Effect on Boiling Heat Transfer of Horizontal Smooth Microchannel

advertisement

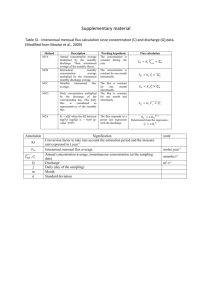

EFFECT ON BOILING HEAT TRANSFER OF HORIZONTAL SMOOTH MICROCHANNEL FOR R-410A AND R-407C Agus Sunjarianto Pamitran, Kwang-Il Choi Graduate School, Yosu National University, Yosu 550-749, Korea Jong-Taek Oh* Dept. of Refrigeration Engineering, Yosu National University, Yosu 550-749, Korea Hoo-Kyu Oh Dept. of Refrigeration and AC Engineering, Pukyong National University, Busan 608-739, Korea Abstract An experimental study of boiling heat transfer with refrigerants R-410A and R-407C is presented. The present paper is focused on pressure drop and boiling heat transfer coefficient of the refrigerants inside a horizontal smooth microchannel. To evaluate the diameter size effect on pressure and heat transfer characteristics, microchannels with inner diameters of 1.5mm and 3.0mm and with lengths of 1500mm and 3000mm respectively are used. The pressure drop increases with mass flux and heat flux for both inner tube diameters and for both the refrigerants. The pressure drop of R-407C is higher than that of R-410A, but the heat transfer coefficient of R-410A is higher than of R-407C at the low quality region. The heat transfer coefficient in the tube with an inner diameter of 1.5mm is higher than that of 3.0mm diameter tube at the low quality region. The comparison of heat transfer coefficient between the result of this study and the predictions of some previous correlations shows a high percentage of deviation. Keywords: R-410A, R-407C, pressure drop, heat transfer coefficient, microchannel Introduction 2.92mm, showed a significant effect of the inner tube diameter, that is, the slug flow pattern regime occurs Over the last two decades many studies of heat transfer over a much larger parameter range, and nucleate characteristics of refrigerant mixtures have been boiling mechanisms dominate the heat transfer in the performed. Processes involving boiling of refrigerant small diameter tube. Peng and Peterson (1996), by mixtures in a compact heat exchanger are extensively using a binary mixture and 0.133mm to 0.367mm encountered in industry. In order to enhance the hydraulic diameters, concluded that the transition Re compact heat exchanger performances, several (Reynolds number) and the transition range (Recr) investigations on boiling heat transfer in microchannels decrease with decreasing microchannel dimensions. have been reported. Wambsganss et al. (1993), by Study of boiling heat transfer by using refrigerant using R-113 in a microchannel with inner diameter of mixtures has also been presented by Zhang et al. (1996). They showed that the mass transfer resistance * Corresponding Author. Tel.: +82-61-659-3273; fax: +82-61-659-3003, E-mail: ohjt@yosu.ac.kr near the interface significantly reduces the heat transfer International Congress of Refrigeration 2003, Washington, D.C. 1 coefficient of the mixture, especially in low quality and low mass flux regions. Jung et al. (1989) concluded that mass transfer resistance was responsible for the heat transfer degradation from the ideal value, but for low vapor-liquid composition difference, mass transfer becomes negligible in the convective region. But these proposed studies are only valid for evaporated tube with moderate inner diameters, namely experimental data of the boiling characteristics for a microchannel is limited. Also experimental studies of the effect on boiling heat transfer of horizontal microchannels is Fig. 1 Experimental test facility rarely found. Hence in this study, the effect of pressure drop and boiling heat transfer coefficient of horizontal inner tube diameters of 1.5mm and 3.0mm is disclosed. 1. Experimental Apparatus and Methods 1.1 Refrigerant loop The experimental facility is schematically shown in Fig 1, and consists mainly of a refrigerant pump, mass flow meter, preheater, evaporator, condenser, subcooler and Fig. 2 Experimental test section receiver. Flow rate of the refrigerant is controlled by a variable A.C output motor controller. The mass flow lengths of 1500mm and 3000mm, respectively. It was meter was placed to measure the refrigerant flow rate. assumed uniformly and constantly heated directly To control quality at the test section inlet, the preheater through the tube wall. The rate of input voltage E and was installed. For evaporation at the test- section, a current I were adjusted in order to control the input certain heat flux was conducted from a variable A.C power to determine the applied heat flux, which was voltage controller. Subsequently vapor refrigerant from measured by a standard multimeter. the evaporator was condensed in the condenser and The test section was isolated by rubber and foam. The subcooler, and thence, supplied to the receiver before it outside tube’s wall temperatures were measured at was pumped through