click here for concept exam1 key

advertisement

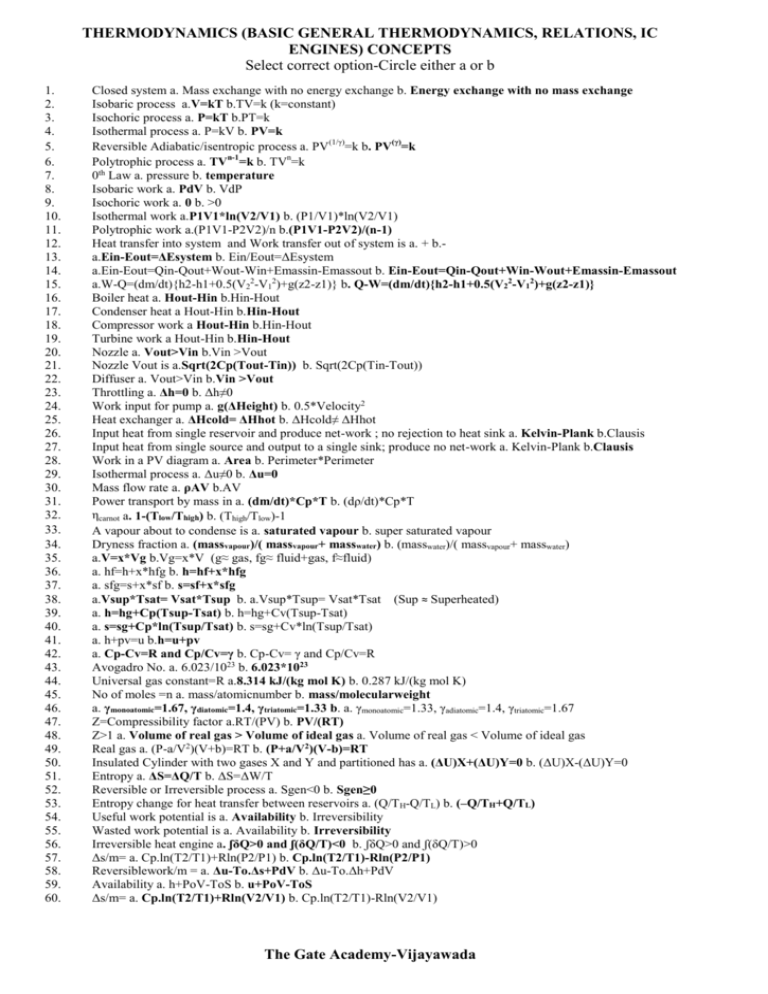

THERMODYNAMICS (BASIC GENERAL THERMODYNAMICS, RELATIONS, IC

ENGINES) CONCEPTS

Select correct option-Circle either a or b

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

Closed system a. Mass exchange with no energy exchange b. Energy exchange with no mass exchange

Isobaric process a.V=kT b.TV=k (k=constant)

Isochoric process a. P=kT b.PT=k

Isothermal process a. P=kV b. PV=k

(1/γ)

(γ)

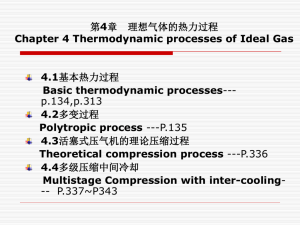

Reversible Adiabatic/isentropic process a. PV =k b. PV =k

n-1

n

Polytrophic process a. TV =k b. TV =k

0th Law a. pressure b. temperature

Isobaric work a. PdV b. VdP

Isochoric work a. 0 b. >0

Isothermal work a.P1V1*ln(V2/V1) b. (P1/V1)*ln(V2/V1)

Polytrophic work a.(P1V1-P2V2)/n b.(P1V1-P2V2)/(n-1)

Heat transfer into system and Work transfer out of system is a. + b.a.Ein-Eout=ΔEsystem b. Ein/Eout=ΔEsystem

a.Ein-Eout=Qin-Qout+Wout-Win+Emassin-Emassout b. Ein-Eout=Qin-Qout+Win-Wout+Emassin-Emassout

a.W-Q=(dm/dt){h2-h1+0.5(V22-V12)+g(z2-z1)} b. Q-W=(dm/dt){h2-h1+0.5(V22-V12)+g(z2-z1)}

Boiler heat a. Hout-Hin b.Hin-Hout

Condenser heat a Hout-Hin b.Hin-Hout

Compressor work a Hout-Hin b.Hin-Hout

Turbine work a Hout-Hin b.Hin-Hout

Nozzle a. Vout>Vin b.Vin >Vout

Nozzle Vout is a.Sqrt(2Cp(Tout-Tin)) b. Sqrt(2Cp(Tin-Tout))

Diffuser a. Vout>Vin b.Vin >Vout

Throttling a. Δh=0 b. Δh≠0

Work input for pump a. g(ΔHeight) b. 0.5*Velocity2

Heat exchanger a. ΔHcold= ΔHhot b. ΔHcold≠ ΔHhot

Input heat from single reservoir and produce net-work ; no rejection to heat sink a. Kelvin-Plank b.Clausis

