Section 3 d ethanol

advertisement

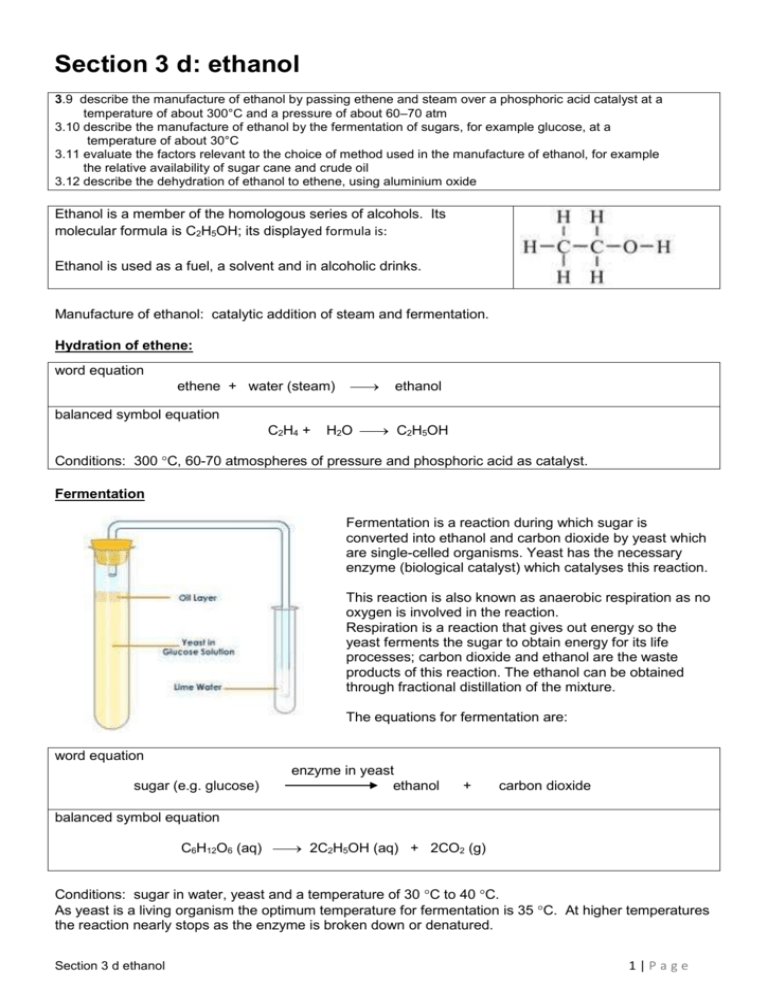

Section 3 d: ethanol 3.9 describe the manufacture of ethanol by passing ethene and steam over a phosphoric acid catalyst at a temperature of about 300°C and a pressure of about 60–70 atm 3.10 describe the manufacture of ethanol by the fermentation of sugars, for example glucose, at a temperature of about 30°C 3.11 evaluate the factors relevant to the choice of method used in the manufacture of ethanol, for example the relative availability of sugar cane and crude oil 3.12 describe the dehydration of ethanol to ethene, using aluminium oxide Ethanol is a member of the homologous series of alcohols. Its molecular formula is C2H5OH; its displayed formula is: Ethanol is used as a fuel, a solvent and in alcoholic drinks. Manufacture of ethanol: catalytic addition of steam and fermentation. Hydration of ethene: word equation ethene + water (steam) ethanol balanced symbol equation C2H4 + H2O C2H5OH Conditions: 300 C, 60-70 atmospheres of pressure and phosphoric acid as catalyst. Fermentation Fermentation is a reaction during which sugar is converted into ethanol and carbon dioxide by yeast which are single-celled organisms. Yeast has the necessary enzyme (biological catalyst) which catalyses this reaction. This reaction is also known as anaerobic respiration as no oxygen is involved in the reaction. Respiration is a reaction that gives out energy so the yeast ferments the sugar to obtain energy for its life processes; carbon dioxide and ethanol are the waste products of this reaction. The ethanol can be obtained through fractional distillation of the mixture. The equations for fermentation are: word equation sugar (e.g. glucose) enzyme in yeast ethanol + carbon dioxide balanced symbol equation C6H12O6 (aq) 2C2H5OH (aq) + 2CO2 (g) Conditions: sugar in water, yeast and a temperature of 30 C to 40 C. As yeast is a living organism the optimum temperature for fermentation is 35 C. At higher temperatures the reaction nearly stops as the enzyme is broken down or denatured. Section 3 d ethanol 1|Page After a few days of fermentation, the process stops as the high alcohol content (maximum is around 14%) kills off the yeast. The aqueous alcohol can be concentrated further by fractional distillation which is what is done in the production of spirits such as whisky, brandy, rum and so on. Comparing both methods of manufacturing ethanol Factor to consider Hydration of ethene Availability of resources Countries where land is scarce or not easy to cultivate and have oil reserves, hydration of ethane will be the favoured process. Reaction conditions 300 C, 60-70 atmospheres of pressure and phosphoric acid as catalyst. This means a lot more energy needed. Faster Rate of reaction Rate of production Quality of product Continuous process, keeps going Ethanol is the only product (pure); a higher yield. Fermentation In countries with no crude oil reserves ethanol is more likely to be made by the fermentation method; in particular if the climate allows sugar cane to grow well and there is plenty of land available sugar in water, yeast and a temperature of 30 C to 40 C. Slow as takes several days Batch process: needs to be stopped at time to collect ethanol and started again. Ethanol is part of a mixture that still contains water, yeast and other sediments; needs further purification to get ethanol – lower yield. Dehydration of ethanol This is basically the reverse reaction to the catalytic addition of steam to ethene as dehydration means a reaction in which a water molecule is removed. The apparatus is shown below. This reaction is also sometimes referred to as the cracking of ethanol. This is basically the reverse reaction to the catalytic addition of steam to ethene as dehydration means a reaction in which a water molecule is removed. The apparatus is shown below. This reaction is also sometimes referred to as the cracking of ethanol. Conditions: heat and a catalyst such as aluminium oxide or porcelain. (from http://www.practicalchemistry.org/experiments/dehydration-of-ethanol-to-form-ethene,237,EX.html visited on 10/1/2011) Section 3 d ethanol 2|Page