loop. every 100 mm axial intervals along the tube’s length from the start of the heated length at the inlet with two 1.2 Test section copper-constantan thermocouples oriented to measure Fig. 2 shows a detail of the test-section. The test- temperature at the top and bottom side of each interval. section was made of stainless steel smooth tubes, with The junctions of copper-constantan thermocouples inner diameters of 1.5mm and 3.0mm and heated were attached to the surface and were electrically International Congress of Refrigeration 2003, Washington, D.C. 2 insulated. The differential pressure was measured by a bourdon tube type pressure gauge and differential pressure transducer at the inlet, middle and outlet of the test section. To visualize the flow, a sight glass with the same inner tube diameter as the test section was installed at the inlet, middle and outlet of the test Table 1 Experimental conditions Refrigerants R-407C, R410A Test Section Horizontal smooth microchannel Inner Diameter (mm) 1.5, 3.0 Tube Length (mm) 1500, 3000 Mass Flux (kg/m2s) 300 – 600 Heat Flux (kW/m2) 5 – 20 Quality 0.0 – 1.0 Inlet temperature (oC) 10 section. 1.3 Testing procedure The experimental conditions performed in this test are shown in tables 1 and 2. It underwent steady-state conditions. The temperature data were recorded by using Darwin DAQ32 Plus logger R9.01 program, and the flow rate data were recorded by Micro Motion ProLink Software version 2.41. Table 2 Experimental conditions of the convective boiling heat transfer test G[kg/m2s] q[kW/m2] q[kW/m2] G[kg/m2s] 300 5, 10, 5 300, 400, 15, 20 500, 600 400 5, 10, 10 300, 400, 15, 20 500, 600 500 5, 10, 15 300, 400, 15, 20 500, 600 600 5, 10, 20 300, 400, 15, 20 500, 600 The local heat transfer coefficients, at position z along 2. Results and Discussion the length of the test-section, were defined as h q Twi Ts (1) 2.1 Effect of inner diameter on pressure drop Fig. 3 shows the pressure drop of R-410A per unit where the heat flux q was calculated by length of the test sections with inner diameters of Q q Do z (2) increases with mass flux and heat flux, with increasing where Q was the electrical input Q EI (3) The inside tube wall temperature Twi was determined considering radial thermal conduction through the wall, D Q Twi Two ln o 2kz Di (4) The local saturation temperature was calculated from the measured saturation pressure and quality x for given overall composition. 3.0mm and 1.5mm. The figure shows the pressure drop The quality x at measurement locations z were determined based on pressure drop at the higher mass flux and heat flux. The pressure drop for the tube with inner diameter of 1.5mm is higher than that of the 3.0mm one, under the heat flux of 5kW/m2, whereas it has no relation with the test conditions of under 10kW/m2. Fig. 4 shows the pressure drop of R-407C per unit length of the test section, with various mass flux and heat flux, for both inner diameters. As is shown in the figure, the pressure drop increases considerably with increasing mass flux and heat flux, and the increase thermodynamic properties x i if i fg rate of pressure drop in inner diameter of 1.5mm, at the (5) condition of similar mass flux and heat flux rate, is International Congress of Refrigeration 2003, Washington, D.C. 3 three times higher than of 3.0mm. Therefore, as In Fig. 6, the effect of heat flux on pressure drop is pressure drop increases with decreasing inner diameter, higher for R-410A than R-407C. Also, it is shown that we must consider an important factor of pressure drop pressure drop increases with increasing mass flux and when designing a heat exchanger using microchannels. heat flux for both the refrigerants at all mass flux test The effect of mass flux on pressure drop is more conditions. clearly depicted in Fig. 5. Pressure drop increases with Heat flux, mass flux and inner diameter give different mass flux and heat flux increase for both refrigerants at effects on pressure drop. The effect of mass flux and all heat flux rate test conditions. It is shown that the inner diameter on pressure drop is higher for R-407C effect of mass flux on pressure drop of R-407C is than R-410A, whereas the effect of heat flux is not. higher than on R-410A. Pressure drop increases with increasing mass flux and Figure 3 Effect of tube diameter on pressure drop at Figure 5 Effect of mass flux on pressure drop at different mass flux and heat flux for R-410A Figure 4 Effect of tube diameter on pressure drop at different mass flux and heat flux for R-407C various heat fluxes for 3.0mm Di Figure 6 Effect of heat flux on pressure drop at various mass fluxes for 3.0mm Di. International Congress of Refrigeration 2003, Washington, D.C. 4 heat flux for both inner tube diameters. The pressure coefficient, at test conditions of constant heat flux and drop is much more decreased with inner diameter size inner diameter of 