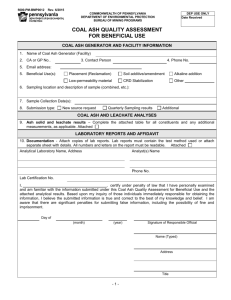

Preparation and Characterization of Activated Carbon

advertisement

Preparation and characterization of activated carbon from South African coal and coal fly ash for adsorption application S.P. Langwenyaa, B.B. Mambaa, S.B. Mishraa*, M. Balakhrishnanb a University of Johannesburg, Faculty of Science, Department of Chemical Technology, PO Box 17011, Doornfontein 2028, RSA b The Energy and Resource Institute (TERI), Habitat Place, Lodhi Road, New Delhi 100003, India *Corresponding Author Email: smishra@uj.ac.za ABSTRACT The objective of this work was to utilize a simple and cost-effective method for the preparation of activated carbon from cheap and readily available sources for the removal of phenol from wastewater. Activated carbon was prepared from South African coal and coal fly ash (CFA) in a furnace using a stainless steel container. Carbonization was achieved in a self-generated atmosphere and activation by mixing carbonized samples with water to form slurry in the temperature range 550˚C-1000˚C for 1h. Pore structure development was measured by Braunner-Emmet-Teller (BET) surface area analysis. Further characterization was achieved by proximate analysis, scanning electron microscopy (SEM) and Fourier Transform Infra Red (FTIR) spectroscopy. Activated carbon with superior properties recorded a surface area of 52.12m2/g and 2.04m2/g for coal and coal fly ash at 1000˚C, respectively. From the SEM images, activated coal samples present a rough surface which is evident of external gasification, whilst activated CFA had pores on the surface. For adsorption application, up to 91% removal of phenol by coal-based activated carbon was achieved and 73% for CFA-based activated carbon. Key words: activated carbon, adsorption, coal, coal fly ash 1 1. Introduction Activated carbon (AC) is a carbonaceous material with large surface area and high porosity. It is widely used in purification processes, water treatment and catalysis (Tancredi et al, 2004). It can be prepared from a large number of sources such as palm shells, wood, coconut shells, coal, carbon fibers and pitch (Joseph et al, 2007). However, bituminous coals are the main precursor because of their inherent microstructure and surface chemical properties (Gryglewicz and Lorenc-Grabowska, 2004; El Qada et al, 2006; Wang et al, 2007). In addition, they have greater density, hardness, and abrasion resistance and are more durable (Teng et al, 1996). Lignite and anthracite (other ranks of coal) have also been used (Gonzalez-Serrano et al, 2004; Lillo-Rodenas et al, 2004; Skodras et al, 2007). Ligninocellulosic materials such as agro-residues and combustion ashes as precursors for AC have been explored. These include bagasse, bagasse fly ash, sawdust, wood ash, rice husk ash, corncob, pinewood, plum kernels, bamboo and coal fly ash (Satyawali and Balakrishnan, 2007; Tseng RL and Tseng SK, 2005); Juang et al, 2000; Wu et al, 1999). South Africa is largely dependent on the combustion of coal for power generation (Petric et al, 2003). However, most South African (SA) power stations utilize poor quality coal with low calorific value hence high yields of ash in boilers after combustion (communication services, ESKOM). The ash may contain non-degradable or conservative mobile inorganic compounds, which were previously sequestered geochemically but through combustion are mobilized. Wet disposal of coal ash has been associated with developmental abnormalities in animals and negative impacts on phyto- and zooplankton (Reijnders, 2005; Issues document, 1997). Efforts to minimize disposal costs through beneficiation techniques such as influencing the characteristics of the fly ash (FA) to optimize its utilization and increase its value have been explored. One of them is the application of FA as an adsorbent for wastewater treatment. It has been utilized raw or modified, converted to zeolitic products, used as a precursor for activated carbons (Hsu et al, 2008; Kao et al, 2000; Wang et al, 2008, Querol et al, 2001; Woolard et al, 2000; Pengthamkeerati et al, 2008; Zhang et al, 2003; Zhao et al, 2005). 