Input heat from single source and output to a single sink; produce no net-work a. Kelvin-Plank b.Clausis

Work in a PV diagram a. Area b. Perimeter*Perimeter

Isothermal process a. Δu≠0 b. Δu=0

Mass flow rate a. ρAV b.AV

Power transport by mass in a. (dm/dt)*Cp*T b. (dρ/dt)*Cp*T

ηcarnot a. 1-(Tlow/Thigh) b. (Thigh/Tlow)-1

A vapour about to condense is a. saturated vapour b. super saturated vapour

Dryness fraction a. (massvapour)/( massvapour+ masswater) b. (masswater)/( massvapour+ masswater)

a.V=x*Vg b.Vg=x*V (g≈ gas, fg≈ fluid+gas, f≈fluid)

a. hf=h+x*hfg b. h=hf+x*hfg

a. sfg=s+x*sf b. s=sf+x*sfg

a.Vsup*Tsat= Vsat*Tsup b. a.Vsup*Tsup= Vsat*Tsat (Sup ≈ Superheated)

a. h=hg+Cp(Tsup-Tsat) b. h=hg+Cv(Tsup-Tsat)

a. s=sg+Cp*ln(Tsup/Tsat) b. s=sg+Cv*ln(Tsup/Tsat)

a. h+pv=u b.h=u+pv

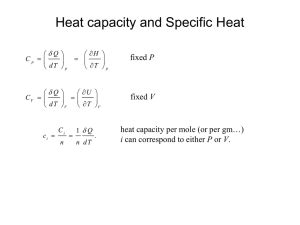

a. Cp-Cv=R and Cp/Cv=γ b. Cp-Cv= γ and Cp/Cv=R

Avogadro No. a. 6.023/1023 b. 6.023*1023

Universal gas constant=R a.8.314 kJ/(kg mol K) b. 0.287 kJ/(kg mol K)

No of moles =n a. mass/atomicnumber b. mass/molecularweight

a. γmonoatomic=1.67, γdiatomic=1.4, γtriatomic=1.33 b. a. γmonoatomic=1.33, γadiatomic=1.4, γtriatomic=1.67

Z=Compressibility factor a.RT/(PV) b. PV/(RT)

Z>1 a. Volume of real gas > Volume of ideal gas a. Volume of real gas < Volume of ideal gas

Real gas a. (P-a/V2)(V+b)=RT b. (P+a/V2)(V-b)=RT

Insulated Cylinder with two gases X and Y and partitioned has a. (ΔU)X+(ΔU)Y=0 b. (ΔU)X-(ΔU)Y=0

Entropy a. ΔS=ΔQ/T b. ΔS=ΔW/T

Reversible or Irreversible process a. Sgen<0 b. Sgen≥0

Entropy change for heat transfer between reservoirs a. (Q/T H-Q/TL) b. (–Q/TH+Q/TL)

Useful work potential is a. Availability b. Irreversibility

Wasted work potential is a. Availability b. Irreversibility

Irreversible heat engine a. ʃδQ>0 and ʃ(δQ/T)<0 b. ʃδQ>0 and ʃ(δQ/T)>0

Δs/m= a. Cp.ln(T2/T1)+Rln(P2/P1) b. Cp.ln(T2/T1)-Rln(P2/P1)

Reversiblework/m = a. Δu-To.Δs+PdV b. Δu-To.Δh+PdV

Availability a. h+PoV-ToS b. u+PoV-ToS

Δs/m= a. Cp.ln(T2/T1)+Rln(V2/V1) b. Cp.ln(T2/T1)-Rln(V2/V1)

The Gate Academy-Vijayawada

THERMODYNAMICS (BASIC GENERAL THERMODYNAMICS, RELATIONS, IC

ENGINES) CONCEPTS

Select correct option-Circle either a or b

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

90.

91.

92.

93.

94.

95.

96.

97.

98.

99.

100.

101.

102.

103.

104.

105.

106.

107.

108.

109.

110.

111.

112.

113.

114.

115.

Rate of entropy generation (Irreversibility rate :pressure drop due to friction) a. mR(ΔP/P1) b. mR(ΔS/S1)

Availability (VdP)= a. (h1-h2)-To(s1-s2) b. (u1-u2)-To(s1-s2)

Irreversibility a. To ΔS b. To/ΔS

Reversible engine with 2 sources and1 sink a. (Q1/T1)+(Q2/T2)-(Q3/T3)=0 b. (Q1/T1)+(Q2/T2)+(Q3/T3)=0

