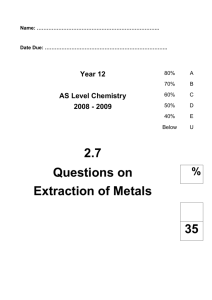

DOI: 10 - GIE

advertisement

Mechanism and chemical transformations of the nanoporous aluminium oxide during “sealing” processes By Emmanuel ROCCAa*, Delphine VANTELONb, Aurelie GEHINa, Myriam AUGROSc, Alain VIOLAc, and Corresponding Author(s)* [a] Emmanuel ROCCA*, Aurélie GEHIN Institut Jean Lamour - CP2S - UMR CNRS 7198 Nancy University - BP 70239 - Vandoeuvre-lèsNancy, 54506 (France)E-mail: emmanuel.rocca@lcsm.uhp-nancy.fr [b] Delphine VANTELON Synchrotron SOLEIL - L'orme des Merisiers Saint-Aubin - BP 48 - 91192 GIF-sur-YVETTE CEDEX (France) [c] Myriam AUGROS, Alain VIOLA Messier-Bugatti (SAFRAN group) – 5 rue Antoine St Exupéry - 67129 Molsheim (France) Keywords: nanoporous oxide, aluminium, sealing, corrosion Nanoporous aluminium oxide made by anodisation of aluminium alloys is used in many fields as membrane, catalysis or nanometric template. The nanostructures are currently used as protection against the corrosion of aluminium alloys, and as tank of corrosion inhibitors at the aluminium alloys surface. This work is focused on the mechanism of incorporation of metallic ions (CrO42-, Ni2+, Ce3+) inside the nanopores and the chemical transformations of nanoporous oxide during the process, called “sealing”. Several chemical analyses have shown that the amorphous anodic oxide constituting the walls of the nanochannels have specific chemical properties, induced by a high content of Al3+ cation in tetrahedral coordination, determined by XANES measurements, and the presence of sulphate anions. So, the diffusion of species inside the nanopores is mainly determined by the electrostatic interactions between the charge of the “sealant” species and the positive surface charges at the surface of the nanopores. Simultaneously, the very rapid water diffusion determine by 18O-tracer experiments provokes the transformation of AlO4 to AlO6 coordination and the partial release of sulphate anions from the nanostructure. 1. Introduction Since several decades, self-organized porous oxide has motivated considerable scientific and technological interest. They are generally produced by electrochemical oxidation of the metal using a set of specific conditions of potential, temperature and electrolyte composition. The nanostructure of these materials is commonly constituted by a layer of nanotubes or nanochannel growing perpendicular to the metal. Since several years, optimized electrochemical conditions can be found to form this kind of layer on a large range of metals as mentioned on these examples of works (Ti [1], Zr [2], Nb [3], Ta [4,5] and Al [6]). On aluminium, the nanochannel electrosynthesis can be simply performed in sulphuric acid, whereas the addition of fluoride ions is necessary to control the dissolution process during the formation of the nanoporous oxide on titanium, or zirconium. The pore diameters and the homogeneity of the channel packing structure are also affected by the alloys composition and the microstructure of the alloys, as mentioned by several authors on aluminum and titanium alloys [7]. These nanostructured oxides are exploited in many applications such as membranes [7], sensors, catalysis systems [8] or as template to form nanometric device with specific physical properties [9] by electrodeposition inside the nanopores [10]. Layers of nanoporous aluminum oxide are also the most used systems to form protective coatings against corrosion of aluminum alloys, especially in aeronautic or mechanical industries. The anodization process is carried out in acid medium as sulphuric, phosphoric or oxalic acids, and the oxide is generally described as “alumina” or “Al2O3” formulae. These layers are then “sealed” in boiling aqueous electrolyte to improve the protection against the corrosion properties. According to the literature [11], the “sealing" process of the anodized 1 41 aluminium is described by the simple filling up of the nano-porosity by a hydratation process of the aluminium oxide. In addition, the “sealing” process is also used to fix corrosion inhibiting compounds, or dyes for aesthetic application in the nanopores. In these cases, the nanostructure is used as tank of corrosion inhibitors or pigments at the surface of the metallic pieces. In practice, the most used “sealing” process was carried out in a chromate-based electrolyte, because it was efficient to protect almost all the aluminium alloys against corrosion and especially the aluminium-copper alloys. Nowadays, the imperative respect of the environmental rules concerning the wastewater rejects in plants implies the development of effective and environmentally friendly anti-corrosion treatment. Then, the search of chromate alternatives needs to understand the chemical structure of the anodic oxide constituting