Project Title:

PREPARATION OF ACTIVATED CARBON FROM SCRAP-COIR IN

VIETNAM BY CHEMICAL ACTIVATION METHOD FOR

POLLUTANTS ADSORPTION IN WATER

PURPOSE OF THE EXPERIMENT

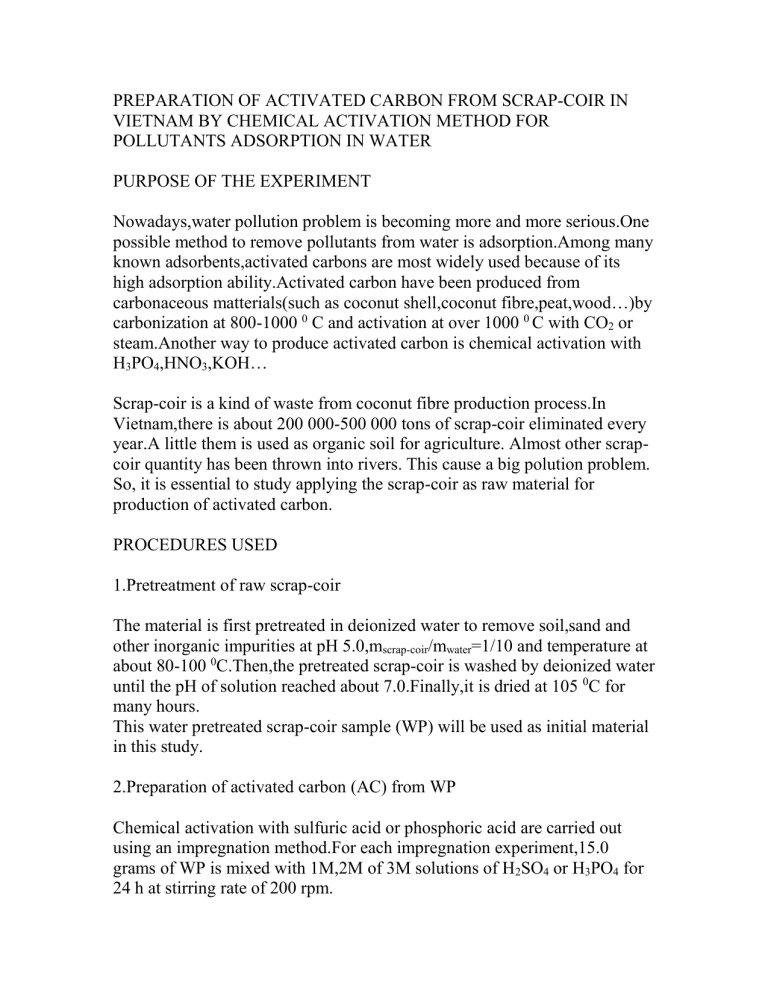

Nowadays,water pollution problem is becoming more and more serious.One possible method to remove pollutants from water is adsorption.Among many known adsorbents,activated carbons are most widely used because of its high adsorption ability.Activated carbon have been produced from carbonaceous matterials(such as coconut shell,coconut fibre,peat,wood…)by carbonization at 800-1000 0 C and activation at over 1000 0 C with CO

2

or steam.Another way to produce activated carbon is chemical activation with

H

3

PO

4

,HNO

3

,KOH…

Scrap-coir is a kind of waste from coconut fibre production process.In

Vietnam,there is about 200 000-500 000 tons of scrap-coir eliminated every year.A little them is used as organic soil for agriculture. Almost other scrapcoir quantity has been thrown into rivers. This cause a big polution problem.

So, it is essential to study applying the scrap-coir as raw material for production of activated carbon.

PROCEDURES USED

1.Pretreatment of raw scrap-coir

The material is first pretreated in deionized water to remove soil,sand and other inorganic impurities at pH 5.0,m scrap-coir

/m water

=1/10 and temperature at about 80-100 0 C.Then,the pretreated scrap-coir is washed by deionized water until the pH of solution reached about 7.0.Finally,it is dried at 105 0 C for many hours.

