III. FAC rate and Mass transfer - Engineering Information Institute

advertisement

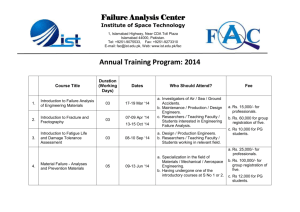

Effect of Mass Transfer On Flow Accelerated Corrosion Downstream an Orifice Wael H. Ahmed*, Meamer A. El Nakla, Abdelsalam Alsarkhi, and Mufatiu M. Bello Department of Mechanical Engineering, King Fahd University of Petroleum & Minerals Dhahran, Saudi Arabia, *e-mail: ahmedw@kfupm.edu.sa Abstract—Local flow parameters play an important role in characterizing the flow accelerated corrosion (FAC) downstream of sudden area change in power plant piping systems. Accurate prediction of the highest FAC wear rate locations enables the mitigation of sudden and catastrophic failures, and the improvement of the plant capacity factor. The objective of the present study is to evaluate the effect of the local flow and mass transfer parameters on flow accelerated corrosion downstream of an orifice. In the present study, orifice to pipe diameter ratio of 0.5 was investigated numerically by solving the continuity and momentum equations at Reynolds number of Re = 20,000. Laboratory experiments, using test sections made of hydrocal (CaSO4.½H2O), were carried out in order to validate the present numerical results. The numerical results were compared to the plants data as well as to the present experiments. The maximum mass transfer coefficient found to occur at approximately 2-3 pipe diameters downstream of the orifice. This location was also found to correspond to the location of elevated turbulent kinetic energy generated within the flow separation vortices downstream of the orifice. The FAC wear rates are well correlated with the turbulence kinetic energy and the wall mass transfer. The current study offered very useful information for FAC engineers for better preparation of plant inspection scope. Keywords-FAC; Local Flow Parameters; Mass Transfer; Restriction Orifice I. INTRODUCTION Flow Accelerated Corrosion (FAC) is a major safety and reliability issue affecting carbon-steel piping in nuclear and fossil power plants. This degradation mechanism results in wear and thinning of large areas of piping and fittings that can lead to sudden and sometimes to catastrophic failures, as well as a huge economic loss. FAC is a process caused by the flowing water or wet steam damaging or thinning the protective oxide layer of piping components. The FAC process can be described by two mechanisms: the first mechanism is the soluble iron production (Fe2+) at the oxide/water interface, while the second mechanism is the transfer of the corrosion products to the bulk flow across the diffusion boundary layer. Although the FAC is characterize by a general reduction in the pipe wall thickness for a given piping component, it is frequently occurs over a limited area within this component due to the local high area of turbulence. The rate of the metal wall loss due to FAC depends on a complex interaction of several parameters such as material composition, water chemistry, and hydrodynamic. Failures due to FAC degradation have been reported at several power plants around the world since 1981 [1]. However, a close attention to the FAC damage did not start before the severe elbow rapture downstream of a tee occurred at Surry Unit 2 power plant (USA) in 1989, which caused four fatalities and extensive plant damage and resulted in a plant shutdown. In 1999, an extensive steam leakage from the rupture of the shell side of a feed-water heater at the Point Beach power plant (USA) was reported by Yurmanov and Rakhmanov [2]. In 2004, a fatal pipe rupture downstream of an orifice in the condensate system due to FAC occurred in the Mihama nuclear power plant Unit 3 (Japan) [2]. More recently, the pipe failure downstream of a control valve at Iatan fossil power plant in 2007 resulted in two fatalities and a huge capital of plant loss as reported by Moore [3]. The recent study by Ahmed [4] indicated that a significant research has been conducted on investigating the effect of fluid chemical properties on flow accelerated corrosion (FAC) in power plants. However, the hydrodynamic effects of single and two-phase flows on FAC have not been thoroughly investigated. In order to determine the effect of the proximity between two components on the FAC wear rate, Ahmed [4] has investigated 211 inspection data for 90o carbon steel elbows from several nuclear power plants. The effect of the velocity as well as the distance between the elbows and the upstream components was discussed. Based on the analyzed trends obtained from the inspection data, the author indicated a significant increase in the wear rate of approximately 70% that was identified to be due to the proximity. The repeated inspections in both fossil and nuclear power plants systems have shown that piping components located downstream of flow singularities, such as sudden expansion or contractions, orifices, valves, tees and elbows are most susceptible to FAC damage. This is due to the severe changes in flow direction as well as the development of secondary flow instabilities downstream of these singularities [4]. Moreover, in two-phase flows, the significant phase redistributions