Honors Thesis Proposal:

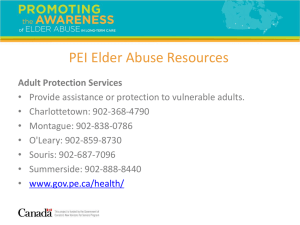

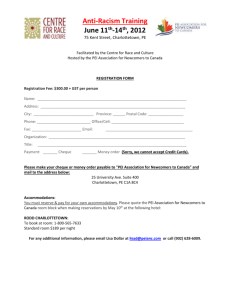

advertisement

Honors Thesis Proposal Synthesis and Characterization of Multifunctional Polymer Nanospheres By Halimatu Sadiya Mohammed Advisor: Dr Devon A. Shipp Research Goal: To synthesize well-defined PGMA nanospheres with uniform particle size distribution, and understand the structure of the nanospheres produced. Introduction: The design and synthesis of composite nanoparticles have recently been the area of great attention due to their diverse applicability.1,2 One of such area where the application of nanoparticles may find significant use is in composites of organic polymers that may host metal or semiconductor nanoparticle. Nanoparticles, as the name suggest, are particles that are less than 100nm in size. They allow flexibility in finely tuning optical, magnetic and mechanical properties of material for their appropriate usage. An increase in the demand of miniaturized devices has also driven one of the greatest potential applications of nanoparticles that can be found in the pharmaceutical industry, where they can be used in drug delivery. Polymeric nanoparticles are being developed to inactivate and kill breast cancer cell.3 Another developing area is the use of nanoparticle polymer supports that can act as building blocks for generating regular large-scale patterned structures.2,4,5 Various applications of polymer supported metal and semiconductor nanoparticles are envisaged for example in areas of catalysis where they are used in the production of cosmetics, and paint,6 nonlinear optical materials, data storage, microelectronics and photonics. Although polymer particles have over the years been used as such supports, the dimensions of support often used are micron or nearmicron.2,4,7 not truly nanometer (ie not < 100nm) in size. This is due in part to the difficulties encountered in making these particles smaller with uniform size distributions. The advantages of uniformly coated and stable nanoparticles have been recognized for some years now, but the controlled coating of polymeric composite nanospheres or nanoparticles with organized layers still remains a technical challenge. Some of the difficulties encountered are the polymer particle host are often prepared via emulsion or microemulsion polymerizations, the presence of surfactant both at the particle surface and free in solution makes it difficult to precisely deposit other species like metals. However, at the same time, colloidal stability of the product would be significantly reduced if one attempts to remove surfactants or modify the particle surface. The presence of surfactant at the particle surface and free in solution as mentioned earlier makes it difficult to deposit metals and any subsequent material precisely. Thus, it will be extremely advantageous to not only develop a method of producing nanospheres that are sufficiently functionalized and stable to allow deposition of polymer, metal or semiconductor particles but to control the size, morphology and chemical functionality of these nanoparticle. This is what my work aims to address. Previous Work: A number of methods of polymerization have been develop for the production of particles that consist of solid cores coated with a shell of polymeric materials8 including monomer absorption onto particles which are then followed by subsequent polymerization,5,9,10 layer-by-layer deposition of polyelectrolytes onto charged particles, emulsion-polymerization, bulk polymerization, and suspension polymerization. The first approach, is one of the often-used methods employed in order to achieve polymer coatings on solid particles. The polymerization reaction can either be initiated by the colloidal particles or catalyzed by an initiator to promote the process. Current and over the last decades research effort have led to lots of new strategies developed for the modifications of particle surfaces that focus on achieving a single-component coatings on particles through conventional polymerization and chemical modification. However, recent techniques that primarily focus on solution self-assembly based strategies have been proven to be highly effective in producing multicomposite, nanostructured coatings. Previous work in the Shipp lab has shown that the synthesis of polyethylenimine (PEI)modified crossliked