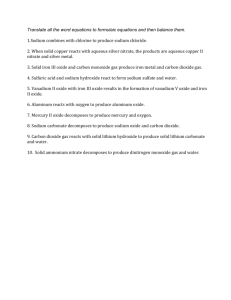

Oxidation and Adhesion on theQuasi-Crystalline AlPdMn

advertisement

Oxidation and Adhesion on the Quasi-Crystalline AlPdMn Surface Studied by Nanolithography J.Smith1,2*, G.Torricelli2, F. Marchi1,3, P.Budau1,4, F. Comin2, J. Chevrier1,2,3 1. LEPES-CNRS – BP 166, F-38042 Grenoble cedex 9, France 2. ESRF - BP 220, F-38043 Grenoble Cedex, France 3. Université Joseph Fourier, Grenoble, France 4. University of Bucharest, Faculty of Physics, Magurele, MG-11, Romania *To whom correspondence should be addressed: Department of Chemistry and Chemical Biology 610 Taylor Rd. Piscataway, NJ 08854-8087 Phone: (732) 445-4351 Fax: (732) 445-5006, email: jasmith@soemail.rutgers.edu 1 Abstract: We present the novel application of a relatively new technique (nanolithography) to the study of quasicrystalline surface oxidation. The 5-fold surface of an AlPdMn alloy was oxidized using a metallized AFM tip. The electrochemical nature of this process was confirmed by investigating the influence of humidity and polarity of the applied voltage on the quasicrystalline oxide. Oxides of different thickness and adhesive properties were created by altering the applied voltage and the humidity during the lithographic process. The technique can be used in an exhaustive study of properties of the various types of oxides that form on the AlPdMn surface and the preliminary results of one such study are reported. KEYWORDS Atomic force microscopy, Adhesion, Oxidation, Surface chemical reaction 2 1. Introduction: Since the discovery of quasicrystals in 1982 [1], the focus of their study has evolved from attempts to clarify the nature of this solid state and its surfaces [2] to attempts to reveal several of the more remarkable quasicrystalline properties of direct practical interest. The extremely low adhesive properties, high hardness, good corrosion resistance and low coefficients of friction [3-8] of quasicrystalline materials make them particularly attractive as wear preventative coatings. Such coatings have found application in turbine blades, cookware, razor blades, pistons and cylinders [9]. While quasicrystalline oxidation has been studied by several groups[10-13], very few have studied the adhesive properties of the oxides that form on quasicrystalline surfaces[14-16] and none have done so on the nm scale. As such alloys oxidize in all but the most chemically inert or reducing environments, properties of the surface oxide (i.e. structure, thickness, chemical composition) determine the adhesive properties of the surface. The goal of the present work is to use the relatively new technique of AFMassisted lithography in order to study the adhesive properties of the various oxides that form on the AlPdMn quasicrystalline surface. Both Atomic Force Microscopy (AFM) and Scanning Tunneling Microscopy (STM) assisted lithography have been demonstrated on Si[17-19]. The process is explained in detail elsewhere [20]. AFM lithography is an electrochemical process characterized by the following brief description. A metallized tip is held close to the sample surface for a few seconds and a large negative bias is applied to the tip with respect to the sample. If the environment is sufficiently humid and the tip-sample 3 distance sufficiently small, a water meniscus will form between the tip and sample. The electric field created by the tip bias ionizes the meniscus and oxidizes the sample surface exactly where the meniscus comes into contact with it. This process is strongly dependent upon three factors: (1) the formation of the water meniscus between the tip and sample surface (i.e. the humidity and tip-sample distance), (2) the creation of a field of sufficient strength to ionize the water meniscus and (3) the duration of the application of that field. This process has been well characterized when performed on Si [17-19]. However, it has not been studied on any quasicrystalline surface to date. The native oxide of AlPdMn is Al2O3 and studies of the adhesive properties of the oxidized surface have been performed [9]. It has been shown that the coefficient of dynamic friction of the 5-fold surface of AlPdMn decreases by 50% with the growth of a very thin (<10 Å) oxide layer. This suggests that the coefficient of dynamic friction of the oxide may decrease with thickness. 