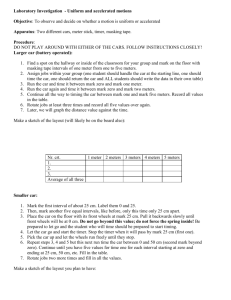

KM-90A WATTHOUR METER TEST SYSTEM

advertisement

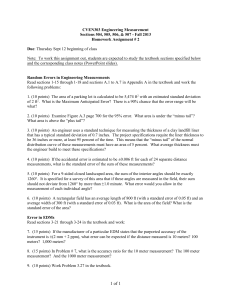

KM-90A WATTHOUR METER TEST SYSTEM Functional Description and Specifications A. General The test system shall: B. include a built-in analyzer/counter dedicated to the purpose of testing watthour meter parameters; allow test sequence setup from an operator programmable menu; provide a "semi-automatic" testing mode wherein the Full Load, Power Factor, and Light Load tests on a meter are performed automatically, without operator intervention; allow set up by form switch and front panel patch leads; allow closed-link testing of single-phase and polyphase meters; provide overall system accuracy of ±0.1% at unity and 50% power factor; use a pneumatically (air) operated test socket which remains closed upon loss of power or air. Test Requirements 1. Tests Performed a. Watthour As Found and As Left results shall be stored separately. Each can be separately recalled to the display, printed out, or sent to a computer or other peripheral device via an RS-232 port (or parallel port). b. KYZ (Pulse Initiators) Pulse initiator testing can be performed in either the "pulses" or "revolutions" mode. Pulses/revolution and its reciprocal shall be calculated and displayed. Additionally, KY and KZ counts shall be displayed. c. Demand Meter Testing Demand testing shall be done by either a time interval (0.1 to 99.9 minutes) or by a number of watthours (as measured by the watthour standard). The unit shall display the average KW applied, the disk revolutions, measured watthours, and the time of the test to the Leaflet No. 1-007 Page 1 of 6 04/2002 nearest tenth of a minute. d. Creep The system shall allow application of test voltage (without test current) for creep testing. e. Reference Standard The system shall be capable of testing external pulse producing standards (open collector output). 2. Meters Tested The system shall test all socket base meters–ANSI (American National Standards Institute) forms 1 through 16 (excluding 11), 19, 20, 21, 24, 26, and 29. All meters shall be tested with their links closed. 3. Other Test Characteristics a. Semi-automatic Sequencing This feature shall allow the test system to automatically sequence through Full Load, Power Factor, and Light Load tests without operator intervention. b. Weighted Average The operator can choose to display the weighted average–which is calculated as [(4FL)+(1LL)]5. It shall be possible to use the following formula for polyphase meters: [(4FL)+(2PF)+(1LL)]7. c. Statistical Calculations The system shall automatically calculate and store the arithmetic mean (bar-x) and standard deviation (sigma) for a group of up to 999 meters. It shall be possible to display the accumulated results on a batch of meters at any time. d. Repeat Tests The system shall allow automatic repeating of a test on a given meter up to 999 times. The results of each test can be automatically printed. Leaflet No. 1-007 Page 2 of 6 04/2002 e. Limits It shall be possible to set limits for series test results and for individual element balance. Out of limit results shall be indicated by flashing the result in the display. f. Test Sequence A custom test sequence can be programmed into the unit. The unit will prompt the operator for the next test in the sequence. g. Display of Test Results Test results shall be displayable as percent registration or percent error. h. Calibration Means shall be provided to calibrate the system against an external reference standard (SC-60, SC-10V, SC-30, RM-11, RM-10, RM-16, A-7, A-6, etc.). Separate calibration factors can be entered for each of the twelve possible watthour tests (Series Full Load, Series Power Factor, ..., Right Light Load). i. Test Voltage Test voltages of 69, 120, 208, 240, 277, and 480 volts shall be selectable. The voltage can be continuously varied from 50% to 110% of the selected value. The voltage shall be ramped from zero to the selected value when turned on, and ramped from the selected value to zero when turned off. The voltage shall be regulated to within ±1% for an input swing of ±10%. Waveform distortion shall not exceed 0.5%. The voltage shall be displayed on a digital meter in percent of full scale. j. Test Current Full load test currents