Gelatine in Historical Paper Production and as Inhibiting Agent for

advertisement

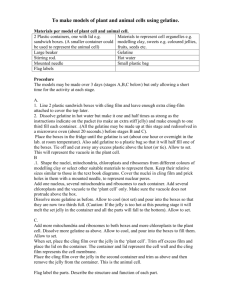

Gelatine in Historical Paper Production and as Inhibiting Agent for Iron-Gall Ink Corrosion on Paper by GESA KOLBE INTRODUCTION In the field of paper restoration various treatments will require the decision as to whether resizing would be advisable and whether any desirable properties could be gained by it. A further question would be what materials could be used for resizing? The history of paper production may provide some answers, and the influence of sizing or resizing on the long term stability of a paper during natural ageing might also help answer this question. The intention of this article is, firstly, to give an introduction to the history of papermaking, focusing on the traditional gelatine sizing technique, and, secondly, to show the results of a research project dealing with resizing in paper restoration, of mainly iron-gall ink manuscripts. HISTORICAL PAPER SIZING Most probably, the very earliest papers, those produced in China since the 1st or the 2nd centuries, had no sizing at all. It seems that sizing paper - whether surface or external sizing using wheat starch paste or other vegetable extracts, applied by brush - , began in the Islamic cultural area, where paper was introduced in die middle of the 8th century1. In Europe, the first sized paper was made at Fabriano (prov. Ancona, Marche; Italy) in the late 13th century. As a sizing agent hide glue, or gelatine was used, applied by soaking. This form of size and method of application was almost exclusively used until the invention of machine made paper and pulp or internal sizing at the beginning of the 19th century2. These days surface sizing using gelatine is only used for special papers, mainly for artistic use, such as watercolour paper for example3. Surface sizing today is also done using wheat starch modifications or cellulose ethers, such as methyl cellulose4. In modern paper production surface sizing has been almost totally replaced by pulp sizing. Until the 1970s the earliest, and virtually the only method of sizing, was alum-rosin sizing, which had been invented in the early 19th century by Moritz Friedrich Illig5. Neutral mass sizes based on synthetic organic compounds have been developed since the middle of the last century6. The synthetic sizing agents, applied only in a neutral or slightly alkaline medium, are thought to contribute to the permanence of the paper produced in this way. Today these sizing systems are even more economical man traditional alum-rosin sizing and consequently they are about to become standard in the paper industry. Neutral size is reactively bound, irremovable and considered to be the most suitable type of size for the production of permanent paper according to the relevant international standard3,7. Definition and terms The terms "gelatine" and "animal hide glue" used above indicate that the correct designation of the historical sizing material may be problematic. In fact, the two terms are often used synonymously in the context of papermaking. According to the modern definition "gelatine" stands for the purest and highest-quality form of soluble collagen, which is produced from bones or hides after hydrolytic decomposition by means of heat and the addition of an acid or an alkali. The term "gelatine" (lat. gelare, gelatus = freeze, frozen; stiff) was coined at the end of the 17th century. At that time, in 1685, the first production in gelatine factories was set up in Europe. Gelatine became more and more popular for cooking and as food supplement at the beginning of the 19th century, later also for pharmaceutical purposes and the production of photographic emulsion layers. According to the technical definition, "animal hide glues" are more hydro-lytically decomposed than gelatine and are cleaned less carefully8. Preparation and qualities Until the 19th century, animal hide glue for paper sizing was mainly prepared on the spot at the paper mill, even though, since the end of the 17th century, it had also been possible to buy dried sheets from professional glue boilers, a trade that arose at this time. Paper mill made sizing glue was not usually dried to form sheets, but used in