International Review of Electrical Engineering (I.R.E.E.), Vol. xx, n. x

Advanced Industrial Crane Controller Based on AC Wound Motor

F. Kolonić, A. Poljugan, A. Slutej

Abstract –Developed speed crane control system which is based on a wound AC motor is an

advanced system for heavy duty tasks especially in the field of industrial cranes and other heavy

duty material handling systems. In order to avoid problems with a mechanical feedback device

(coupling, vibration, no space for build in, etc.), actual speed information is calculated from a

rotor voltage frequency estimation unit. The controller is developed as a modular system capable

to deal with control, communication, protection and other specific industrial demands. It is a

multiprocessor system in stand-alone version realized with microcontroller MC68332 (application

program running), two SAB 82532 microcontrollers (distributing control system), two MC68302

(process I/O communication) and two DSP ADMC300 (speed and electromagnetic torque

estimation). Speed and torque estimation algorithms are realized on the separate hardware

modules and integrated with other components in the control system via fast communication link.

Investigation of sensorless speed and torque control as well as fully automatic control of the rotor

resistor switching, was the crucial point in the design process of a new industrial drive controller

aimed mostly for the revitalization of industrial cranes. Performance of the speed and torque

sensorless crane controller is evaluated on the laboratory testbed and in different real industrial

environment.

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved.

Keywords: crane control, revitalization, rotor frequency measurement, speed estimation, torque

estimation, wound AC motor.

kR

Nomenclature

E2(U ,V ,W )

- non-filtered (measured) rotor voltage of

E2 filt

the U, V, W phase

- filtered rotor voltage

f ALL _ PHASE - estimated rotor voltage frequency in the

fs

f1

f2

f 2(U ,V ,W )

low frequency operating regime

- cut-off frequency of the rotor voltage LP

filter

- rotor frequency estimation error

- estimated rotor voltage frequency mean

value in high frequency operating regime

- sampling frequency of a speed estimation

- stator frequency

- rotor frequency (measured, estimated)

- frequencies of the rotor voltages U,V,W

id

I lim

- current disturbance signal

- stator current limit

is

is ( a ,b , c )

- stator current vector

- stator current components in abc

is ( , )

stationary frame

- α, β components of the stator current

fc

ferr

f MEAN

Manuscript received January 2007, revised January 2007

K0 ,.., K3

nlev

n filt

ns

n, n2

p

Rc

RiC , RiW

Rm

- percent change in resistor value caused by

temperature

- rotor contactors

- speed level for frequency measurement

method switchover

- calculated rotor speed of the last sampling

- synchronous mechanical rotor speed

- rotor mechanical speed

- number of pole pairs

- cable resistance, from rotor to ext. resistor

- ith external rotor resistor value in cold and

warm case

- rotor phase resistance

- stator phase resistance

- external rotor resistors

- equivalent motor unity resistance

R100

- motor slip

s

- rated (nominal) slip

sn

sign( sl ) - sign of the motor slip (oversynchronous “-“

sign(tq) - sign of the motor torque

siCM , siWM - maximal slip for ith external rotor resistor for

cold and warm case

- possible motor torques in cold and warm

Tic , Tiw

case

Rs

R1 ,.., R5

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights

reserved

F. Kolonić, A. Poljugan, A. Slutej

TIME _ U (V ,W ) - the number of pulses between two

consecutive zero voltage crossing of

the rotor phase U,V,W

- maximal motor torque for ith external

TM

resistor

- voltage disturbance signal

ud

us

us ( a ,b , c )

- stator voltage vector

- stator voltage components in a,b,c

u s ( , )

frame

- α, β components of stator voltage

s

s ( , )

- stator flux vector

- α, β components of stator flux

I.

Introduction

In the last fifty-sixty years AC wound motors have

been widely used in many industrial tasks, such as

material handling systems, pipe and paper mills, steel

and rolling mills, container loading/unloading cranes,

power plants, engineering workshops, etc. In the

beginning, the control of these drives was mainly

focused on the rotor motor side using speed based rotor

contactor switching for discontinuous additional

external rotor resistor change. Thanks to that, it was

surely the unique electrical AC machine at this time,

capable to start with maximal available torque and at the

same time drawing the minimal stator current from the

mains. At that time it was a very pragmatic solution to

use AC wound motors for those tasks, because of its

high robustness and very simple and effective

speed/torque control from the rotor side. Emerging

power electronic switches, especially thyristors, with an

additional AC/AC converter in the stator side, AC

wound motors have got a new perspective in the control

domain. Since the basic phase thyristor control from

stator side is not satisfactory (limiting control region

app. 10 to 30% around the nominal speed), the resistor

control from the rotor side was added which resulted in

outstanding features. With appropriate external rotor

resistors switching and phase control of the stator

voltage, all working points within the nominal speed and

torque of four quadrant (4q) operation can be reached.

The history of such controller type started in 1970's,

when the Swedish company ASEA developed analogue

ASTAT controller specially intended for the material

handling crane purposes, [1]. It was designed for heavy

duty installations with static components which required

less space than a comparable relay based systems for the

same purposes and with tachogenerator connection for

the speed control loop. The voltage and current ratings

were 3x220-3x500V and 18A-1700A. All the control

electronics were in modular exchangeable circuit boards

and the system was proven in more than 6.000

installations.

Controller had all needed function for the crane

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

applications but suffered in the lack of flexibility

(controller’s parameter change), pure communication

and monitoring capabilities, and from time to time had

problems with components sensitivity due to the hard

environmental conditions (temperature, dust, humidity).

Afterwards, Siemens designed the SIMOTRAS HD

crane controller with voltage and current ratings from

3x220-3x500V and 60A-900A, [2]. It was characterized

with identical functions as ASTAT®, but built in a new

technology, on the same platform as SIMOVERT

Masterdrives and SIMOREG DC MASTER for DC

drives. It uses tachogenerator and pulse encoder as

speed feedback devices. The communication with the

controller is realized via PROFIBUS-DP and as a user

interface it’s possible to use operational panel OP1S or

PC-program SIMOVIS. Comparing to the old analogue

ASTAT® version, the advantage is more flexibility, in

user interface and in communication capabilities with

other devices in complex automation process.

The age of digital technique gives completely new

dimensions in the crane control possibilities. Request

from unavoidable industrial automation in the complex

industrial systems resulted in the use of smart

components for every specific function in the frame of

complex industrial task. Considering the crane control

issues, the requests are very large. With the new

technical age, the crane controller has to be seen as an

open control system from outside. Recognizing that,

some OEMs (Original Equipment Manufacturers)

developed new generation of crane controllers based on

the wide spread AC wound motors, intended not only

for the new drives, but for a revitalization of the old

drives too.

The Purpose of revitalization is not only to extend

the lifetime of electrical equipment, but also to include

such control systems with new equipment on the global

trend towards information systems which see cranes as

crucial components in different industrial applications,

e.g.

material

handling

systems,

container

loading/uploading etc.

