Env E 432_final - University of Alberta

advertisement

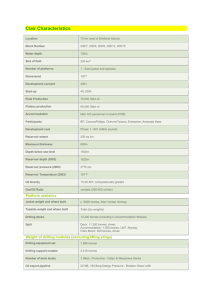

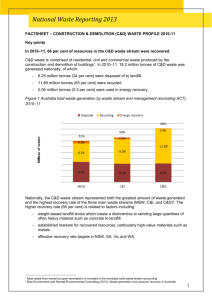

Solid Waste Management: Final Report Env E 432 Matthew Scott, 1055898 Group: Waste Watchers April 13, 2007 Abstract The population at the University of Alberta is projected to be approximately 48500 in 2010 and 70650 by 2029. At the waste usage this yields 4650 and 6780 tonnes respectively. The cumulative waste until 2029 is expected to be 135830 tonnes. Currently 47% of the waste is landfilled, 36% is potentially recyclable, and 17% is potentially compostable. The current waste has a C-N ratio of 31 and nitrogen content of 1.4%. The bulk densities of the Recycle, Compost and Landfill stream are 47.2, 359.5 and 17.6 kg/m3 respectively. ‘ Currently 2 trucks are needed to pickup the waste from campus, while the number of truckloads needed for the entire week is 17. The UofA currently has only two recycle streams, fibre and beverage containers (BC), and the current total recovery percentage is 41.8%. A current total recovery of 45.2% has been obtained for the fibre stream, while the BC stream only manages 20.6%. At the projected 80% recovery target a total of around 10120m3 would be saved from being landfilled. The amount of organic waste projected to be collected from the pilot buildings is 13.0m3 and 6.4 tonnes per week, while the yearly totals are 674.5m3 and 330.5 tonnes. At the assumed 40% MC for wood chips, $5147 (345.5m3) of wood chips would be needed and the MC for the compost would be 61.9%. The free air space was 46.1% and the resulting C-N ratio was 33.6. The area needed for the compost facility is about 1580m2. An area of 10062m2 will be needed for the landfill, based on a 30m depth, and 135831 tonnes of waste. Currently a total of 22268 tonnes of methane as carbon would be released during the lifetime of the landfill. This is reduced to 13360 tonnes-C would be released if the composting targets are met. The 25-year carbon credit would be $2,805,725. If the methane were converted to CO2 using flaring, the credit would be $200,409. 2 Table of Contents Introduction 4 1. Waste Characteristic 5 2. Collection System 10 3. Material Recovery Facility 13 4. Compost System 18 5. Landfill Stream 20 6. Summary and Conclusions 22 References 23 Appendices 24 3 Introduction This report examined solid waste management at the University of Alberta (UofA). The current waste generation has been examined, along with population growth, to get baseline waste quantities for the study period. These waste quantities have been examined to ascertain the different properties related to solid waste: wet weight, specific weight, carbon to nitrogen (C-N) ratio, bulk densities, and so forth. The waste has been divided into different categories, recyclables, compostables, and landfill material. The third floor on the Natural Resources Engineering Facility (NREF) has been evaluated for the placement, type and size of collection containers. Improvement recommendations will be made based on the findings. The collection system has been analyzed to determine the number of truckloads generated and the number of trucks needed to transport the waste will be analyzed. The volume of the mass for each day and week has been found. The quantities of waste picked up each day are organized in a manner that will provide the most even distribution throughout the week, based on restrictions for pickup days and frequencies. The current and potential material recovery at the UofA has been analyzed. The current recovery (mass and percent) for the fibre and beverage container recycle streams at the UofA has been determined. Using proposed targets of 80%, the mass and volume recovered and landfilled have been calculated. These are estimated for the fibre and beverage container streams, as well as the proposed tin cans, plastic, and glass stream. The 80% target is compared to other institutions and Canadian recovery targets. Recovery percentages for a Materials Recovery Facility (MRF) are given and a flow chart illustrating the mass recovery of the proposed facility. 