of 2.5, 5, 10, 15, 20 ,25, 30, and 50 amperes shall be selectable. The respective light load values (10%) are automatically selected. The current can be continuously varied from 50% to 110% of the selected value. The current shall be ramped from zero to the selected value when turned on, and ramped from the selected value to zero when turned off. The current shall be regulated to within ±1% for an input swing of ±10%. Waveform distortion shall not exceed 0.5%. The current shall be displayed on a digital meter in percent of full scale. Leaflet No. 1-007 Page 3 of 6 04/2002 C. Operation 1. Meter Test Setup A panel-mounted form switch shall be provided to set up the system for testing different form number meters. The form switch shall be able to be used for patching the system for ANSI form numbers 1 through 16 (excluding 7 and 11). In addition to the form switch, a voltage and current patch panel shall be provided on the front of the system in order to configure it to test meters which are not covered by the form switch. 2. Optics Means to count disk revolutions using the reflect method shall be provided. Visual and audible indications of each revolution shall be provided. 3. Calculation of Test Result The counter shall automatically calculate and display the test result. Any user entered calibration factors shall be automatically included in the test result. 4. Protection Circuitry The system shall include circuitry to protect for inadvertent switch changes with power applied to a meter-under-test. The circuitry shall ramp down the voltage and/or current, check for an overload condition, and, if none is detected, ramp up the voltage and/or current. The system shall include circuitry to detect voltage and current overloads. Audible and visual alarms shall be provided to alert the operator of an overload condition. 5. System Setup The counter shall be capable of comparing the system voltage and current switch settings with any bar code entries and shall indicate an error if the system is not set up correctly. Leaflet No. 1-007 Page 4 of 6 04/2002 D. Input/Output 1. I/O Ports Two serial (RS-232C) ports shall be provided to: export test results to an external computer, and import data from a bar code reader. One parallel (Centronics) port shall be provided to export data to a printer. E. Miscellaneous 1. Input Power Input power requirements shall be 120 VAC (±10%), 60 Hz., single-phase at 500 VA maximum. A separate circuit breaker shall be provided to energize the watthour standard independently of the main system on/off switch. 2. Dimensions The console shall measure approximately 32.4 in. (82.3 cm) Wide by 18.2 in. (46.2 cm) High by 14.3 in. (36.3 cm) Deep. 3. Weight The system shall weigh less than 150 lbs. (68 kg.). 4. Environmental Operating temperature range: 55 to 90 F. (13 to 32 C.) 5. Portability The system shall be able to be placed in a van for field use. The system shall be capable of being powered by a portable generator. 6. Auxiliary Outlets The system shall be provided with two 120 volt, 3-wire grounded outlets for auxiliary use. Leaflet No. 1-007 Page 5 of 6 04/2002 7. Reference Standard The system shall contain a built-in solid-state reference standard. 8. Generation of Voltage and Current The voltage and current applied to the meter-under-test shall be electronically generated and monitored. F. Options 1. Printer The printer shall be an Epson FX-series or equivalent. 2. Varhour Meter Testing It shall be possible to purchase the test system with a varhour standard for the purpose of testing varhour meters. 3. Bar Code Hardware The bar code hardware shall be a Symbol Technologies Reader and Wand. The bar code software shall be included with the standard system. 4. A-Base Adapter This adapter shall allow testing of bottom-connected single-phase and network meters. 5. P-Base Adapter This adapter shall allow testing of bottom-connected polyphase meters. 6. Solid-State Meter Probe It shall be possible to purchase a probe which allows testing of solid-state (electronic) watthour meters by sensing the meter's infrared pulse output. The circuitry required to use this probe shall be included with the standard test system. 7. Desk It shall be possible to purchase the test system mounted on a desk. Leaflet No. 1-007 Page 6 of 6 04/2002