ORNL-TM-1851 - Energy from Thorium

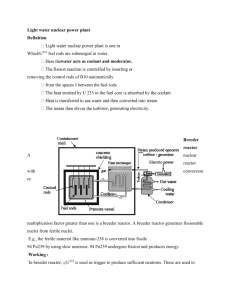

advertisement