2. Experiment Initial Sample Preparation The purpose of the initial sample preparation was to create a well-defined surface for AFM lithography and the adhesion studies. The procedure outlined in this section was performed only one time prior to all AFM work (i.e. it was not repeated prior to each experiment). The quasicrystalline sample involved in this work was Al70.3Pd20.6Mn 9.1. Its 5-fold surface was polished (in ambient air) to 0.25 μm using standard SiC and diamond polishing papers. This process yielded a shiny, mirror-like surface, whereas the 4 unpolished surface is rough, dull and relatively non-reflective. It should be noted, however, that even the polished surface is considerably less shiny than those resulting from cleaving the quasicrystal under Ultra High Vacuum (UHV) conditions The surface treatment was performed in a (10-10 Torr) vacuum and consisted of cycles of Ar ion bombardment (20 minutes, 1keV < Ein < 2keV) and anneal (3 hours) at 600ºC. The cycles of bombardment and anneal were continued until a 5-fold LEED pattern was obtained. Subsequently, the sample was removed from the chamber and allowed to oxidize in ambient air (density of water vapor of approximately 7x10 -6 g/cm2) for several hours. AFM Studies The AFM studies were performed in ambient air and in flowing gaseous nitrogen at room temperature using the Digital Instrument NANOSCOPE 3100 system. The humidity of the experimental environment was measured using a high sensitivity fast response thermometer-hygrometer [21]. Relative adhesive properties of the various oxides were obtained using the AFM tip as the probe in a nm-scale probe tack experiment. This is done by obtaining the “Force curve” [22,23] (i.e. the deflection of the cantilever vs. the tip-sample separation) as the AFM tip approaches, contacts and then withdraws from the sample surface. The tip deflection is linearly related to the force of tip-sample interaction through the cantilever spring constant. Then the force of adhesion, which is the force needed to disengage the tip from contact with the surface, can be directly extracted from such a force curve. The force of adhesion is usually a few nN and is related to the irreversible 5 work of adhesion. All adhesion measurements presented were performed with a single non-metallized SiC tip. Spring constants mentioned in this work are those supplied by the manufacturer. Normal deflection spring constants and tip radii are 0.60 N/m and 20 to 50 nm. The results presented here were all obtained using the same tip in as dry an environment as possible (h = relative humidity ~ 19%, corresponding to a density of water vapor of approximately 3x10-6 g/cm2). This was done in order to minimize the effect of adsorbed moisture on the measurement. After the lithography and surface analysis were performed, the chemistry and depth of the native oxide on the surface were analyzed. Using Scanning Electron Microscopy in conjunction with depth profile micro-Auger spectroscopy, we measured the thickness of the native oxide layer on our sample to be approximately 2 nm. The composition of the native oxide of AlPdMn was seen to be essentially Al2O3, which is consistent with the literature [24]. 3. Results: A. Lithographic Process The electrochemical nature of the lithographic process needed to be confirmed as this study marked the first attempt to apply AFM-assisted lithography to quasicrystalline materials in general, and to the AlPdMn system in particular. In other words, it could not be concluded a priori that any observed protrusions created on the surface were indeed oxide. These could easily have been caused by other phenomena due to the high magnitude (on order of 109 V/m) of the field created between the tip and sample. For 6 example, this field might cause damage and subsequent deposition of some part of the AFM tip (e.g. the metallic outer layer) or direct surface damage. Either such phenomenon would result in bumps on the surface that would be indistinguishable from electrochemically created oxide using only AFM. The volume of electrochemically created oxide, however, should strongly depend on the ambient humidity while tip deposition or surface damage should not. Therefore, the dependence of the results of the lithographic process on humidity was verified and taken and as confirmation of the electrochemical formation of surface oxide. Results from this experiment appear in Figure #1. Twelve patches of oxide, or