purity oxide

advertisement

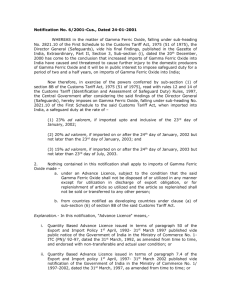

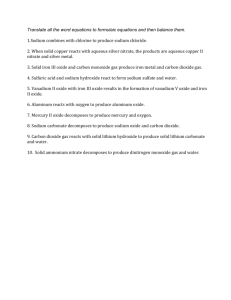

1. FERRIC OXIDE OF FERRITE/MAGNETIC GRADE 1. PRODUCT CHARACTERISTICS Ferrite is an important component in the electronic industry. With the rapid growth of electronic industry in India and all over the world, the demand for ferrites are also rapidly increasing with stress on special grades and stringent specifications. The Ferric oxide is an important input for the manufacture of soft and hard ferrites. Product specifications of high purity Ferric oxide Item Assay (dried at 120 deg.C) Drying loss Acid insolubles, max. Water solubles, max. Sulphate, max. Copper, max. Alkali and alkaline earths (as oxides) Silica, max. 2. Percentage >99.90 <0.30 0.02 0.10 0.005 0.005 0.10 max 0.02 PRODUCT APPLICATIONS Ferric oxide is mainly used in the manufacture of hard and soft ferrites. Hard ferrites are a group of ceramic permanent magnetic materials containing barium, strontium or lead oxide in their lattice apart from ferric oxide. The name hard ferrites results from the ability of these materials to generate high coercive forces. Hard ferrites are used in the manufacture of communication devices, high density magnetic optic memory devices. Soft ferrites are used in the manufacture of recording/erase heads for audio, video, computer tapes and T.V. components etc. Magnetic Iron Oxide is used for the coating of audio tapes, video tapes, computer tapes and floppy discs. 3. IMPORTS The present import level of Ferric oxide of ferrite and magnetic grade is around 4000 tonnes per annum. Safeguard duty on gamma ferric oxide imports The Finance Ministry has imposed safeguard duty for a period of two and a half years on imports of gamma ferric oxide/magnetic iron oxide (GFO) into India. Based on the recommendation of the Director-General (Safe-guards), the Revenue Departments has imposed a safeguard duty of 23 percent on imports of GFO up to January 23, 2002. All imports of GFO from January 24, 2002 to January 23,2003 would attract a safeguard duty of 20 percent. Further, imports of GFO from January 24, 2003 to July 23, 2003 would attract a safe guard duty of 15 percent. It has, however, been held that the safeguard duty will not be applicable to GFO imported under an advance licence, subjected to certain conditions and also in respect of imports from countries that have been notified as developing countries under Section 8B (6)(a) of the Customs Tariff Act, 1975. The Director-General (Safe-guards) had concluded that increased imports of GFO into India have caused and threatened to cause further serious injury to the domestic producers of GFO and it will be in the public interest to impose safeguard duty for a period of two and a half years on imports of GFO into India. The safeguard investigation was restricted only to audio grade GFO, which is used for manufacturing audio tapes. 4. EXPORTS 5. INDIAN MANUFACTURER Marginal quantity The Associated Cement Co. Ltd., has set up a synthetic Ferric oxide plant of ferrite grade of capacity 10,000 tonnes per annum at Falta near Calcutta, at an estimated project cost of Rs.25 crores. The company has tied technical collaboration with IROX-NKK, Japan and International Steel Services Inc. Pittsburgh (USA). National Mineral Development Corporation, Hyderabad produces Ultra pure Ferric oxide at Visakhapatnam capacity of plant 1000 tonnes per annum of ferrite grade. Herdillia Oxides and Electronics Ltd.,is the producer of Ferric oxide of magnetic grade in the country of capacity 2000 tonnes per annum. It started production in 1991 to cater primarily to the domestic requirement of Magnetic Iron Oxide (MIO) or Gamma Ferric Oxide (GFO) as an import substitute for the Magnetic casting of audio video and computer tapes. It has now reached an understanding to export these oxides to the US, from where the technology was procured. This plant is reported to be the latest and only magnetic media plant operating outside USA, Germany, Japan and China, where this technology had been closely held. The manufacture of MIO in India was possible with the technology obtained from Magnox Inc., which was an erstwhile division of Hercules Inc., Delaware, USA who have equity share holding in the promoting company, Herdillia Chemicals Ltd. The company started its production in January 1991 and the product is well accepted in terms of quality and as an import substitute. 6. DEMAND SUPPLY TREND Present Indian demand for high purity Ferric oxide of Fe2O3 above 99% of ferrite grade and magnetic grade : 9000 tonnes per annum Estimated growth rate in demand: 7 to 8% per annum 7. MANUFACTURING PROCESS FOR FERRITE GRADE Synthetic Iron oxides of high purity required for soft ferrites are generally prepared by the following methods. I. Ferrous salt is reacted with alkali and the resulting precipitate is filtered and washed. This process is repeated till highly pure Ferric oxide of desired purity is obtained. II. Ferric chloride is vapourised and in the vapor state steam hydrolysed to produce pure and fine Ferric oxide powder. 8. GLOBAL SCENARIO Global demand 9. : 0.8 million tonnes per annum RECOMMENDATIONS Considering the expected growth in the ferrites and electronic industries, it is important to create additional capacities for Ferric oxide of magnetic and ferrite grades. The acquisition of technology, particularly magnectic grade iron oxide could require considerable efforts. The import of the product is likely to continue. Recommended capacity 10000 tonnes per annum Estimated project cost Rs.40 crores