4 A conceptual design for a windrow composting facility has been prepared. The amount of organics to be collected from the site has been determined. A compost recipe is recommended based on wood waste properties, as well as a change to the recipe based on differing wood waste properties. The costs for the mixes are also determined. A compost mix recipe including recycled material is given based on moisture content and other essential properties. The compost facility will be preliminarily designed based on area requirements for a windrow facility. This chapter has prepared a conceptual design for a sanitary landfill facility. The amount of solid waste intended for landfill from 2005 to 2009 at the University of Alberta (UA) is estimated. The area needed for this amount of waste will has also predicted, with the estimate including space for containment, final cover, water, and equipment areas. The methane generation potential for the sanitary landfill design is examined, assuming no recovery and that 80% recyclable and 25% composting targets are met. The difference in methane generation with and without recovery is examined and a carbon credit amount is estimated, based on the reduced carbon generation when meeting recovery targets. Flaring has also been looked at as a mean to reduce the methane release. 1. Waste Characteristics 1.1 Solid Waste Generation and Population Growth Waste generation is directly related to population, so it is necessary to examine the population growth when designing a waste management solution that will be used into the future. Based on historical population data (Appendix 1), Figure 1 shows the projected population growth until the design year of 2029. The current per capita waste 5 generation was found to be 0.096 tonnes, using the current population of 43751 and landfill waste of 4200 tonnes per year. The population in 2029 is expected to be around 71000 people, which corresponds to a waste generation of approximately 6780 tonnes. The total waste generated from 2005 until 2029 is expected to be 135831 tonnes. The waste amounts and population for each year can be seen in Table 1-1 of Appendix 1. This waste was categorized by the building type (large classroom, small classroom, office building, food services, residences) as well as the fate of the waste it, recycled, compost, or landfilled. The percentages for the source of the waste (projected until 2010) and the waste stream type and shown in Figures 2 and 3 respectively. A target of 50% diversion would see 18% of recyclables and 24% of compostables avoiding landfilling. The individual waste sub-types and their masses, in addition to the mass totals can be found in Table 1-3 of Appendix 1. Total Population (FTE) Population Projection of the University of Alberta 50000 49000 48000 47000 46000 45000 44000 43000 42000 41000 40000 39000 38000 37000 36000 35000 34000 33000 1996 y = 1168.3x - 2E+06 R2 = 0.9801 1998 2000 2002 2004 2006 2008 2010 2012 Year 6 Figure 1: Population Projection of the University of Alberta 2010 Wet Weights By Source 6% 19% 21% office class food residence 54% Figure 2: 2010 Wet Weights By Source Wet Weights By Stream 17% 36% Recycle Stream Compost Stream Landfill Stream 47% Figure 3: Wet Weights By Stream 1.2 Waste Stream Characteristics When analyzing the waste streams, it is important to examine the composition, and qualities of the waste. Moisture contents can be found for all the sub-categories and from this the mass without water can be found, seen in Figure 4. The minor categories for each 7 of the streams have varying moisture contents and weights, these can be found in Appendix 1. The mass of moisture present in each waste stream can be seen in Figure 5. This mass is significant because it represents mass and volume that may not need to be transported, treated or stored. The moisture contents for the waste streams can be seen in Figure 5. Carbon to Nitrogen ratio and Nitrogen content are of concern as microorganisms rely on the chemicals of the compost materials for food. For this waste analysis the total C-N ratio for compost is 32, and the nitrogen content is 1.4%. The compost consists of other elements that are of note, and these are shown in Figure 6. The composting sub-categories have differing C-N ratios and nitrogen contents, and these are shown in Table 1. Relative