oxide dots, are shown. Each dot was created by tapping mode lithography while using the same metallized AFM tip. The dots were formed in succession, starting with the bottom left and finishing with the top right, as indicated by the large white arrow in the figure. During the deposition, the tip was held for 20 s at a constant bias of –9V and within several nm of the grounded sample surface. The partial pressure of nitrogen gas was controlled in order change the relative humidity of the experimental environment during the creation of each of the dots. The map on the right hand side of the figure gives the humidity during the creation of each of the dots. The dots in the lower left were created at maximum humidity (~45%) which corresponds to ~10-5 g/cm3 of water vapor. The humidity was then decreased continuously (from lower left to upper right in the image) until two dots were made at the minimum (~19%). These dots are indicated in the figure. In the progression, one can easily see that dot volume decreases substantially as the humidity decreases in the tested range 45-19%. This corresponds to a decrease in the density of water vapor in the 7 experimental environment from 10-5 to 3x10-6 g/cm3. Finally, the humidity was again increased to maximum (~45%, ~10-5 g/cm3 of water vapor) in order to create the two dots in the upper right portion of the image. The volume of these last two dots is nearly identical to that of the dots created under conditions of maximum humidity at the beginning of the experiment (lower left of image). This confirms that the observed decrease in dot volume was due to changes in humidity as opposed to a gradual degradation in the quality of the tip or to an effect of surface structure on the lithographic process. Unexpectedly, the shape and width of these dots in the plane of the surface does not appear to change with humidity. During the lithographic process, the dot width would be expected to decrease with humidity as the volume of the water meniscus between the tip and surface decreases. The absence of this effect in the image is perhaps due to the impact of the tip shape. As the tip diameter is comparable to the lateral dimensions of the dots, the images of the dots in Figure #1 result from a convolution of both the physical shape of the dots and the physical shape of the tip. Then, only the dot dimension perpendicular to the surface could be considered to be measured accurately by AFM. This dimension is referred to as the relative “height” of an oxide dot or line. It was measured by taking the difference between the height of the feature in the topographic AFM image and the average height of the adjacent surface over 2 square nm. By this measure, the decrease in relative humidity from 47 % to 24 % causes a decrease in dot height from 25.1 nm to 4.1 nm (Figure #1). In other words, a decrease in the humidity from its maximum to half this value results in an 84 % decrease in dot height. 8 An electrochemical process, as outlined in the introduction, would require a negative tip bias. Therefore, the effect of a change in polarity of the tip bias on the process was also investigated. A bias of +9V was applied to the tip as it was held within a few nm’s of the surface for 20 s. The mark created by this process on the surface was then compared to that which was left by repeating the process on a neighboring region with a negative tip bias (–9V). While positive bias ‘lithography’ did induce changes on the surface (possibly due to deposition of some part of the tip), the difference between these changes and those observed for negative bias lithography was dramatic. While the former process created a form on surface less than a few nm’s in height and width, the latter created an oxide dot more than 20 nm tall and approximately 20 nm wide. The facts that this process is shown to require the presence of water and a negatively biased tip are consistent with the process of tip –assisted oxidation. They are wholly inconsistent with tip deposition or field-induced surface damage. B. Lithographic Parameters The effect of change in tip bias on lithography was investigated. For this series of experiments, lithography was performed in contact mode with W2C coated tips. Five oxide lines were drawn under high humidity (~35%) conditions, each with a different tip bias ( –10, -8, -6, -4 and –2V ). This experiment was