2 Phenols are high priority pollutants because of their high toxicity and possible accumulation in the environment (Lin and Juang, 2008). Along with their derivatives phenols represent an important group of refractory organic compounds present in a variety of industrial wastewaters because they are used as intermediates in the synthesis of dyes, pesticides, explosives, insecticides, etc (Gonzalez-Serrano et al, 2004). In addition to the unpleasant odor, they contribute to unpleasant taste too (Ahmaruzzaman, 2008). The Environmental Protection Agency has set a water purification standard of less than 1ppb of phenol in surface waters (Busca et al, 2008). Adsorption process has proved to be an effective method for their removal especially on activated carbons as shown by several workers (Gryglewicz et al, 2002; Savrolpoulos et al, 2008; Tseng RL and Tseng SK, 2005; Podkoscielny et al, 2006; Salame and Bandoz, 2003; Hameed and Rahman, 2008; Tseng et al, 2003; Tancredi et al, 2004). Commercial AC is normally produced by chemical or physical activation. In physical activation, the first step is carbonization of the raw material in an oxygen-free environment followed by activation in an oxidizing environment, usually steam or CO2 (Rubio et al, 2007; Cuhadoroglu and Uygun, 2008; Gryglewicz et al, 2002; Ciu et al, 2007; Tan et al, 2008).39-44 Air flux has also been used in the activation step (Tancredi et al, 2004). Commercial ACs specifically, have a large capacity for phenol adsorption and can be easily modified to increase their adsorption properties (Ahmaruzzaman, 2008). However, their expensive regeneration and production using expensive precursors is unjustified for most pollution control applications, (Ahmaruzzaman, 2008; Busca et al, 2008; Streat and Patrick, 1995) hence the need to search for economic adsorbents. FA can be utilized as a precursor since it has already undergone devolatilization during combustion in the furnace thus only requires activation (Izquierdo and Rubio, 2008; Baltrus et al, 2001; Maroto-valer et al, 1999). Hence the objective of the study was to employ a simple and cost effective method for production of ACs from coal and coal fly ash via physical activation in the temperature range 550˚C-1000˚C. The method employed was adapted from work done by Satyawali and Balakrishnan (2007), previously employed to agro-residues. 3 2. Experimental 2.1 Materials Coal and coal fly ash samples were supplied by ESKOM, South Africa. The coal was sourced from Kusile and Kriel Power stations whereas the fly ash was from Matla and Camden Power station. The coal samples were ground and milled to obtain a particle size fraction in the range 425µm – 106 µm and for the purposes of this study they were labeled KU for Kusile and KR for Kriel. Coal fly ash (CFA) samples were sieved and the particle size fraction obtained was below 120mesh size. These were labeled FAC (Camden) and FAM (Matla). Phenol, of analytical grade, was supplied by Qualigens Fine Chemicals, Mumbai, India; pure 4-amoniantipyrene by Merck, Mumbai, India. 2.2 Activated Carbon Preparation 2.2.1 Carbonization/ pyrolysis Known amounts of precursors were filled in cylindrical stainless steel (SS) containers with a tight lid. The containers were placed in another larger SS container and sealed with a tight lid. In order to ensure an inert atmosphere (except for the air trapped in the voids of the adsorbent) the annular space between the two containers was filled with sand to the brim of the larger container and this arrangement also provided uniform and efficient heat. This was heated in a muffle furnace at temperature ranges 550-1000˚C. 2.2.2 Steam activation 4 A fixed amount of the thermally treated samples was mixed with distilled water to form slurry and the same arrangement was prepared as described earlier and heated at the same temperature range. However, for fly ash samples, only the activation process was applied since these had already undergone devolitilization process in the combustion chamber. 