This water pretreated scrap-coir sample (WP) will be used as initial material in this study.

2.Preparation of activated carbon (AC) from WP

Chemical activation with sulfuric acid or phosphoric acid are carried out using an impregnation method.For each impregnation experiment,15.0 grams of WP is mixed with 1M,2M of 3M solutions of H

2

SO

4

or H

3

PO

4

for

24 h at stirring rate of 200 rpm.

The resultingmixture is filtered and dried at 105 0 C overnight.Then impregnated WP is carbonized in a horizontal furnace,under a nitrogen gas flow(2.51 min -1 ).The furnace temperature is increased from room temperature to 400 0 C,500 0 C or 600 0 C with heating rate of 20 0 C.min -1 and held at this temperature for different ti mesof 30 min,90 min or 180 min.

To estimated the effect or sulfuric acid on the characteristic of resulting materials,WPsample without impregnated H

2

SO

4

or H

3

PO

4

solution should be carbonized at 400 0 C,500 0 C or 600 0 C for 30 min.The other carbonization conditions are as in the chemical activation process.

OBSERVATIONS/DATA/RESULTS

A)Characterization of the materials

1.Ash content (%) is determined by the method of Ahmedna.According to that,approximately 2 grams of sample is placed into weighed ceramic crucibles.Sample and crucibles are dried overnight at 80 0 C and reweighed to obtain the dry material weight.Then,they are heated at 760 0 C for at least

6 h.The crucibles are cooled in a desicator and ash are weighed.

2.Porous characteristics

-Mesopore (2nm-50nm) and macropore (>50nm)size distributions are estimated with a MICROMERITICS AUTOPORE VI 9500 mercury porosimeter up to 2,000 atm,to estimate the volume constituted by all pores with a diameter from 100 000 nm down to 8.5 nm.

-To determine specific surface area and micropore characteristics,nitrogen adsorption/desorption isotherms are performed at 77k with a CHEMBET

3000 surface area analyzer.The specific surface area is calculated by

Brunauer-Emmett-Teller equation.The mesopore (2nm-50nm) and micropore (<2nm) volumes are estimated according to Barrett Joyner

Halenda and Horvath Kawazoe theories,rspectively.

-Size and morphological features was studied by Scanning electron microscopy (S-4800 UHR-FE-SEM-Hitachi,Japan)after fibers metallization with 100 0A platinum.

3.Surface chemistry

-The pH of point of zero charge is measured following Franz method.Titrations by 0.1N solutions of NaOH or HCl are carried out at 298

K,after stirring during 24 h of 500 mg AC product in 50 ml of NaCl electrolyte solutions(0.1N,0.05N and 0.01N)

-The surface acidic oxygen functional groups of AC product are determined by the Boehm titration method.500 mg of AC is stirred for 24 h in 25 ml of

0.1 N solutions of base with different strengths:sodium ethoxide

(NaOC

2

H

5

),sodium hydroxide (NaOH),sodium carbonate (Na

2

CO

3

) or sodium bicarbonate (NaHCO

3

).After this time,the slurry is filtered and a 10 ml aliquot is titrated with 0.1 N HCl.The results of titration are expressed as mol H + equivalent/g carbon.

B)Adsorption of organic compounds or metallic ions in water

Phenolic compounds and Cu +2 ion (from CuSO

4

)are selected to test pollutant adsorption ability of AC products.They are chosen because of their popularity in municipal and industrial wastewater.

The method used in this study is performed in stoppered glass reactor,kept in a temperature-controlled water bath at 25±1.0 0 C with contant stirring rate of

300 rpm.

For each pollutant,isotherm experiments are performed at 293 K.Given weights of are stirred in 0.250 L of an aqueous solution containing the pollutant with an initial concentration ranging from 5 to 100 mg L -1 .The contact time needed to reach equilibrium is set to 48 h for phenol and 120 h for copper on the basis of kinetic experiments carried out in previous works.In the case of copper adsorption,pH is maintained at a value of 5.0 by adding 0.1N NaOH.

CONCLUSIONS

To produce activated carbon powder from waste coconut fibre in

Vietnam,with application for pollutants removal from water.