Percent Dry Weight Landfill 19% 673.30 Tonnes Recycle 48% 1706.57 Tonnes Compost 33% 1187.25 Tonnes Figure 4: Relative Percent Dry Weight 8 Moisture Content Percentages 60.0 Moisture Content (%) 50.0 40.0 30.0 20.0 10.0 0.0 Recycle Compost Landfill Waste Stream Figure 5: Moisture Content Percentages Ash 5% S 0% Dry Com post Elem ents N 1% C 47% O 41% H 6% Figure 6: Dry Compost Elements Table 1: Composting Material Nitrogen content and C-N ratio Dry % N content Food Waste (average) Paper Towels/Tissues (stock paper pulp) Animal Bedding (straw bedding) C:N Ratios 2.6 0.3 3.4 18.46 145.00 14.06 9 The bulk densities for each stream, shown in Table 2, were determined using the mass of each sub-category and average unit weights of the sub-category. (Vesiland et al, 2002) Table 2: Bulk Density by Stream Waste Stream Recycle Compost Landfilling Bulk Density (kg/m3) 47.2 359.5 17.6 2. Collection System 2.1 NREF Field Sketch Please refer to Appendix 2.A: Field Sketch for the bin locations on the 3rd floor of the NREF building. An electronic scan is also available at http://www.ualberta.ca/~mrscott/host/hw/enve432/. Improvements on the bin location, type, and distribution can be made. The recommendations are as follows: Location B – Recycle bin needed, loose cardboard and mixing of wastes Location L (Reception Copy Room) – Signage to prevent cross contamination into paper stream. Location K (Coffee Room) – Potential for recycling. Pop bottles, cans, newsprint and other papers. Cabinet cutouts not in use Bin placement near higher traffic areas such as doorways, for easier disposal of waste Bin Labeling improvement, minimize cross contamination Scrap paper for reuse in copy rooms 10 2.2 Waste Collection To determine the number of truckloads needed it is necessary to find the total volume of waste being generated across campus. This volume is dependant on the size and the number of collection bins located throughout university property. These volumes assume a compaction ratio of 2 for waste not pre-compacted and a compaction ratio of 1.5 for bin compactors. The total volume of waste generated is approximately 377 m3 per week, with the distribution shown in Figure 7. Balancing of the days was attempted, but due to the constraints of the pick up days, Mondays and Fridays still have larger pickup amounts. These routes were balanced over all 3 campuses as the transit time between campuses was assumed to be negligible compared to the time required to drive to the waste disposal facility. Using the in truck compacted density of 210 kg/m3, the total mass per day is shown in Figure 8. The total weekly mass of waste is 79.05 tonnes. Yearly this works out to about 4111 tonnes. The calculations for individual days can be found in Appendix 2.B to 2.G. Volume of waste per day 80.00 60.00 40.00 20.00 y Fr id a y Th ur sd a y ne sd a y W ed Tu es da on da y 0.00 M volume (m3) 100.00 Day Figure 7: Volume of waste per day 11 Fr id ay ay ur sd Th W ed Tu ne es sd da ay y 20.00 18.00 16.00 14.00 12.00 10.00 8.00 6.00 4.00 2.00 0.00 M on da y mass (tonnes) Mass of waste per day Day Figure 8: Mass of waste per day 2.3 Truck Loads Transportation of the waste is done by garbage truck. The trucks have a storage capacity of 27m3. Table 3 shows the number of truckloads per day, as well as the rounded truckloads. Due to the fact that the trucks are able to make 3 trips per day, the actual number of trucks needed per day is included. Appendix 2.H shows the methodology. Table 3: Truck Loads Truck Loads Remaining Capacity (m3) Trucksloads (rounded) Trucks needed Trucks needed (rounded) Monday Tuesday Wednesday Thursday Friday 3.16 2.32 2.70 2.46 3.27 22.67 18.28 8.11 14.70 19.80 4.00 3.00 3.00 3.00 4.00 1.33 1.00 1.00 1.00 1.33 2.00 1.00 1.00 1.00 2.00 The number of trucks needed, based on the constraints given, is 2. It may be possible to reduce this by shifting certain pickup days. For example, the 0.16 truckloads on Monday at the end of the day could be moved to Tuesday without increasing the number of trucks 12 needed on Tuesday. A fraction of the Friday load might be able to be picked up late Thursday, in order to reduce the total trucks needed to 1. Another option would be to pay overtime to the driver on Monday and Friday, as this may be cheaper than buying or contracting a second truck. Currently the number of truckloads needed for the entire week is 17. 