(DCS) Model - Pure - Queen`s University Belfast

advertisement

Assessment of the benefits of Discrete

Conditional Survival Models in modelling

ambulance response times

Karen J. Cairns, Adele H. Marshall

Centre for Statistical Science and Operational Research (CenSSOR),

Queen’s University Belfast.

Keywords: Time-to-event data; Distribution-fitting; Data-mining; Ambulance

response.

Acknowledgements: KJC is supported through an Engineering & Physical

Sciences Research Council (EPSRC) RCUK Academic Fellowship.

Corresponding Author:

Dr Karen Joanne Cairns

Centre for Statistical Science and Operational Research (CenSSOR)

Sir David Bates Building, Room 01.008

Queen’s University Belfast

University Road

Belfast BT7 1NN

Email: k.cairns@qub.ac.uk

Telephone: +44 (0)28 9097 6058

Fax: +44 (0)28 9097 6061

Assessment of the benefits of Discrete Conditional Survival

Models in modelling ambulance response times

Abstract: Many of the challenges faced in health care delivery can be informed

through building models. In particular, Discrete Conditional Survival (DCS)

models, recently under development, can provide policymakers with a flexible

tool to assess time-to-event data. The DCS model is capable of modelling the

survival curve based on various underlying distribution types and is capable of

clustering or grouping observations (based on other covariate information)

external to the distribution fits. The flexibility of the model comes through the

choice of data mining techniques that are available in ascertaining the different

subsets and also in the choice of distribution types available in modelling these

informed subsets. This paper presents an illustrated example of the Discrete

Conditional Survival model being deployed to represent ambulance responsetimes by a fully parameterised model. This model is contrasted against use of a

parametric accelerated failure-time model, illustrating the strength and usefulness

of Discrete Conditional Survival models.

1

Introduction

Policy makers and health care providers must determine how to provide the most

effective health care to citizens using the limited resources available to them.

They need effective methods for planning, prioritisation, and decision making, as

1

well as effective methods for management and improvement of health care

systems (Brandeau et al 2004). Operational Research (OR) techniques can inform

these processes with a wide range of health OR illustrated in the literature (Davies

and Bensley 2005, Brailsford and Harper 2007, Baker et al 2008, Royston 2009).

Methodologies considered vary with the problems being addressed and range

from ‘soft’ OR techniques to more quantitative approaches such as mathematical

modelling, simulation, queuing theory and system dynamics.

Emergency response issues are amongst the problems being addressed, with much

of the earlier research focusing on location planning issues particularly in urban

areas (Simpson and Hancock 2009). Part of this research area, originating in the

research of Kolesar and Blum (1973), has examined the relationship between

emergency response times and distance (the ‘square-root law’). The derivation of

such relationships has informed and aided understanding, and has formed the

cornerstone of further analytic models developed (Green and Kolesar 2004,

Budge et al 2010). Indeed, Erkut et al (2008) indicates that it is generally more

useful to know the entire response time distribution, rather than considering just

specific quantiles of it – something which many performance measures typically

correspond to (e.g. the percentage of urgent emergency incidents reached within 8

minutes is a performance measure used within the National Health Service in the

United Kingdom (Department of Health 2009)).

This paper presents the family of Discrete Conditional Survival (DCS) models

recently under development. This toolkit of models aims to aid understanding of

2

time-to-event data, by modelling the entire time-to-event distribution through a

fully parameterised model, and should be flexible to modelling many forms of

such data within health care. In particular this paper presents the application of the

DCS model to a particular emergency response example – modelling ambulance

response times.

The paper first presents some background information on the data being analysed.

An outline of Discrete Conditional Survival models is then presented, together

with information on the choice of techniques deployed from the toolkit for this

particular example. In order to assess the usefulness of this model, a comparison

has then been made with results from one of the most common regression-based

techniques used to fully parameterise survival data, namely the parametric

accelerated failure-time model (Kalbfleisch and Prentice 1980).

2

Data Set of Ambulance Response Times

Ambulance response time data has been examined from a region of the United

Kingdom (Northern Ireland), where the Northern Ireland Ambulance Service

(NIAS) is responsible for providing emergency medical response. NIAS currently

responds to over 115,000 emergency calls in a year, through a fleet of over 300

ambulances, operating from 52 ambulance stations and sub-stations. It serves a

population of over 1.7 million, with an operational area of 14 000 square

kilometres (Northern Ireland Ambulance Service, 2009a).

3

The data set considered contains dispatch event details (for example, the date and

time of an event, its geographical position, and the perceived severity

categorisation of the emergency call) together with response time information

(e.g. response time(s), type of emergency vehicle(s) responding) for all

emergency calls in Northern Ireland in the year 2003.

The illustrated example considered in this paper considers the sub-set of all

emergency response activations where an ambulance response to the incident was

achieved (i.e. excludes cancellations, where the ambulance never reached the

scene) and considers only the best response time (in the case where multiple

vehicles are dispatched). In 2003, there were 75,774 such responses to emergency

incidents across the entire Northern Ireland region. Removal of records where

either the response time has not been collected, or geographical location

information is incomplete reduces the number of observations to 73,190 (96.6%).

For the purposes of assessing how well the DCS and parametric accelerated

failure-time models perform, the data was separated into training (50%) and test

sets. It was ensured that training and test sets contained observations across the

Northern Ireland region, at locations both close and far away from ambulance

stations.