solutions of varying consistencies, according to practical experience, without computing the concentration exactly9. For production at the site of the paper mill animal wastes and remnants from tanneries were kept simmering for 24 hours. The glue sludge was then sieved and treated with additives (see below). The paper sheets were passed through the warm (24°-30°C) glue solution, couched subsequently in the glue press and hung up for air drying. We can only rely on information provided by de la Lande for an idea of the concentration used, he states that six thousand pounds of paper required five hundred pounds of brochette - animal waste. Practically, sizing was done in different ways depending on empirical values in relation to the quality and the use of the paper10. According to de la Lande, before each sizing action a sample sheet had to be made. For the quality of brochette de la Lande differentiated very precisely which tannery waste was usable. He preferred waste scraps of tawed goat and lamb skin and bleached bark-tanned scraps of cattle skin, as they gave a "weaker", but brighter and more beautiful glue. Dutch fish glue (isinglass) was regarded, even though expensive, as being the highest quality; the second choice was colle de Flandre, i.e. Flemish joiner's glue. Since the middle of the 19th century the use of gelatine had been considerably influenced by the development of industrial gelatine production and of photographic techniques11. This influenced paper sizing practice insofar as the amount, availability and variety of qualities increased and more and more higher-quality gelatine was used. An author for papermaking of this time suggested that "white gelatine" should be preferred to a joiner's glue because of its brighter colour10. Purpose and effect The purpose of sizing is to make paper hydrophobic to such an extent that aqueous inks and colours can be applied. Moreover, the mechanical properties of paper are enhanced and its resistance to tearing and abrasion is improved4. Surface sizing with gelatine in particular results in considerably increased paper solidity and, in addition to the water repelling effect, in protection against oil-based materials. A surface size based on starch would not have this effect to any comparable degree. Surface sizing with gelatine made the paper, to some extent, similar to vellum, which had been the writing support in Middle-Age Europe. This might have contributed to the acceptance of the new material and sizing technique. Early historical sources mention that the thickness of sizing was regarded as appropriate if the sized sheet gave a sound like vellum when creased2. The comparable surface of vellum and paper sized using animal glue is obvious with regard to the affinity of iron-gall ink. The ink components act as lo- cally active tanning agents; the ink is reactively bound to the protein units at the surface of the vellum as well as to those of the gelatine at the surface of the paper, thus becoming insoluble, i.e. indelible in water. Reactions of the ink components with the cellulose fibres of the paper also take place, but there is no tanning effect comparable to that between ink components and the proteinaceous substance of vellum or animal glue. The general intensity of a size depends on the use of the paper. Watercolour or writing papers need a thicker size than paper for letterpress. Paper for incunabula and other early printed books had only a weak or even no sizing at all, since the printing inks were oily and viscous, which made it possible to omit the expensive and difficult sizing process2 (de la Lande, ref. 9). Sizing was considered one of the most difficult steps in papermaking. In particular, the even wetting of a large number of sheets with the gelatine solution required experience and skill. As a standard, one pile consisting of 400 sheets was dipped in one and the same operation. A good result was also dependent upon the weather; at high humidity the freshly sized sheets, hanging up to dry, could become mildewed and thus useless as could the previously prepared glue. Additives Historical sources for paper making reveal a great number of additives facilitating the sizing process. The most important was alum, i.e. originally and mainly the natural