Form RC/38 - Department of Industrial and Systems Engineering

SUBJECT DESCRIPTION FORM

Subject title: Special Topics in Modelling and Optimization of Assembly Lines

Subject code: ISE6833

Credit value: 3

Responsible staff and department:

Dr C.Y. Chan (ISE)

Pre-requisite: (Subject title and code no, if any)

Nil

Recommended background knowledge:

Basic knowledge in queuing theory and programming experience may have advantage.

Mutual exclusions:

Nil

Learning approach:

The subject is conducted in Mode II. Mode II is operated for guided study subjects with no relevant

MSc subject/short course available. The student is required, under the supervision of the subject supervisor, to read specified monographs, journal publications and books. The student and the subject supervisor will meet once per week to discuss the progress in the subject. Coursework such as the literature survey reports and the presentations would be included. At the end of the semester the student will be examined, normally both orally and in written form.

Assessment:

Model II:

Objectives:

Coursework:

Examination:

40%

60%

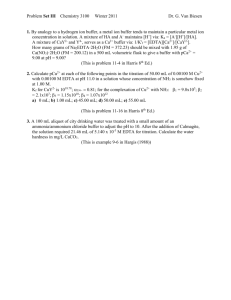

1.

To understand concepts of modelling an assembly line and its complexity in real world.

2.

To investigate the use of Queuing theory in tackling assembly line problems.

3.

To optimize assembly line buffer, with the consideration of production schedule and toleration for unknown errors.

Keyword syllabus:

Assembly line

Assembly line design, buffer design, assembly line balancing, downtime toleration

Queuing theory

Queuing modeling, queuing network, Little’s theorem, process delay, transmission delay

Optimization techniques

Integer programming, constraint programming, Graph Theory, basic Artificial Intelligence techniques

Learning outcomes:

1. To acquire basic knowledge of assembly line. (Objective 1)

2. To be able to model the assembly line by using Queuing theory approach. (Objective 2)

3. To be able to apply various optimization techniques to support assembly line design.

(Objective 3)

Indicative reading list and references:

1.

Hideaki Yamashita, Tayfur Altiok, (1998). Buffer capacity allocation for a desired throughput in production lines. IIE Transactions, 30, 883-891

2.

John Miltenburg, (2000). The effect of breakdowns on U-shaped production lines. Int. J. Prod.

Res., 38(2), 353-364

3.

Brahim Rekiek, Pierre De Lit, Alain Delchambre, (2000). Designing Mixed-Product Assembly

Lines. IEEE Transactions on Robotics and Automation, 16(3), 268-280

4.

Liu Chiun-Ming, Chen Chung-Hwa, (2002). Multi-section electronic assembly line balancing problems: a case study. Production Planning & Control, 13(5), 451-461

5.

Yan HS, Xia QF, Zhu MR, Liu XL, Guo ZM, (2003). Integrated production planning and scheduling on automobile assembly lines. IIE Transactions, 35(8), 711–725

6.

Becker C, Scholl A, (2006). A survey on problems and methods in generalized assembly line balancing. European Journal of Operational Research, 168(3), 694-715

7.

Scholl A, Becker C, (2006). State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. European Journal of Operational Research, 168 (3), 666 – 693

8.

Hedelind M, Funk P, Milic M, (2006). Intelligent buffer storage system enabling fast and flexible assembling with industrial robots. Journal of Intelligent & Fuzzy Systems, 17(4), 367-376

9.

Gusikhin O, Caprihan R, Stecke KE, (2008). Least in-sequence probability heuristic for mixedvolume production lines. International Journal of Production Research, 46(3), 647–673

10.

Stephen G, Powell, David F.P., (1998). Buffering unbalanced assembly systems. IIE

Transactions, 30, 55-65

11.

Huang M.G., Chang P.L, Chou Y.C., (2002). Buffer allocation in flow-shop-type production systems with general arrival and service patterns. Computer & Operations Research, 29, 103-121

(December 2009)