3

Discrete Conditional Survival (DCS) Model

Discrete Conditional Survival (DCS) models are a family of models capable of

representing a skewed survival distribution as a Process Component preceded by a

4

set of related variables that determine the clustering or grouping of entities (or

observations) into distinct classes (the discrete classes), that may be referred to as

the Conditional Component. The models possess the following characteristics:

The Conditional Component comprises a structure that captures the nature of

the data by representing the various inter-relationships between variables, and

thus can categorise observations into a number of discrete classes.

The Process Component represents the skewed survival distribution of each

discrete class by an appropriate distribution form.

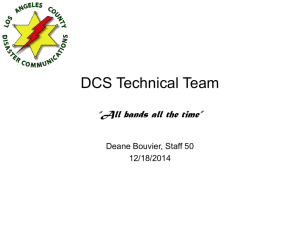

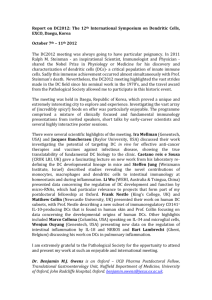

Figure 1 illustrates the general form of the DCS model comprising these two

components. This figure illustrates that many kinds of data-mining techniques

could represent the Conditional Component, with the illustrated example in this

paper utilising multinomial logistic regression. The figure also highlights that a

number of survival distribution forms can be considered for the Process

Component, with the DCS model incorporating the assessment of the most

appropriate fit.

This model expands previous research which had led to the development of the

Conditional Phase-type (C-Ph) model, which describes duration until an event

occurs in terms of a process consisting of a sequence of latent phases (the Process

Component) which are conditioned on a set of inter-related variables represented

by a Bayesian network (the Conditional Component) (Marshall and McClean

2003). Previous research fitted the C-Ph model, a special type of DCS model, by

considering the model structure as having one entity for which the likelihood

5

value was calculated. This led to very cumbersome and difficult calculations for

the likelihood value of every possible Conditional Component structure along

with every possible survival distribution fit. To ease this process, the flexible

nature of the DCS model allows for the two components in the model to be fitted

separately combining the result in an overall likelihood. To do this, requires the

separate inspection of each combination of component variables and how they

relate to survival. As a result this will ultimately reduce the complexity in model

fitting.

3.1

Conditional Component

The Conditional Component of the DCS model categorises observations into a

number of discrete classes, with the aim that the survival of entities in each

discrete class differ (and so the resulting survival distributions of the discrete

classes will be distinguishable). To achieve this, various data-mining techniques

(see Figure 1) can be used to consider the influence of covariates on survival or,

has in previous research, on a correlated intermediate variable (Marshall and

Burns 2007).

3.1.1 Multinomial Logistic Regression

In this illustrated example multinomial logistic regression is used with the aim to

accurately predict the most probable response time-band for each emergency

incident (through the consideration of the influence of other covariates). In

multinomial logistic regression, a special case of the discrete choice model

6

introduced by McFadden (1974), the probability a response, Y, belongs to the ith

of k+1 classes satisfies the following relationship:

Pr(Y i | x)

'

log

i β i x

Pr(Y k 1| x)

i 1,

,k

(1)

where Y is the discrete response of an entity (or observation) taking one of k+1

possible values (discrete classes), x is the vector of explanatory variables for the

entity, 1 ,

, k are the k intercept parameters, and β '1 ,

, β ' k are k vectors of

parameters.

The fitting of multinomial logistic regression models is possible in a number of

software packages. This work was performed in SAS (version 9.2), using the

PROC LOGISTIC procedure.

3.1.2 Application to Ambulance Response Time Data

To fit such a model the continuous ambulance response time variable had to be

converted into a discrete response, Y. The discrete response, Y, considered was

directed by the target and performance measures of NIAS. Over the last number

of years performance has been monitored and targets set by considering the

proportion of incidents responded to within 8 minutes and again within 18

minutes (Northern Ireland Ambulance Service, 2004 and Northern Ireland

Ambulance Service, 2009b). However, rather than limit the response, Y, to just

three response time-bands: [0, 8); [8, 18); and [18, ], the following five response

time-bands: [0, 5.5); [5.5, 8); [8, 11.5); [11.5, 18); and [18, ∞) were considered.

7

The reason for further subdividing was to enhance the quality of the resulting

multinomial logistic regression model (bearing in mind the large volume of data

available).

Within the ambulance response time data set there are a number of covariates

available that could be incorporated into the vector of explanatory variables x .

These covariates may provide information on either the geographical location of

an incident, temporal information on when an incident occurred, or information

relating to the response deployment. The functional form utilised for these

covariates within the model may improve the goodness of fit. Table 1 provides

details of the different covariates that have been considered for inclusion in

different multinomial logistic regression model fits. Notice in the case of some

pairs of the categorical covariates listed (e.g. u and , h and g), the covariates

actually correspond to different levels of sub-grouping of categorical variables,

and thus only one is potentially selected in any given set of explanatory variables

x . Similarly, for highly correlated variables (e.g. the geographical location

information r2 and s2) only one is potentially selected in any given set of

explanatory variables x .

Over 100 different sets of covariates have been

considered for inclusion in different multinomial logistic regression model fits.

All of these sets included either r1 or s1, a measure of the distance between the

incident and the closest ambulance station, given its strong influence on response

time (Kolesar and Blum 1973). Some of these sets also considered the effects of

interaction between different covariates e.g. the interaction between u and r1. Fits

8

were also performed based on utilising backward elimination and forward

selection techniques.