The crane’s logistic information system is more

and more used for production cranes. The overriding

level has to know precisely where materials (or cranes)

are located and has to perform all operations quickly,

consistently and reliably, [3],[4]. It is used for

production orders, crane condition monitoring as well as

for the set-up of crane motion controllers. The requests

on the new advanced crane controller (revitalized or

new) to communicate with an existing or new plant

management system must be fulfilled.

The Swedish company ABB together with the Faculty

of Electrical Engineering and Computing, University of

Zagreb (Croatia) has developed the first version of the

new digital ASTAT® crane controller in the beginning

of 2000, [5]. The first installed digital ASTAT®

controller was in EOT (Electric Overhead Travelling)

hoist crane in Husum paper mill (Sweden) in 2000.

Today, the improved version of this controller type is

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

the most advanced controller in the field of crane control

with AC wound motor, where the speed and torque

control can be performed without mechanical sensors.

Some industrial applications, which are supported by

this controller, show diversity of functions. For example,

16t and 170t hoist cranes in nuclear plant Forshmark

(Sweden); 5 winch coordinated drive for power fleet

mining mooring system with 80kw motors (Bangka,

Indonesia); electrical shaft in steel factory Avesta

(Sweden); 2 EOT ladle cranes; 3 planetary gearbox

drive for 450t/80t (1.4MW) ladle hoist in BaoSteel,

Baoshan steel making plant (China), etc. Some of these

applications use estimated speed and/or torque feedback

for the main control tasks.

II.

Control System Description

The structure of the developed controller is

presented in Fig. 1. Application program is running on

the Main control board in Control module, built up

around the Motorola MC68332 microcontroller unit and

supported by a local operating system. The Main control

board exchanges data with process by Process units (one

unit is in Main control board, two process units are

Cabin unit No.1 and No.2.). It is possible to connect up

to 16 process I/O (Input/Output) units to the Main

control board, [3], [4], [6].

The frequency of the rotor voltage (needed for speed

estimation and presented in Control module as Rotor

frequency estimation unit, Fig.1.) is determined by

advanced digital filtering. Electromagnetic torque

estimation is realized in Torque estimation unit in the

same Control module.

Estimated torque is used as actual torque for the torque

control loop. For actual speed detection in

oversynchronous regenerative mode of operation when

speed sensorless control is used (no mechanical speed

feedback), the sign of torque is used for accurate

oversynchronous speed determination. In order to find

optimal rotor resistor for each working point, automatic

on-line rotor resistor optimization requires actual torque

calculation too. This optimal resistor switching logic

will be explained in details in chapter V.

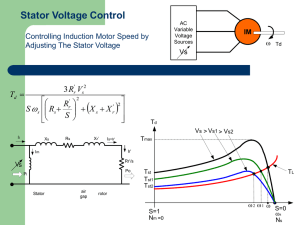

By means of a thyristors pairs in each phase, stator

voltage is continuously controlled with AC/AC phase

controlled thyristor converter, Fig.2, [7]-[9]. The Main

control board sends the firing pulses to the Firing unit in

Thyristor module. Using five thyristor pairs (three pairs

in each phase and two pairs for reversing), four quadrant

operation is realized, Fig.2.

Forward torque direction is defined by thyristor pairs 1,

2 and 3 (forward bridge) and reverse torque direction by

1, 4 and 5 thyristor pairs (reverse bridge). In the hoist

type of motion, when the drive is lowering the load,

motor may regenerate energy back to the line in the most

robust manner. Due to the safety reasons, the rotor

resistor is minimized in this control region, ensuring

regenerative mode with slightly higher motor speed than

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

synchronous and the special open loop control routine is

then activated bypassing outer speed control loop, [9].

Power supply

Signalization

Fault tracing

Cabin unit

No.1.

Communication to

high auttomation

level

Signalization

Fault tracing

Cabin unit

No.2.

Thyristor

module

Control module

Main control board

PC

Servis terminal,

Service Tool,

Developing

system

Process

unit

Rotor

frequency

estimation

unit

Firing unit

with current

feedback

Rotor

adaptation

unit

Wound

motor

Brake

Torque

estimation

unit

External

rotor

resistors

Rotor contactors

Fig.1. The block structure of industrial crane controller

The Main control board communicates with all other

units in the drive controller and includes all usual

function for crane control such as joystick handling,

limit switch logic with slow down and stop, automatic

brake application approaching zero speed, automatic

rotor contactor switching logic, etc.

All control system connections to high automation

level (Master/Follower, Motion control, Overriding

control communication), and Process control (including

cabin I/O communication) are made by optical fiber.

The communication is realized by two communication

microcontrollers SAB82532. Details can be found in

[3]-[6].

speed

L3

L2

3

4

L1

2

Tyristors

1, 2 i 3

1

5

torque

M

Tyristors

1, 4 i 5

a)

b)

Fig.2. Four quadrant AC/AC thyristor converter a) and torque vs.

speed drive characteristics b).

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

With such controller design applied for

revitalization, all requirements are fulfilled for the

integration of these drives in the CDA (Complex

Distributed Application), based on the crane control

network facilities, [10].

The general description of the speed control system is

presented in Fig.3. The inner current control loop is

subordinated to the outer speed or torque control loop,

selected via parameter. Controllers are generally PID

type, with parameters and structure dependent on the

specific industrial applications. Usually, reference value

can be sent from master or cabin I/O units using

joystick, or from overridden system via communication

link. Optionally, speed feedback can be pulse encoder

(E), tachogenerator (TG) or estimated speed (soft speed

sensor). Considering nonlinear relationship between

motor torque and current, nonlinear compensation block

is added.

torque

estimation

torque

controller

torque/speed

control

nref

+

+

n

Speed (torque)

reference

handling

-

PID

torque direction

logic selector

torque/speed

control

+

PID

speed

nonlinear

controller compensation

is

-

PID

arcos

AC/AC

converter

current

controller

AM

u

TG

E

R

stator current

scaling

rotor resistor

selection logic

speed feedback

scaling

speed feedback

select

speed

estimation

Fig.3. Simplified control block structure of industrial crane controller based on the wound AC motor

The automatic on-line rotor resistor optimization

algorithm, i.e. rotor resistor switching (selection) logic,

insures minimal stator current taking into consideration

the momentary line voltage and required torque. Plug

braking and oversynchronous regenerative braking in

hoisting mode is possible.

In short, this controller is like a modern car; the

control system insures cruise control (stator voltage

control) and automatic gearbox (optimization of rotor

characteristics).

Speed and torque estimation logic as a separate plugin unit (according to modular design strategy).

The speed and torque estimator are developed using a

DSP based microprocessor boards in order to fulfill

signal processing requirements, Fig.4. These boards are

integrated in the modular structure of the industrial

control system via I/O unit using high speed serial link

RS422 (speed 1-4Mbs).