3.0mm. The figure shows that the decrease for R-407C, in other words the effect of inner effect of mass flux on heat transfer of R-407C is higher diameter on pressure drop is higher for R-407C. than on R-410A. The heat transfer coefficient increases with increasing mass flux for R-407C at all test 2.2 Effect of heat flux and mass flux on heat conditions. For R-410A, the higher mass flux does not transfer coefficient always mean there is a higher heat transfer coefficient, At the low quality region under test conditions of but it depends on heat flux and inner diameter. The varying heat flux and constant mass flux for similar effect of mass flux on the heat transfer coefficient, in inner diameters, it is shown that the higher heat flux the case of comparison of both refrigerants at the same yields to the higher heat transfer coefficients for both test condition, is somewhat similar as the effect of heat refrigerants, whereas at the high quality region, the heat flux on heat transfer coefficient. Namely, the heat transfer coefficient shows a different trend. Fig. 7 transfer coefficient of R-407C is lower than of R-410A shows the effect of heat flux on the heat transfer at the low quality region, as is depicted in Fig. 8. The coefficient for the tube with an inner diameter of maximum value of the heat transfer coefficient, which 1.5mm. The figure shows that the heat transfer is the dry out point, under all test conditions, appears coefficient of R-410A is higher than of R-407C. The earlier for R-410A; this being similar to the trend with maximum value of the heat transfer coefficient, which the effect of heat flux on the heat transfer coefficient, is the dry out point, at all test conditions appears earlier as cited above. for R-410A. The figure shows that the effect of heat flux on the heat transfer coefficient of R-410A is higher 2.3 Effect of inner diameter on heat transfer than on R-407C, especially before the dry out point. coefficient Fig. 8 shows the effect of mass flux on the heat transfer Fig. 9 shows the effect of inner diameter on the heat Figure 7 Effect of heat flux on heat transfer coefficient at constant mass flux for 1.5mm Di. Figure 8 Effect of mass flux on heat transfer coefficient at constant heat flux for 3.0mm Di. International Congress of Refrigeration 2003, Washington, D.C. 5 Fig. 10 shows the effect of inner diameter on heat transfer coefficient, under test condition of a constant mass flux of 300kg/m2s and heat flux of 15kW/m2, for R-407C. As shown in the figure, the heat transfer coefficient increases with increasing quality for both inner tube diameters. The difference of the heat transfer coefficient, between inner diameter of 3.0mm and 1.5mm, is small at the start of evaporation, but after a quality of 0.2, the heat transfer coefficient of the tube with an inner diameter of 1.5mm is higher than for Figure 9 Effect of inner diameter on heat transfer coefficient at constant mass flux of 300kg/m2s and heat flux of 10kW/m2 for R410A 3.0mm, and at a quality of 0.7 the difference reaches more than 50%. The heat transfer coefficient of both inner diameters decreases rapidly by dry out, at a high quality of more than 0.7. 2.4 Heat transfer coefficient comparison with previous correlations The heat transfer coefficient in this study, in a quality range of 0.0 to 0.9, is compared with the predicted heat transfer coefficient of Chen (1963a), Gungor-Winterton (1986) and Jung et al. (1989) correlations. All comparisons show high deviation, in both tubes with diameters of 3.0mm and 1.5mm. Fig. 11 and 12 depict the R-407C heat transfer coefficient of the present Figure 10 Effect of inner diameter on heat transfer coefficient at constant mass flux of 300kg/m2s and heat flux of 15kW/m2 for R407C. study against the predicted one of the GungorWinterton correlation, in tubes of 3.0mm and 1.5mm inner diameter, respectively. The figures show that the transfer coefficient for constant mass flux of 300kg/m2s predicted heat transfer coefficient with the smaller and heat flux of 10kW/m2 for R-410A. As shown in the inner diameter is higher than of the larger one, this figure, the increase of the local heat transfer coefficient for both inner diameters is low with increasing quality in the range of qualities from 0.0 to 0.5, but the heat transfer coefficient in the tube with an inner diameter of 1.5mm increases by about 40% higher than in that of the 3.0mm one, till dry out occurs at a quality of 0.7. occurring for both refrigerants. Comparison between the heat transfer coefficient of this study and of the predicted one by the Jung et al. correlation, in tubes with inner diameters of 3.0mm and 1.5mm for R-410A, is depicted in Figs. 13 and 14, respectively. High deviation is clearly shown in the figures, and the deviation in the tube with an inner International Congress of Refrigeration 2003, Washington, D.C. 6 Figure 11 Comparison