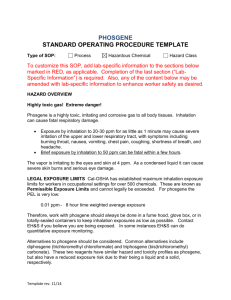

Why does the market need a new Phosgene indicator badge

advertisement

Why does the market need a new Phosgene indicator badge? Usage of Phosgene Phosgene (COCl2) is a non combustible but very toxic gas. It is a raw material for plastics like Polycarbonates (i. e. Macrolon) or Polyurethanes. Monitoring of Phosgene Plants using or manufacturing Phosgene of course underlay strict safety regulations. Therefore they are equipped with portable and fixed gas detectors for Phosgene. While portable instruments are mostly used for personal monitoring (i. e. Monitox) or leak detection (i. e. Tracer), the purpose of fixed systems (i. e. Statox, Statox 501, Statox 505) is plant safety. These instruments reliably give an alarm in case of a Phosgene release. If a release occurs, the plant itself as well as the area and buildings around the plant will be evacuated. In case of an emergency even the process will be shut down. After a Phosgene event, the essential question is, who of the exposed personnel needs medical treatment. The majority of the people present in the plant will not be equipped with gas detectors. Therefore the first responders and the emergency doctor need a tool to make a quick decision how to proceed. This tool is a Phosgene indicator badge that must be worn by any personnel entering the plant. The badge is buttoned to the clothing or fixed with a clip close to the breathing area, normally at the chest pocket or hard hat. The indicator is impregnated with a reagent that turns red if exposed to Phosgene. With the help of a color comparator which is provided free of charge with every package of badges, this tool is on hand wherever and whenever needed. Reading apparatuses may be slightly more accurate, but are probably not available at the right place in time. This would delay vital decisions. For the emergency doctor it is essential to make an immediate decision. He cannot rely on symptoms, as a Phosgene intoxication will develop symptoms only hours after exposure! Therefore he needs an objective tool, monitoring the total exposure. Medical treatment of exposed personnel Phosgene is a widely known substance. For many years the philosophy was: The lower the alarm threshold, the better for safety. Consequently in Europe the alarm threshold has been reduced to 20 ppb in the early nineties. But things are not as simple as they look. It is very unlikely that an exposure of a person will go unnoticed, as Phosgene is monitored in every plant nowadays. A potential big health risk is overdoing therapy and thus create a potential hazard. In the past there was no binding international therapy standard for Phosgene exposed personnel. Depending on where an event took place, personnel with equal exposure was sent back to work in one plant, and may have ended up in the intensive care unit, if the event happened in another plant. The classic therapy of Phosgene exposure includes application of Steroids, ventilation and repeated X-ray – not useful at all if unnecessary. Especially in different countries there was no common strategy. Recently medical scientists and safety specialists from the industry are struggling to issue common best practice rules. The „Toxycopy Effect“ A person exposed to a toxic gas will develop symptoms even if the exposure has been far below the critical dose. As an example just imagine the following scenario: After a mushroom dinner the host proudly tells his guests that he – not being an expert - has collected all mushrooms by himself. His little son with a smile remarks that had put all the mushrooms his dad had sorted out, back into the dish to avoid waste. Pretty sure some of the guests will spontaneously develop symptoms of intoxication. Scientists call this effect „Toxicopy“. Just the chance to be poisoned can engender symptoms with some people. To prevent this effect and to avoid unnecessary therapy measures, a new study was commissioned in the USA. The purpose of this study was to determine reliable thresholds above which a medical treatment makes sense. New study about the toxicity of Phosgene In the summary this study shows, that the toxicity of Phosgene has been overrated to the disadvantage of workers health. New thresholds The study provides clear guidelines for therapy based on new scientific knowledge. The following thresholds for medical treatment have been determined: Below 50 ppm * min: No therapy, no monitoring – reassure and discharge. 50 – 150 ppm * min: Monitor vital signs and pulse, oximetry every 30 min, repeated auscultation, chest x – ray if required e. g. after 8 hours. Steroids max. dose per inhalation or i. v. hospitalization – intensive care unit! Above 150 ppm * min: Monitoring vital signs, blood gases and continuous pulse, oximetry, frequent auscultation, repeated chest x – ray. Steroids i. v.and or per inhalation, EPAP / CPAP ventilation, N-Acetylcystein inhalation, Aminophyllin, ß-mimetics. As an immediate effect of this new knowledge the German TLV has been risen from 0,02 to 0,1 ppm, the ceiling value is now at 0,2 ppm. A proposal was made to the EU commission to implement this regulation throughout the EU. It is expected that this will happen in due time. This seems to be the first time, that the trend to always lower alarm thresholds has been inversed – to the benefit of the worker. It has been discovered that lowering TLVs is not in any case a contribution to better health and safety. Consequences in gas detection Now instrument technicians have one headache less: Gas detection in the low ppb range is a real challenge. It requires more frequent preventive maintenance compared to gas detectors operating in low ppm range. Consequently many plants have immediately converted their systems to a measuring range back to 0 – 0,3 ppm after the change of regulation had been published. A new indicator badge was required For the manufacturers of Phosgene indicator badges this was a new challenge. A badge had to be developed that starts developing a stain at a well defined dose. To avoid the toxicopy effect, medical doctors, industrial hygienists and plant operators agreed, that a threshold of 10ppm*min would be the most appropriate. The reagent of the classic badges starts producing a red stain with the very first molecule reacting with the reagent. Beginning with 0,2 ppm * min the stain starts to be noticeable for the naked eye. This is far below the first threshold of 50 ppm * min. Specialists in industry required a threshold of 10 ppm. This value is calculated from: Total allowable dose per shift = 0,1 ppm * 6 min * 8 = 48 ppm * min (rounded up to 50 ppm * min) Detectable limit = 50 ppm * min / 5 = 10 ppm * min With 50 ppm being the exposure at which medical treatment is required divided by a safety factor of 5. An additional requirement was addressed by the doctors: In order to decide which treatment intensity is required, an extension of the measuring range at the upper end was required. Now the entire range needed to be stretched to 300 ppm * min. The solution to this problem was to reduce gas access by applying a diffusion orifice in front of the indicator paper. In fact the combination of both tools – new chemistry plus orifice – could fulfill even this requirement. The resulting measuring range is 10 – 300 ppm * min The application of an orifice required a complete redesign of the badge holder. The new badge is therefore a disposable device. Technical data The shelf life of the new badge is one year plus. The stain of the exposed badge is very stable. As the access of gas is now reduced, also the impact of environmental parameters and pollutants is reduced too. Thus the operating life in non – tropical climate could be extended to 5 days. Picture: New badge Impact of temperature, humidity and sunlight The orifice is made of UV absorbing material, as it is used for sunglasses. The result is that nor sunlight, nor temperature, nor humidity have any impact on the performance of this badge. Quite in the opposite: as any environmental impact is strongly reduced by the orifice, the badge can now be used for 5 days instead of 3 days. Interferences Interferences are restricted to very few substances Which are very toxic too. Even high high concentrations of HCl do not bleach the badge. The new badge has been introduced to industry in 2010. Medical doctors, industrial hygienists, safety specialists and plant managers appreciated the new technology. All manufacturing and quality control facilities are in place and up and running. The badge is now sold to our industrial customers. The well – known “classic” Compur badge in the blue badge holder will not be discontinued. Due to its low price and good performance it has found many other applications besides medical. It is used as a tool for leak detection and workplace assessment.