III. Basic concept of a speed estimation

In order to avoid mechanical speed sensor or/and

ensure a speed measurement devices redundancy when

mechanical speed sensor exists, the speed estimation

system was developed.

Before speed estimation process analysis it has to be

emphasized that design process is based on a strictly

defined industrial sponsor’s requests frame. This frame

summarizes the following issues:

AC wound motor as the actuator for the crane drive

applications,

Realization of the stator voltage control by means of

AC/AC 4q thyristor phase converter,

Optimization of the speed-torque characteristics by

means of the external rotor resistors change,

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

Fig.4. The speed and torque estimator boards (hardware realization);

speed estimator (upper board), torque estimator (bottom

board)

Considering the speed estimation, the conventional

techniques used for the vector controlled squirrel cage

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

induction machine (Field Oriented Control, FOC) can

not be used in this application. That is why different

solutions for the speed estimation considering the above

defined sponsor's requests frame were needed. Since a

wound motor is used, rotor voltage can easily be

measured on the rotor rings, [11]. The idea for the speed

estimation can therefore be described with the simple

well known relations,

f 2 s f1 ;

n (1 s) n s

between 0-120 Hz. That is the reason why the adaptive

filter was designed. The filter selects appropriate cut-off

frequency, based on the speed estimator output value,

Fig.5.

1

1 sT

E2

1

1 sT

1

1 sT

E2filt

fc

(1)

low_freq

III.1. Rotor voltage frequency measurement

Because the large amount of higher harmonics

produced by stator phase controlled AC/AC converter is

transformed on the rotor, low pass rotor voltage filtering

must be applied to the rotor voltage frequency

estimation. This is connected to the desirable frequency

(speed) estimation accuracy. Rotor frequency is

determined by measuring the time period between two

consecutive zero passing of the filtered rotor voltage

waveform. For specific drive operating conditions (e.g.

reversing from over synchronous regenerative speed),

the frequency of the rotor voltage may be approximately

|nfilt|

<

fc/2

fc

nlev

Fig.5. Block structure of the realized variable rotor voltage filtering

The presented filter is variable in the sense of cut-off

frequency change, but the filter structure, type and order

remains unchanged. The base structure of the variable

filter is the cascade of the three 1st order low pass (LP)

filters. The main criterion for the selection of an

appropriate cut-off frequency fc is the calculated rotor

speed of the last sample nfilt, Fig.5, and Fig.6., [9].

Rotor frequency measurement in the HIGH frequency operating regime

|nfilt|

relay

E2U

time

positive

derivation measurement

LP filter

f2U

T

|nfilt|

nlev

|nfilt|

relay

E2V

positive

time

derivation measurement

LP filter

f2V

T

|nfilt|

E2W

relay

MEAN

VALUE

fMEAN

>

fALL_PHASE

fMEAN

low_freq

f2

positive

time

derivation measurement

LP filter

f2W

T

Rotor frequency measurement in the LOW frequency operating regime

time

positive/negative

measurement

derivation

fALL_PHASE

OR

T

Fig.6. Simplified block diagram of the frequency (speed) estimation algorithm

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

International Review of Electrical Engineering, Vol. xx,

n. x

International Review of Electrical Engineering (I.R.E.E.), Vol. xx, n. x

25

E2-filt [V]

E2 [V]

20

15

f2=3,5 Hz

10

5

t[s]

0

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

-5

-10

-15

-20

-25

a)

200

E2 [V]

E2-filt [V]

150

100

50

t[s]

0

0

0,005

0,01

0,015

0,02

0,025

0,03

0,035

0,04

-50

The sampling frequency of the rotor and stator

frequencies measurement unit is 10 kHz, so the

estimation error with cycle ΔT=0.1ms is

T

f err (%)

100 T f 100 0.01 f . (3)

T

The error is directly proportional to the frequency, e.g. if

the estimated frequency is 100Hz, error is 1%.

For the low rotor voltage frequencies (less than 25

Hz), time between two consecutive zero passes (positive

and negative) of any rotor voltage (U, V or W) is

measured and estimated frequency fALL_PHASE is derived.

This modification provides six times faster refreshment

of the frequency (speed) estimated value, which is

important for the stability of the speed control loop. For

example, if the rotor voltage frequency is 5 Hz, then

refreshment time (time needed to establish new

estimated value) will change from 200 ms to 200/6=

33,3 ms. The illustration of the rotor voltage frequency

measurement modification is shown in Fig.8.

f2=41 Hz

E2 [V]

Manuscript received January 2007, revised January 2007

100

0

-100

T/6

-200

Based on the comparison between the estimated speed

absolute value and predefined value, the selection

between the two filter cut-off frequencies is provided by

signal selector low_freq, Fig.5. There is a possibility of

a more cut-off frequency values selection, but applied

testing shows that the increasing number doesn’t

improve considerably estimation performance, [12].

Results of filtering for the rotor voltage frequencies 3,5

Hz and 41 Hz is shown in Fig.7.

If the drive operating points result in the rotor voltage

frequencies lower than a predefined limit (signal nlev,

Fig. 6.), another frequency estimation algorithm will be

activated. It is achieved by the same low_freq selector,

in the block Rotor frequency measurement in the LOW

frequency operating regime, see Fig. 6. In this algorithm

rotor frequency measurement is based on the time

distance between two consecutive zero voltage crossing

of all three rotor phases (signal fALL_PHASE). For the high

rotor voltage frequencies region (e.g. over 25 Hz, close

to the rated condition) frequencies for each rotor phase

f2U, f2V and f2W are calculated from non-filtered rotor

phases E2U, E2V, E2W, and the mean value estimated

frequency fMEAN is derived.

The zero rotor voltage passing is determined by a

positive derivation block which produces impulses for

time counter, Fig.6. Then the frequency of the rotor

voltage is calculated according to the equation

3 fs

.

(2)

f2

TIME _ U TIME _ V TIME _ W

-300

b)

Fig.7. Original and filtered rotor voltage waveform with frequency

20Hz a) and 41HZ b).

-400

-200

200

300

-150

400

-100

T/2

0

0.002

0.004

0.006 0.008

t [s]

0.01

0.012

0.014

0.014

0.018

0.02

Fig. 8. Illustration of the rotor voltage frequency measurement

modification

Based on the Fig.6, the frequency estimation

algorithm is experimentally verified on the speed control

system, Fig. 9, where the speed reference is changed

from +nmax to -nmax. The frequency change is close to

100 Hz (maximal slip is s2). One can notice that the

rotor voltage frequencies before and after speed

reversing are practically the same, but the speed values

have different sign. This indicates that for speed

determination some drive condition signals have to be

used in order to establish exact speed values. Block

diagram of the rotor voltage frequency estimation

realized with digital signal processor ADMC 300 is

presented in the Fig.10.

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights

reserved

F. Kolonić, A. Poljugan, A. Slutej

120

f2 [Hz]

III.2. Rotor speed measurement

100

80

It is simple to calculate the estimated speed from the

estimated frequency (2) by knowing the right position of

motor operating point inside 4q operation region of

speed/torque characteristics. Actual motor speed is

calculated using equation

sign(tq) 60 f1 signsl f 2

.