the nanoporosity and the reactivity inside the nanopores to develop new “sealing” treatments. Even if some “sealing” treatments of anodized aluminium are known for many decades, the knowledge of the chemical reactivity of the oxide nanopores remains often empirical and purely practical. For example, some authors have recently observed unusual gas absorption properties of TiO2 nanotubes [1]. On the other hand, the molecular transport properties inside an individual oxide nanopore were studied with a specific design for analytical applications by B. Zhang et al. [12]. So the chemical behaviour of the oxide nanopores is almost unknown, especially when the pore diameter has the same order of magnitude of the electrochemical double layer or “compact layer of Stern”. So, the purpose of this work is to obtain a comprehensive study of the chemical reactivity of the nanoporous aluminum oxide layer on aluminum alloys in boiling aqueous electrolyte. The nanoporous oxide structure was synthesized by anodization in sulphuric acid medium of an Al-Cu-Zn-Mg alloy. The morphology was characterized by scanning electron microscopy with a field emission gun (FEG-SEM), and chemical analyses were performed by electron probe microanalysis (EPMA), infra-red spectroscopy (IR) and thermogravimetry coupled with mass spectroscopy (TG-MS). X-ray absorption spectroscopy allowed us to describe the local bonding environment of the aluminum atoms in the oxide. Finally, the transport properties of water, chromate and cerium salts in the aluminum oxide nanopores were studied by specific tracer experiments used H218O and electrokinetic measurements. 2. Materials and experimental methods Nanoporous oxide synthesis and chemical analysis The nanoporous oxide layer were realized by electrochemical oxidation of AA7175 T73 alloy (composition: 1.6 wt.% Cu, Zn 5.8 wt.%, 2.5 wt.% Mg) in H2SO4 200g/l at 18°C in a twoelectrode cell. The anodization sequence was: 12V during 15mn followed by 18V during 12 mn. The cathodes were plates of lead. After anodising, the aluminium alloys plates were rinsing and “sealed” in a boiling electrolyte at 95°C during 30 min. Different “sealing” electrolytes were used: distilled water at pH=6.5 called water sealing, K2Cr2O7 30g/l called Cr-sealing, Ce(CH3COO)3,5H2O 5 10-3 mol/l called Ce-sealing, and Ni(CH3COO)2 5 g/l called Ni-sealing. The layers were analysed by X-ray diffraction (PHILIPS X'Pert PRO diffractometer) using copper K radiation (d=1.5418 Å) and by infra-red spectroscopy (FTIR Perkin Elmer 2000 spectrometer). The morphology was observed with the FE-SEM (Hitachi S4800) with an acceleration voltage of 1 to 2 kV without any metallization. For the cross section observation by FE-SEM, the samples were mechanically fractured. The elemental analyses were performed by EPMA (Cameca SX100) on polished cross-sections after embedding in epoxy resin as previously described [13]. 2 42 The TG-MS measurements allowed us to confirm the composition of the oxide, and were performed under argon flux from 50 to 1200°C at 2°/min (Setaram Setsys coupled with Pfeifffer Ominstar). For these experiments, the samples were prepared from foils of 25 µm thickness, anodized in the same conditions in order to have a very low aluminium mass in the samples. Then the anodized samples were cut in small pieces and placed in the Pt crucible of the thermobalance. H218O-tracer experiment The sealing process with H218O-tracer was realized in an pure water containing 95 wt.% of H218O in a sealed micro-cell (V=1 ml). Then, the samples were analyzed by secondary ion mass spectroscopy (SIMS Lab VG) [14] X-ray absorption spectroscopy X-ray absorption near-edge spectroscopy (XANES) experiments at the Al K-edge were performed on the LUCIA beamline (Swiss Light Synchrotron) [15]. Measurements were performed at room temperature, under vacuum (~1 Pa) with a beam size on the sample of 4 x 6 µm2. The energy of the double crystal KTP(011) monochromator was calibrated by setting the first peak of the first derivative of an Al foil spectrum at 1559.6 eV. XANES scans were carried out with a step size of 2 eV and a counting time of 2 s in the pre-edge region, 0.2 eV and 2 s in the edge region and 1 eV and 3 s in the post-edge region. Measurements were performed in total electron yield mode (TEY) by recording the drain current of samples. For an aluminium oxihydroxide matrice, calculations give a tenth nanometers probed for the TEY mode (according to X-ray absorption cross section and electron mean free paths calculated for an incident beam at 1600 eV). Normalized spectra were extracted by subtracting a first-order polynomial fit to the pre-edge region (-35 to -12 eV) and dividing through a first-order polynomial fitted to the post-edge region (14 to 32 eV). Signals were corrected