The optimal choice of model (and the explanatory variables to be retained) was

selected using Schwarz’s Bayesian Criterion (SBC) (Schwarz 1978), calculated as

follows:

SBC model with set of explanatory variables i pi ln(n) 2ln( Li )

(2)

where pi is the number of parameters to be estimated for the model with a set of

explanatory variables i, n is the number of observations, and Li is the maximised

value of the likelihood function (in this case based on a generalised logit model

with a set of explanatory variables i). The model with the set of explanatory

variables corresponding to the lowest SBC value was selected. The SBC tends to

penalise overly complex models (more than the Akaike’s Information Criterion

(AIC) (Akaike 1974)) and is useful for finding the simplest model that still

represents the data accordingly.

The multinomial logistic regression model has been fitted to the training data from

each of the 26 Local Government Districts (LGDs), with optimal model fits

determined in each case using SBC. Examination of these optimal models

suggests that the explanatory variables (influencing the prediction of response

time-band) vary across the 26 LGDs. For 4 of the 26 LGDs only the radial

distance r1 is suggested by the optimal model to influence the prediction of the

9

response time-band. In other LGDs however a number of covariates are found to

influence the prediction of the response time-band.

Ards Local Government District

For example, in the case of Ards LGD (LGD=2), in the east of Northern Ireland,

the optimal model is found include interaction terms between the radial distance r1

and the urban/rural indicator variable, u, such that:

1i 3 i

r2 1 4i

Pr(Y i | x) e i 2 i r1 1

Pr(Y k 1| x) ei r1 1 1i r2 1 4 i

if urban

i 1,

,k

(3)

if rural

This model suggests that within this LGD changes in response time-band

predicted may occur at comparably shorter radial distances in urban areas in

comparison to that of rural areas. The model also suggests the predicted response

time-band is also influenced by proximity to the second closest ambulance station.

A few illustrative situations for the model of this LGD are considered in Figure 2.

For example, consider an incident occurring in an urban region, where there are

two ambulance stations relatively close (r1≤r2=2.4 miles). In this case the

response is likely to be quick, with the predicted response time-band being either

band 1 or 2 (i.e. predicted below the 8 minutes target), except for values of

r1>2.14 miles where the response time-band changes to band 4 (i.e. predicted

below the 18 minutes target). The second sub-plot of the figure illustrates the

prediction for an incident occurring in an urban region where the second closest

ambulance station would be considered at a large distance away (r2=7.4 miles).

10

Here the predicted response is below the 8 minutes target provided r1<1.5 miles

(not as large as when there are two ambulance stations relatively close), otherwise

it is predicted below the 18 minutes target.

In contrast, consider an incident occurring in a rural region of Ards LGD, where

there are two ambulance stations relatively close (r1≤r2=3.8 miles). The predicted

response is below the 8 minutes target for r1<2.45 miles, and below the 18

minutes target otherwise. Also if an incident occurs in a rural region with the

second closest ambulance station being relatively far away (r2=15.5 miles), the

response is likely to be very short (band 1) if the closest ambulance station is

nearby (r1<3.42 miles), or very long (band 5) otherwise.

Such interpretations of the models predicted by the Conditional Component can

aid decision-makers in understanding and identifying combinations of covariate

values that often lead to longer response times. Indeed, plotting such information

on colour-coded choropleth maps may also be beneficial.

Magherafelt Local Government District

As an additional example, results are also summarised for the Local Government

District of Magherafelt (LGD=20). In this case the optimal multinomial logistic

regression model fit was also found to include interaction terms between the radial

distance r1 and the urban/rural indicator variable, u, with relative probabilities

satisfying the following:

11

1i 3 i

Pr(Y i | x) e i 2 i r1 1

Pr(Y k 1| x) ei r1 1 1i

if urban

i 1,

,k

(4)

if rural

Figure 3 illustrates how the most probable response time-band varies with r1 in

urban/rural regions. The model suggests that in the urban regions the response is

likely to be below the 8 minutes target when r1<1.46 miles, otherwise it is likely

to be well below the 18 minutes target. In the rural regions the response is likely

to be below the 8 minutes target when r1<1.9 miles, otherwise it is likely to be

below the 18 minutes target. No responses were predicted within response timeband 5.

3.1.3 The Discrete Classes

Using the model to predict the response time-band of each observation in the

training set, it is then possible to visualise the survival distribution of observations

from each of the discrete classes. Figure 4 illustrates the distribution of actual

response times in the five discrete classes (or response time-bands) for Ards LGD.

Each of these exhibit a skewed survival distribution, with the peak in the

probability density function clearly shifting to larger response times as one moves

through the 5 discrete classes. Notice also the range of the distributions appear to

spread as one moves through the 5 discrete classes – that is, the Conditional

Component has been much less successful at classifying observations as the

response time-band increases.

12

A similar trend is found on examining the response times from the four discrete

classes in the case of Magherafelt LGD (see Figure 5).

3.2

Process Component

Once the training data had been separated into the discrete classes by the

Conditional Component of the DCS model, the Process Component of the DCS

model requires the skewed survival distribution of each discrete class to be

represented by an appropriate distribution form.

3.2.1 Survival Distributions

A number of forms of survival distribution can be considered for the Process

component. In the case of the illustrated example in this paper, these include the

log-logistic distribution; a two-term log-logistic distribution; a 2-phase Coxian

phase-type distribution (Cox 1955), and the log-normal distribution. In particular,

the probability density function for the log-logistic distribution has the following

form:

f ( x)

x 1

1 x

2

(5)

,

where , >0 are the parameters of the distribution. The two-term log-logistic

distribution has the following form:

f ( x) p

1 x 1

1

1 1 1 x

1

1

1

2

(1 p)

2 x

2 1

2 1 2 x

2

13

2

2

2

(6)

where 1 , 2 , 1 , 2 >0 and 0 p 1 are the parameters of the distribution.