double-salt potassium aluminium sulphate (KA1(SO4)2 x 12 H2O), and later synthetic aluminium sulphate (A12(SO4)3)3,12. Alum had already been used in the 14th century in Italy, the main paper producing country of that time, it became generally used from the late 17th century. Several properties were attributed to alum by the old papermakers, or the authors of books on this art. Today, we know that alum used for pulp sizing makes the sheet acidic; however, used for surface sizing in reasonable quantities it has many advantages. With regard to the traditional technique of paper sizing in a pile, it prevented blocking of the sheets. Alum added to the gluing solution improved its adherence at the paper surface. Moreover, it hardened the surface by tanning the gelatine, thus making the paper more resistant towards scratching and towards water. Gelatine sized watercolour papers of the 18th century were treated, additionally, with alum water to improve further their water resistance and the adherence of the colours. Another advantage of using alum was its ability to reduce the danger of microbiological infestation. Old papermaking handbooks often state that paper, which got mouldy in the drying room, may be used if treated with alum10,12. Another additive to animal glue used for sizing the paper and mentioned in more recent books on papermaking was sodium carbonate (Na2CO3). Its purpose was to make the glue solution more resistant towards rotting in the warm season. Limewater (Ca(OH)2) was thought to eradicate clouding. Furthermore sodium hydrogen carbonate (NaHCO3) or soap was mentioned for the same or comparable purposes10. As a curious additive, the use of white or green vitriol (zinc or cupric sulphate: ZnSO4, CuSO4) is worth mentioning. Vitriol was believed to enhance the positive results of alum application, but it was known that it had negative side effects, such as giving the paper a yellowish or even brownish tint (de la Lande, ref. 9). It was also noticed that vitriol caused undesired reactions with ink by forming "a kind of black dust" (de la Lande, ref. 9). As a last, but non-reactive additive to the animal glue solution used for sizing paper, a blue colouring agent has been mentioned, used to suppress a possible yellow tinge of the paper after sizing (Schachtner, ref. 9). MATERIAL COMPOSITION - STATE OF CONSERVATION From studying old papermaking techniques it becomes obvious that the term "gelatine sized rag paper" can cover a great variety of material compositions. In spite of the variety of the recipes and materials, all these papers, made across six centuries, have one thing in common: their excellent long term stability. There are differences, however. Timothy Barrett and co-workers have found by statistical evaluation that papers containing a thick gelatine size are generally better preserved and show a brighter colour than those with only a weak sizing9,13. This seems to be an important aspect with regard to paper permanence. Of course, further characteristics, such as the presence of calcium carbonate, of sulphate, chloride, copper(II), iron(II), etc. have an influence on the ageing stability of gelatine sized paper. However, it seems that the sizing technique and the composition of the sizing agent are of similarly high importance. Two aspects are to be emphasised: • Gelatine forms rather dense films on the surface of the cellulose fibre web. This film is considerably repellent to cold liquid water and it ad- and desorbs water vapour from surrounding air to a much smaller degree than cellulose. It provides a dynamic equilibrium with the climatic conditions and works as an effective barrier against humidity fluctuations and possibly even against atmospheric pollutants. • As a protein, gelatine is built up of amino acids. Amino acids have an ampho-teric character; they function as an electrolyte. Proteins are able to react with ions according to the environmental pH. The macromolecule gelatine may tie or complex transition metal ions, such as iron and possibly copper which are able to catalyse the oxidative decomposition of cellulose8,12. It may be assumed that the fixing of the transition metal ions within the protein layer may cause them to lose their catalytic activity towards cellulose. Paper can