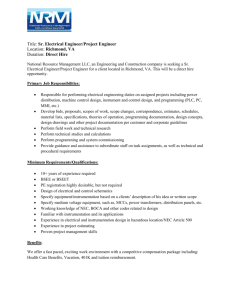

Process Engineer

advertisement

Job Description (Exempt) Position Title: Location: Reports To: I. Process Engineer Chicago Heights, IL Director of Engineering Date: Grade: July 1, 2014 H-G Primary Purpose/Objectives of the Job: The Process Engineer initiates, develops and helps implement projects to lower costs, improve quality, evaluate new technologies, evaluate new raw materials, and/or generate new business. This includes studying existing and new processes to help identify and implement improvement opportunities. The engineer also initiates projects that make plant facilities safer; reduce costs in such areas as energy, maintenance, and raw material usage; maintain the infrastructure of company facilities; and increase capacity. The process engineer also develops engineering studies (order of magnitude estimates, feasibility studies, etc.) to support business decisions. II. Key Responsibilities: Approximate % of time PROCESS DEVELOPER Develop and/or assist others in developing workable process solutions to meet the requirements of the business (e.g. increased capacity, new product development, reduced costs, improved quality, improved process safety, improved environmental impact). Investigate, research, assess, evaluate, and/or propose ideas for new or modified processes and products. Clarify process issues early in the project life in order to minimize resource utilization and development costs. As a rule, the Process Engineer will use a structured approach in his/her role as a process developer. 50% PROCESS SUPPORT PROVIDER & VALIDATOR Provide technical support to the manufacturing plants within Innophos, including conceptualization of capital projects, troubleshooting, training, management and/or providing support of process changes (MOC) and implementation of the specified solutions. In this role, the Principal Process Engineer will validate MOC projects as needed, and either lead or take an active part in post-start-up reviews and assessments. As a rule, a structured project management approach will be used. 25 % KNOWLEDGE CAPITALIZATION GUARDIAN Document the technology associated with the manufacture of company products: ensure that the practical and theoretical knowledge on which equipment sizing, critical variables set points, process deviation decision charts and training manuals are based is adequately documented. 10% TECHNOLOGY CONSULTANT Provide technical input to the business, manufacturing, R&D, and marketing organizations in support of process improvement efforts, R&D programs, capital plans, and business plans. Consolidate company intelligence on competitor technology. 15% OTHER Maintain safe and environmentally sound operation of units through periodic safety meetings, encourage reporting of all incidents, investigation and corrective actions proposal for all incidents, as well as ensuring that no major environmental incidents occur via proper inspections. Help ensure food safety and product quality through the proper design of manufacturing processes. III. Required Skills, Knowledge and Experiences: (essential to the position) Minimum Bachelor degree in chemical engineering Preferred 10 years engineering experience in a manufacturing environment, chemical industry experienced desired Practical knowledge of chemical processing design calculations and equipment Demonstrated ability and growth potential to progress to a leadership position within the organization Good verbal/written communication and organizational skills Basic project cost estimating and scheduling ability desirable Familiarity with field construction methods and safe work practices desirable Proficient in using engineering and business related computer software IV. Dimensions: Number of employees supervised: None Directly Exempt: Non-exempt: Hourly: Total: Indirectly V. Nature and Scope: Major Position Challenges: Initiation, development, and implementation of successful projects, on time, within budget, and with no EHS incidents or issues. Cost reduction/EHS concerns. Staying abreast of latest technology. Devising innovative solutions to both simple to complex problems. Workflow: Work is assigned by the Director of Engineering. Due to the plant’s size, age and diversity of products, assignments are never the same with projects varying extensively in both cost and complexity. Most projects originate within the production/process engineering groups. Corporate projects and projects at other plant sites can also be assigned to the engineer. Environment: Position is subject to plant/corporate policies and procedures. Completion deadlines are usually dictated by production or business needs and requirements. Safety and environmental concerns are always a high priority. Latitude: New, innovative solutions of problems are always encouraged. Restrictions are limited to keeping within the risk tolerance of the company. Key Contacts: Plant/Corporate technical personnel, Production and Maintenance Management, Plant EHS group, Vendors, Outside Contractors VI. Physical Requirements: (Describe the physical abilities required to perform the essential job functions, although exceptions may be made to these requirements based on reasonable accommodations. Use additional space as needed.) ACTIVITY Lifting Squatting Climbing Standing Bending Operates mobile equipment Operates heavy equipment Temp. changes Office Work Plant field visits CONSTANT FREQUENT OCASS RARE X X X NEVER X X X X X X X COMMENTS Max 20 lbs. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. Constant Frequent Seldom Rare 80% of more of the time 60 – 70 % of the time 30 – 60 % of the time < 30 % VII. Organizational Chart: Director of Engineering Process Engineer The duties described herein are representational of the position/role and are not necessarily all inclusive. Some responsibilities may differ from those outlined and other duties, as assigned, are part of this and any job. Disclaimer Updated: May 30, 2014 An Equal Opportunity Employer