Parameter estimates relevant to each distributional form were estimated via

Maximum Likelihood Estimation (MLE). Schwarz’s Bayesian Criterion (SBC)

(Schwarz 1978) was again utilised to measure the goodness of fit of each

distribution form and determine the optimal form. This aspect of the work was

carried out in Matlab (version 7.8.0.347), using the FMINSEARCH procedure.

3.2.2 Application to Ambulance Response Time Data

Figures 4 and 5 illustrate the various distribution fits to each of the discrete classes

or (response time-bands) considered in the case of Ards and Magherafelt LGD.

Using SBC, the optimal distribution forms are found to be either the log-logistic

or the two-term log-logistic. In the case of Ards LGD, response time-bands 1, 2, 4

and 5 were found to be best represented by two-term log-logistic distributions,

while time-band 3 is best represented by a log-logistic distribution. In the case of

Magherafelt LGD, response time-bands 1 and 3 were found to be best represented

by two-term log-logistic distributions, while time-bands 2 and 4 are best

represented by a log-logistic distribution.

3.3

Simulating Data from the DCS Model

The DCS model represents ambulance response times, where the Conditional

Component consists of a multinomial logistic regression model, which categorises

the responses as belonging to one of 5 response time-bands, based on covariate

information. The Conditional Component acts as a filter variable that can be used

14

to create 5 different streams of ambulance response time distribution, which are

then fed into the second component of the DCS model. In the Process Component

of the DCS model, the distributions of the response times in each discrete class (or

response time-band) are represented by either a log-logistic or a two-term mixed

log-logistic distributional form.

Simulated data, corresponding to observations in the test set, can be generated

with the DCS model. For each observation in the test set, the multinomial logistic

regression model is first applied to determine the most probable response timeband (based on the covariate information relating to the observation). Then,

depending on the response time-band predicted, data can then be simulated from

the appropriate log-logistic/two-term log-logistic distribution.

Figure 6 illustrates how data simulated from the DCS model compares to the

observed response times in the test set, for observations in Ards and Magherafelt

LGD. Here cumulative response time distributions have been determined for both

observed and simulated data, by first separating observations in the test set

according to how close the nearest ambulance station is - observations in each

LGD were first divided into four groups, depending on the r1 value, then the

cumulative response time distributions were determined.

In each case, the cumulative response time distribution obtained from the DCS

model simulated data, agrees reasonably well with that observed in the test set

(see also Appendix 1 for results for all 26 LGDs). Notice however that the

simulated data demonstrates that there may be some uncertainty in the position of

15

the cumulative response time distribution determined by the DCS model,

particularly at larger response times. For example, consider observations from

Magherafelt LGD with r1 values in the first quartile. In this case there is little

spread in cumulative response time distributions determined across the

simulations for response times below around 6 minutes. Beyond this time

however, the cumulative response time distribution determined for each

simulation shows more variability in its position, and so this is reflected in a

spread in the 95% confidence interval for the cumulative response time

distribution (beyond t=6 minutes).

4

Assessing the DCS Model

The DCS model is a recently developed approach that attempts to utilise the

benefits of previous modelling conventions to aid understanding of time-to-event

data. Most importantly, the DCS model models the entire time-to-event

distribution through a fully parameterised model.

In order to assess the usefulness of the DCS model, a comparison has been made

with results from one of the most common regression-based techniques used to

fully parameterise such data, namely the parametric accelerated failure-time

model (Kalbfleisch and Prentice 1980).

16

4.1

Modelling ambulance response with the parametric accelerated

failure-time model

A parametric accelerated failure-time model has previously been utilised to model

ambulance response times in a sub-region of Northern Ireland (Cairns et al 2010).

This model fully parameterises the ambulance response-time distribution and

accounts for the effect of multiple covariates on the response.

In the parametric accelerated failure-time model the response time T satisfies:

T exp xcβc T0

(7)

where x c is the vector of covariates (not including the intercept term), β c is a

vector of unknown parameters, and T0 is a response time sampled from the

baseline distribution. Numerous baseline distributions can be considered (e.g.

exponential, generalized gamma, log-normal, Weibull, log-logistic), depending on

the software package used, though are usually limited to standard distributions. In

this work, fits to the parametric accelerated failure-time model were performed in

SAS (version 9.2), using the PROC LIFEREG procedure.

In order to be able to compare the results from the parametric accelerated failuretime model with that from the DCS model, this work has involved using the same

training set of data (as was used in determining the DCS model) to fit the

parametric accelerated failure-time model. As in the DCS case, separate

parametric accelerated failure-time models were produced for each of the 26

LGDs. In each case, the same sets of covariates (see Table 1 for list of covariates)

17

were considered as those used when generating potential model fits for the DCS

model - resulting in over 100 potential models fits for each LGD. The optimal

choice of parametric accelerated failure-time model in each LGD was then

selected, again based on using SBC. Note that in each model fit the baseline

distribution was chosen to be log-logistic. This choice was based on previous

analysis on sub-regions of Northern Ireland (Marshall et al 2006) and evidence

from some test calculations run as part of this work – which suggest this form of

baseline distribution consistently provides better model fits compared to those fits

obtained when other standard distributions are used (e.g. exponential, Weibull

etc.).

