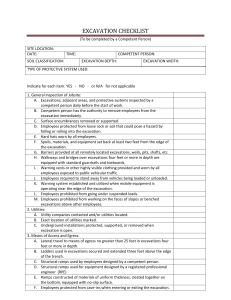

Excavation Checklist: Safety in Construction Projects

advertisement

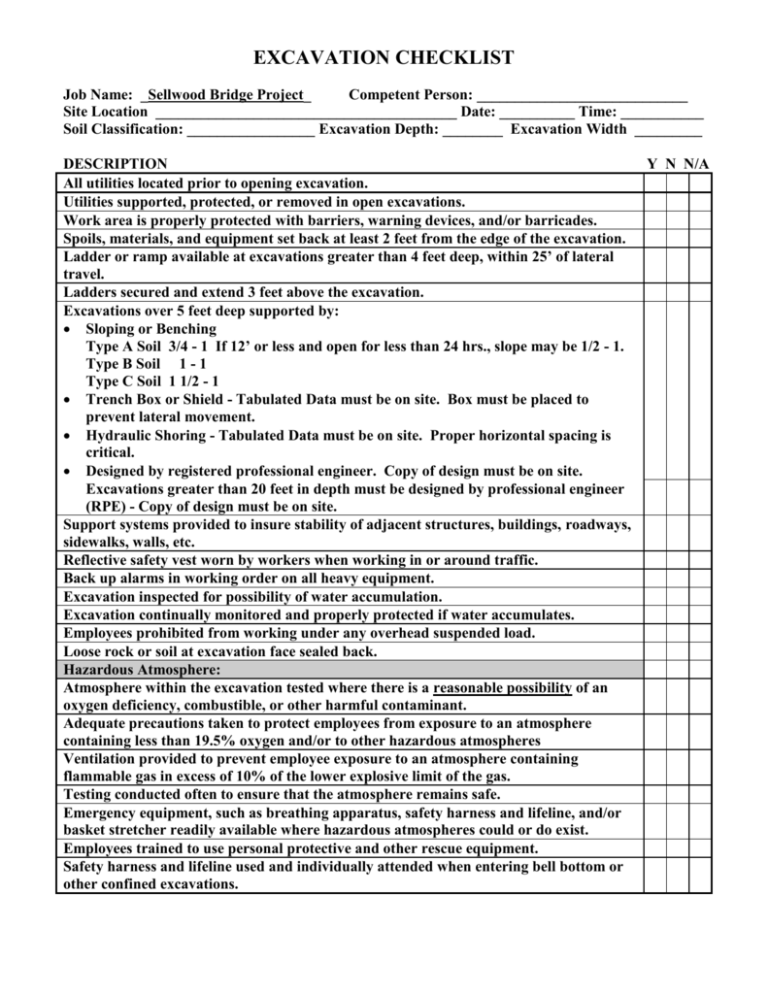

EXCAVATION CHECKLIST Job Name: _Sellwood Bridge Project_ Competent Person: ____________________________ Site Location ________________________________________ Date: __________ Time: ___________ Soil Classification: _________________ Excavation Depth: ________ Excavation Width _________ DESCRIPTION All utilities located prior to opening excavation. Utilities supported, protected, or removed in open excavations. Work area is properly protected with barriers, warning devices, and/or barricades. Spoils, materials, and equipment set back at least 2 feet from the edge of the excavation. Ladder or ramp available at excavations greater than 4 feet deep, within 25’ of lateral travel. Ladders secured and extend 3 feet above the excavation. Excavations over 5 feet deep supported by: Sloping or Benching Type A Soil 3/4 - 1 If 12’ or less and open for less than 24 hrs., slope may be 1/2 - 1. Type B Soil 1 - 1 Type C Soil 1 1/2 - 1 Trench Box or Shield - Tabulated Data must be on site. Box must be placed to prevent lateral movement. Hydraulic Shoring - Tabulated Data must be on site. Proper horizontal spacing is critical. Designed by registered professional engineer. Copy of design must be on site. Excavations greater than 20 feet in depth must be designed by professional engineer (RPE) - Copy of design must be on site. Support systems provided to insure stability of adjacent structures, buildings, roadways, sidewalks, walls, etc. Reflective safety vest worn by workers when working in or around traffic. Back up alarms in working order on all heavy equipment. Excavation inspected for possibility of water accumulation. Excavation continually monitored and properly protected if water accumulates. Employees prohibited from working under any overhead suspended load. Loose rock or soil at excavation face sealed back. Hazardous Atmosphere: Atmosphere within the excavation tested where there is a reasonable possibility of an oxygen deficiency, combustible, or other harmful contaminant. Adequate precautions taken to protect employees from exposure to an atmosphere containing less than 19.5% oxygen and/or to other hazardous atmospheres Ventilation provided to prevent employee exposure to an atmosphere containing flammable gas in excess of 10% of the lower explosive limit of the gas. Testing conducted often to ensure that the atmosphere remains safe. Emergency equipment, such as breathing apparatus, safety harness and lifeline, and/or basket stretcher readily available where hazardous atmospheres could or do exist. Employees trained to use personal protective and other rescue equipment. Safety harness and lifeline used and individually attended when entering bell bottom or other confined excavations. Y N N/A