from self absorption using the Athena software [16] taking into account the samples elemental composition given by EPMA. After normalization and absorption correction, the XANES data were analyzed by linear combination fitting using XANES data obtained from pure standard compound with the help of Athena software. Several standards were used for the valuation of the octahedral coordination of aluminium, AlO6, in different symmetry site: - boehmite -AlOOH synthesized from the Yoldas’ method [17]. - gibbsite Al(OH)3 and an hydrous aluminium oxide (HAO): Hydrous aluminium oxide (HAO) [Al(OH)3.xH2O] was synthesised by forced hydrolysis, following the method of Schwertmann modified by A. Hofmann [18]. A solution of Al(NO3)3.9H2O 0.1 mol/l was neutralized until pH7 by adding a 1M KOH solution at a rate of about 5 ml/min, and maintained at this pH during 12 hours. Then, the obtained suspension was centrifuged, rinsed in deionising water, and finally dried at 35°C and stored in a dessicator. This compound is composed by amorphous nanoparticles with a gibbsite like structure. For the tetrahedral coordination AlO4, the used standard was albite, NaAlSi3O8, which is a tectosilicate (feldspath) containing 100% of aluminium in tetrahedral coordination, AlO4. Zeta potential measurements The zeta potential of the flat oxide surface was evaluated from the measurements of streaming potential using an asymmetric clamping cell (EKA apparatus, Anton Paar). The theoretical and experimental details of the measurements in these conditions are exposed in the literature 3 43 [19] . The zeta potential (sample) at a flat plate can be calculated from the streaming potential ΔUS εε0 ζ ref ζ sample . (Us/P) as follow : ΔP μκ 2 sample and ref are the zeta potentials of the sample surface and the PMMA reference surface, Us is the streaming potential, P is the applied pressure (ramp from 0 to +/-600mbar), µ is the dynamic viscosity of the solution, 0 is the permittivity of free space, is the dielectric constant of the solution, is the solution conductivity. Before each measurement, the cell was flushed in each direction several times to equilibrate the surface. The electrolyte was a 10 -4 NaCl solution (V=400 mL) and. The measurements in pH lower than 6.5 was performed a 104 mol/l HCl electrolyte. Then, the pH was adjusted by addition of 0.01 mol/l NaOH solution. The conductivity was measured before each measurements acid and the potential vs. pressure curves were checked to verify the linearity of the measurements. The zeta potential of PMMA surface (ref) was measured in the same conditions to calculate sample. 3. Results 3.1. The surface morphology and the chemical structure before sealing The FEG-SEM micrographs of the nanoporous oxide layer are displayed in the figure 1. As mentioned by some authors [5], the nanopores are homogeneously distributed on the surface (fig. 1c). The transversal cross-section carried out by fracture of the sample at room temperature show that the layer has a columnar structure with a pore arrangement perpendicular to the surface. The pores are well-oriented on all the layer thickness (fig. 1d). On this aluminium alloy and with these anodization conditions, the nanopores have a diameter of about 6 to 8 nm and the wall between the columnar pores have a thickness of about 20 to 25 nm. The total layer thickness is 7 µm (fig. 1a). X-ray diffraction analysis reveals that the layer is totally amorphous. This amorphous character was also confirmed at the 10 nm-scale by transmission electron microscopy observation. On the other hand, the elemental analysis of the oxide carried out by EPMA and confirmed by Glow Disccharge Optical Emission Spectroscopy (GD-OES) show that the oxide is mainly constituted by aluminium, oxygen and sulphur elements. Especially, the alloying elements of 7175 alloy (copper, zinc and magnesium) were not detected by the used techniques. EPMA results give a stoechiometry close to Al2O3 with approximately 4.5 wt.% of sulphur. Nevertheless, the sulphur distribution evaluated by a sulphur X-ray map, displayed in the fig. 1b, shows clearly that this element is homogeneously distributed overall the thickness. Infrared spectroscopy allows us to precise the chemical composition of the oxide. On the fig. 2, the characteristic vibration bands are assigned as follows [20]: - The broad band between 3000 and 3700 cm-1 is characteristic to the vibration of hydroxyl groups OH-. According to C. Monterra et al., the band at 3060 cm-1 is characteristics of the vibration of OH group in the boehmite structure [21]. - The vibration frequency at 1620 cm-1 is specifically assigned to the vibration of HOH bonds in the water molecule. - Between 1250 and 900 cm-1, the vibration bands of the SO4 tetrahedral corresponds to the presence of