In the case of Magherafelt LGD, the optimal parametric accelerated failure-time

model was found to depend on the radial distance r1, such that:

T (r1 1)0.6028 T0

(8)

In terms of the dependence on radial distance r1, the findings of this optimal

model are in agreement with Kolesar et al (1975) – being between the square root

relation they found for short trips and the linear relation they found for long trips.

Note however more covariates were found to influence response within the

Conditional Component of the DCS model for this LGD (see Equation 4).

In the case of Ards LGD, the optimal parametric accelerated failure-time model

was found to depend on a number of covariates, such that:

18

T (r1 1)0.6812 T0

if in group 1

1

1.151 if in group 2

1.108 if hour = 0-7

1.030 if in group 3 0.946 if hour = 8-9

1.666

if

in

group

4

0.975 if hour = 10-13

1.666 if in group 5 1

if hour = 14-23

1.034 if in group 6

1.081 if unclassified

1.095 if rural

1.037 if not high priority

if urban

1

1

if high priority

(9)

Thus the optimal parametric accelerated failure-time model in this LGD (Equation

9) would suggest more covariates influence response (e.g. incidents occurring in

the early morning (hours 0-7) are likely to take longer, as too unclassified/low

priority calls) , than was found via the Conditional Component of the DCS model

(see Equation 3). However, it is important to note that this optimal parametric

accelerated failure-time model was based on the underlying assumption of a loglogistic baseline distribution.

Such an assumption may be inappropriate,

particularly given the influence of performance targets on response, and so could

have resulted in additional covariates appearing influential. Also, as will be

demonstrated in Section 4.2, one also needs to consider how well each model

captures the entire time-to-event distribution and assess whether simulated data

from this model would be comparable to that observed in unseen test data.

19

4.2

Comparing with the parametric accelerated failure-time model

In order to compare the DCS model and the parametric accelerated failure-time

model, simulated response times were also generated using the parametric

accelerated failure-time model. The simulated data was based on using the

covariate information for each of the observations in the test set. For each

observation, data was first simulated from the appropriate baseline log-logistic

distribution (depending on LGD) and then scaled according to its covariate

information (e.g. using Equations 8/9).

Figure 6 illustrates how data simulated from the parametric accelerated failuretime model compares to the observed response times in the test set, for

observations in Ards and Magherafelt LGD. In each LGD the parametric

accelerated failure-time model appears to fail in capturing the cumulative

response time distribution for observations from the lowest quartile of r1 values.

Therefore while the results from the DCS model display more uncertainty (seen in

their large 95% confidence interval), the overall placement of its cumulative

response time distribution appears more appropriate than that obtained through the

parametric accelerated failure-time model.

5

Conclusions

This paper considers the Discrete Conditional Survival model used to model

ambulance response times, and can potentially identify emergency incidents at

risk of having long response times.

As well as identifying risk, this fully

20

parameterised model enables simulation-based techniques to be deployed to

compare ambulance response times to the response of other organisations (such as

the First Responders in Cairns et al (2010)).

Use of such methods can aid

policymakers in their decision making process.

Whilst other models exist to produce fully parameterised models of time-to-event

data, this toolkit approach provides the user with a choice of unlimited datamining techniques to be used for the Conditional Component of the model, and

the choice of unlimited distribution forms to represent the skewed time-to-event

data within each discrete class (the Process Component).

The Conditional Component of the DCS model aims to aid understanding of what

influences the time-to-event through inclusion of appropriate covariates. Any

inadequacies in the Conditional Component of the model will be reflected in the

spread of the time-to-event data in each of the discrete classes. Even if

inadequacies exist however, the DCS model is still able to fully parameterise the

data due to the Process Component reflecting any inadequacies.

In the illustrative example of this work, results from the DCS model were

compared to results from the parametric accelerated failure-time model.

Differences were found between these models in what covariates were found to

influence ambulance response times in the various LGDs. These differences in

influential covariates could be attributed to the potentially inappropriate

assumption within the parametric accelerated failure-time model of an underlying

log-logistic distribution.

21

Within the illustrative example, a comparison was also made between observed

data (on which models were not trained) and data simulated from the DCS and the

parametric accelerated failure-time models. These results suggest that the DCS

model is a tool capable of modelling data on which it has not been trained, while

the parametric accelerated failure-time model may not – particularly in situations

where response is likely to be influenced by performance targets.

In general, the DCS toolkit of models aims to aid understanding of time-to-event

data and should be flexible to modelling many forms of such data within health

care. In particular it is likely to be very useful in modelling health care data with a

non-standard underlying distribution (such the Coxian phase-type distribution –

found as the most appropriate distribution for total wait times in Accident and

Emergency in the case of admitted patients (Burns 2007)). Such health care data

could not be readily modelled by the likes of the parametric accelerated failuretime model using most standard software packages – the option of such a baseline

distribution would be unavailable. The DCS toolkit however is flexible to

modelling such data.

22

References

Akaike, H. (1974), A new look at the statistical model identification, IEEE

Transactions on Automatic Control, 19 (6): 716–723.

Baker, R.D., Chaussalet, T.J. and Utley, M. (eds.) (2008), Special issue on IMA

conference, Health Care Mngt Sci, 11: 87-213.

Brailsford, S. and Harper, P. (eds.) (2007), Special issue: Operational research in

health, J Opl Res Soc, 58: 147-270.

Brandeau, M.L., Sainfort, F. and Pierskalla, W.P. (2004), Operations research and

health care: a handbook of methods and applications, Kluwer Academic

Publishers, Massachusetts.