3. Material Recovery Facility 3.1 Current Recovery The University of Alberta currently has only two recycle streams, fibre and beverage containers (BC). The total mass saved and percent recovered from these two streams are shown in Figure 9 and the current total recovery percentage is 41.8% Current Total Mass per stream 1200.00 1135.62 Mass (tonnes) 1000.00 815.51 800.00 600.00 400.00 200.00 0.00 Waste Stream Audit Recycle Stream Figure 9: Current Total Mass per stream A current total recovery of 45.2% has been obtained for the fibre stream, while the BC stream only manages 20.6%. The masses for each of the streams are shown in Figure 10. The sub-categories for each stream can be found in Table 3-1 of Appendix 3. 13 Waste and Recycle Masses 1000.00 921.14 900.00 800.00 760.00 Fibre Waste Mass (tonnes) 700.00 Fibre Recylce 600.00 BC Waste 500.00 BC Recycle 400.00 300.00 214.48 200.00 55.51 100.00 0.00 Stream Figure 10: Waste and Recycle Masses 3.2 Proposed Recovery The UofA has proposed recovery targets of 80% for the two current recycle streams, in addition to the new stream with tin cans, plastic and glass. At 80% the recovery is nearly doubled and the mass per stream are shown in Table 4. The volume saved from landfilling is shown in Figure 11. The sub-categories for each stream can be found in Table 3-2 of Appendix 3. Table 4: Landfill and Recycle Mass at 80% Recovery Mass (tonnes) Stream Recycle Landfilled Fibre 1344.91 336.23 BC 311.66 77.92 14 Volume Saved from Landfill 8000.00 7277.62 7000.00 Volume (m3) 6000.00 5000.00 Fibres 4000.00 Beverage Containers 2841.14 3000.00 2000.00 1000.00 0.00 Stream Figure 11: Volume Saved from Landfill at 80% Recovery The potential recycle stream has large volume savings, particularly due to the plastics sub-category. This is shown in Figure 12. The masses recovered by the inclusion of these sub-categories are presented in Figure 13. 18689.72 1373.28 Total 0.00 HDPE #2 196.39 Plastics Grades 1, 3, 4, 5, 6, 7 56.14 Electronic Waste 14.96 Aluminum (Foil, Food Containers) 17048.95 Metal (Tin Cans) 20000.00 18000.00 16000.00 14000.00 12000.00 10000.00 8000.00 6000.00 4000.00 2000.00 0.00 Glass (Clear) Volume (m3) Target Volume Potential Recyclable Stream Potential Recyclable type Figure 12: Target Volume Potential Recyclable Stream 15 Potential Recyclables at 80% Recovery Mass (tonnes) 400.00 300.00 200.00 100.00 0.00 Glass (Clear) Metal (Tin Aluminu Electroni Plastics HDPE #2 m (Foil, c Waste Grades Target Recycle Stream 24.00 28.32 5.61 0.00 227.65 26.08 311.66 Target Landfill Stream 6.00 7.08 1.40 0.00 56.91 6.52 77.92 Total Potential Recyclable type Figure 13: Potential Recyclables at 80% Recovery 3.3 Benchmarks Comparing the UofA target of 80% to other institutions is necessary to ensure the quality of our waste management system is maintained and world class. According to Leo Girard Canada’s long term recovery goal is 70%. 16 3.4 Fibre MRF Flow Chart Fibre Stream Cardboard (OCC) 233.7 Tonnes Newspaper (ONP) 291.5 Tonnes Mixed Paper (Glossy & Magazines) 699.7 Tonnes Office Paper (White Only) 120.0 Tonnes Contaminants 27.4 Tonnes Total (1372.3 Tonnes) Cardboard (95%) 222.0 Tonnes Newspaper (ONP) 291.5 Tonnes Mixed Paper (Glossy & Magazines) 699.7 Tonnes Office Paper (White Only) 120.0 Tonnes Contaminants 27.4 Tonnes Residuals 11.7 Tonnes Total (1150.3 Tonnes) Newspaper (90%) 262.4 Tonnes Mixed Paper (Glossy & Magazines) 699.7 Tonnes Office Paper (White Only) 120.0 Tonnes Contaminants 27.4 Tonnes Residuals 40.8 Tonnes Total (887.9 Tonnes) Office Paper (90%) 108.0 Mixed Paper (Glossy & Magazines) 699.7 Tonnes Contaminants 27.4 Tonnes Residuals 52.8 Tonnes Total (779.9) Contaminants (98%) 26.9 Tonnes Mixed Paper (Glossy & Magazines) 699.7 Tonnes Residuals 53.3 Tonnes Total (753 Tonnes) 17 4 Compost System 4.1 Organic Collection The amount of organic waste projected to be collected from the pilot buildings are shown in Table 5. The volumes and wet tonnes are shown per week and per year. The totals for all buildings are 13.0m3 and 6.4 tonnes per week, while the yearly totals are 