repeated 10 times. It was found that lithospeed in the formation of lines needed to be between 10-30nm/s. Below 10 nm/s, the shape of the oxide pattern was clearly non-linear, while 30 nm/s was too fast to create substantial amounts of lithographic oxide on the surface. Topographic images were then taken and used to deduce the relative heights of the lines. The results from a representative attempt appear in Figure #2. The figure 9 shows an obvious correlation between the magnitude of the applied bias and line height. In order to make the comparison quantitative, relative oxide line height vs. applied tip voltage is plotted in Figure #3 as averaged over the ten trials. The results clearly show a strong and possibly linear dependence of lithographic oxide height on the magnitude of the applied voltage. Indeed, the figure shows that changing the voltage from - 4 to - 10 V results in a change in line height from 6.1 ± 2.2 to 27.2 ± 7.0 nm. Thus, a six volt increase in the magnitude of the applied voltage results in an increase in dot height which is on order of hundreds of percent. Note that the results in Figure #3 show that the threshold voltage for lithography on AlPdMn has been determined to lie within –2 and –4V. A similar lithographic study on CVD Al metal, performed under the same conditions and with the same equipment, showed a threshold also within the range of -2 and -4 V. The threshold is the same order of magnitude when measured on oxidized silicon [25]. These results are consistent with the hypothesis that the lithographic threshold depends primarily on the water meniscus formed between the tip and sample and, so, is relatively substrate independent. C. Adhesion Results Adhesion measurements show a definite difference in the characteristics of the lithographic oxide from those of the native oxide. In total, 360 adhesion measurements were performed on 12 different lithographic oxides and 240 adhesion measurements on 10 different areas of native oxide. Two representative force curves appear in Figure #4 and the force of adhesion is indicated in the figure. Note that the scales in Figures 4a,b are identical. Both force curves were obtained using the same tip under identical conditions. It is evident from Figure #4 that the measure of adhesive force presented for 10 the native oxide is nearly twice that for the lithographic oxide. On average, the AFM tip adhesion to the lithographic oxide surface is only 68% as strong as the adhesion measured on the native oxide. This difference was observed for the entire series of measurements. 4. Discussion: We note that the variance of the measurement of the force of adhesion on the native oxide was 21% over 240 measurements. On the lithographic oxide, the variance in this measurement was closer to 29% over 360 separate measurements. To date, we have not measured how the chemical composition of the oxide varies laterally on the surface. If this is substantial, it is one possible source of this error. While chemical inhomogeneity in the lithographic and native oxides remains an issue for further study, we may say with confidence that it will not affect the major conclusion we draw from the results presented here, i.e. that the adhesive properties of the lithographic oxide are significantly weaker than those for the native oxide. Previous studies by Dubois et al have shown [26,27] that simply increasing the thickness of the amorphous, native oxide surface layer (below 12 nm) substantially decreases the adhesive properties of quascrystalline surfaces. The results presented here are consistent with those of Dubois et al. A detailed understanding of the chemical composition and structure of the oxide produced by nanolithography would help to clarify whether our results are fully explained by their conclusion, i.e. that this effect is due to the influence of the electronic structure of the underlying quasicrystal. While we 11 have not yet succeeded in this rather difficult experiment, we can discuss the results obtained in the context of the literature. All studies to date have shown that oxidizing the surface of the AlPdMn quasicrystal under a variety of conditions yields a surface layer that is nearly chemically identical to the native oxide of aluminum metal, i.e. Al2O3 [14-16,26,27]. Then, the simplest plausible description of the lithographic oxide is to consider it is an amorphous layer