3. Characterization Chemical analysis of the fly ash samples was determined by X-Ray fluorescence (Spectro, X-Lab 2000). The surface area, for both raw and the activated samples, was measured by N2 adsorption at 77K using a surface area analyzer (TriStar 3000, Micrometrics Instrument Corporation, USA). For microporosity and mesoporosity of activated samples, the Iodine and methylene blue numbers were determined according to ASTM D 2330 and ASTM D 4607, respectively. Coal samples and ACs were characterized by proximate analysis according to ASTM standards. Scanning electron microscopy (SEM) was carried out to study their surface textures and development of porosity by means of a JEOL JSM-5600 scanning electron microscope with an accelerating voltage 15.0kV. In addition, the surface functional groups of the prepared activated carbon were detected by FTIR spectroscopy and the spectra was recorded from 4000 to 400cm-1. 4. Adsorptive Properties The equilibrium adsorption isotherms for phenol were determined at room temperature. Known amounts of AC were weighed and added to stoppered elernmeyer flasks containing 50-100ml of known concentrations of phenol solutions. These were agitated at 150rpm for 24h which was sufficient to reach equilibrium. After filtration, the residual phenol was determined by UV-spectroscopy using the aminoantipyrine method. Kinetic batch adsorption studies were done using a fixed amount of adsorbent 5 for 4h with activated coal and 6h with activated fly ash which, from preliminary adsorption is sufficient for adsorption to reach equilibrium. Sampling times were 5, 10, 15, 30, 60, 120, 180, 240, 300, 360min. The effect of initial concentration was also tested by increasing the initial concentration keeping all other parameters constant. 5. Results 5.1 Physicochemical characterization Table 1 and 2 present the characteristic properties of coal and CFA used as precursors for activated carbon production. Table 1: Characteristics of Coal Samples Property Kriel Coal Kusile Coal (KR) (KU) %Volatile matter 25.4 21.5 %Ash 27.8 40.1 %Moisture 2.0 3.0 Table 2:Physicochemical Properties of CFA Sample BET surface area m2/g LOl %Fixed carbon 44.8 35.4 VM/Ash 0.91 0.54 FAC 0.64 1.60 FC/ash 1.61 0.88 FAM 0.79 1.88 BET surface area 5.72 7.31 (m2/g) Chemical FAC FAM SiO2 61.1 60.1 Al2O3 26.7 27.2 Fe2O3 1.64 1.71 composition % mass 6 TiO2 1.94 1.55 SO3 0.223 0.405 CaO 3.54 4.27 P2O3 0.374 0.422 MgO 1.12 1.03 MnO 0.007 0.008 Na2O 0.551 0.561 Cl 0.063 0.066 K2O 0.774 0.707 KR was a low ash coal with 44% fixed carbon whereas KU had high ash content, about 40%. Volatile matter differed by 4% between the two coals. Surface areas recorded were 5.71m2/g and 7.31m2/g for KR and KU, respectively. For CFA, there were slight differences between the two fly ash samples. They both had low surface area, 0.64m2/g and 0.79m2/g for FAC and FAM respectively. This may be due to the low %loss on ignition, which represents the percentage of unburned carbon. They recorded %LOI of 1.60 (FAC) and 1.88 (FAM). From chemical analysis, the FAs turned out to constitute, mainly, oxides of silicon and aluminium (≈ 87%). Additional oxides are those of iron, titanium, calcium and magnesium. The characteristics of the activated samples are presented in Table 3 showing the activation temperatures, burn-off and BET surface areas. Table 3: Characteristics of ACs Sample Activation Burn off BET surface area temperature ˚C (wt%) (m2/g) KU 550 13.8 6.11 KR 550 20.7 5.90 KU 700 20.1 29.2 KR 700 21.3 45.8 KU 1000 24.7 52.12 Coal 7 KR 1000 28.8 23.91 FAC 550 3.4 1.23 FAM 550 2.7 0.63 FAC 700 3.7 1.47 FAM 700 3.9 0.82 FAC 1000 6.0 1.96 FAM 1000 4.8 2.04 Fly ash Effect of temperature and precursor used on activation It has been reported that lower rank coals such as sub-bituminous and lignite can be activated more easily and produce better quality activated carbons than high rank coals such as semi-anthracite under similar activation conditions.35, 39 In this study KU (FC = 35.4%) activated better than KR (FC = 44.8%) at high temperatures. Activation temperature had an effect on the surface area of the resulting ACs. With increasing activation temperature i.e. from 550˚C -1000˚C, surface area increased continuously for KU whereas with KR it increased from 550˚C -700˚C then decreased at 1000˚C. The increase in surface area with increasing temperature may be due to the thermally unstable volatiles components being liberated at higher temperatures. At high temperatures there is increased devolatilization of reactive macerals. 