(4)

n

p

Characteristics of the speed estimator for 10% and

100% square wave speed reference in both directions

are presented in Fig.11. and Fig.12. The comparison

between speed signal from tachogenerator (TG)

feedback device and estimated speed from the rotor

voltage frequency measurement has been experimentally

performed. The experiment is based on the control

scheme in Fig.3, where the speed control loop is closed

with the mechanical feedback sensor (TG). As it can be

seen from experiments in Fig.11. and Fig.12, the speed

estimation error in steady state is smaller when the speed

reference is set as +100% (-100%) than +10% (-10%).

Speed error is larger in transient state in both cases; it is

due to the inherently slow process of the frequency

estimation which increases refreshment time of the new

estimated frequency value.

60

40

20

t [s]

0

0.03

1.63

3.22

4.81

6.41

Fig.9. Estimated rotor voltage frequency under full speed reversing

(from +n_max to –n_max)

It is possible to estimate frequency and speed for 4

motors at the same time. After the first stage of analogue

signal processing and A/D conversion in the second

stage, digital filtering of rotor voltages is performing in

the third stage. After that, information is sent to the

Process I/O unit via fast serial RS422 link, see Fig.1.

motor 1.

ANALOGUE

SIGNAL

PROCESSING

(rotor voltages

adoption unit)

motor 2.

motor 3.

DIGITAL

FILTERING

A/D

conversion

motor 4.

ROTOR

VOLTAGES

comm.

link to

control

process

board

Fig.10. Block diagram of the rotor voltage frequency and speed

estimation realized with digital signal processor

SPEED ERROR [rpm]

SPEED [rpm]

(2)

(1)

time [s]

time [s]

a)

b)

Fig.11. Estimated (1) and measured (2) speed a), estimated speed error b) for 10% speed reference (150 rpm)

SPEED [rpm]

SPEED ERROR Speed

[rpm] error (w RFM -w TACHO)

Speed(RFM and TACHO)

80

1500

60

40

speed(r/min)

speed(r/min)

1000

500

0

-500

(1)

-1000

20

0

-20

-40

-60

(2)

-1500

-80

0.1

2.9

5.8

8.6

11.5

14.3

time [s] time(s)

c)

17.2

0.1

2.9

5.8

8.6

11.5

14.3

17.2

time

[s]

time(s)

d)

Fig.12. Estimated (1) and measured (2) speed a), estimated speed error b) for 100% speed reference (1500 rpm)

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

The speed estimation equation (4) is valid as long as

the rotor voltage frequency is properly estimated. There

are three basic (specific) operation states where 4q

speed control system, based on the estimated speed,

doesn't work properly. Those are: AC/AC converter

dead time (switch-over state), operation region with

small load and operation region with small slip (close to

synchronous).

For the purpose of accurate speed estimation in the all

operating regimes, the speed estimation freezing logic

(SEFL) is designed, Fig.13. It should be emphasized that

the proposed logic can eliminate all influences caused

by specific operation states on the estimated speed

accuracy. The estimator output nest is frozen every time

when the new speed estimated value is physically

unacceptable. Physical acceptability means that the

difference between two consecutive samples of the

estimated speed cannot be significantly large (a few

percent of the estimator output value).

speed reference change, as opposed to SEFL (green

line), which works correctly.

dE2/dt>0

n_ref [rpm]

1200

1000

800

600

400

200

t [s]

0

-200

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

5,5

6

6,5

7

7,5

8

8,5

-400

-600

-800

-1000

-1200

-1400

-1600

Fig.14. Comparison between

a) estimated

reverziranje speed with (green) and

without (red) use of the output freezing logic in the case of speed

1600

n_est_nofreeze

n_ref

[rpm]

n_taho [rpm]

n_est_noFIFO

[rpm] rpm)

n_est [rpm]

reference

change

(from

1500 rpm

to -1500

1400

1200

n_taho [rpm]

n_est_noFIFO [rpm]

n_est [rpm]

n_ref [rpm]

Unloading the machine from ~50 % of Tn to zero, leads

1400

to

a similar problem, Fig.15. Because of the speed

1200

1000

increase,

control system requests reverse torque in order

to800

equalize

reference and actual speed value. After the

600

t [s]

control

system processing time, which includes

400

200

converter's

dead time, reverse bridge is turning on and

t [s]

0

speed

starts.

problem

of 8 rotor

0,5

1 control

1,5

2

2,5

3

3,5 Due

4

4,5to 5 the

5,5

6

6,5

7

7,5

8,5

-200

-400

frequency

estimation during converter's switching dead

-600

time,

speed

estimator gives incorrect value on the output

-800

in

the

first

moment

after dead time elapse, see Fig.15.b).

-1000

b) rastrećenje

-1200

However, owing to the proposed freezing logic (SEFL),

-1400

accurate estimated speed value is attained.

-1600

1600

1000

800

rasterećenje

(s ~50% Mn na 0)

400

OR

n_est [rpm]

1400

600

tfreeze>tmaks

n_est_nofreeze

n_est_noFIFO [rpm]

n_taho [rpm]

1600

200

0

AND

abs

freeze

-200

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

5,5

6

6,5

7

-400

-600

a>b

-800

+

-

X

-1000

-1200

0.05

nest

new estimated value

old estimated value

(estimator output)

output

freezing

-1400

a) reverziranje

1600

Fig.13. Simplified block diagram of the speed estimation freezing

logic (SEFL)

n_ref [rpm]

n_est_nofreeze

[rpm]

n_est_noFIFO [rpm]

n_taho [rpm]

n_est [rpm]

1400

1200

1000

If acceptability condition is not fulfilled, the new

estimated value is rejected and the estimator sets the old

estimated value on its output (frozen state). However,

for the safety reason, estimator output unfreezes when

the maximal allowed freezing time is exceeded and/or

the rotor voltage amplitude increment is detected. The

rotor voltage amplitude increment implicates the

machine torque increment and, as a consequence, the

operating point changes. The comparison between the

estimated speed with and without SEFL in the case of

speed reference change from 1500 rpm to -1500 rpm is

presented in the Fig.14. When the speed reference

command for opposite direction is set (t=3.3sec, see

Fig.14.), subordinated current controller requests

negative torque, i.e. switching from forward to reverse

thyristor bridge in AC/AC converter, see Fig.2. This

logic, very similar to AC/DC dual converters for DC

drive, leads to unavoidable converter’s safety dead time

(10ms), which results in a rotor voltage frequency

estimation error and consequently speed error too. One

can see from the Fig.14 that the estimated speed (red

line) has a large dynamic error in the moment of the

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

800

600

unloading

rasterećenje

~50% Mto

0) M )

n na

(from(s~50%

0%

n

400

200

t [s]

0

-200

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

5,5

6

6,5

-400

-600

-800

-1000

-1200

-1400

a)

b) rastrećenje

b)

Fig.15. Comparison between estimated speed with (green)

and speed without (red) SEFL in the case of the machine unloading

a); enlarged part b).