Budge, S., Ingolfsson, A. and Zerom, D. (2010), Empirical Analysis of

Ambulance Travel Times: The Case of Calgary Emergency Medical

Services, Mngt Sci, 56 (4): 716-723.

Burns, M.L. (2007), MPhil Thesis: Modelling Waiting Times for Accident and

Emergency Patients, Queen’s University Belfast, Belfast.

Cairns, K.J., Marshall, A.H. and Kee, F. (2010), Using Simulation to assess a

Novel Public Health Scheme with Stochastic and Spatial Complexities,

accepted by J Opl Res Soc, doi:10.1057/jors.2010.27.

Cox, D. (1955), A use of complex probabilities in the theory of stochastic

processes, Proceedings of the Camb Phil Soc, 51: 313-319.

23

Davies, R. and Bensley, D. (eds.) (2005), Special Issue: Meeting health challenges

with OR, J Opl Res Soc, 56: 123-233.

Department of Health (2009), NHS Performance Framework: Implementation

guidance,

http://www.dh.gov.uk/en/Publicationsandstatistics/Publications/PublicationsP

olicyAndGuidance/DH_098525, accessed 31/07/2010.

Erkut, E., Ingolfsson, A. and Erdogan, G. (2008), Ambulance deployment for

maximum survival, Naval Res Logist, 55 (1): 42-58.

Green, L.V. and Kolesar, P.J. (2004), Improving Emergency Responsiveness with

Management Science, Mngt Sci, 50 (8): 1001-1014.

Kalbfleisch, J.D. and Prentice, R.L. (1980), The Statistical Analysis of Failure

Time Data, John Wiley & Sons, New York, NY.

Kolesar, P. and Blum, E.H. (1973), Square root laws for fire engine response

distances, Mngt Sci, 19 (12): 1368-1378.

Kolesar, P., Walker, W. and Hausner, J. (1975), Determining the relation between

fire engine travel times and travel distances in New York City, Oper Res, 23

(4): 614-627.

Marshall, A.H. and Burns, M.L. (2007), A Bayesian Network Hybrid Model for

Representing Accident and Emergency Waiting Times, Proceedings of the

20th IEEE Symposium on Computer Based Medical Systems (CBMS),

Maribor, Slovenia: 91-96.

24

Marshall, A.H., Cairns, K.J., Kee, F., Moore, M.J., Hamilton, A.J. and Adgey,

A.A.J. (2006), A Monte Carlo Simulation Model to Assess Volunteer

Response Times in a Public Access Defibrillation Scheme in Northern

Ireland, Proceedings of the 19th IEEE International Symposium on

Computer-Based Medical Systems (CBMS), Salt Lake City: 783 - 788.

Marshall, A.H. and McClean, S.I. (2003), Conditional Phase-Type Distributions

for Modelling Patient Length of Stay in Hospital, International Transactions

in Operational Research, 10 (6): 565-576.

McFadden, D. (1974), Conditional Logit Analysis of Qualitative Choice

Behaviour. In: Zarembka, P. (ed.) Frontiers in Econometrics, Academic

Press, New York.

Northern Ireland Ambulance Service, (2004), Northern Ireland Ambulance

Service Annual Report 2003/04,

http://www.niamb.co.uk/docs/documents/annual_reports/annual_report_03_0

4.pdf, accessed 31 July 2010.

Northern Ireland Ambulance Service, (2009a), Northern Ireland Ambulance

Service Annual Report 2008/09,

http://www.niamb.co.uk/docs/documents/08833%20NIAS%20Annual%20Re

port.pdf, accessed 31 July 2010.

Northern Ireland Ambulance Service, (2009b), Emergency Services and Support,

http://www.niamb.co.uk/docs/our_services_index.html, accessed 31 July

2010.

25

Royston, G. (2009), One hundred years of Operational Research in Health – UK

1948-2048, J Opl Res Soc, 60: S169-S179.

Schwarz, G.E. (1978), Estimating the dimension of a model, Annals of Statistics,

6 (2): 461-464.

Simpson, N.C. and Hancock, P.G. (2009), Fifty years of operational research and

emergency response, J Opl Res Soc, 60: S126-S139.

26

Naïve Bayes

Neural Networks

Classification Trees

Gamma

Weibull

Log-normal

Coxian Phase-Type

CONDITIONAL

COMPONENT

PROCESS

COMPONENT

Outcome

Log-logistic

Exponential

Pearson

Erlang

Bayesian Networks

Logistic Regression

Clustering

Figure 1: Schematic diagram illustrating the key components of the Discrete

Conditional Survival (DCS) model.

27

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

10

Urban

100002

9000

7000

10

6000

10

3000

2000

10000

4000

10

2000

10000

Urban

9000

0

0.5

08000

2

3

4

Radial distance r1 (miles)

2.5

5

0

6

0

8000

6000

10

4000

3000

4

4000

10

2000

10

3 1000

10

10

10

1

2

3

4

Radial distance r1 (miles)

5

6

1

0

-1

0

8

6

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

4

3

1000

0

2

7

5

Ards Local Government District (LGD=2)

Rural: Radial distance r2=15.5 miles

5

3000

2000

2

3

4

5

6

Radial distance r1 (miles)

2

3

4

Radial distance r1 (miles)

5000

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

5

1

1

7000

6000

5000

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

2

Urban

-2

1000

10

9000

Ards Local Government District (LGD=2)

Rural: Radial distance r2=3.8 miles

7000

6

1

1.5

Radial distance r1 (miles)