40 Lu et al, 41 elaborated that surface area is created when gaseous products are liberated, then the agglomerates disintegrate and more heat is carried away from the particles hindering particle growth hence leading to larger surface area. Low surface area at low temperatures may therefore be due to incomplete carbonization. For KR, the reduction in porosity may be due to thermoplastic property of the coal, which is the loss of rigidity, and hence the collapsing of the frames blocks the pores at higher temperatures or due to thermal degradation thus lower surface area.23 With KU, it might possibly be that this type of coal 8 does not go through thermoplastic phase. Due to its high ash content, there may be possible formation of a stable phase which prevents collapse of the pores. Overall, the optimum activation temperatures for KR and KU were 700˚C and 1000˚C respectively. With the fly ash samples, surface area development was very low probably due to the presence of a high concentration of dense minerals. Increasing the activation temperatures led to an increase in surface area for both FAC and FAM. The highest value obtained was 2.04m2/g for FAM which initially had a surface area of 0.79m2/g after activation at 1000˚C. During heat-treatment at high temperatures as 1000˚C there may be possible decomposition of alkaline metal salts leading to generation of gases,37, 38 and this could have contributed to the slight porosity development in the FA. Both FAs had a high percentage of SiO 2 (>60%) rendering them chemically stable hence the lower reactivity during activation. Also, the tiny fraction of unburned carbon in the FA samples has undergone devolatilization while in the combustor at temperatures probably much higher than those used in our study thus the reactivity of the fly ash is relatively low hence the poor surface area development.29 Morphology SEM micrographs for activated coal and fly ash are presented in fig.1-6. For the coal-based activated carbon, the micrographs reveal that the activation process seems to affect the external structure of the coal. Raw coal had a smooth surface whereas its activated counterparts had a rough and eroded surface. This may imply that gasification and pore development occurred on the external surface. The level at which the surfaces are eroded could be related to pore development, since Fig. 4 which is KU-1000°C presented a more rough surface yet recorded the highest surface area after activation. Activation also resulted in fine particles adhering on surfaces of larger particles. There was also an increase on the ash content on the surfaces of the ACs. Such observation is supported by proximate analysis whereby the ash content increased from 40.1% to 51% in KU. For the fly ash, activated samples are characterized by pore 9 development as depicted in fig.6 even though BET analysis recorded a slight development in terms of surface area. Fig.1 SEM image of raw coal Fig.3 SEM image of activated KR at 700˚C Fig.4 SEM image of raw CFA Fig.2 SEM image of carbonized coal Fig.4 SEM image of activated KU at 1000˚C Fig.6 SEM image of activated CFA Spectral analysis 10 Figure 7 depicts representative spectra of raw and activated coal samples. After activation, some peaks disappeared and more pronounced peaks became less intense. The –OH peak around 3600cm-1 and -CH peak at 2920 cm-1 disappeared, C=C band at 1600 cm-1 was lowered due to possible occurrence of conjugation, C-O band at 1436 cm-1 disappears. Such observations proved the occurrence of carbonization. Also noted was the lowering plus broadening of the absorption band at 1028 cm-1, which could be associated with Si-O and C-O. According to Gomez-Serrano et al,44 peaks in the spectral region which occur below 1200 cm-1 are associated with absorptions mainly caused by mineral matter of coal. For the activated coal, these peaks were observed to disappear which may be due to loss of volatile mineral matter. 