International Review of Electrical Engineering, Vol. xx,

n. x

7

F. Kolonić, A. Poljugan, A. Slutej

IV. Basic concept of a torque estimation

In order to fulfill the control system application

requirements as well as to achieve system

competitiveness a torque control loop was added, Fig.3.

The estimated torque is important variable for the speed

estimation and for the automatic on-line rotor resistor

optimization.

The use of conventional methods for measuring

torque on the shaft coupling a motor to a load by means

of strain gauges yields to the accurate values for a

constant or slowly varying torque. Furthermore a

mechanical sensor must be selected according to the

motor's speed and size. This can be difficult and

expensive if you work with a variety of motors at the site

testing, where installation and mounting of mechanical

sensors could be very costly and time consuming. Also,

sometimes the site is difficult or dangerous to access and

it may not be practical to install a mechanical measuring

sensor for torque as well as for speed measurement.

The described solution of dynamic torque

measurement does not need any mechanical elements.

The algorithm of the electromagnetic torque estimation

is based on the estimation of the stator flux in the

stationary reference frame (- frame). The

instantaneous values of the stator voltages and currents

are measured and the stator flux is calculated using

voltage equation

u s Rs i s

d s

.

dt

(5)

us

1

3

usa

2

3

usb , is

1

3

isb .

(12)

From (1) to (5) yields final expression for the

electromagnetic torque.

2

2

Te p s is p s is s is .

3

3

(13)

Before the real time implementation, mathematical

model of induction motor with short-circuited rotor in coordinate system is realized and tested in

Matlab/Simulink in order to test the validity of model

described by (5)-(13).

[rpm]

120

100

80

60

40

20

0

-20

0

0.2

0.4

0.6

0.8

[s] 1

Fig. 16. Speed response under sine-wave voltage step reference

[Nm

]

350

300

250

From (5) follows the stator linkage flux

200

150

s (u s Rs is )dt .

(6)

100

Based on the (5) and (6), - components of the stator

linkage flux Ψs (Ψs , Ψsβ) are calculated as

50

0

-50

s (us Rs is )dt

,

(7)

s (us Rs is )dt

.

(8)

For "Y" stator windings connection, - components of

the stator voltage and current are calculated from

measured a-b-c components as

2

1

u sa u sb ,

is isa ,

3

3

1

2

1

usb , is

isa

isb ,

3

3

3

u s

us

(9)

(10)

and for the "" connection respectively

us usa ,

is

2

1

isa isb ,

3

3

(11)

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

-100

0

0.2

0.4

0.6

0.8

[s] 1

Fig. 17. Estimated electromagnetic torque response under sine-wave

voltage step reference

Step responses with sinus-wave stator voltage supply

and nominal load step (75Nm) in t=0.6 s are presented

in the Fig.16. and Fig.17. The simulation results show

validity of the model described by (5)-(13), with ideal

sinus voltage supply and short-circuited rotor. Real-time

torque estimation performance will be presented in the

section VI with experimental results.

Considering real time application, it is important to

emphasize that special attention has to be paid to the

flux calculation (6) in order to suppress any offset in the

numerical integration without influencing the current

and voltage aperiodic components, [13]-[16].

The flux estimator defined with (6) is referred as

the stator voltage model. This model is difficult to apply

in practice since unavoidable disturbances in voltage

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

and current, ud and id, are superimposed to the ideal

measured signals, us and is, Fig.18. Typical examples of

those undesirable effects are offset and drift which

originate from analogue signal measurement.

Experimental results with estimator in [16] show that the

ideal estimation is possible only if the stator resistance

Rs of the estimator is identical to the estimated

(measured) resistance of the machine and if the

measured current and voltage are without any errors

such as noise or offset errors. This ideal estimation is

happening even though the rotor current differs from

zero.

In order to avoid the stator flux drift and saturation,

the integrator in (6)-(8) is replaced with an adequate

filter, Fig.18, [15]. Using the filter instead of integrator,

low frequency signal (i.e. dc signal) will be attenuated,

but the high frequency signal (ac components) will be

not affected.

us

ud

1

s

Rˆ s

id

is

Fig.18. Calculation of the stator flux using filter instead of pure

integration

As one can see from Fig.18, only electrical stator

values are needed for the electromagnetic torque

calculation. The difference between the obtained

electromagnetic (air gap) torque and the mechanical

(shaft) torque is in the losses originated from friction,

bearings and ventilation, which are mainly a function of

the speed. These quantities can be determined during a

no-load run of the machine.

Functional block diagram of electromagnetic torque

calculation realized on DSP ADMC300 is presented in

Fig.19. After voltages and currents signal processing in

DSP, information of electromagnetic torque is sent to

the overriding system by the fast serial link RS422.

On-line rotor resistor automatic

optimization

In order to achieve effective speed control, rotor

resistor optimization logic is added. This logic changes

the amount of the external added resistance in the rotor

circuit by means of the rotor contactors, Fig.1. Proposed

optimization logic minimizes the stator current of the

motor, taking into consideration the momentary line

voltage, required torque and resistors value tolerance.

In each sampling time at the momentary motor speed,

optimization algorithm calculates maximal torque

produced for each external rotor resistor. Among all

calculated torques available for each additional rotor

resistor, one resistor (the best in optimality sense) will

be chosen and connected to the rotor by means of

contactor. All contactors are handled by digital outputs

(DO) of the process I/O board, Fig.1. The criteria for

external rotor resistor selection can be defined in

software, but usually the criteria is developed maximal

torque. Using this algorithm, the start up adjustment is

reduced, the motor can be used with a less stable line

supply and it is easier to use existing resistors in

revitalization tasks. The schematics of the 5 steps rotor

resistors (R1-R5) with 4 contactors (K0-K3) driven by

process I/O digital outputs (DO1-DO4) respectively is

presented in Fig.20. The resistor value ΣRi in (14) has to

be chosen according to specific industrial application.

For different types of movements (e.g. hoisting, plug

mode lowering, oversynchronous regenerative mode

lowering, traveling, etc) the values suggested in [5] give

trouble-free performance in most situations. Resistor

value ΣRi is calculated as

Rm Rc R1 R2 Ri

100 % ,

R100

where R100 is unity resistance and defined as

Pn

.

R100

2

3 I r 1 s n

Ri

A/D

conversion

TORQUE

ESTIMATION

ALGORITHM

FILTERING

comm.

link to

control

process

board

Fig. 19. Block diagram of the electromagnetic torque estimation

realized with digital signal processor ADMC300

(15)

(16)

Now all the elements for Ri calculation, based on (14),

are noun. Influence of the resistor change in dependence

of the temperature, is considered through the following

equations

Ri C Ri (1 0.9 ( K R / 100 )) ,

(17)

RiW Ri (1 0.6 ( K R / 100 )) .