sulphate anions. The free-sulfate in solution belongs to Td symmetry groups and one only vibration band is observed at 1100 cm-1. In our case, the complexation of SO42- in the oxide leads to the activation of the stretching vibration band at around 955 cm-1 and two asymmetric stretching vibration at 1040 and 1170 cm-1, which indicates that sulphate anions are probably in monodentate geometry i.e. in C3v symmetry group [21]. So, the sulphate in the oxide structure is incorporated 4 44 during the oxide growth from the sulphuric acid bath, as previously observed by some authors [22]. - At low-frequency, the baseline of the spectra increases in intensity. This phenomenon is due to the overlap of AlOx vibration bands and the bending vibration band of the sulphate species. Thus, an accurate analysis is difficult in this region. The periodic oscillations which are visible in the 2600 – 1700 cm-1 range is due to a diffusion process induced by the periodic, well-oriented and parallel porosity. Because of several band overlap, infrared spectroscopy is not sufficient to completely describe the amorphous oxide. On the other hand, as observed by infrared spectroscopy, the thermogravimetric experiments coupled with mass-spectroscopy measurements of the gas release confirms the presence of water and sulphate anions in the oxide structure. In fact, we can observe on the fig. 3 two main releases of water (m/z=18) by increasing of temperature by increasing the temperature. The first one occurs at 100°C and corresponds to the adsorbed water or free-water. Then a progressive and low dehydratation is observed between 100 and 400°C which is probably due to the bounded water or OH group, as observed during the thermal decomposition of hydrated aluminium sulphate, Al2(SO4)3,18H2O [23]. Around 600°C, another low weight loss may be attributed to the departure of OH group inside the structure, leading to the formation of transition alumina. Finally, the more important weight loss of the oxide appears at 900°C and is due to the decomposition of sulphate ions into SO2/SO3 gas. This decomposition is identified by the detection of SO fragment (m/z=48) and the m/z=32 fragment which can correspond to O2 gas in equilibrium with SO2/SO3 gas. According to XRD analysis at different temperature, the crystallization of the amorphous oxide into the corundum structure -Al2O3 is only observed after the release of sulphur from the structure, above 900°C. If we assume that the weight loss at 900°C is mainly attributed to the sulphate decomposition, the sulphur content in the oxide can be evaluated to about 4 wt.%, which is the same order of magnitude than the results obtained by EPMA. The weight loss at 100°C, 400°C and 900°C are summarized in the table 1. In order to characterize the chemical bonding of aluminium atoms in the nanoporous oxide, X-ray absorption spectroscopy was carried out directly on the layer without preparation. The aluminium K-edge X-ray absorption spectrum is characterised by an absorption edge at about 1560 to 1570 eV in the fig. 4 and corresponds to a 1s to 3p transition of the aluminium atom [24] . For the unsealed nonporous layer, the XANES spectra is characterized by the position of the absorption edge at 1565.2 eV followed by a first peak A at 1566.5 eV which reveals clearly the presence of the tetrahedral coordination for aluminium atoms in the oxide, AlO4 (fig. 4a). We can note also a second absorption peak C, located at 1571.5 eV with almost the same intensity. However, the XANES spectrum of aluminium compound containing 100% of fourfold coordinated are generally distinguished by a strong edge absorption at 1565.4 eV followed by less intense absorption peaks at high energy, as observed in the albite spectra displayed in the fig. 4b and also mentioned by the systematic study of P. Ildefonse et al. [25]. So, in our case, the high intensity of the second peak C at 1571,5 eV, compared to the peak A can be attributed to the presence of aluminium in octahedral coordination, AlO6. Consequently, a correct fitting of the XANES spectra of the unsealed sample is obtained with a linear combination of XANES spectra of albite (AlO4 coordination) and gibbsite (AlO6 coordination). By using the standards displayed in the fig. 4b, the relative concentration of AlO4 versus AlO6 coordination in the amorphous structure can be evaluated and is noted in the table 2. The unsealed nanoporous oxide mainly contains approximately 2/3 of aluminum atoms in tetrahedral coordination. 