674.5m3 and 330.5 tonnes. Table 5: Compostable Material Building Number 11 22 51 66 75 75 101 Building Name (m3) Biological Sciences 2.0 ECERF 1.5 CAB 2.2 SUB 2.6 Hub E Side 1.3 Hub SE Corner 1.3 Lister Centre 2.0 Totals 13.0 Target Compostable Per Week (Tonnes,wet) (Tonnes, Dry) 1.0 0.7 1.1 1.3 0.6 0.6 1.0 6.4 0.3 0.2 0.3 0.4 0.2 0.2 0.3 1.9 Target Compostable Per Year (m3) (Tonnes,wet) (Tonnes, Dry) 106.0 51.9 79.5 38.9 112.6 55.2 135.1 66.2 67.6 33.1 67.6 33.1 106.2 52.0 674.5 330.5 4.2 Compost Recipe Compost piles require proper mixture for optimum efficiency. The recommended moisture content (MC) range is 40~65% percent. It was assumed that the wood chips used for the bulking agent have a MC of 40%. A recovery of 80% was chosen for the compostable material. Using the WCDM model (Appendix 4), The volume of woodchips needed is 345.4m3, with a cost of $5147 per year. The recipe used is shown in Table 6. The MC was found to be 61.9%, and the food waste to wood chip volume ratio was 1.95:1. The free air space was 46.1% and the resulting C-N ratio was 33.6. 18 15.6 11.7 16.6 19.9 9.9 9.9 15.6 99.2 Table 6: Initial Recipe at 40% MC woodchips Amount of each material required: a. Wet 330.5 wet t/yr 99.2 dry t/yr b. Dry 110.2 wet t/yr 66.1 dry t/yr c. Other. 0.0 wet t/yr 0.0 dry t/yr d. Recycle. 0.0 wet t/yr 0.0 dry t/yr 440.7 wet t/yr 165.3 dry t/yr TOTALS 674.5 m3 / year 345.4 m3 / year 0.0 m3 / year 0.0 m3 / year 1019.9 m3 / year If the average MC for the wood chips were 21.4%, the recipe would change to the amounts shown in Table 7. The resulting MC would be 57.9% and the C-N ratio would be 48.6. The food waste to wood chip volume ratio would stay at 1.95:1. Table 7: Initial Recipe at 21.4% MC woodchips Amount of each material required: a. Wet 330.5 wet t/yr 99.2 dry t/yr b. Dry 110.2 wet t/yr 86.6 dry t/yr c. Other. 0.0 wet t/yr 0.0 dry t/yr d. Recycle. 0.0 wet t/yr 0.0 dry t/yr 440.7 wet t/yr 185.7 dry t/yr TOTALS 674.5 m3 / year 345.4 m3 / year 0.0 m3 / year 0.0 m3 / year 1019.9 m3 / year 4.3 Facility Design With the wood chips meeting the 40% MC specified and in accordance with the previous compost mix design, it is preferable to recycle the wood material, as to reduce cost and facility volume. Using the WCDM spreadsheet (Appendix 4), the ratios of food (wet), wood (dry), and recycle material can be found, and are shown in Figure 14. This recipe results in a bucket ratio of food waste to remaining mix of 3.91. 19 Windrow Design Percentages 0 12.5 12.5 a. Wet b. Dry c. Other. d. Recycle. 75 Figure 14: Windrow Design: Mixture Recipe The total area of the windrow composting facility depends upon the areas needed for material storage, composting, curing, compost storage, equipment storage and water handling. Considering all these factors, the area needed for the facility is about 1580m2, and is setup as shown in the sketch in Appendix 4.The windrow turning frequency is very dependant of site conditions, but an estimate of 1 turn per week is reasonable. 5 Landfill Stream 5.1 Landfill Area The landfill volume needed for the projected amount of waste can be calculated using the bulk density for a medium compacted landfill, as shown in Table 5-2 of Appendix 2. A bulk density of 450kg/m3 for 135831 tonnes (Appendix 1) yields a volume of about 301846m3 for the waste. An area of 10062m2 will be needed for the landfill, based on a 30m depth. Table 8 shows the different dimensions of the landfill, in addition to the 20 addition areas needed for water storage and ancillary equipment areas. Assumption for these calculations can be found in Appendix 5, Table 5-3. Table 8: Landfill Geometry Landfill Height (m) 30.00 Length (m) 100.31 Width (m) 100.31 Clay Clay Liner Cover (m) pg. (m) pg. 134 153 1.50 2.30 Total Ancillary Surface Volume Area (20%, Water Area (m^3) m^2) (10%, m^2) 340079.89 2012.31 1207.38 5.2 Methane Generation As waste decomposes it generates methane gas. Methane gas is a potent greenhouse gas, and its emissions need to be examined when considering the impact of a landfill. Solid waste can be separated into slowly decomposing (SD) and rapidly decomposing (RD) material, which both contribute to methane generation. Estimating a chemical formula for the SD of C150H223O26N and for the RD of C63H100O46N, the methane generation can be approximated. The calculations to generate these chemical formulas are shown in Appendix 5, Tables 5-5, 5-6 and 5-7. As shown in Tables 5-8 and 5-9 in Appendix 5, SD generates 2368 tonnes-C (tonnes as carbon) of methane, and RD generates 19900 tonnesC. Assuming that the 80% recycling target, and 25% composting target were met in every year of the study period, the methane generation from SD is 1420 tonnes-C while RD generates 11940 tonnes-C of carbon. This is shown in Table 5-10 of Appendix 3. 