contain iron or other transition metal ions in different concentrations and of different origins: impurities of the process water, abrasion from metallic particles from stamping and grinding mills. The main sources are metallo gallic inks (e.g. iron-gall ink) and partly water soluble colouring materials, such as verdigris brought onto the finished paper during use. Gelatine sizing can be seen as a means of protecting the paper against their detrimental effects. IRON GALL INK CORROSION Two main reaction mechanisms cause the damage that threatens hundreds of thousands of documents, written in iron-gall ink, in our archives and libraries: • Acid hydrolysis of cellulose, i.e. depolymerisation of the cellulose chain; • Oxidation of cellulose, rapidly catalysed by transition metal ions. In its initial stages the damage appears as brown discolouration on the verso of the paper, it then becomes brittle and finally is visible as perforation in the areas of the ink strokes and writing. To stop the decomposition, both mechanisms must be inhibited15. From the observations reported above, the idea arose as to whether resizing with gelatine could be an interesting means for this purpose16. EXPERIMENTAL For our investigation the properties and the permanence of various modern gelatine qualities were examined. Their suitability as resizing agents on manuscripts were evaluated in comparison with other materials commonly used in conservation as resizing or strengthening agents, such as cellulose ethers or starch paste. The above mentioned capability of proteinaceous compounds to tie or complex destructive transition metal ions led to the idea to evaluate specifically the possible inhibiting effects a gelatine size might have on iron-gall ink corrosion of paper. To carry out these experiments, mock-ups were prepared on which iron-gall ink with a surplus of iron(II)-sulphate was applied. The molar ratio Fe: Tannin was 5.5 : 1. This recipe was a simplification of historical iron-gall inks insofar a; the resulting ink was free of other transition metal ions such as copper. Therefore, all results presented here only refer to the interaction of iron(II)-ions with the sizing agents under investigation. Equal lines of ink were applied on paper samples (Whatman no. 1 *) using a computer plotter. The ink was prepared according to Neevel's recipeI5: • 1.23 g tannic acid**, • 1.05 g iron(II)-sulphate (iron(II)-sulphate heptahydrate)***, • 15 ml distilled water, • 10 ml of a gum arabic solution***(78.5g/l H2O). *Merck, Darmstadt (Germany); 516A3133 **Sigma-Aldrich, Steinheim (Germany); 40.304-0; 95% *** Merck; 3965 **** Fluka, Buchs (Switzerland); 51200 The samples were pre-aged in a climate chamber (Heraeus Votsch HC 0020) at 70°C and 50% RH for 3 days and then brushed with the following resizing agents: • Food gelatine type B, 220 Bloom*, 1% • Methyl cellulose MH 300"; 1% • Wheat starch paste***; highly diluted *DGF Stoess AG, Eberbach (Germany); GELITA, type B, 220 Bloom, Lot 920 497, a beef collagen produced under alkaline conditions **Hoechst AG, Frankfiirt (Germany) ***Crespel & Delters, Ibbenburen (Germany); type "3 Hasen" The horizontal or vertical migration of water soluble iron(II)-ions indicated their availability as catalysts for the oxidative decomposition of cellulose. The extent of the migration was easily detectable by means of a specific reagent - batho-phenatroline in ethanol - which formed a nonbleeding red compound in the presence of iron(Il)-ions1'. The result of spraying this reagent onto the samples resulted in virtually no colour change to red in the samples sized with gelatine, but there was a significant change in the other samples (Fig. 1). From this, the conclusion can be drawn that free iron(II)-ions were tied to the gelatine and were not reactive thus not forming the red compound with the indicator reagent. Iron(II)-ions tied to the protein structure were not further active as oxidative catalysts for the decomposition of cellulose. This could be demonstrated in additional experiments carried out on paper manuscripts with iron-gall ink writing from the 18th century by means of artificial ageing at elevated temperature (90°C) and a fluctuating relative humidity of between 35% and 80% in three hourly cycles. This so-called