1

10

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

-1

3000

1000-1

10

0

5000

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

40000

10

10

6000

5000

10

1

8000

70001

10

10

9000

8000

10

Ards Local Government District (LGD=2)

Urban: Radial distance r2=7.4 miles

2

Urban

10000

10

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

10

Ards Local Government District (LGD=2)

Urban: Radial distance r2=2.4 miles

3

1

2

3

Radial distance r1 (miles)

4

10

2

0

10

10

10

1

2

3

4

Radial distance r1 (miles)

5

1

0

-1

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Radial distance r1 (miles)

Figure 2 Visualisations based on the optimal multinomial logistic regression

model (see Equation 3) found for Ards Local Government District. The model

predicts the relative probability an observation lies in one of 5 response timebands depending on the radial distances to the two closest ambulance stations (r1

28

6

and r2), and whether an observation occurs at an urban/rural location. The red

shaded regions indicate values of r1 not applicable/not observed, given the values

of r2 and the urban/rural indicator variable.

29

Urban

10

Urban

10000

10000

9000

9000

8000

8000

Magherafelt Local Government District (LGD=20)

7000

Urban

2

Magherafelt Local Government District (LGD=20)

Rural

7000

10

4

6000

6000

4000

10

5000

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

1

3000

2000

1000

10

0

0

10

10

1

2

3

4

Radial distance r1 (miles)

5

6

-1

-2

0

1

2

3

4

Radial distance r1 (miles)

5

6

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

Ratio of Probability in Response Timeband

i to Probability in Response Timeband 5

5000

10

Response Timeband 1

Response Timeband 2

Response Timeband 3

Response Timeband 4

Response Timeband 5

3

4000

3000

10

2

2000

10

1000

1

0

10

10

10

1

2

3

4

Radial distance r1 (miles)

-1

-2

0

5

10

Radial distance r1 (miles)

model (see Equation 4) found for Magherafelt Local Government District (LGD).

The model predicts the relative probability an observation lies in one of 5

response time-bands depending on the radial distance to the closest ambulance

station (r1), and whether an observation occurs at an urban/rural location. The

red shaded regions indicate values of r1 not observed in the urban/rural areas of

30

6

0

Figure 3 Visualisations based on the optimal multinomial logistic regression

the LGD.

5

15

Ards Local Government District (LGD=2)

Proportion of Incidents

0.2

0.1

0

0

0.2

0.1

0

0

0.2

Timeband 1

5

10

15

5

10

15

20

5

10

15

20

0.05

0

0

30

25

30

Timeband 4

0.1

0

0

0.1

25

Timeband 3

0.1

0

0

0.2

20

Timeband 2

data

log-logistic

Coxian252 phase

30

two-term log-logistic

log-normal

5

10

15

20

25

30

15

20

Response Times (minutes)

25

30

Timeband 5

5

10

Figure 4: Distribution of observed response times within the training set of Ards

Local Government District, where the data has been separated into five discrete

classes (or response time-bands) using the Conditional Component of the DCS

model. The plot illustrates possible distribution fits to these, based on various

distribution forms (log-logistic, 2-phase Coxian, two-term log-logistic and lognormal).

31

Magherafelt Local Government District (LGD=20)

Timeband 1

0.1

0.05

Proportion of Incidents

0

0

0.1

5

10

15

20

Timeband 2

data

log-logistic

Coxian 2 phase

25log-logistic

two-term

log-normal

30

0.05

0

0

5

10

15

25

30

25

30

Timeband 3

0.1

0.05

0

0

0.1

20

5

10

15

20

Timeband 4

0.05

0

0

5

10

15

20

Response Times (minutes)

25

Figure 5: Distribution of observed response times within the training set of

Magherafelt Local Government District, where the data has been separated into

four discrete classes (or response time-bands) using the Conditional Component

of the DCS model. The plot illustrates possible distribution fits to these, based on

various distribution forms (log-logistic, 2-phase Coxian, two-term log-logistic and

log-normal).

32

30

LGD=2 Q1<r1<=Q2

LGD=2 r1>Q3

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

1

0.9

Proportion

1

0.9

0.3

0

LGD=20 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=20 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

8

16

24

Response time (mins)

0.1

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=20 r1>Q3

1

0.5

0

LGD=20 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

LGD=2 Q2<r1<=Q3

1

0.9

Proportion

Proportion

LGD=2 r1<=Q1

1

0.9

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

Figure 6: This figure compares data simulated from the Discrete Conditional

Survival (DCS) model and from the parametric accelerated failure-time model to

that observed in the test set for the Local Government Districts (LGDs) of Ards

(LGD=2) and Magherafelt (LGD=20) (where simulated response times are based

on using each of the fully parameterised models together with covariate

information from each of the observations in the test set). The cumulative

response time distributions of observed/simulated data are determined and plotted

separately for the different r1 quartiles of each Local Government District.

33

Variable

Description

Geographical Location Information

Relative to ambulance stations:

r1

radial distance between incident and closest ambulance station

r2

radial distance between incident and second closest ambulance station

Based on quartiles of r1 and r2 (6 categories):

s1

1. r1≤Q1

2. Q1<r1≤Q2

3. Q2< r1≤Q3 and r2≤ Q2

4. Q2< r1≤Q3 and r2> Q2

5. r1>Q3 and {r2≤Q1 or r2> Q3}

6. r1>Q3 and Q1<r2≤Q3

road distance between incident and closest ambulance station

s2

road distance between incident and second closest ambulance station

Location of incident: Depending on the Census Output Area that the incident

occurred in, the location is classified as...

u

an urban/rural area (2 categories)

one of 8 classification band categories ranging from open countryside

to metropolitan urban area

Temporal Information

h

Incident hour (24 categories)

g

Incident hour group (4 categories: 0-7;8-9;10-13;14-23)

w

Day of week: 7 categories

Response Deployment Information

Ω

β

Categorical variable indicating whether an incident was

1. classified as high priority

2. not classified as high priority

3. unclassified

Binary variable indicating if observation corresponds to a Rapid

Response Vehicle response

Table 1: Variables considered for inclusion in the Discrete Conditional Survival

(DCS) model and the parametric accelerated failure-time model.