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

(14)

Unity resistance is defined as resistance that will hold

the motor at zero speed with nominal load and nominal

voltage. The values 8, 18, 38, 65, and 100% of the unity

resistance R100 have been chosen for ΣRi as mostly used

values in industrial applications. The resistors Rm and Rc

are defined as

Rm R100 sn , Rc 0,02 R100 .

stator

voltages

stator

currents

V.

(18)

International Review of Electrical Engineering, Vol. xx,

n. x

International Review of Electrical Engineering (I.R.E.E.), Vol. xx, n. x

START

Uef

n

YES

n > ns

YES

SUP_K3=0

K2 = 1

K3 = 0

NO

YES

TREQ = LIMN

E

R

R

O

R

TORQUE

CALCULATIONS

NO

MODE=0

K2 = 0

K3 = 1

TREQ = LIMP

TORQUE

CALCULATIONS

E

R

R

O

R

NO

NO

T1 > TREQ

NO

T2 > TREQ

NO

T3 > TREQ

NO

T4 > TREQ

YES

YES

YES

YES

K3 = 1

K0=K1=K2=0

K2 = 1

K0=K1=K3=0

K1 = 1

K0=K2=K3=0

K0 = 1

K1=K2=K3=0

NO

T5 > TREQ

YES

Ki = 0

T5 > TREQ

YES

Ki = 0

NO

T4 > TREQ

NO

T3 > TREQ

NO

T2 > TREQ

NO

T1 > TREQ

YES

YES

YES

YES

K0 = 1

K1=K2=K3=0

K1 = 1

K0=K2=K3=0

K2 = 1

K0=K1=K3=0

K3 = 1

K0=K1=K2=0

Fig.20. Flowchart diagram of the automatic on-line rotor resistor optimization

Before the maximal torques calculation logic starts

(Fig.20), mode of operation must be defined. This is

because the rotor contactor logic is working in a

different way for different modes. With the first decision

block in flowchart diagram, it is assigned whether the

drive is in a subsynchronous or in oversynchronous

(plugging or regenerative) region. Drive mode is defined

on the base of direction of the motion requested,

direction of the field (converter state), type of the

motion (hoisting potential loads, traveling reactive

loads) and actual motor speed. The motor must be able

to produce requested torque (TREQ); LIMP is assigned

in Fig.20. as requested torque for positive and LIMN for

negative mode. Then the possible motor torques for each

Ri resistor at each speed for cold and warm state are

calculated according to the following equations

2

2 U 2 TM siCM s I lim

U 2 Ri C

TiC MIN

;

, (19)

s

s 2 siCM 2

2

2 U 2 TM siW M s I lim

U 2 RiW

TiW MIN

;

. (20)

s

s 2 siW M 2

Here TiC and TiW are possible torques in cold and

warm state for i-th rotor resistor at slip s (as a multiple

of nominal torque) and U and Ilim are supply voltage and

current limit. At maximal (breakdown) torque T M, the

values of slip in cold and warm state siWM and siCM are

defined as

Manuscript received January 2007, revised January 2007

si CM Ri C (TM TM2 1) ,

(21)

si CW RiW (TM TM2 1) .

(22)

What are the basics of the automatic rotor resistor

optimization strategy? Check possible motor torques T 5,

T4,..,T1 in sequence to find a Ti that is bigger than

TREQ, Fig.20. As such Ti is found, the right external

resistor (i.e. right contactor switching) is defined.

It is experimentally confirmed in the following section

that the algorithm for on-line rotor resistor calculation

has excellent features in all requested modes of

operation and can replace successfully standard speedbased rotor contactor handler where contactor switching

points has to be calculated in advance, each time for

new industrial application. From an industrial point of

view, this means no extra cost for additional

commissioning caused by speed-based switching points

determination.

VI. Experimental results

Laboratory setup for experimental verification of the

system's performances is presented in Fig.21. (M1wound AC motor: 3x380V, 38,5A, 18,5kW, n=1480

rpm; M2-DC motor, 220V, 91A, 17kW, n=1500 rpm;

separate excitation). Target AC wound motor (M1)

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights

reserved

F. Kolonić, A. Poljugan, A. Slutej

driven by developed controller ASTAT in speed control

mode is mechanically coupled with DC motor (M2).

The latter is driven by the SIMOREG controller in

torque mode loading target AC motor.

2.0

x1000 rpm

Nm

160

1.5

120

1.0

80

Torque

0.5

SIMOREG

40

ASTAT

0.0

0

-40

-0.5

Application software

development and

commissioning tool

M2

M1

E

External rotor

resistors

R

-80

Speed

-1.0

-120

-1.5

-2.0

TG

200

- 160

s

0

2

4

6

8

10

12

14

16

18

20

- 200

Fig.22. Estimated torque and speed feedback in 4q sub-synchronous

operation with potential load (typical hoist drive in crane

applications)

Fig.21. Laboratory test bench for experimental verification

Experimental results have been performed mainly in

the laboratory, but some of them in industrial

environment too (at the site). For the program designed,

data acquisition, measurement, monitoring and

recording, two different platforms during the project

design are developed. The first one is based on the

microcontroller MC68332; PCASE tool for code design

and ASTAT tool as monitoring, recording and

Commissioning and Maintenance Tool (CMT) for the

main application program design. The second one is

based on the digital signal processor ADMC3000 with

alternative tools for code design and CMT; CADSTAR

and PARNAD [5].The latter platform is related to the

speed and torque estimation tasks only.

In this chapter we would like to emphasize that the

following tasks are realized in the design process of

presented controller: speed control task in the industrial

crane

applications

with

mechanical

sensor

(tachogenerator /pulse encoder) and speed estimator;

SEFL logic as effective method for accurate speed

detection in the critical condition mentioned in the

section III.2 (Fig.12); estimated electromagnetic torque

needed for torque feedback loop, for accurate speed

estimation and for automatic on-line rotor resistor

selection.

One of the basic experiments is 4q operation in

hoisting condition with potential load. The result of

testing is presented in Fig.22. For the maximum

trapezoidal-like speed reference in hoisting condition,

drive with emulated load is accelerating with automatic

external rotor resistors switching, which can be seen on

the torque response particularly in the interval of 1-4s.

Afterwards, the full speed reference for lowering a

potential load in reverse current braking (plugging)

mode is ordered. The load is lowering in nonregenerative mode with slip more than 200%! In this

case the load is approximately 70% of nominal motor

torque Tn; at the same time this is a maximal achievable

load torque produced by the DC drive.