dynamic ageing leads to the accelerated decomposition of organic materials - especially of cellulose - through oxidation and hydrolysis. It is particularly suitable for the simulation of iron-gall ink corrosion on paper items. Thus, the efficacy of a conservation intervention by chemical means can be ranked and compared with other treatments under defined conditions. In order to make long term effects of different conservation interventions visible, samples of an original manuscript were divided into three parts and treated differendy: • no treatment • deacidification with a saturated aqueous solution of calcium bicarbonate* • deacidification and subsequent sizing with a 1% gelatine solution type B * 430 mg Ca2+/l, pH 6.0, immersed twice, each bath lasting 20 minutes All samples were artificially aged under identical conditions. As a result of the accelerated ageing (12 days), iron-gall ink corrosion was developed reproducibly on all three samples of the tested objects. However, it was evident that samples sized with gelatine clearly showed far less brown discolouration and damage in the areas of ink strokes. In contrast to the untreated samples or deacidified samples without subsequent gelatine sizing, brown discolouration under the ink at the verso side of the paper occurred only to a limited extent (Fig. 2). These positive interactions between iron-gall ink and gelatine coatings were supported additionally by the retention of strength of standard samples after artificial ageing. This was concluded from bursting strength measurements carried out on Whatman paper samples where the iron-gall ink was applied with a computer plotter in equal lines. The samples were submitted to treatments and artificial ageing as described above. Studies using bursting strength to quantify ink corrosion extent were based on investigations by Neevel15,I8. CONCLUSION Our results prove that sizing with gelatine may result not only in a mechanical, but also in a chemical stabilisation of papers written in iron-gall ink. Gelatine has a considerable capacity to fix free iron(II)-ions present in unbalanced iron-gall inks, thus making them inert. Other sizing agents used in paper conservation, such as cellulose ethers or starch paste, do not have comparable properties. Therefore, the traditional sizing agent for historical rag paper, i.e. animal glue or gelatine, is to be strongly recommended as a resizing agent for aqueous treated iron-gall ink manuscripts (Fig. 3.) The best results can be expected from using gelatines of type B and of high or medium Bloom degree (> 200 g). A type B gelatine is produced under alkaline conditions from beef collagen. During production a typical molecular structure with characteristic reactive groups along the macromolecular chains develops. The Bloom degree determinates the jelly value and indirectly the degree of hydrolytic decomposition of a gelatine. Modern gelatines differ from historical proteinaceous glues by careful and controlled processing techniques and there are only small quality fluctuations19. A food quality gelatine is sufficient in purity (ash content <1%). A gelatine of type B, 220 Bloom, e.g., has a hydrolytically low decomposition because of its production conditions; it can form elastic films with a high capacity for binding free ions. At environmental pH >4.7-5.4, which is the isoelectric point of the gelatine, the molecular chains of such a type B gelatine have a high content of dissociated, negatively charged carboxyl groups, which may fix transition metal ions16. ACKNOWLEDGEMENTS The report given above is based on the author's diploma dissertation and on a follow-up research project of the Staatliche Akademie der Bildenden Kunste Stuttgart (Academy of Applied Art and Design Stuttgart). The author wishes to express her thanks to all the people and institutes, who helped for their friendly and support, and in particular, to Gerhard Banik (Stuttgart Academy), to Judith Hofenk de Graaff, Johan G. Neevel and Birgit Reissland (Instituut Collectie Nederland, Amsterdam). SUMMARIES Gelatine in Historical Paper Production and as Inhibiting Agent for Iron-Gall Ink Corrosion on Paper Since the beginning of papermaking in Europe gelatine has been used as a sizing agent in order to make the