Carnot Cycle a. 2 adiabatic and 2 isentropic b. 2 adiabatic and 2 isothermal

Stirling Cycle a. 2 isochoric and 2 isothermal b. 2 isochoric and 2 isentropic

Ericson Cycle a. 2 isochoric and 2 isentropic b. 2 isobaric and 2 isothermal

Reversible process a. dW=VdP and dQ=SdT b. dW=PdV and dQ=TdS

a. dU=TdS-PdV b. dU=TdS+PdV

a. dH=TdS-VdP b. dH=TdS+VdP

Helmholtz a. dA= -SdT-PdV b. dA= -SdT+PdV

Gibbs a. dG= -SdT+VdP b. dG= -SdT-VdP

a. (δT/ δV)S= -(δP/ δS)V b. (δT/ δV)T=-(δP/ δS)P

a. (δT/ δP)S= -(δV/ δS)P b. (δT/ δP)S= (δV/ δS)P

a. (δS/ δV)V= (δP/ δT)T b. (δS/ δV)T= (δP/ δT)V

a. (δS/ δP)T= -(δV/ δT)P b. (δS/ δP)P=(δV/ δT)V

Volume Expansivity a. β=( δV/ δT)*(1/V) b. β= -( δV/ δP)*(1/V)

Isothermal Compressibility a. α=( δV/ δT)*(1/V) b. α = -( δV/ δP)*(1/V)

a.Cp-Cv=(VT α 2)/ β b.Cp-Cv=(VT β2)/ α

a. Cp≥Cv b. Cv≥Cp

At Temperature =0 K a. Cp-Cv ≈ 1 b. Cp-Cv ≈ 0

Joule Thompson Coefficient a. μjt =(δT/ δP)h b. μjt =(δT/ δP)S

a. Cooling = μjt > 0, Warming = μjt < 0 b. Cooling = μjt < 0, Warming = μjt >0

a. μjt = [T(δv/ δT)P-v]/Cp b. μjt = [T(δv/ δT)P-v]/Cv

For IC engines a. Weight:Power is maximum a. Weight:Power is minimum

Piston rings are made of a. Steel b. Silicon Cast Iron

Bearings are made of a. White Metal b. Soft Grey Metal

Cylinder liners are made of a. Al -alloy steel b. Ni- alloy steel

Piston Swept Volume (Vs) a. Area*Length b. Perimeter2*Length

(Compression Ratio-1) a. Vs/Vc b. Vc/Vs

Volumetric Efficiency a. 4stroke>2stroke b. 4stroke<2stroke

4stroke has __;2stroke has ___ a. ports ; valves b. valves; ports

Thermal Efficiency a. Diesel> Petrol b. Diesel< Petrol

Indicated Thermal Efficiency a. IP/(mf*Lower Heat Calorific Value) b. IP/(mf*Higher Heat Calorific Value)

Brake Thermal Efficiency a. BP/(mf*Lower Heat Calorific Value) b. BP/(mf*Higher Heat Calorific Value)

Mechanical Efficiency a. IP/BP b. BP/IP

Volumetric Efficiency a. Swept.Vol/Act.Vol b. Act.Vol/Swept.Vol

Relative Efficiency a. Actual.Therm.η /Air.Std. η b. Air.Std. η / Actual.Therm. η

Brake Specific fuel Consumption & Ind. SFC a. mf/(BP-IP), mf/(IP-BP) b. mf/(BP), mf/(IP),

Single Cylinder-4 Stroke Ind.Mean.Eff.Pressure/60 a. (2*IP/(LAN)) b. (IP/(LAN))

Equivalence Ratio for rich mixture is Air Fuel Ratio a. Act/ Stoic b. Stoic/ Act

Equivalence Ratio for rich mixture is a.<1 b.>1

Otto Cycle a. Heat Addition and rejection @ Cv b. Heat Addition and rejection @ Cp

Otto Cycle Efficiency a. 1- [1/r(γ-1)] b. 1- [1/r(γ)]

Diesel Cycle a. Heat Addition @ Cv and rejection @ Cp b. Heat Addition @ Cp and rejection @ Cv

γ

Diesel Cycle Efficiency if {(ρ -1)/(ρ-1)} =c a. {1- [1/r(γ-1)]}*c b. {1- [1/r(γ-1)]}*(c/γ)

Diesel Cycle a. Cut-off Ratio = Comp.ratio/Expan.ratio b. Cut-off Ratio = Expan.ratio/Comp.ratio

Dual Cycle has a. 2 Cp and 1 Cv processes b. 2 Cv and 1 Cp processes

For Max.Pressure and Max.Temperature Efficiencies a. diesel>dual>otto b. diesel<dual<otto

Idling(I),Cruising(C),Max.Power(P),ColdStarting(S) |A/F ratios | a. S>P>I>C b. S>I>P>C

Mean Eff.Pressure a. (Work Done/Cycle)/ Swept Volume b. (Work Done/Cycle)/ Clearance Volume

Mass of Air Fuel Mixture if A/F is air fuel ratio a. (A-F) kg/kg of fuel b. (A+F) kg/kg of fuel

In 4stroke Swept Volume/second a. 0.8*D2*L* no.of cylinders*rpm/60 b. 0.8*D2*L* no.of cylinders*rpm/120

In 4Stroke no. of revolutions in one cycle a. 1 b.2

Torque in Nm, Power in kW is, N in rpm a. (2πNT/60000) b. (2πNT/60)

The Gate Academy-Vijayawada