5 45 3.2. The morphology and the chemical structure after sealing After the “sealing” process with different solution at boiling temperature (98°C), two kinds of morphology can be distinguished (fig. 5): - With bichromates “sealing”, the surface morphology seems unchanged. The pores at the top of the layer are yet opened, but the diameter of some of them is reduced. Inside the nanoporaous layer, the columnar pores look like unaffected (fig. 5a and b). - With cerium “sealing”, the surface of the nanoporous layer is covered with flakeshaped compound (fig. 5c). As can be observed in the fig. 5d, the top of the columnar pores is also modified, and it is difficult to distinguish to columnar pores. On the other hand, the pores at the bottom of the layer are very poorly affected by the sealing process. In the two cases, the analysis of infra red spectrum of oxide after sealing reveals that the layer is enriched in water as illustrated by the increase of the OH vibration band (between 2900 and 3700 cm-1). Moreover the presence of sulfate anions is also confirmed by the three vibration bands around 1000 cm-1. In the case of Ni and Ce-sealing, the CH3 vibration band at around 2900 cm-1 and the doublet between 1400 and 1600 cm-1 corresponding the symmetric and antisymmetric vibrations of COO group show that small amount of acetate anions (CH3COO-) is incorporated in the nanoporaous structure (fig. 2). For the Cr-sealing, the vibration bands of the CrO42- anions are overlaid with those of SO42- anions. The periodic oscillations between 2600 and 1700 cm-1, characteristic of the columnar porosity, are still observable after the process of sealing. The sulphur and free-water content was evaluated by thermogravimetric measurements, as noted in the table 1. As observed by infrared spectroscopy, the water content increase after the sealing processes and it is interesting to note that the sulphate content has also significantly decreased. The incorporation of cerium and chromium inside the structure was confirmed by the EPMA measurements, carried out on metallographic cross-section of the layer (fig. 6). The two elements, Ce and Ni, are mainly integrated in the top of the layer, especially in the case of Cesealing. In contrary, the incorporation of chromate seems to be easier, and chromium is incorporated in the layer structure overall the thickness. So, the diffusion of cations and anions is not similar in the nanopores. Concerning the chemical bonding of aluminium atoms in the oxide, all the XANES spectra of the sealed nanoporous oxide show a shift of the absorption edge position towards the high energies, as noted in the table 2. For all the sealed oxide, this change of the edge position is mainly due to the decrease of the A peak and the appearance of a third absorption B peak around 1568.5 to 1569.5 eV, as we can see in the fig. 4a.This change brings to light a change of the aluminium coordination from tetrahedral to octahedral configuration [25, 26]. In the Ni-sealed spectra, the A peak remains present, which is confirmed by the fit results in the table 2. Indeed, it remains approximately 25% of aluminium in tetrahedral coordination in the Ni-sealed nanoporous oxide. In contrary, the disappearance of A peak and the absorption edge position in the absorption spectra of Cr- and Ce-sealing indicate the quasi-total transformation of AlO4 tetrahedra into AlO6 octahedra. The fit results show that these spectra can be well simulated by only one compound with 100% of AlO6 octahedra (table 2). To summarize, the incorporation of water in the nanostructure is clearly associated with the transformation of aluminium coordination in the amorphous oxide from tetrahedral to octahedral configuration during the “sealing” processes. 3.3 The water diffusion inside the pore Considering the nanometric diameter of the pores, experiments with H2O18 (95 wt.%) as tracer were carried out to evaluate the wetting of the whole pores length with the “sealing” water. Then, the SIMS profil analysis of the O18-enriched samples are displayed in the figure were 6 46 analysed by SIMS. Preliminary experiments were performed to verify that the elements present on the surface of the layer are not pushed by the ionic beam inside the porosity until the metal/oxide interface during the SIMS measurements [27]. As can be observed in the fig. 7, the diffusion of water at 95°C inside the nanopores is very rapid. After 5 min of immersion, water penetrates inside the 7 µm of nanopores.. And when the “sealing” time increases (20 min), the fig. 7 shows that the 18O-enrichment slightly increases. So, the 18-oxygen exchange or incorporation seems to be rapidly limited to about 7 to 10 at.% after 20 min of dipping. 