paper suitable for writing using aqueous ink and more resistant towards abrasion. Over six centuries the technology and quality of gelatine sizing has been modified. Generally, heavily gelatine-sized papers are more durable than those with weak sizing. A look at the hypothesis as to what amount the positive activity of gelatine is rooted in its capability to bind reactive metal, especially iron(II)-ions, which is a general quality of proteins, is taken with especial interest in its suitability to resize iron-gall ink manuscripts after an aqueous treatment. Accelerated ageing tests have demonstrated that resizing such manuscripts using gelatine has a significantly better blocking effect towards ink corrosion than the other resizing agents commonly used for paper conservation. La gelatine dans la production historique du papier et en tant qu 'agent inhibiteur dans la lutte contre la corrosion de I'encre gallique sur le papier La gelatine constitue depuis le tout debut de la production du papier en Europe 1'agent d'en-collage utilise pour rendre le papier apte a recevoir 1'ecriture a I'encre aqueuse et pour ameliorer sa resistance contre 1'abrasion. Au cours de plus de six siecles la technique et la qualite de l´en- collage a la gelatine se sont constamment modifiees. En general les papiers encolles a Faide d'une plus forte dose de gelatine font preuve d'une plus grande durabilite que les autres. On cherche a verifier 1'hypothese pour savoir dans quelle mesure Peffet positif de la gelatine reside dans sa capacite a Her les ions metalliques reactifs, en particulier les ions de fer, ce qui la qualifie de proteine. Cette propriete est particulierement interessante pour la restauration de manuscrits contenant de I'encre gallique apres un traitement aqueux. Des tests de vieillissement accelere ont mis en evidence que le reencollage des manuscrits a Faide de la gelatine a un effet significativement meilleur de blocage centre la corrosion de I'encre que les autres agents communement utilises dans la restauration du papier. Gelatine in der historischen Papierherstellung und als Mittel gegen Tintenfra auf Papier Gelatine ist das seit den Anfangen der Papierproduktion in Europa verwendete Leimungsmittel, um Papier mil waBrigen Tinten beschreibbar und widerstandsfahiger gegen Abrieb zu machen. Im Laufe von mehr als sechs Jahrhunderten haben sich Technik und Qualitat der Leimung im-mer wieder modifiziert. Stark gelatinegeleimte Papiere zeigen eine bessere Dauerhaftigkeit als solche mit schwacher Leimung. Es vvird der Hypothese nachgegangfen, inwieweit die positive Wirkung der Gelatine auf deren Bindungsfahigkeit fur reaktive Metallionen, speziell Eisen(II)-ionen zuruckgefiihrt werden kann, welche sie als Protein aufweist. Diese Eigenschaft erscheint besonders auch fur die Nachleimung waBrig vorbehandelter eisengallustintenbeschriebener Manuskripte interessant. Es wird in Versuchen mit Hilfe kiinstlicher Aliening gezeigt, daB die erganzende \achleimungsbehandlung mit Gelatine im Gegensatz zu anderen in der Restaurie-rung gebrauchlichen Leimungsmitteln die Entwicklung von TintenfraB deudich blockieren kann. REFERENCES 1. Bosworth, C.E.: The book of curious and entertaining information. Translation of: Abd-al-Malik Ibn Muhammad Ibn Ismalil at Tha'alibi (961-1038): Latd'ifal-ma'drif. Edinburgh: Univ.Pr. 1960: 140. 2. Garlick, K.: A brief review of the history of sizing and resizing practices. AIC Book and Paper Group Annual 4 (1986): 94-107. 3. Green, S.: The historical development of sizing agents. IPC Conference Papers Manchester 1st-4th April 1992, ed. Sheila Fairbrass. Leigh 1992: 197-200. 4. Sizing/Resizing. The Paper Conservation Catalog, ed. W. Henry & D. Hamburg. Washington: The American Institute for Conservation for Historic and Artistic Work (AIC), The Book and Paper Group 1988: chapter 17. 5. Illig, M. F.: Anleitung auf eine sichere, einfache und wohlfeile Art Papier in der Masse z,u leimen. 1807. Reprint ed. Armin Renker & Berthold Comely. Mainz: Forschungsstelle Papiergeschichte 1959. 6. Weisgerber, C. A., J. W. Davis & W. H. Roberson: A new sizing agent for paper-alkylketene dimers. Tappi 39 (1956): 21. 7. ISO 9706: Information and documentation - Paper for documents: Requirements for permanence. 1994. 