of Al2O3. However, we do expect the precise composition and structure of the oxide to depend somewhat on the fabrication process, as has been observed in the case of the oxidation of Si (100) by nanolithography [28]. Indeed, our experimental observations indicate an oxidation mechanism that depends upon experimental details such as the precise level of humidity, the tip quality as well as parameters such as the applied voltage and normal force. To a first approximation, however, it is reasonable to consider the oxide surface in contact with the AFM tip as the same as the surface of the native oxide layer. In this case, our results show that the thickness of the oxide layer is inversely related to the adhesive properties of the oxide (Figure #4). That this difference cannot be ascribed to changes in the lateral dimension of the oxide (i.e. changes from that of the surface covering native oxide with its effectively infinite lateral extent to the finite lithographic oxide), can be assumed because the lateral dimension of the lithographic oxide (300-500nm) is greater than the radius of the tip (20-50nm) by at least an order of magnitude. Then, even the lithographic oxide has a large lateral dimension with respect to the tip. The nm scale changes in oxide thickness (Figures #1-3) are known be of the scale over which substantial variations in Van der Waals interactions occur in any 12 materials system. As the extraordinary adhesive properties of quasicrystals are suspected to lie in their peculiar Van der Waals interactions [26,27], our results show that nanolithography provides a practical method to probe changes in adhesive properties quasicrystalline oxides in detail. 5.Conclusions and Future Directions: The primary result of this study is to show the first successful use of AFMassisted lithography to create various oxides on the quasicrystalline AlPdMn surface. We have proved the electrochemical nature of this process by demonstrating the effect of humidity and the polarity of applied voltage on it. We also have determined the “lithographic range” (i.e. the range necessary to perform lithography on this surface) of for several key parameters. These include the humidity (23 – 47%), tip bias: -(4 - 11V) and lithospeed in the formation of lines (10-30nm/s). We have studied effect of changing several of the lithographic parameters on oxide thickness. First, we determined that a decrease in humidity to half its maximum value decreases oxide height by 84 %. Next, we observed that the increase in the magnitude of the tip bias by 6V (from -4V) introduces an increase in oxide height that is on order of hundreds of percent. We have also demonstrated the utility of this technique in the study of the adhesive properties of quasicrystals. Our results show that the adhesion of the thicker lithographic oxide to a SiC probe is 32% weaker than that measured if the same experiment is performed on the native oxide of AlPdMn. This result along with the size scale of the difference in the thickness of these layers are consistent with the hypothesis 13 Van der Waals interactions play a key role in the peculiarity of the adhesive properties of these surfaces. While it is difficult to extend this analysis further without a better knowledge of the oxide layer, this raises an issue that merits future study. Further, the work shows that it would also be useful to measure the adhesive properties of the quasicrystalline surface in the absence of oxidation, i.e. in UHV just subsequent to the surface preparation described in the introduction. In such an experiment, adhesive properties can be quantified via the non-contact interaction between a tip and the surface at distances varied from a few nanometers up to 500nm. The analysis of such results, using the Lifschitz formula for the non retarded Van der Waals interaction at distance shorter than the plasma length, will lead to accurately quantifying the adhesive force between the tip and the sample. This work is currently in progress. Finally, these results suggest that it may be possible to diminish the already phenomenally weak adhesive properties of AlPdMn by increasing the thickness of its oxide. If such a procedure is developed it would have a very significant impact in the use of quasicrystalline materials as wear-resistant coatings. 