between experimental and predicted heat transfer coefficient of Gungor-Winterton correlation with 3.0mm Di for R-407C. Figure 13 Comparison between experimental and predicted heat transfer coefficient of Jung et al. correlation with inner diameter of 3.0mm for R-410A. Figure 12 Comparison between experimental and predicted heat transfer coefficient of Gungor-Winterton correlation with 1.5mm Di for R-407C Figure 14 Comparison between experimental and predicted heat transfer coefficient of Jung et al. correlation with inner diameter of 1.5mm for R-410A. Table 3 Percentage of deviation of heat transfer coefficient comparison between the previous present data Previous Correlations Inner tube Refrigerant Chen Gungor-Winterton diameter (mm) M A M A 3.0 34.86 -22.49 39.09 37.29 R-410A 1.5 98.71 73.13 175.67 172.71 3.0 48.34 -6.12 63.08 57.02 R-407C 1.5 67.84 51.03 145.57 145.57 M Mean Deviation 1 n h pred hexp 100 1 n h pred hexp 100 , A Average Deviation n 1 hexp n 1 hexp International Congress of Refrigeration 2003, Washington, D.C. 7 correlation and the Jung et al. M A 71.84 52.66 251.73 243.60 70.17 68.51 183.08 181.64 diameter of 1.5mm is higher than for 3.0mm. The comparison of the heat transfer coefficient Table 3 shows the comparisons for the percent between this study and the predicted of correlations of deviation. It is clear that the deviation of the smaller Chen, Gungor-Winterton and Jung et al. shows high inner diameter is higher than for the bigger one, and the deviation both in tube diameters of 3.0mm and 1.5mm. deviation of R-407C is higher than of R-410A. The The predicted heat transfer coefficient with inner predicted heat transfer coefficient of the Chen diameter of 1.5mm is higher than of 3.0mm, for both correlation is better than of the others. The high the refrigerants. The deviation of R-407C is higher than deviation shows that the previous correlations are over- R-410A. The high deviation shows the necessity to predicting for both refrigerants inside the small develop a new correlation for this purpose. diameter tube, therefore it is needed to develop a new correlation for this purpose. Acknowledgements-The authors wish to acknowledge that this wok was supported by the Ministry of Concluding Remarks Maritime Affairs & Fisheries of Korea (KMI Grant No.20010144) and Reitechnology Co. The effects of inner diameter on pressure drop and the References boiling heat transfer coefficient of R-410A and R-407C are presented. The pressure drop increases with the 1. increase of either both mass flux and heat flux, in both inner diameters of 1.5mm and 3.0mm. Pressure drop of R-407C is higher than of R-410A, in the same experimental condition. Under test conditions of 2. constant mass flux and heat flux, the increasing of pressure drop of R-407C with inner diameter of 1.5mm is three times higher than that of 3.0mm. The effect of 3. inner diameter on pressure drop, by using working fluid of R-407C, is higher than of R-410A. The heat transfer coefficients with inner diameter of 4. 1.5mm increase over 40% higher than those of 3.0mm for R-410A. In test with R-407C under experimental 5. condition of constant mass flux and heat flux, the heat transfer coefficients with inner diameter of 1.5mm increase by about 50% higher than of 3.0mm, at a 6. quality of 0.7. The heat transfer coefficient of R-410A is higher than R-407C at the low quality region. Dry out occurs earlier on R-410A in both the inner diameters. 7. Gungor, K.E., Winterton, R.H.S., 1987, Simplified general correlation for saturated flow boiling and comparisons of correlations with data, Chem.Eng.Res., vol. 65, p. 148-156. Jung, D.S., McLinden, M., Radermacher, R., Didion, D., 1989, A study of flow boiling heat transfer with refrigerant mixtures, Int J. Mass Transfer, vol. 32, no. 9, p. 1751-1764. Jung, D., Radermacher, R., 1993, Prediction of evaporation heat transfer coefficient and pressure drop of refrigerant mixtures, Int J. Refrig., vol. 16, no. 5, p. 330-338. Klandikar, S.G., 1998, Boiling heat transfer with binary mixtures: Part II – Flow boiling in plain tubes, AMSE Trans, 120, p. 388-394. Peng, X.F., Peterson, G.P., 1996, Forced convective heat transfer of single-phase binary mixtures through microchannels, Experimental Thermal and Fluid Science, 12, p. 98-104. Stephan, K., 1995, Two-phase heat exchange for new refrigerants and their mixtures, Int J. Refrig., vol. 18, no. 3, p. 198-209. Wambsganss, M.W., France, D.M., Jendrzejczyk, J.A., Tran, T.N., 1993, Boiling heat transfer in a horizontal small-diameter tube, AMSE Trans., 115, International Congress of Refrigeration 2003, Washington, D.C. 8 8. p. 963-975. Zhang, L., Hihara, E., Saito, T., Oh, J.T., 1997, Boiling heat transfer of a ternary refrigerant mixture inside a horizontal smooth tube, Int J. Mass Transfer, vol. 40, no. 9, p. 2009-2017. International Congress of Refrigeration 2003, Washington, D.C. 9