8. Seiz, H. & F. Moll: Gelatine. Ullmanns Encyclopadie der Technischen Chemie. Weinheim, New York : Verlag Chemie 12 (41976): 211 - 220. 9. The author has consulted the following books and articles on historic papermaking and glue production: De la Lande, J. J. F.: Die Kunst Papier zu machen, kommentiert van Heinrich Gottlob vonjusti. 1762. Reprint ed. Alfred Bruns: Munster: Landschaftsverband Westfalen-Lippe, Westfali-sches Archivamt 1984. Beckmann,J.: Papiermacherey. Gottingen: Wittwe Vandenhoeck 1777. Reprint: Basel: Basler Papiermuhle 1990. Schachtner, S.: Die Papiermacherei und Are Geschichte in Bergisch Gtadbach. Berg. Gladb. 1990. Barrett, T.: Early European papers / contemporary conservation papers. A report on research undertaken from fall 7984 to fall 7987. The Paper Conservator 13 (1989). Willers, H.: Herstellung son tierischem Leim und seine Verwendung im Bereich der Tafel- und FaJS-malerei nach Angaben deutschsprachiger Quellenliteratur des 16. bis zur Mitte des 19. Jahrhunderts. Diploma dissertation 1980. Schriftenreihe des Instituts fiir Museumskunde an der Staatlichen Akademie der Bildenden Kiinste Stuttgart ed. K.-W. Bachmann. 2 (1986). 10. Mierzinski, S.: Handbuch der praktischen Papier-Fabrikation. 1: Das Biitten- oder Handpapier. Wien, Pest, Leipzig: Hartleben 1886. Reprint: Basel: Basler Papiermuhle 1989: 48-56. 11. Koepff, P.: History of industrial gelatine production (with special reference to photographic gelatine]. Photographic Gelatine, Proceedings of the Fourth IAG Conference, ed. H. AmmannBrass & J. Pouradier. Fribourg: Internationale Arbeitsgemeinschaft fur Photogelatine 1985: 3-31. 12. Briickle, I.: Aspects of the use of alum in historical papermaking. IPC Conference Papers Manchester lst~4tjl April 1992 ed. Sheila Fairbrass (cf. ref. 3): 201-206. 13. Barrett, T.: Evaluating the effect of gelatin sizing with regard to the permanence of paper. IPC Conference Papers Manchester (cf. ref. 3): 228-233. — & C. Mosier: A review of methods for the identification of sizing agents in paper. Loc. cit. 207213. — & C. Mosier: The role of gelatin in paper permanence. JAIC 34 (1995): 173-86. — , P. LangJ. Water-house, J. Cook, S. Cullison, B. Fuller, S. Telles, & J. Pullmann: Non-destructive measurement of gelatin and calcium content of European papers: 1400 - 1800. International Conference of Conservation and Restoration of Archive and Library Materials, Erice, April 22nd - 29th 1996. Preprints. Roma: Institute Centrale per la Patalogia del Libro 2 (1996): 517533. 14. Clark, R. C. & A. Courts: The chemical reactivity of gelatine. The Science and Technology of Gelatine, ed. A. G. Ward & A. Courts., London et al: Academic Press 1977: 209-241. 15. Banik, G.: Phanomene und Ursachen van TinfenfrajS auf Papier - eine Einfuhrung. TintenfraBschaden und ihre Behandlung, ed. G. Banik & H. Weber. Stuttgart: Kohlhammer 1999: 13-24. Krekel, C.: Chemischt Struktur historischerEisengallustinten,. Loc. cit. 25-36. Neevel, J. G.: Phytate: a potential conservation agent for the treatment of ink corrosion caused by Iron-galllnks. Restaurator 16 (1995): 143-160. 16. Kolbe, G.: Gelatine und ihre Verwendung in der Papierrestaurierung, Diploma dissertation 1999. Staatliche Akademie der Bildenden Kiinste Stuttgart. Kolbe, G.: Gelatine - Eigenschaften und Auswahlkriterien in der Papierrestaurierung. PapierRestaurierung2 Suppl. (2001): 41-56. 17. Neevel, J. G.: SOPStandaard Onderzoeks-Procedure No. 54. Niet-uitbloende test voor ijz.er(II)ionen., Amsterdam: Instituut Collectie Nederland 1997. 18. Neevel, J. G.: SOP Standaard Onderzoeks-Procedure No. 53. Simulatie en Kwantificiering van Inktvraat. Amsterdam: Instituut Collectie Nederland 1997. 19. Alleavitch,J. & W.A. Turner: Gelatin. Ullmann's Encyclopedia of Industrial Chemistry, ed. B. Elvers, S. Hawkins, M. Ranescroft, J. F. Rounsaville & G. Schulz. Weinheim: VCH Verlagsgesellschaft mbH. Vol. A 12 (51989): 307-312. Keenan, T. R.: Gelatin. Encyclopedia of Chemical Technology, ed. R. E. Kirk & D. F. Oth-mer. New York etc: Wiley. Vol. 12 (41994): 406-416. 20. Reissland, B.: Ink Corrosion Aqueous and Non-Aqueous Treatment of Paper Objects - State of the Art. Restaurator 20 (1999): 167-180 Gesa Kolbe Fritz Konzertstr. 6 A-6020 Innsbruck Fax (+43)-512-585212 E-mail: post@kolbe-restaurierung.de