3.4 The surface charge of the oxide The typical value of acidity constant of Al-OH groups are pKa1=6.5 for Al-OH2+/Al-OH couple and pKa2=10.9 for Al-OH/Al-O- couple. So, the point of zero charge (PZC) of aluminium oxyhydroxide is at a pH value around 8.5 to 9 [28]. According to the evaluation of zeta potential of the nanoporous oxide from the measurements of streaming potential, the PZC value is around 10.5 as noted in the fig. 8. On a large range of pH (pH<PZC), the superficial charge density is then positive. If we assume that the main positive surface group is Al–OH2+, we can conclude that the oxide surface has an important acidic character in the Lewis sense. After sealing, the curves of zeta potential versus pH of Cr- and Ce-sealed samples show also behaviour of positive-charged surface. Nevertheless, the PZC of the sealed samples is located around 8.5 to 9, which reveals a slight decrease of the positive surface charge density. The electrostatic behaviour of the “sealed” nanoporous surface gets closed to the one of aluminium oxyhydroxide, as boehmite or gibbsite. 4. Discussions and mechanism Since several decades, nanoporous aluminium oxide formed by anodization was extensively studied and used for its particular morphology, a self-organized nanochannel material. However, in many studies, the composition of the oxide is simply described as “alumina” or “Al2O3”. Even if this chemical composition is a right description of the reality in a first approximation, the results obtained through this study show that this simple chemical description is not sufficient to explain the particular chemical reactivity of the nanochannels of anodic aluminium oxide. On the other hand, the chemical analysis and the morphology of Cr and Ce-sealed samples show that the incorporation of elements in the nanochannels strongly depends of the kind of “sealing” elements. 4.1 Structural model of anodic aluminium oxide TG-MS experiments, infrared spectroscopy and EPMA analysis clearly reveal the presence of sulphate ions, around 5wt.% of sulphur, hydroxyl groups and molecules of water in the amorphous oxide constituting the nanochannels. The water weight loss at 100°C is about 1 wt.%. Moreover, the analysis of XANES spectra shows that the major part of Al3+ cations in the oxide adopts a tetrahedral configuration, AlO4, in the oxide. So the chemical structure seems to be very particular. The hypothesis of a dry alumina as -Al2O3, oxyhydroxyde as boehmite AlOOH and hydroxide as gibbsite Al(OH)3 are not compatible with our results. We have to imagine an amorphous structure in which around 60 % of aluminium is in AlO4 coordination and 40% are in AlO6 in which sulphate anions are homogeneously distributed. It is important to note that this structure crystallize when the water excess and sulphate ions are released from the oxide. So the presence of sulphate and hydroxyl groups seems to be closely related to the amorphous character of the structure. The high content of tetrahedral aluminium is responsible for the surface chemical properties of walls constituting the nanochannel. Indeed the AlO4 cluster has a strong Lewis acidity, and can be easily hydrolysed into the more stable octahedral coordination, AlO6. According to molecular theory calculations, J. A. Van Bokhoven et al. has evaluated the charge of Al atoms 7 47 in octahedral sites at about +0.572, and that in tetrahedral site at about +0.737, which illustrate the electrophile character of tetrahedral aluminium [29].. The oxide surface behaves as an electrophile compound or a Lewis acid. This surface behaviour is comparable with the behaviour of some zeolite enriched in tetrahedral aluminium and used as catalysts. Consequently, tetrahedral aluminium on the oxide surface can be easily reacts with water molecules during the “sealing” processes. 4.2 Mechanism of “sealing” processes For the application of corrosion protections, the objectives of “sealing” processes is to incorporate inside the nanopores protective compounds and/or to fill the pores to improve the barrier effect of the oxide layer. The water diffusion across the layer monitored by 18O-tracer shows that, even though the nanometric diameters and micrometric length of the nanochannels, the diffusion of water molecules in these long tubes is very rapid. In fact, a water molecule reaches in few minutes the metal/oxide interface in the conditions of “sealing” processes. No phenomenon of capillarity inhibits the diffusion of water. Two main changes simultaneously occur in the chemical structure of the amorphous oxide: - The tetrahedral aluminium is transformed into octahedral aluminium, which explains the incorporation of 18O during the “sealing” treatment. The hydrolysis of AlO4 into AlO6 cluster in the oxide is also confirmed by the incorporation of the OH- group detected by the TG experiments at 400°C. This transformation by hydrolysis should induce a release of protons, and a decrease of pH inside the pores. - The sulphate anions are partially released from the structure, which can be also explained by the hydrolysis of aluminium sulphate complex (table 1). In solution, the hydrolysis of