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

The performances of the speed control loop with

mechanical sensor and estimated speed (soft) sensor are

presented in Fig. 23 and Fig.24. Recorded variables are,

stator current is, rotor speed n2 and speed reference after

prefilter n_ref_pf. The prefilter is added in the speed

reference only for the laboratory testing. This is because

the parameter of PID speed controller is determined

through the Ziegler-Nichols closed loop test, where such

obtained P and I gains result in high overshoot under

step reference test. Fig. 23. and Fig. 24. present a speed

control system with mechanical sensor and with speed

estimator respectively under positive and negative speed

reference step change in the range of 50-70-50% ns. It

can be seen that the control system with speed estimator

has expected inferior characteristics due to the inherent

delay in estimator explained in section III.2. Introducing

the rotor voltage frequency measurement modification,

see Fig.8, this delay is minimized, which enables

application of proposed controller in large variety of

industrial applications. It can also be seen that for the

both alternatives, the control system considerable

suppress disturbance caused by the rotor resistor change.

The performance of the control system with

tachogenerator (TG) as mechanical sensor in

subsynchronous regime is presented in Fig. 25. It is

hoist drive with active load, where the speed reference is

trapezoidal-like and it is set by joystick. The shape of

the reference can be defined in application software. In

experiment a) active load is 23% of the nominal load T n

and in b) experiments the active load is maximal 70% of

nominal load Tn. For the both experiments automatic online rotor resistor optimization is used. It can be seen

after acceleration in forward direction that minimal

forward torque is needed for braking and speed

reversing in case a); practically, active load is enough to

accelerate in reverse direction.

Since the plugging mode has been chosen and reference

speed is set as synchronous (ns), the controller keeps the

actual speed value just as synchronous by means of

forward motor torque. It would be the same situation

even for the maximal load torque. For b) case, only

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

higher forward motor torque is needed to keep the

lowering (synchronous) speed. When the drive lifts the

load, speed error in steady state is proportional to the

lifting load. This error is a consequence of the actuator

saturation, because synchronous (maximal) speed is set

as the reference speed. The automatic on-line rotor

resistor optimization performance is presented in Fig.

26. For the regenerative mode selected, lowering speed

is higher than synchronous and motor regenerate energy

back to the mains. For this mode of operation special

open loop logic is used which bypass speed controller,

[9]. Active load is then tightly connected to the mains

and designed control logic ensures bumpless return to

the closed speed control loop with TG mechanical

sensor. This experiment evidently confirms that

automatic procedure for the rotor resistor selection

works well. The experiments in Fig.27. show a good

performance of the sensorless drive which uses

estimated speed value based on the estimated rotor

voltage frequency. In both experiments control system in

lowering mode uses different active loads for

regenerative braking.

1200

1200

n_ref_pf [rpm]

n [rpm]

n_ref_pf [rpm]

is [x 0.1A]

1000

1000

800

800

600

600

400

400

n [rpm]

is [x 0.1A]

External rotor

resistor change

200

200

t [s]

0

0

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

0

5

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

Fig.23. Step response of the speed control system with mechanical sensor, speed reference 50-70-50% of synchronous speed.

1200

1200

n_ref_pf [rpm]

n [rpm]

n_ref_pf [rpm]

is [x 0.1A]

1000

1000

800

800

600

600

400

400

200

200

n [rpm]

is [x 0.1A]

External rotor

resistor change

t[s]

t [s]

0

0

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

Fig.24. Step response of the speed control system with estimated speed, speed reference 50-70-50% of synchronous speed.

a)

b)

Fig.25. System responses for the speed reference profile (1500rpm, maximal), TG sensor, automatic resistor selection; plugging braking; active

load; a)23%; b)75%; blue-ref speed and red-actual speed, 0,25ns/div; black-estimated torque, 0,5Tn/div; 2sec/div

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

a)

b)

Fig.26. System responses for the speed reference profile (1500rpm, maximal), TG sensor, regenerative braking; active load 55%; automatic a)

and manual b) resistor selection; blue-ref speed and red-actual speed, 0,25ns/div; black-estimated torque, 0,5Tn/div; 2sec/div

a)

b)

Fig.27. System responses for the speed reference profile (1500rpm, maximal), speed estimator, automatic resistor selection; regenerative

braking; active load; a) 23%; b) 55%; blue-ref. speed and red-actual speed, 0,25ns/div; black-estimated torque, 0,5Tn/div; 2sec/div

a)

b)

c)

Fig.28. Testing at the site (Okselesund, Sweden, 80tones hoist drive), speed control system, speed estimator; regenerative braking a); plugging

b); Testing at the site , BaoSteel, Baoshan, China, 450 tones hoist drive, c); blue-ref speed and red-actual speed (0,25ns/div); black-stator current

(0,5isn/div); green-forward and pink-reverse bridge; time scale1sec/div

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

The Fig.28. a) and b) present the results of the crane

control system monitoring during the commissioning at

the site. The first one is 80 tones hoist drive with speed

estimator presented in regenerative a) and plugging b)

mode of operation. The second one is 450 tones ladle

hoist crane with mechanical sensor, Fig. 28.c). All

recording has been performed by means of the CMT

monitoring tool designed during this project.

VII. Conclusion

We would like to emphasize that the developed

control system is not a servo drive system! It is not

designed for high precision speed control tasks. It is

aimed prior for revitalization tasks of old drives based

on the AC wound machine, but controlled by

components based on the up-to-date technology. The

proposed system provides safe, reliable and simple

control in industrial applications such as heavy duty

material handling systems, steel and rolling mills,

container unloading and uploading cranes, power plants,

etc. Our contributions in the design of proposed

controller are expressed through the following issues:

original rotor speed estimation technique based on the

rotor voltage frequency estimation with implementation

on the industrial crane controller (method and device

patented!); related to the speed estimation, nonlinear

estimation freezing logic (SEFL) is designed for

accurate speed estimation in the operating region where

the rotor voltage signal is not acceptable for accurate

frequency estimation (AC/AC converter dead time,

operation region with small load and with small slip);

implementation of the electromagnetic torque estimator,

based on the stator voltages and currents measurements,

needed for accurate speed estimation, for automatic online rotor resistor selection and for the feedback sensor

in the torque control loop; original algorithm for

automatic on-line rotor resistor optimization logic which

selects rotor resistor in order to get maximal developed

motor torque at each microcontroller’s sampling time.

It is experimentally confirmed on the laboratory test

bench and through recording at the site, that speed

control system with soft sensor achieves good

performances. SEFL logic involved in the control

approved the safe operation which has been attained in

all operation modes, especially in the regenerative mode

of operation, which is particularly important in the hoist

crane drives. The experiments confirmed good

functionality of the speed open-loop logic in the

regenerative mode owing to the bumpless technique we

applied. The process of energy recuperation is very

simple and more effective than in the case of a

frequency controlled AC squirrel cage motor supplied

by inverter.

The experimental tests of the automatic on-line rotor

resistor optimization logic confirm excellent features in

the all requested operating modes and proposed logic

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

can replace successfully standard speed-based rotor

contactor handler. Comparing to the classical (manual)

speed-based rotor resistor switching, there is no

considerable difference in performances in the first

moment. However, in speed-based rotor contactor logic

switching points have to be calculated in advance, each

time for the new industrial application, which leads to

extra cost for additional commissioning.