3.6 coal AC 3.4 3.2 3.0 Si-O, C-O 2.8 absorbance 2.6 2.4 2.2 -OH 2.0 1.8 1.6 C=CC=O -CH 1.4 1.2 1.0 0.8 0.6 4000 3500 3000 2500 2000 1500 1000 500 wavenumber (cm-1) Fig.7 FTIR spectra of raw and activated KU Adsorptive Properties The important property of the activated carbon is its adsorptive capacity which is related to the specific surface area. MB molecule gives information on mesoporosity whereas Iodine molecule gives 11 information on microporosity of ACs. Methylene blue and Iodine number tests were inapplicable for our samples. These may probably be due to poor development of both micropores and mesopores. Adsorption experiments were carried out using phenol as representative organic pollutant/ model compound it this study. Figure 8-10 show the effect of contact time and concentration on adsorption capacity of the activated coal (KU) and CFA (FAM). 20 Qt (mg/g) 16 12 8 50ppm 80ppm 100ppm 4 0 0 60 120 180 240 300 tim e(m in) Fig.8 Adsorption capacity vs. contact time at various initial phenol concentrations Figure 9. Effect of contact time on phenol uptake by FAM concentration on phenol uptake by FAM Figure 10. Effect of initial 12 For activated KU, equilibrium adsorption was almost attained within the first 15min; however, the contact time required for the phenol solutions to reach equilibrium was 4h. It was also observed that the amount of phenol adsorbed increased with contact time. The amount of phenol adsorbed at equilibrium time reflects the maximum adsorption capacity of the adsorbent under those operating conditions. 44 Adsorption capacity at equilibrium increased from 8.395mg/g to 18.220mg/g with increasing initial concentration from 50mg/l to 100mg/l. Also, the overall percentage removal increased from 80.9% to 91.4%. The effect of contact time on the adsorption capacity of activated FAM is shown in fig.9. As presented in the graph, the sorption rate expressed as time variation of the adsorbed amount, increased rapidly within the first hour and about 69.9% of phenol had been removed. After this time the amount adsorbed increases until it reaches equilibrium after 5-6h. Figure 10 gives a graphical presentation of the effect of initial concentration on the adsorption of phenol at equilibrium. With increasing initial concentration, the percentage removal decreases at equilibrium adsorption. This may possibly be due to occupation of total active sites which hinders access of more adsorbate on the adsorbent. At the concentration range studied here it was found that the amount of phenol adsorbed was 0.0271mg/g which seemed to be the limiting value hence adsorption on the FA dependent on availability of active sites. Wang et al,36 stated that the uptake of adsorbates is higher at low concentration than at high concentrations which agrees with our findings. The adsorption capacity (0.0271mg/g) recorded for the activated fly ash is far low than the one generally obtained for typical activated carbons which is normally above 100mg/g, however, it was slightly higher than that obtained by Potgieter et al,49 on raw South African coal fly ash who recorded 0.0233mg/g. Conclusion With the method employed, the high ash coal, KU activated better with maximum surface area of 52.12m2/g and the surface area increased with increasing temperature within the range studied. For the fly ash with LOI less than 2%, the method was not promising. In preparing activated carbons from fly ash the 13 amount of unburned carbon plays a significant role in the development of porosity. Although there was some development of porosity (0.64m2/g-1.96m2/g for FAC and 0.79m2/g - 2.05m2/g for FAM) high temperatures were used only give a slight increment in surface area thus not an economical method for the type of fly ash used in our study. Utilizing this type of fly ash for zeolite production or activation by other chemical means would be a better option. However, phenol uptake by the activated fly ash was very promising. Up to 73% removal efficiency was achieved with FAM and 56% with FAC, which shows its potential in water treatment application, specifically activated FAM, which recorded the highest % removal. Activated KU on the other hand, recorded up to 92% phenol removal and the adsorption capacity increased with increasing concentration. Acknowledgements My sincere gratitude goes to my supervisors listed as co-authors for their support and encouragement, the National Research Fund (NRF), Nanotechnology Innovation Centre (NIC) and the University of Johannesburg for Financial support, and finally The Energy and Resource Institution for collaborative research. References Ahmaruzzaman Md. Advances in Colloid & Interface Science 143 (2008) 48-67 Bagreev A., Menendez J. A., Dukhno I., Tarasenko Y., Bandosz T.J. Carbon 42 (2004) 469-476 Baltrus J.P., Wells A.W., Fauth D.J., Diehl J.R., White C.M. Energy Fuels 15 (2001) 455-462 Busca G., Berardineli S., Recini C., Arrighi L. Journal of Hazardous Materials 160 (2008) 265-288 Communication Services, ESKOM. 