Control Volume Analysis

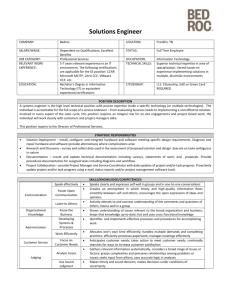

advertisement

Control Volume Analysis Used for flow through systems HEAT CONTROL VOLUME WORK Use closed system analysis (fixed system mass M) to derive expressions for conservation of mass and energy Time t MS(t) = MCV(t) + mi Time t+t MS(t+t) = MCV(t+t) + me Note: mi doesn’t have to be equal to me since MCV(t) doesn’t have to be equal to MCV(t+t) 74 For a closed system MS(t) = MS(t+t), so MCV(t) + mi = MCV(t+t) + me MCV(t+t) - MCV(t) = mi - me Divide through by t to get time rate quantities M CV (t t M CV (t) mi me t t t Taking limit as t0, closed system and control volume boundaries coincide M CV (t t M CV (t) lim m i m e Δt 0 t Note: m is called the mass flow rate with units kg/s, subscript i is for inlet and e is for exits dM CV m i m e dt Time rate of change of mass contained within the control volume equals the net mass flow rate m into the control volume 75 For multiple inlets and outlets dM CV m i m e i e dt For steady-state (dMCV/dt=0) i m e m i e Mass flow rate in terms of local properties Consider a small quantity of matter flowing with velocity V across an incremental area dA, in a time interval t V Vt A Vnt dA Vn is the normal component of the velocity vector The volume of matter in the cylinder is VntdA Mass of matter crossing dA in t is m=VntdA 76 Divide through by t and take the limit as t0 defines the mass flow rate through the area dA, m m dA lim Vn dA t 0 t Integrating over the entire area A yields the total mass flow rate m Vn dA A If the flow is one-dimensional across area A, i.e.,: (i) Flow velocity V is normal to area A (ii) Intensive properties are uniform across area A VA v Substituting into mass conservation m VA dM CV AV AV i e dt Mass flux defined as mass flow rate per unit area m V units kg/m 2 s e.g., V A v Volumetric flow rate defined as m VA units (m 3 /s) 77 Conservation of Energy for a Control Volume Perform closed system analysis where the system at time t includes the fluid in the CV and inlet region i Time t Time t+t At time t, the energy of the system is: ES (t) ECV (t) mi(ui Vi 2 / 2 gZi ) At time t+t, the energy of the system is: ES (t t) ECV (t t) me(ue Ve2 / 2 gZe ) 78 First law applied to the closed system gives: ES (t t) ES (t) QS WS ECV (t t) me(ue Ve2 / 2 gZ e ) [ ECV (t) mi(ui Vi 2 / 2 gZ i )] QS WS ECV (t t) ECV (t) QS WS mi(ui Vi 2 / 2 gZ i ) me(ue Ve2 / 2 gZ e ) The change in energy in the CV is equal to the energy transferred to the system by heat and work plus the energy entering into the CV by mi less the energy leaving the CV by me Divide through by t, take limit as t0, closed system and control volume boundaries coincide, note Q s Q CV , W s W CV dECV (t) Q W m i(ui Vi 2 / 2 gZ i ) dt m e(ue Ve2 / 2 gZ e ) where ui, Vi, Zi are evaluated at the inlet ue, Ve, Ze are evaluated at the exit 79 Consider the work term Work consists of shaft type work and flow work Wshaft Work to push mi into CV Work to push me out of CV Consider the inlet of cross-sectional area A Fluid mi enters CV in time t Pi x Flow work is the energy used to get fluid into CV in time t W Fx ( Pi Ai )x Dividing through by t and taking limit as t0 W x lim ( Pi Ai ) lim t 0 t t 0 t 80 This yield the rate of work done, note m i i AiVi Wi ( Pi Ai )Vi Pi ( AiVi ) Pi (m i / i ) Flow work at the inlet is Wi m i ( Pi vi ) Similarly, flow work at the exit W e m e ( Pe ve ) Substituting into the energy conservation equation dECV (t) Q W shaft m i Pi vi m e Pe ve dt m i(ui Vi 2 / 2 gZ i ) m e(ue Ve2 / 2 gZ e ) Generalizing for multiple inlets and exits and substituting for h = u + pv dECV (t) Q W shaft m i(hi Vi 2 / 2 gZ i ) i dt m e(he Ve2 / 2 gZ e ) e 81 Common engineering applications involve one inlet and one exit and the flow is steady, dE dt 0, m i m e m dE dt Q W shaft (hi Vi 2 / 2 gZi ) (he Ve2 / 2 gZ e ) m m m 0 q w s (hi Vi 2 / 2 gZi ) (he Ve2 / 2 gZe ) W shaft Q where q , w are heat added and shaft work m m done per unit mass, units are J/kg Note q , w are not rates, i.e., J/s 82