poly(glycidyl methacrylate) (PGMA) nanospheres and the subsequent placement of CdS and Ag nanoparticles to the surface of these nanospheres, as shown in Scheme 1, can be achieved.2 To prepare the crosslinked PGMA nanospheres with desired particle size, an emulsion polymerization was used. After making the PGMA nanosphere they coated it with the surfactant (SDS). PEI was then reacted with the PGMA nanoshperes. As the PEI is deposited onto the PGMA, the surfactants are removed and replaced by PEI. Zeta potential measurements at pH 7 on the particles before and after PEI modification were used to ascertain the attachment of PEI. In order to prepare the CdS and Ag nanoparticles on the surface of PEI-modified PGMA nanosphere, Cd2+ or Ag+ complex as were formed with PEI on the polymer particle surface and subsequent reduction yield the silver metal and precipitation gave CdS nanoparticle. Scheme 1: Preparation of CdS, Ag nanoparticles on the surface of PEI-modified PGMA nanospheres. KPS, SDS O O O Glycidyl methacrylate H2O, 60oC Divinyl benzene The PGMA provided a highly functionalized nanoparticle that can be modified via various simple ring-opening reactions involving the glycidyl group. Attachment of PEI, gives the resulting nanoparticle/colloid both stability and functionality that allows for complexation with metal ions of interests.1 As shown by the TEM image below, the sizes are not well-defined and not uniform, however they were all in the nanometer range (<100nm). Fig 1. TEM Image of PEI mdified PGMA Nanosphere. This approach provides a means of overcoming the problems associated with colloidal and other polymeric particle stability encountered in previous systems, which are typically carboxylated latex particles. This concept of nanosphere synthesis and modification could easily be extended to other metals, alloys and semiconductor, which mean creating colloidal nanoparticles with well-defined structures and sizes while controlling the functionality. In my thesis, I intend to make a more uniform particle sizes and to understanding the process of PEI modification and final nanosphere structure. Proposed Research: In the preliminary work in the Shipp lab, PEI modified crosslinked poly (glycidyl methacrylate) (PGMA) nanospheres were synthesized. However, questions that remained unanswered or not fully clear relate to the control of the size distribution, morphology and chemical functionality of these nanoparticles. The technique of emulsion polymerization will be employed in the synthesis of PGMA nanosphere. This will hopefully help answer questions like, how to make smaller and welldefined PGMA nanospheres. Emulsion polymerization is a technique used in the synthesis of polymer particles. This technique uses water as a heat-transfer agent. Water and a monomer are the basic starting material but for this type of polymerization surfactants, chain-transfer agent and a water-soluble initiator are also needed for the polymerization to occur. In the proposed work, the monomer, glycidyl methacrylate is first mixed with the divinyl benzene a crosslinking agent, and hydrophobic molecules form large droplets. These monomer droplet are then stabilized by the surfactant, SDS molecules that have their hydrophilic side towards the outside and the hydrophobic end facing the monomer droplet. The size of the monomer droplets depends on the agitation, concentration of surfactants and amount of the monomer used and the surfactant above certain concentration align themselves to form micelles. Polymerization occurs in the presence of the water at 600C when the initiator potassium persulfate (KPS) decomposes into radicals. In order to minimize the size of the particles, I will firstly increase the concentration of the surfactant because typically, the more surfactant used in the polymerization the smaller the polymer particle will be. Also thorough sonication on the reaction mixture before polymerization and increased mechanically mixing the reaction will reduce the particle size. Secondly, I intend investigating the morphology of these nanoparticles. In the preliminary work, it was shown that, the PEI replaces the surfactant but it is not clear as to the distribution of the PEI on the PGMA. That is, whether the particle is core-shell in terms of PEI distribution. If the PEI remains on the surface of the PGMA or some penetrates the PGMA particle. The