Within the development of the advanced industrial

crane controller based on the AC wound machine, we

have designed a modular system capable to deal with

control, communication, protection and other specific

industrial demands. Such controller, either as new drive

or revitalized, can be integrated as a client in the control

network, used in crane motion concept with digital drive

controller system.

Acknowledgement

The project of industrial controller (with commercial

name ASTAT®) is a result of joint cooperation between

the Faculty of Electrical Engineering and Computing,

the University Zagreb (Croatia) and the Swedish

company ABB, and it is financially supported by ABB.

As a result of this cooperation, over 3000 industrial

applications, especially in the crane and other heavy

duty material handling systems are installed all over the

world.

Based on our investigation of the crane control

system related to the sensorless speed control technique,

our industrial partner ABB patented the method of speed

estimation:

Patent No: WO01/27637 Device and a method for

estimating the speed of a slip ring asynchronous

machine

References

[1] ….., ASTAT, Semiconductor controller for slip-ring motors

[2]

[3]

[4]

[5]

[6]

Manual, ABB Industrial Systems AB, Crane & Harbour

Systems, ReklamCenter AB (6032), Västerås, Sweden, 05/1996.

….., SIMOTRAS HD – Der neue Drive für Krane mit

Schleifringläufermotoren, Excellence in Automation & Drives,

Siemens, Erlangen, 04/1999.

A. Slutej, F.Kolonić, Ž.Jakopović, The new crane motion control

concept with integrated drive controller for engineered crane

application, Proceedings of the IEEE International Symposium

on Industrial Electronics, ISIE’99, July 12-16, 1999. Bled,

Slovenia.

A. Slutej, F. Kolonić, Control network as a backbone of the

crane motion control system, Proceedings of the 10th EPEPEMC 2002 (CD ROM), September, 9-11, 2002,Dubrovnik,

Croatia.

...., ASTAT Crane Motion Control, (CD-ROM), Manual, ABB

Automation System, 2003.

A. Slutej, L.T. Hansson, F. Kolonic, Steel mill crane motion

control with a new integrated drive controller, Proceedings of

International Review of Electrical Engineering, Vol. xx,

n. x

F. Kolonić, A. Poljugan, A. Slutej

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

the 10th International Symposium EDPE’98, October 14-16,

1998, Dubrovnik, Croatia

N. Mohan, T.M. Undeland, W.P. Robins, Power Electronics:

Converters, Applications and Design (John Wiley and Sons,

1989).

B.K.Bose, Power Electronics and AC drives (Prentice–Hall,

1986).

A. Poljugan, Speed estimator design for industrial controller

based on AC wound machine, Mr.sc. Theses (in Crotian), Dept.

of.El. Machines, Drives and Automation, Faculty of El. Eng.

and Computing, University of Zagreb, Croatia, 2005.

A. Slutej, F. Kolonić, A. Poljugan, Crane control Network, 13th

International Conference on Electrical Drives and Power

Electronics, (2nd Joint Croatia_Slovakia Coference),

EDPE'05, September 26. – 28, 2005, CD-ROM, Dubrovnik,

Croatia

P.W. Lefley, W. Peasgood, R. Ong, J.K.J.Wong, Sensorless

closed loop control of a slip ring induction machine using

adaptive signal processing, Applied Power Electronics

Conference and Exposition, APEC apos;99. Fourteenth

Annual, 14-18 March, 1999.

Poljugan, Alen; Kolonić, Fetah; Slutej, Alojz. DSpace Platform

for Speed Estimation AC Slip-Ring Motor in Crane

Mechatronic System, Proceedings (and CD-ROM) of the 11th

International Power Electronics and Motion Control

Conference, EPE – PEMC ’04, Riga, Latvia.

C. Lascu, G. Anfreescu, Sliding-Mode Observer and Improved

Integrator With DC-Offset Compensation for Flux Estimation

in Sensorless-Controlled Induction Motors, IEEE Transactions

on Industrial Electronics, vol. 53, no. 3, June 2006, pp. 785794.

Mihai Comanescu, Longya Xu, An Improved Flux Observer

Based on PLL Frequency Estimator for sensorless Vector

Control of Induction Motors, IEEE Transactions on Industrial

Electronics, vol. 53, no. 1, pp. 50-56, February, 2006

J.Holtz, Sensorless Control of Induction Machines-With or

Without Signal Injection, IEEE Transactions on Industrial

Electronics, vol. 53, no. 1, February, 2006, pp. 7-30.

B. Peterson, Induction Machine Speed Estmation Observations on Observers, Ph.D. dissertation, Dept. of Ind.

El. Eng. and Automation (IEA), Lund Institute of Technology

Lund, Sweden, 1996.

Copyright © 2007 Praise Worthy Prize S.r.l. - All rights reserved

Fetah Kolonić (1956) received his

Ph.D.E.E. in 1997, M.S.E.E. in 1990 and

B.S.E.E. in 1980 at the University of

Zagreb, Croatia. He is currently associate

professor at the Faculty of Electrical

Engineering and Computing, University of

Zagreb. His major fields of study are control

of electrical drives and power converters,

optimal and robust control of industrial

systems and integration structure in the complex mechatronic

systems.

He has been author of many papers published in journals and

presented at national and international conferences. As principal

investigator and project leader he has been conducting several

projects funded by international and Croatian industries as well as by

the Croatian government. His teaching and research include

application of advanced control techniques in industrial systems.

Dr. Kolonić is a member of K¸oREMA (Croatian Society for

Communication, Computing, Electronics, Measurement and Control,

IEEE (Robotics and Automation Society, Industrial Electronics

Society) and the Croatian section of Cigre (International Council for

Large Electric Systems).

Alen Poljugan (1977) received his

M.S.E.E. in 2005 and B.S.E.E. in 2001 at

the University of Zagreb, Croatia. From

2001 he has been working as assistant at the

Faculty of Electrical Engineering and

Computing (Department of electrical

machines, drives and automation). His fileds

of interests are control of electrical drives

and power converters, optimal and robust control of industrial systems

and integration structure in complex mechatronic systems.

He has been co-author of several papers published at national and

international conferences.

Alojz Slutej (1950) received his Ph.D.E.E.

in 1986, M.S.E.E. in 1981 and B.S.E.E. in

1980 at the University of Zagreb, Croatia.

He is employed as Senior System Engineer

and works as technical expert in ABB Crane

& Harbour division in Sweden. Partly, he is

engaged as associate professor at the Faculty

of Electrical Engineering and Computing,

University of Zagreb. His interest is mostly

in hardware and software development regarding automated container

cranes activities.

He has been co-author of many papers published in journals and

presented at national and international conferences.

Dr. Slutej is a member of the IFAC CCD Technical committee for

distributed control systems, AISE (USA Association of Iron and Steel

Engineers) and KoREMA (Croatian Society for Communications,

Computing, Electronics, Measurement and Control).

International Review of Electrical Engineering, Vol. xx,

n. x