Paper on manufacturing for VAT purposes January 2016

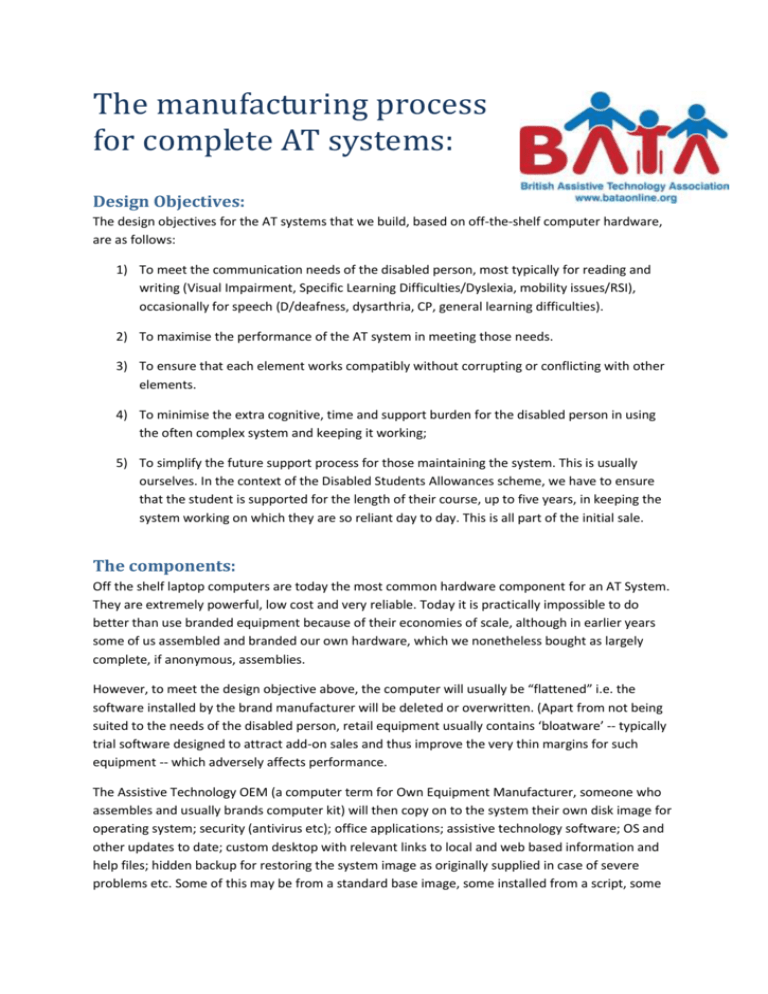

advertisement

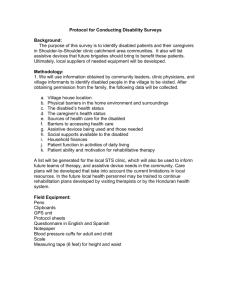

The manufacturing process for complete AT systems: Design Objectives: The design objectives for the AT systems that we build, based on off-the-shelf computer hardware, are as follows: 1) To meet the communication needs of the disabled person, most typically for reading and writing (Visual Impairment, Specific Learning Difficulties/Dyslexia, mobility issues/RSI), occasionally for speech (D/deafness, dysarthria, CP, general learning difficulties). 2) To maximise the performance of the AT system in meeting those needs. 3) To ensure that each element works compatibly without corrupting or conflicting with other elements. 4) To minimise the extra cognitive, time and support burden for the disabled person in using the often complex system and keeping it working; 5) To simplify the future support process for those maintaining the system. This is usually ourselves. In the context of the Disabled Students Allowances scheme, we have to ensure that the student is supported for the length of their course, up to five years, in keeping the system working on which they are so reliant day to day. This is all part of the initial sale. The components: Off the shelf laptop computers are today the most common hardware component for an AT System. They are extremely powerful, low cost and very reliable. Today it is practically impossible to do better than use branded equipment because of their economies of scale, although in earlier years some of us assembled and branded our own hardware, which we nonetheless bought as largely complete, if anonymous, assemblies. However, to meet the design objective above, the computer will usually be “flattened” i.e. the software installed by the brand manufacturer will be deleted or overwritten. (Apart from not being suited to the needs of the disabled person, retail equipment usually contains ‘bloatware’ -- typically trial software designed to attract add-on sales and thus improve the very thin margins for such equipment -- which adversely affects performance. The Assistive Technology OEM (a computer term for Own Equipment Manufacturer, someone who assembles and usually brands computer kit) will then copy on to the system their own disk image for operating system; security (antivirus etc); office applications; assistive technology software; OS and other updates to date; custom desktop with relevant links to local and web based information and help files; hidden backup for restoring the system image as originally supplied in case of severe problems etc. Some of this may be from a standard base image, some installed from a script, some even installed using the normal end-user process. As may be obvious, disk images and scripts allow for a much quicker, less error-prone, more automated setup than doing normal file downloads or copies and installation. But to set up an image requires more work and testing than just setting up an individual machine for an individual user. Peripherals may be added – sometimes these are zero-rateable in their own right. For example, some specialist keyboards and Braille displays. Sometimes these are mass market printers, scanners, multifunction printers, mice, but usually carefully selected because of specific features that make them particularly relevant to the specific needs of the disabled person for whom the system is being manufactured. Software packages will be activated on behalf of the customer as far as possible, settings will be tweaked to suit the particular disabled person’s needs, peripherals and their software installed and the whole checked. The system: We build systems to our own design onto the building blocks of the branded computer, software components and peripherals and with some elements of our own materials, using our own manufacturing processes. Although we use mass-production techniques, each system ends up more or less unique, ‘hand crafted’ or customised corresponding to the requirements specified in an individual report produced by a professional needs assessor for each individual student. The manufacturing process for the branded computer manufacturers (Toshiba, HP, Lenovo etc) is not so different. The work of assembling physical components bought from others is mostly subcontracted. Their final software build process is not very different from ours though more standard/mass produced and less complex. In their case the final software build will often also be subcontracted. After it is built, the AT system is handed over to a disabled person at their own home or place of work; we ensure that it is working on site as intended in the workshop; we usually have a session to familiarise the disabled person with the system that has been prepared for them; and then further training sessions as necessary to teach them how to use the system as a whole and the software packages that are included in it. This training is not just to show them the features of the packages, but to explore with them how to use the AT system to overcome their disabilities and to carry out tasks involved in working, studying and living. Needless to say, to buy an AT system designed and built in this way is pointless for a non-disabled person, although the computer would still normally be usable by a non-disabled person albeit with some inconvenience and many pointless features. But the process adds costs, in addition to that of any software and extra hardware that have been incorporated, and of course people who are not disabled would not be able to buy it zero rated anyway. If HMRC accept that we are in this way manufacturing systems “designed solely for use by a disabled person” there may need to be some revision to the process whereby we get approval for zero rating a new product. The current process is that each new product needs clearance from HMRC, organised by the manufacturer or importer, before the supply chain can zero rate it with confidence (when sold to a disabled person, etc, obviously). This clearance is based on evidence from design, manufacturing and marketing to show that the product has indeed been “designed solely for use by a disabled person.” This is not viable, however, in the context of complete AT systems, where individual components change daily, and where even the central component, the computer, may change at very short notice. However, as the number of specialist assistive technology suppliers working in that way is relatively limited, we suggest that they can be self-certified (subject of course to VAT inspection), perhaps with the additional measure of being subject to the Disabled Students Allowances Quality Assurance Framework, or a member of BATA. British Assistive Technology Association 1 December 2015