zeta potential and particle size of these synthesized nanoparticles will be closely monitored at each stage of the reaction. Changing the percentage of divinyl benzene content will also change the crosslinking density of the nanosphere. It is expected that increasing the DVB content will increase the crosslinking density of the nanosphere thereby decreasing the amount of PEI that goes inside the particle. After making particles of various percentage of DVB, an elemental analysis will be done on the particle to for instance determine the total content of nitrogen atoms. If the nitrogen atom content decrease as the percentage of DVB is increased, then it means there is less PEI in the inside of the particle compared to the surface. Nitrogen content will then be determined using elemental analysis. Lastly, I intend monitoring the chemical functionality of the PEI-PGMA nanospheres. This includes investigating the amount or percentage of the PEI that is actually deposited on the PGMA, and whether the PEI removes all the surfactants or if some of the surfactants still remain on the particles after deposition of the PEI. I will test the effect of using PEI of different molecular weights and conduct elemental analysis on the resulting PEI-modified nanospheres. Analytical Techniques & Data Analysis: The particle size and ζ-potential will be measured using an ALV particle sizer and Zeta-PALS respectively. The particle sizer is a light scattering instrument. The amount of light and the angle at which the light is scattered by the sample gives information about the size of the particle. So far, previous work done have shown that the particle size of the modified particles remain close to that of the unmodified PGMA as expected because the cationic layer around particles ensures colloidal stability. The ζ-potential measurements of these particles give information about the surface charge of these particles. Conductivity measurements will be used to determine if there still remain some PEI in the solution which will tell us if the PEI has attach to the PGMA or not, and finally electron microscopy will be used to get the image of the particle to see if they are uniformly distributed or randomly distributed. Preliminary Work: In my two semesters experience in Dr Shipp’s lab, I used the Layer-by-Layer approach technique to modify silica particles by alternating the deposition of the polyelectrolytes, PEI, a positively charged polymer and a negatively charged polymer, polystyrenesulfonate (PSS) onto silica particles. To do this, I prepare separate silica PEI and PSS solutions. I then alternate the deposition of these two polymers whiles carefully removing excess PEI or PSS using centrifugation. The zeta potential and particle size measurement of each layer at pH 7 was measure. I have been able to build up several layers of polyelctrolytes, alternating the PEI and then PSS on silica particles of 80nm in diameter. The technique of zeta potential, and particle size measure and polymer modifications will be applied in this proposed research. Schedule: Below is the tentative schedule for the progress of my proposed work: Month Main Project 9/04 - 11/04 Emulsion Polymerization 12/04 & 01/05 PEI - Reactions 02/05 Morphology studies 03/05 04/05 05/05 First draft of thesis Start final draft Final draft of thesis completed Sub/ break down i. Prepare polymers Investigation/control of the ff: ii. Stirring rate iii. Initiator iv. Uniform particle size v. surfactants Investigation of the following: i. PEI of different MW ii. PEI Concentration iii. PEI Removal TEM NMR Reference: (1) Fendler, J. H., Ed Nanoparticles and Nanostructured Films; Preparation, Characterization and Applications; Wiley-VCH; Weinhein, 1998. (2) Z., Hanying ; Li, Yuzhuo; Shipp, D. A. Submitted to Adv. Fund. Mater. 2004 (3) http://www.atip.or.jp/ (4) Zhang, J.; Coombs, N; Kumacheva, E. J. Am. Chem. Soc. 2002, 124, 14512 (5) Zhang, J; Coombs, N; Kumacheva, E; Lin, Y; Sargent, E. H Adv. Mater. 2002, 14, 1756. (6) For a review, see; C.H. M Hofman-Caris, New J. Chem. 1994, 18, 1087 (7) Mayer, A.B. R.; Grebner, W.; Wannemacher, R. J. Phys. Chem. B. 2000, 104, 7278, and references therein. (8) W.D. Hergeth, U. J. Steinau, H.J. Bitrich, K. Schmutzler,. Wartewig, Prog. Colloid (9) A. M. van Herk, NATO ASI Ser, Ser. E. 1997, 335,435. (10) L. Quaroni, G. Chumanov, J. Am. Chem. Soc. 1999, 121, 10642.