:

Separation and refinement techniques for small granule starches from amaranth and quinoa.

Starch/Starke 1998,50,7-13.

[78] G. H. Zheng, R. S. Bhatty: Enzyme-assisted wet separation of starch from other seed

components of hull-less barley. Cereal Chem. 1998, 75, 247-250.

[79] J. Zhao, R. L. Whistler: Isolation and characterization of starch from amaranth flour. Cereal

Chem. 1994, 71, 392-393.

[80] R. L. Whistler, U.S. Pat. 5453281 (1995). Lafayette Applied Chemistry Inc.

[81] J. A. Radley: The minor starches of commerce: the manufacture of rice, arrowroot and sago

starch, in Starch Production Technology. (Ed. J. A. Radly) Applied Science Publishers, London,

1976.

[82] E. Malinski, J. R. Daniel, X. X. Zhang, R. L Whistler: Isolation of small granules and

determination of their fat mimic characteristics. Cereal Chem. 2003, 80,1-4.

[83] R. L. Whistler, U.S. Pat. 5651828 (1997). Lafayette Applied Chemistry Inc.

[84] S. T. Lim, J. L. Jane, S. Rajagopalan, P. A. Seib: Effect of starch granule size on physical

properties of starch-filled polyethylene film. Biotechnol. Prog. 1992, 51-57.

[85] N. T. Ahamed, R. S. Singhal, P. R. Kulkarni, D. D. Kale, M. Pal. Studies on chenopodium

quinoa and amaranthus pani-culatas starch as biodegradable fillers in LDPE films. Carbo-hydr.

Polym. 1996, 37,157-160.

[86] J. Zhao, R. L. Whistler: Spherical aggregates of starch granules as flavor carriers. Food

Technol. 1994, 48,104-105.

(Received: March 28, 2003) (Revised: July 18, October 10, 2003) (Accepted: October 13, 2003)