5.3 Carbon Credits If diversion results in lower methane generation the landfill may qualify for carbon credits. Assuming an average credit amount of $15/tonne-C of CO2 ($315.00/tonne-C methane), and meeting the diversion goals, the 25 year carbon credit would be $2,805,725. If the methane were converted to CO2 using flaring, the credit would be $200,409. The assumptions and values are shown in Tables 5-11 and 5-12 of Appendix 5. 21 It may be possible to increase the number of carbon credits received by altering the treatment technologies. If waste to electricity incineration is used, before landfilling, it is likely that methane will not be generated. Also, the waste burn energy has lower emissions than a coal burning energy facility; therefore using electricity from the waste burn instead of the coal burn should result in even more carbon credits. (Finnveden, 1998) 6. Summary and Conclusions The population at the University of Alberta is projected to be approximately 48500 in 2010 and 70650 by 2029. At the waste usage this yields 4650 and 6780 tonnes respectively. The cumulative waste until 2029 is expected to be 135830 tonnes. Currently 47% of the waste is landfilled, 36% is potentially recyclable, and 17% is potentially compostable. The current waste has a C-N ratio of 31 and nitrogen content of 1.4%. The bulk densities of the Recycle, Compost and Landfill stream are 47.2, 359.5 and 17.6 kg/m3 respectively. ‘ Currently 2 trucks are needed to pickup the waste from campus, while the number of truckloads needed for the entire week is 17. The UofA currently has only two recycle streams, fibre and beverage containers (BC), and the current total recovery percentage is 41.8%. A current total recovery of 45.2% has been obtained for the fibre stream, while the BC stream only manages 20.6%. At the projected 80% recovery target a total of around 10120m3 would be saved from being landfilled. The amount of organic waste projected to be collected from the pilot buildings is 13.0m3 and 6.4 tonnes per week, while the yearly totals are 674.5m3 and 330.5 tonnes. 22 At the assumed 40% MC for wood chips, $5147 (345.5m3) of wood chips would be needed and the MC for the compost would be 61.9%. The free air space was 46.1% and the resulting C-N ratio was 33.6. The area needed for the compost facility is about 1580m2. An area of 10062m2 will be needed for the landfill, based on a 30m depth, and 135831 tonnes of waste. Currently a total of 22268 tonnes of methane as carbon would be released during the lifetime of the landfill. This is reduced to 13360 tonnes-C would be released if the composting targets are met. The 25-year carbon credit would be $2,805,725. If the methane were converted to CO2 using flaring, the credit would be $200,409. Reference Finnveden, G. 1999. Methodological aspects of life cycle assessment of integrated solid waste management systems. Resources, Conversation and Recycling. 26: 173-187. Harris, D.C. 2003. Quantitative Chemical Analysis; Sixth Edition. W.H. Freeman and Company. New York USA. McCartney, D. 2007. Personal correspondence, class/course notes, Solid Waste Management. Tchobanoglous, G., Theisen, H., Vigil, S. 1993. Integrated Solid Waste Management Enginnering Principles and Management Issues. Irwin McGraw-Hill, Inc. Boston, USA. Vesiland, P.A., Worrell, W., Reinhart, D. 2002. Solid Waste Engineering. Brooks/Cole. Paciface Grove, CA. 23 Appendices Appendix 1. Waste Characteristic Appendix 2. Collection System Appendix 3. Material Recovery Facility Appendix 4. Compost System Appendix 5. Landfill Stream All excel spreadsheets can be found online at http://www.ualberta.ca/~mrscott/host/hw/enve432/final/ 24