Al2(SO4)3 at high temperature provokes its dissociation, following the general scheme: Al2(SO4)3 + 6H2O 2Al(OH)3 + 3H2SO4 Despite the fact that the chemical structure of the amorphous oxide change, these transformations have a slight effect on the morphology of the nanochannels, as can be observed on the fig. 5. However, the rapid diffusion of water does not assure the rapid diffusion of “sealing” compound as we can see in the concentration profile of cerium or chromates in the fig. 6. According several studies in the field of filtration [30], the diffusion of charged species in nanoporous membrane is strongly dependent on the electrostatic interactions with membrane surface. This observation can be explained by the measurement of transport across a glass nanopore electrode of G. Wang et al. [31]. In fact, the surface charges of the oxide generate an electric field that is radially located into the pores. If we assume that the electric field can be extended until a distance of 3*-1 where -1 is the Debye length, the field extend can be evaluated to about 10 nm in 0.01 M electrolyte. The electric field created by the electric surfaces can entirely fill the nanopores, and the structure of the electrolyte inside the pores is completely determined or “frozen” by the surface charges of the oxide in very small pores diameter (5 to 10 nm). In our case, as the surface charges of the oxide constituting the wall of channels are positive, the diffusion of anionic species as chromates inside the channels is more rapid than the diffusion of neutral molecules or cationic species. This phenomenon also explains the difficulty to incorporate very charged cations as Ce3+ in this nanoporous structure. Moreover, the formation of this superficial flakes-shaped film enriched in cerium tends to limit the supply of cerium cations towards the layer surface. 8 48 5. Conclusion Layers of self-ordered anodic oxide of aluminium are commonly used for their geometric properties, because they constitute continuous layers to protect aluminium alloys against corrosion, or their nanometric pores constitute templates to build up nano-objects or membranes. Throughout this study, we have shown that the anodic oxide constituting the walls of the nanochannels have also specific chemical properties, induced by the chemical structure of the oxide. The amorphous nature of the oxide is probably due to the presence of around 5wt.% of sulphate in the oxide and a high content of Al3+ cation in tetrahedral coordination. At the surface of the nanochannels, the oxide is positively charged because of the acid Lewis character of the tetrahedral aluminium. Consequently, during the “sealing” processes, the diffusion of species inside the nanopores strongly depends on electrostatic interactions between the charge of the “sealant” species and the positive charges of the surface porosity. At the same time, the hydrolysis phenomenon at high temperature provokes a transformation of AlO4 to AlO6 coordination and the partial release of sulphate anions from the nanostructure. Acknowledgements: ANR RNMP project PROXY3A [1] J.M. Macak, H. Tsuchiya, A. Ghicov, K. Yasuda, R. Hahn, S. Bauer, P. Schmuki Current Opinion in Solid State and Materials Science 2007, 11, 3 [2] H. Tsuchiya, J.M. Macak, L.V. Taveira, A. Ghicov, P. Schmuki, Corros. Sci., 2005; 43, 3324. [3] J. Choi, J.H. Lim, J. Lee, K.J. Kim., Nanotechnology; 2007; 18, 055603 [4] H. El-Sayed, S. Singh, M.T. Greiner, P. Kruse, Nano Lett., 2006; 6, 2995 [5] G. Thompson, G.C. Wood in Anodic films on aluminum. Treatise on materials science and technology, vol. 23, Academic Press, New York; 1983. [6] S. Berger, H. Tsuchiya, P. Schmuk Chem. Mater. 2008, 20, 3245–3247. [7] S. Kipke, G. Schmid, Adv. Mater. 2004, 14, 1184 [8] N. Lopez, T.V.W. Janssens, B.S. Clausen, Y. Xu, M. Mavrikakis, T. Bligaard,. J Catal 2004; 223, 232. [9] J.Y. Lyang, H. Clink, A.J. Yin, J. Xu, J. Appl. Phys, 2002, 91, 2544 [10] M.S. Sander, L.S. Tan, Adv. Mater. 2003, 13, 393 [11] T.P. Hoar, G.C. Wood, Electrochim. Acta, 1962, 7, 333 [12] B. Zhang, Y. Zhang, H. S. White, Analytical Chemistry, 2004, 76, 6229 [13] E. Rocca, J. Steinmetz, J. of Electroanal. Chem., 2003, 543, 153 ; G. Bourguignon, A. Maitre, E. Rocca, J. Steinmetz, L. Torcheux, J. of Power Sources, 2003, 113, 301 [14] E. Rocca, J. Steinmetz, S. Weber, J. of Electrochem. Soc., 1999, 146, 54. [15] A.M. Flank, G. Cauchon, P. Lagarde, S. Bac, M. Janousch, R. Wetter, J.M. Dubuisson, M. Idir, F. Langlois, T. Moreno, D. Vantelon, Nuclear Instruments & Methods in Physics research section B, 2006, 246, 269 [16] B. Ravel, M. Newville, Journal of Synchrotron Radiation, 2005, 12, 537 [17] B.E. Yoldas, J. of Appl. Chem. and Biotech., 1973, 23, 803 [18] U. Schwertmann and R.M. Cornell in Iron Oxides in the Laboratory: