excavations in Hong Kong

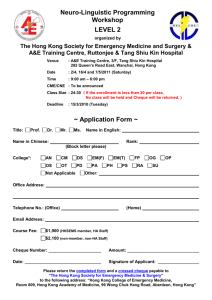

advertisement

-1Henry Tho LAM, The Hong Kong Polytechnic University, Hung Hom, Hong Kong, e-mail: ICHLAM@POLYU.EDU.HK, fax: (852) 2334 4634 INTERNATIONAL SYMPOSIUM “ENGINEERING EDUCATION – 98” EXCAVATION IN HONG KONG ABSTRACT The detailed geological description of the rocks of Hong Kong will be given in the presentation. Two major rock types occur in Hong Kong: granitic rock and volcanic rock. Coarse grained granite rocks underlie kowloon, the central part of Hong Kong Island and the lower levels of Victoria Peak, Shatin, Tsuen Wan. Generally, finer grained volcanic rocks underlie the middle and upper levels of Victoria Peak, the southern part of Hong Kong Island and much of the New Territories. The granite suites of rocks are younger than the volcanic and have been intruded into the latter in the form of a batholith or stock, with irregular outlines. Civil engineering works and excavations in Hong Kong for urban building development are usually carried out up to the property boundary and often required batters or shoring which are not stable without structural support. Some of the structural systems, which have been used to provide lateral support to the ground, are the retaining walls. The following retaining wall types are commonly used in Hong Kong to support excavations: a) sheet-pile wall b) soldier pile wall c) diaphragm wall The above retaining wall types can be further divided into the following three categories according to the form of support provided: a) cantilevered or unbraced wall b) counterfort wall c) tied-back or anchored wall This document is intended as a guide to all whom do excavation work. It aims to explain in simple terms the different types of the permanent lateral support for the deep excavation and also the dangers arising in this kind of work. -2Rocks Two major rock types of igneous origin occur in Hong Kong : granitic and volcanic. The granite suite of rocks is younger than the vocanic. The granites are widely jointed with typical joint spacing between 0.5 m to 2m. Sheet joints are often present near the surface. The granitic rocks are visually similar and are normally composed of feldspar, quartz, hornblende and biotite. The volcanic suite of rocks contains a mixture of lithologies including recrystallized and welded tuffs, fine tuffs, coarse tuffs, trachyandesitic and rhyolitic lava flows. The rocks are closely jointed with typical joint spacing between 50mm and 200 mm. Excavation The programming of works involving excavations must take into account Hong Kong’s heavy seasonal rainfall which usually begins in April and ends in October, so that excavations should preferably start in October and be completed by April. If excavations are carried out during the wet season, the surfaces of the slopes formed must be protected and drained, when excavation proceeds, drainage around the crest of the proposed excavation should be provided as a preliminary operation. Excavation in the slightly weathered to fresh zones normally requires blasting. To avoid blast damage, rock may be pre-split. Pre-splitting is accomplished by drilling a row of closely spaced and small diameter holes along the line of final face. In Hong Kong rocks, a hole diameter of about 75 mm at spacing of 700 mm has been found effective for pre-splitting. Excavation in the completely weathered rock zones may be carried out using conventional bulk excavation methods, but care must be taken to avoid loosening the finished surface, which may lead to severe surface erosion and siltation. Trimming should be carried out with light earthmoving equipment or by hand as appropriate. Lateral supports Sheet piles Sheet piles are relatively flat and wide in cross-section so that when they are driven side by side they form a wall. Steel sheet piles have been developed for special purposes such as cofferdams, wharves and retaining walls. Some have Z-shaped cross-sections to provide rigidity and most all types are made to interlock with adjacent sheet piles to form a wall. In some cases, even the use of a powerful pile hammer and heavier steel sheet pile sections is unable to split or aside the boulders, part of a line of sheet piles is replaced by a group of soldier piles installed in predrilled holes through the obstruction. Soldier piles The soldier piles provide the primary support to the retained soil as a result of the arching effect. Spacing of the piles is chosen to suit the arching ability of the soil and -3the proximity of any structures sensitive to settlement. A spacing of 2m to 3m is commonly used in strong soils and it is reduced to 1m to 2m in weaker soils or near sensitive buildings. Soldier piles have two basic components: H piles (vertical component) and lagging (horizontal component). H-piles are either driven or placed in pre-drilled holes, which are backfilled to the ground surface with lean concrete. Lagging is wedged against the inside flanges and serves as a secondary support to the soil face and presents progressive deterioration of the soil arching between the piles. If large voids exist between the soil and the lagging, they can be filled with grout or motor to provide full contact with the soil. Diaphragm walls The basic procedure is to replace the excavated spoil with the bentonite slurry as the work proceeds. The slurry forms a soft gel at the interface of the excavation sides with slight penetration into the subsoil. Hydrostatic pressure caused by the bentonite slurry thrusting on the gel is sufficient to hold back the subsoil and any ground water, which may be present. Diaphragm walls constructed by this method are executed in alternate panels from 4.5 m to 7.0 m long with widths ranging from 500 mm to 900 mm using a special hydraulic grab attached to a standard crane. To form an interlocking joint at each end of the panel, circular stop end pipes are placed in the bentonite filled excavation before the concrete is placed. The operation of concreting the panel is carried out using a tremie pipe. Cantilever retaining wall Cantilever wall is used for heights up to 9m. Structurally the cantilever wall is a wide cantilever beam acted upon by pressure that increases uniformly to a maximum at the point of restraint. It is reinforced in the vertical direction to resist the bending moments and in the horizontal direction to prevent cracking. Counterfort wall Counterfort wall consists of a vertical flat slab supported on two sides by buttressed and on the bottom by the wall foundation. Counterforts are on the backside of the walls in order to provide more usable space in front. Tied-back wall Prestressed ground anchors are commonly used for retaining excavations in Hong Kong. The connecting elements between anchorage and anchor heads are usually tie rods. Because the tie rods are commonly made of high strength steel, usually only a small area of steel is required to give the necessary capacity. Safety Precautions Any excavation, in rock strata, should be carefully examined to ascertain its stability. Fissures or splits in the rock layers which slope towards the cut face may lead to crumbling or rock falls when exposed to the atmosphere for long periods. -4Any deep excavation on a building site is a potential hazard. Approximately 1 in 10 accidents occurring in deep excavation are fatal. Every contractor is responsible for the safety of his own employees and every person employed must co-operate in observing the various requirements of the regulations. If an employee discovers any defect or unsafe condition in a working area, it is his duty to report the facts to his employer, supervisor or Safety Officer. Before excavation starts All excavation work must be planned. Before digging begins on site, the following arrangements must be checked: 1 Location of underground services if any – check with utilities companies, use cable/pipe detectors 2 Ground conditions and adequate lateral support system 3 Interaction of proposed excavations and existing structures 4 Edge protection for all excavations 5 Experienced and competent person directly supervising the work 6 Necessary drawings and sketches 7 Brief and instruct operatives 8 Site security, particularly in relation to preventing children getting on to the site 9 Adequate working space for plant, materials and spoil heaps 10 Temporary bridge / gangway if required 11 Adequate and sufficient ladders for access 12 Appropriate personal protective equipment 13 Lighting and ventilation References (1) Roberts, Albert F., “Applied Geotechnology”, Oxford, New York Pergamon Press 1981. (2) Lazenby D. W., “Cutting for Construction”, London: Architectural Press New York J. Wiley 1978. (3) Geotechnical Control Office, “Geotechnical Government Publication Centre. (4) Church Horace, “Excavation hand Book”, New York McGrav-Hill 1981 Manual for slopes”, HK