14 REFERENCES [1] D. Schectman, I. Blech, D. Gratias, and J.W. Cahn, Phys. Rev. Lett. 53 (1984) 1951. [2] K. Chattopadhyay, S. Ranganathan, G.N. Subbanna and N. Thangaraj, Scripta Metall. 19 (1985) 767. [3] J.M. Dubois, S.S. Kang, Y. Massiani, J. Non.-Cryst. Sol. 153-154 (1993) 443. [4] J.M. Dubois, S.S. Kang, A. Perrot, Mater. Sci. Eng. A 179-180 (1994) 122. [5] J.M. Dubois, A. Proner, B. Bucaille, P. Cathonnet, C. Dong, V. Richardt, Y. Massiani, S. Ait-Yaazza, E. Berlin-Ferré, Ann. Chim. Mater. 19 (1994) 3. [6] S.S. Kang, J.M. Dubois, J. Von Stebut, J. Mater. Res. 8 (1993) 2471. [7] N. River, J. Non-Cryst. Sol. 153-154 (1993) 458. [8] J.S.Ko,A.J.Gellman,T.A.Lograsso,C.J.Jenks,P.A.Thiel,Surf. Sci. 423 (1999) 243. [9] M. F. Besser and T. Eisenhammer, MRS Bulletin 22 (1997) 59. [10] V. Demagne, J.W. Anderegg, J. Ghanbaja, F. Machizaud, D.J. Sordelet, M. Besser,P. Thiel, J.M. Dubois, Appl. Surf. Sci. 173 (2001) 327. [11] B.I. Wehner, U. Koester, in: New Horizons in Quasicrystals Research and Applications, Ed. A.I. Goldman, J.M. Dubois, D.J. Sordelet, P.A. Thiel (World Scientific Publishing Company, Incorporated, 1997) p. 152. [12] M. Gil-Gavatz, D. Rouxel, P. Pigeat, B. Weber, J.M. Dubous, Phil. Magazine A. 9 (2000) 2083. [13] S.L.Chang,W.B.Chin,C.M.Zhang,C.J.Jenks,P.A.Thiel,Surf. Sci 337 (1995) 135. [14] E. Fleury, J.S. Kim, D.H.Kim, W.T. Kim,. J. Mater. Res., 18 (2003) 1837. [15 ]E. Huttunen-Saarivirta, E. Turunen, M. Kallio, J. Alloys & Compounds 354 (2003) 269. [16] C. Mancinelli, J.S. Ko, C.J. Jenks, P.A. Thiel, A.R. Ross, T.A. Lograsso, A.J. Gellman, Mater. Res. Soc. Proc. 643 (2001) K8.2.1. [17] H. Sugimura, T. Yamamoto, N. Nakagiri, Appl. Phys. Lett. 65 (1994) 1569. [18] E.S. Snow, P.M. Campbell, P.J. McMarr, Appl. Phys. Lett 63 (1993) 749. [19] P.Avouris, T. Hertel, R. Martel, Appl. Phys. Lett. 71 (1997) 285. [20] R.Garcia, M. Calleja, H. Rohrer J.Appl.Phys. 86, (1999) 1898. [21] Humidity Meter KM8004 - Comark Limited, UK [22] B. Capella, G. Dietler, Surf. Sci. Rep. 34 (1999) 1. [23] S. Decossas, G. Cappello,G. Poignant, L. Partrone, A.M. Bonnot, F. Comin, J. Chevrier, Europhys. Lett.53 (2001) 742. [25] P. Dubot, P. Cénédèse, D. Gratias, Phys. Rev. B 68 (2003) 033403. [24] F. Marchi, PhD Thesis, Université d’Aix-Marseille II (2000). [26] J.M. Dubois, J. Non-Cystal. Sol. 334&335 (2004) 481. [27] J.M. Dubois, V. Fournée, E. Berlin-Ferré, Mat. Res. Soc. Symp. Proc. 805 LL8.6.1. [28] J.A. Dagata, T. Inoue, J. Itoh, K. Matsumoto, H. Yokoyama J.Appl.Phys. 84 (1998) 6891. 15 Figure Captions Figure #1 a) AFM tapping mode topographic image of oxide dots made on AlPdMn . Large white arrow indicates the direction of tip motion in the formation of dots. The dots imaged in a) are labeled in b) by the humidity as they were created. Figure #2: Oxide Lines created by lithography: a) Topographic image in contact mode showing four oxide lines, each labeled by the lithographic voltage used to create them. The green dotted line marks the section of a) used to create the plot in b). b) Section (averaged) showing decrease in height of oxide lines in a) with decrease in magnitude of applied voltage. Lines are labeled by the applied voltage used to create them. Figure #3: Oxide line height as a function of applied voltage on surface of AlPdMn. Data is averaged over 10 trials. Figure #4: Force curves obtained on a) the native oxide b) the lithographic oxide using a SiC in a dry (19%, 3x10-6 g/cm2) environment. Tip deflection is measured which can be related to tip-sample force, plotted on the y-axis, through the spring constant of the tip. The x axis is the lateral displacement of the tip from sample where “0.0 nm” denotes contact. The measure of the force of adhesion is labeled in the figure. 16 3.0 Last Dot Formed Dust Particles 45% 45% 3.0 19% 18% Formed under conditions of lowest humidity 2.0 μm 2.0 μm 23% 27% 25% 1.0 1.0 26% 28% 47 % First Dot Formed (highest humidity) 0.0 1.0 a) μm 2.0 0.0 3.0 43% 0.0 1.0 b) 35% μm 0.0 2.0 3.0 Figure #1 15.0 -10 V -6 V -8 V -4 V μm 30.0 μm 15.0 5.0 0.0 10.0 0.0 5.0 μm a) 10.0 -10V -8V -6V -4V 0.0 15.0 b) Figure #2 17 Height of Oxide Line (nm) 40.0 35.0 30.0 25.0 20.0 15.0 10.0 5.0 0.0 0.0 2.0 4.0 6.0 8.0 10.0 12.0 Magnitude of Voltage Applied to the Tip (V) Figure #3 0.0 -5.0 Measure of adhesive force -10.0 Force (nN) Force (nN) 0.0 Measure of adhesive force -5.0 -10.0 a) 0.0 75.0 150.0 Lateral Displacement (nm) 0.0 b) 150.0 75.0 Lateral Displacement (nm) Figure #4 18 19