1996:1-3. Duvha coal-fired giant. Technical Information 14 Cuhadoroglu D., Uygun O.A. African Journal of Biotechnology 7 (2008) 3703-3710 El Qada E.N., Allen J.S., Walker G.M. Chemical Engineering Journal 124 (2006) 103-110 Gonzalez-Serrano E., Cordero T, Rodriguez-Mirasol J., Cotoruelo L., Rodriguez J.J. Water Research 38 (2004) 3043-3050 Gryglewicz G., Lorenc-Grabowska E. Carbon 42 (2004) 667-671 Gryglewicz G., Grabaz K., Lorenc-Grabawska E. Carbon 40 (2002) 2403-2411 Hameed B.H., Rahman A.A. Journal of Hazardous Materials, 2008: Article in Press Hong Cui, Yan Cao, Wei-Ping Pan. J. Anal. Appl. Pyrolysis 80 (2007) 319-324 Izquierdo M.T., Rubio B. Journal of Hazardous Materials 155 (2008) 199-205 Joseph C.G., Bono A., Khrishaniah D., Soon K.O. Materials Science 13 (2007) 83-87 Juang R.S., Wu F.C, Juang R.S., Tseng R.L. J. Colloid Interface Sci. 227 (2000) 437 Lillo-Rodenas M.A., Carzona Amoros D., Linares-Solano A., Beguin F., Clinard C., Rouzaud J.N. Carbon 42 (2004) 1305-1310 Lin S., Juang R. Journal of Environmental Management (2008) 1-14. Article in Press Maroto-valer M.M., Taulbee D.N., Schobert H.H., Hower J.C., Andresen J.M. International Ash Utilization Symposium, Paper #19, 1999 Minnesota Office of Environmental Services. Issues document: Part 1 coal ash, 1997. www.dot.state.mn.us/environment/research Pengthamkeerati P., Satapanajaru T., Chularuengoaksorn P. Fuel 87 (2008) 2469-2476 Petrik F.L., White R.A., Klink M.J., Somerset V.S., Burgers C.L., Fey M.V. International Ash Utilization Symposium, University of Kentucky, Paper #61, 2003. www.flyash.info Ping-Chung Kao, Jau-Hwang Tzeng, Tsz-Ling Huang. Journal of Hazardous Material 76 (2000) 237-249 15 Podkoscielny P., Nieszporek K., Szabelski. Colloids & Surfaces A: Physicochem. Eng. Aspects 277 (2006) 52-58 Potgieter J.H., Bada S.O., Portgieter-Vermaak S.S. Water SA 35 (2009) 89-96 Querol X., Umana J.L., Plana F., Alastuey A., Lopez-Soler A., Medinacelli A., Valero A., Domingo M.J., Garcia-Rojo E. Fuel 80 (2001)857-865 Reijnders L. Resources, Conservation and Recycling 43 (2005) 313-336 Rubio B., Izquierdo M.T., Mayoral M.C., Bona M.T., Andres J.M. Journal of Hazardous Materials 143 (2007) 561-566 Salame I.I., Bandosz T.J. Journal of Colloids & Interface Science 264 (2003) 307-312 Satyawali Y., Balakrishnan M. Bioresource Technology 98 (2007) 2629-2635 Skodras G., Diamantopoulou Ir., Sakellaropoulos G.P. Desalination 210 (2007) 281-287 Stavrolpoulos G.G., Samaras P., Sakellaropoulos G.P. Journal of Hazardous Materials 151 (2008) 414421 Streat M., Patrick J.W., Camporo Perez MJ. Water Research 29 (1995) 467 Tan I.A.W., Ahmad A.L., Hammed B.H. Desalination 222 (2008) 13-28 Tancredi N., Medero N., Moller F., Piriz J., Plada C., Cordero T. J. Colloid Interface Sci. 279 (2004) 357363 Teng H., Ho J., Hsu Y., Hsieh C. Ind. Chem. Eng. Res. 35 (1996) 4043-4049 Ting-Chu Hsu, Chung-Chin Yu, Chin-Ming Yeh. Fuel 87 (2008) 1355-1359 Tseng R.L., Tseng S.K. J. Colloid Interface Sci. 287 (2005) 428-437 Tseng RL, Wu FC., Juang RS. Carbon 41 (2003) 487-495 Wang HL, Jiang WF. Ind. Eng. Chem. Res. 46 (2007) 5405-5411 Wang S., Ma Q., Zhu Z.H. Fuel (2008). Short Communication Wang Q., Zhang X., Xu D., Chen Q. J. China Univ. Mining & Technol. 17 (2007) 494-497 Woolard C.D., Petrus K., van de Horst M. Water SA 26 (2000) 531-536 Wu F.C. Tseng R.L., Juang R.S. J. Environ. Sci. Health A 34 (1999) 1753 16 Zhang Y., Lu Z., Maroto-Valer M., Andresen M.J., Schobert H.H. Energy & Fuels 17 (2003) 369-377 Zhao N., Wei N., Li J., Qiao Z., Cui J., He F. Chemical Engineering Journal 115 (2005) 133-138 17