Preparation and Characterization, Wiley, VCH , New-York,, 2000. [19] S.L. Walker, S. Bhattacharjee, E.M.V. Hoek, M. Elimelech, Langmuir, 2002, 18, 2193 [20] K. Nakamoto, in Infrared and Raman spectra of Inorganic and Coordination compounds (Volume B), Wiley-Intersciences, 5th Edition, 1997 [21] C. Monterra, G. Magnacca,, Catalysis Today, 1996, 27, 497 [22] V. Balasubramanian, S. John, B. A. Shenoi, Surface Technology, 1983, 19, 993 9 49 [23] A. Gehin, PhD Dissertation, October 2007, University Henri Poincaré, Nancy (France) [24] D.A. McKeown, Physics and Chemistry of Materials, 1989, 16, 678 [25] P. Ildefonse, D. Cabaret, P. Sainctavit, G. Calas, A.M. Flank, P. Lagarde, Physics and Chemistry of Minerals, 1998, 25, 112 [26] J.A. Van Bokhoven, H. Sambe, D.E. Remaker, D.C. Koningsberg, J. of Phys. Chem B, 1999, 103, 7557 [27] E. Rocca, J. Steinmetz, S. Weber, J. of Electrochem. Soc., 1999, 146, 54 [28] L. Ermakova, M. Sidorova, N. Bogdanova, A. Klebanov, Colloids and surfaces A : Physicochemical and Engineering Aspects, 2001, 192, 337 [29] J.A. van Bokhoven, T. Nabi1, H. Sambe, D.E. Ramaker, D.C. Koningsberger, J. Phys.: Condens. Matter, 2001, 13, 10247 [30] J.M.M. Peeters, M.H.V. Mulder, H. Strathmann, Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1999, 150, 247; J.M.M. Peeters, M.H.V. Mulder, H. Strathmann, Journal of Membrane Science, 1998, 145, 199 [31] G. Wang, B. Zhang, J. R. Wayment, J. M. Harris, H. S. White, J. Am. Chem. Soc., 2006, 128, 7679 10 410 a) b) c) d) Figure 1. FEG-SEM micrographs of the nanoporous oxide layer after anodization of 7175 alloy. (a) Polished cross-section. (b) X-ray map of sulfur measured by EPMA (c) surface. (d) Transversal cross section after fracture. Absorbance Cr-sealed Ni-sealed unsealed 500 1000 1500 2000 2500 3000 Wavenumber / cm 3500 4000 -1 Figure 2. Infrared spectra of the unsealed, Ni-sealed and Cr-sealed nanoporous oxide layer on 7175 alloy. 11 411 1,00 -1,00 m/z=18 MS count / a.u Weight loss / % 0,00 -2,00 m/z=32 -3,00 -4,00 m/z=48 -5,00 -6,00 -7,00 0 200 400 600 T / °C 800 1000 1200 Figure 3. TG-MS measurement of unsealed nanoporous oxide layer between 50°C and 1200°C under argon flux. The weight loss is in bold line. Normalized absorption / a.u. Normalized absorption / a.u. AB C unsealed Cr-sealed Ni-sealed Ce-sealed 1560 1570 1580 1590 exp fit gibbsite albite 1600 1560 Energy /eV 1570 1580 1590 1600 Energy / eV b) a) Figure 4. (a) XANES spectra for unsealed and sealed nanoporous layer. (b) Superposition of fit performed on the unsealed sample with the two standards used for the fitting procedure 12 412 a) surface b) Cross-section by fracture c) surface d) Cross-section by fracture Figure 5. SEM micrographs of the nanoporous oxide layer after Cr- and Ni-sealing (a, b) and after Ce-sealing (c, d) 100 Ce x30 Ni x30 80 wt. % Cr x30 60 40 20 0 0 2 4 6 8 Depth /µm 10 Figure 6. Concentration profile measured by EPMA in the nanoporous oxide layer after 30 min of Cr-sealing, Ni-sealing or Ce-sealing at 95°C. 13 413 100 % at. Al 18 % at. O - unsealed 18 % at. O - 5 mn sealed 18 % at. O - 20 mn sealed 90 80 70 % at. 60 50 40 30 20 10 0 0,0 0,2 0,4 0,6 0,8 1,0 1,2 % of abrasion layer Figure 7. SIMS analysis of nanoporous oxide layer without sealing and after 5 mn and 20 mn of water-sealing at 95°C containing 95 wt.% of H218O 80 unsealed Ce-sealed Cr-sealed 60 mV 40 20 0 -20 3 4 5 6 7 8 9 10 11 pH Figure 8 . potential in function of pH Free water (%wt. loss at 100°C) OH group (%wt. loss at 400°C) Sulfate content (%wt. loss at 900°C) Unsealed 0,4 % 1.5 % 9% Cr-sealed 0,8 % 3.8 % 4% Ce-sealed 1,1 % 2.4 % 2% Nanoporous layer Table 1. Weight loss measured by thermogravimetry with a bi-layer foil Nanoporous layer Untreated Ni-sealed Cr-sealed Ce-sealed Edge position (eV) 1565.2 1566 1567.8 1567.8 Fit results 65% albite 35% Gibbsite 25% albite 75% Gibbsite 100% Hydrous Amorphous Oxide 100% boehmite 14 414 AlO4/(AlO6+AlO4) coordination ratio 0.65 0.25 0 0 Table 2. Absorption edge position of the XANES spectra, fit results and coordination ratio (TEY detection) The table of contents entry should be fifty to sixty words long, written in the present tense, and refer to the chosen figure. Keyword (see list) Emmanuel ROCCA*, Delphine VANTELON, Aurelie GEHIN, Myriam AUGROS, Alain VIOLA Mechanism and chemical transformations of the nanoporous aluminium oxide during “sealing” processes Nanopores on the surface 8 nm Nanochannels + + + + + + + + + + Easy diffusion of water and anions + + + + + + 7 µm During the “sealing” processes of nanoporous aluminium oxide, the diffusion of ionic species inside the nanochannels is mainly controlled by the positive charges of the surface porosity. Simultaneously, the easy water diffusion leads to the transformation of AlO4 into AlO6 clusters in the oxide. Al 15 415