34

Appendix 1: The cumulative response time distribution observed in the test set,

where observations in the different r1 quartiles of each Local Government

District (LGD) are plotted separately. These have been compared to results

simulated from the Discrete Conditional Survival (DCS) model and from the

parametric accelerated failure-time model, where in each case simulated

response times are based on covariate information from each of the observations

in the test set.

35

LGD=1 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=2 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=2 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=3 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=3 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=4 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=4 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

8

16

24

Response time (mins)

0.1

36

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=4 r1>Q3

1

0.9

0.4

0

LGD=4 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=3 r1>Q3

1

0.9

0.4

0

LGD=3 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=2 r1>Q3

1

0.5

0

LGD=2 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

0.6

0.3

0.2

32

Proportion

0.9

Proportion

1

0.2

Proportion

LGD=1 r1>Q3

1

0.3

Proportion

LGD=1 Q2<r1<=Q3

1

Proportion

Proportion

LGD=1 r1<=Q1

1

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

LGD=5 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=6 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=6 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=7 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=7 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=8 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=8 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

8

16

24

Response time (mins)

0.1

37

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=8 r1>Q3

1

0.9

0.4

0

LGD=8 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=7 r1>Q3

1

0.9

0.4

0

LGD=7 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=6 r1>Q3

1

0.5

0

LGD=6 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

0.6

0.3

0.2

32

Proportion

0.9

Proportion

1

0.2

Proportion

LGD=5 r1>Q3

1

0.3

Proportion

LGD=5 Q2<r1<=Q3

1

Proportion

Proportion

LGD=5 r1<=Q1

1

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

LGD=9 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=10 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=10 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=11 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=11 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=12 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=12 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

8

16

24

Response time (mins)

0.1

38

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=12 r1>Q3

1

0.9

0.4

0

LGD=12 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=11 r1>Q3

1

0.9

0.4

0

LGD=11 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=10 r1>Q3

1

0.5

0

LGD=10 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

0.6

0.3

0.2

32

Proportion

0.9

Proportion

1

0.2

Proportion

LGD=9 r1>Q3

1

0.3

Proportion

LGD=9 Q2<r1<=Q3

1

Proportion

Proportion

LGD=9 r1<=Q1

1

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

LGD=13 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=14 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=14 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=15 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=15 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=16 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=16 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

8

16

24

Response time (mins)

0.1

39

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=16 r1>Q3

1

0.9

0.4

0

LGD=16 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=15 r1>Q3

1

0.9

0.4

0

LGD=15 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=14 r1>Q3

1

0.5

0

LGD=14 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

0.6

0.3

0.2

32

Proportion

0.9

Proportion

1

0.2

Proportion

LGD=13 r1>Q3

1

0.3

Proportion

LGD=13 Q2<r1<=Q3

1

Proportion

Proportion

LGD=13 r1<=Q1

1

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

LGD=17 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=18 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=18 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=19 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=19 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=20 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=20 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

8

16

24

Response time (mins)

0.1

40

0

32

0.6

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=20 r1>Q3

1

0.9

0.4

0

LGD=20 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=19 r1>Q3

1

0.9

0.4

0

LGD=19 Q2<r1<=Q3

1

0.5

Observed

DCS Model

Failure-time model

0.2

0.9

0.6

32

0.3

Observed

DCS Model

Failure-time model

0.2

32

8

16

24

Response time (mins)

LGD=18 r1>Q3

1

0.5

0

LGD=18 Q2<r1<=Q3

1

0.6

Observed

DCS Model

Failure-time model

0.2

1

Proportion

Proportion

0.6

0.3

0.2

32

Proportion

0.9

Proportion

1

0.2

Proportion

LGD=17 r1>Q3

1

0.3

Proportion

LGD=17 Q2<r1<=Q3

1

Proportion

Proportion

LGD=17 r1<=Q1

1

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.2

0.1

32

0

0

8

16

24

Response time (mins)

32

LGD=21 Q1<r1<=Q2

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.6

0.5

0.4

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.1

0

0.6

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0

LGD=22 r1<=Q1

0.5

0.4

8

16

24

Response time (mins)

0.1

0

0.5

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

32

0.6

0

LGD=22 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.9

0.9

0.9

0.8

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.4

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.9

Proportion

1

0.6

0

LGD=23 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=23 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9

Proportion

1

0.9

0.6

0

LGD=24 r1<=Q1

8

16

24

Response time (mins)

0.1

0

0.6

0.5

0.4

0

LGD=24 Q1<r1<=Q2

8

16

24

Response time (mins)

0.1

0

32

0.8

0.8

0.8

0.7

0.7

0.7

0.7

0.3

0.4

0.3

Observed

DCS Model

Failure-time model

0.2

0.1

0

0.5

0

8

16

24

Response time (mins)

Observed

DCS Model

Failure-time model

0.1

0

0.6

0.5

0.4

0.3

0.2

32

Proportion

0.8

Proportion

1

0.9