downstream of these singularities may aggravate the problem. Therefore, it is important to identify the main flow and geometrical parameters require in characterizing FAC damage downstream of pipe fittings. These parameters are: the geometrical configuration of the components, piping orientation, and the flow turbulence structure which will affect the surface shear stress and mass transfer coefficients. For single phase flow, the secondary vortices and/or flow separation downstream of pipe fittings considered to be important parameters need to be analyzed and modeled while predicting the most FAC wear rate location. For example; the secondary flows in elbows induce a pressure drop along the elbow wall that can significantly increase the wall mean and oscillatory shear stresses as discussed by Crawford et al. [6]. Also, orifices and valves promote turbulence close to the wall in the downstream pipe and thus enhance the rate of mass transfer at the wall [5]. These mechanisms have been identified as the governing factors responsible for FAC as explained by Chen et al. [6]. In summary, the pipe downstream of an orifice is found to be one of the locations where aggressive FAC occurs. Therefore, the main objective of the present study is to characterize FAC downstream of an orifice in order to identify the location of the highest FAC wear rate. The effect of local flow and mass transfer parameters on FAC wear rate is evaluated. The findings will enable the mitigation of sudden and catastrophic failures due to FAC and consequently improve the plant capacity factor. of Class 2M. The measured wear is calculated by measuring the difference between the actual scanned surface and a CAD model representing the new pipe without corrosion. Wear measurements were obtained by scanning the cut pipe with a measurement accuracy of ±.037 mm. KUBE software was used to laser measurement capturing and GEOMAGIC studio software was used for data processing for each test section. After the cut-test section was scanned, the point cloud data was optimized by reducing the data noise, over lapping triangular mesh and overhanging data. Then data was merged into polygons and converted into one stretched water-polygon structure. It should be noted that no data modification or smoothing operation carried out in order to keep the original data trend. After the data imported in to GEOMAGIC studio, reference CAD geometry was created to represent the new pipe. The wear data were obtained for segments of 10mm strips along the pipe as shown in “Fig. 3”. This method is representing similar reduction of inspection data in power plants. The average wear is calculated for the 10mm strip and carried out over the length of the test section to determine the variation of wear along the pipe axis. 6 7 II. EXPERIMENTAL FACILITY Experiments are performed in a flow loop shown in “Fig. 1” that is designed to accommodate different test section geometries as well as running single and two-phase flow test conditions. Water is supplied from a 50 Liter reservoir through a centrifugal pump driven by a variable speed electric motor. In the present condition, the air line is shut off and only water is allowed through the test section. The flow rates are controlled by controlling the pump rotational speed in addition to a gate valve located on the water flow line. The water flow rate is measured using a turbine flow meter, and the temperature is measured using thermocouples at various locations along the flow loop. Experiments were performed using a 1-inch diameter straight tubing at a Reynolds number of 20,000. A straight section of approximately 75 diameters is installed upstream of the straight test section to ensure fully developed inlet flow conditions. An additional straight section of 100 diameters is installed downstream of the straight test section. The test section downstream of the orifice is made of hyrdical (CaSO4.½H2O), as shown in “Fig. 2”, in order to obtain wall wear patterns in a reasonable test time. This technique applied and tested before by Poulson, [7] and the dissolution of the wall material depends on the mass transfer of hydrocal from wall into the bulk flow and used to simulate FAC wear in carbon steel piping components. Although the changes to the surface occurring from the mass transfer of the hydrocal to the flow may not be exactly the same as that would occur in carbon steel piping systems in power plants, the wear pattern developed from hydrocal is expected to be reasonably similar to that generated over a longer period of time in carbon steel piping component. The overall mass transfer over the entire hydrocal test section surface is determined by measuring the electrical conductivity, using EU Tech-PC300 meter with an accuracy of ±1%, of the circulating water within the flow loop. The wear measurements were obtained using FARO-Axis CMM with Laser Scanner D100 attached to laser power source 5 10 Air 11 9 8 12 13 Water 4 3 1 2 1 2 3 4 5 6,7 Water tank Centrifugal pump Turbine flow meter Rotameter Air-water mixer (two-phase experi Pressure gages Figure 1. 8,9 10 11 12 13 Void fraction meters Hydrocal test section Air-water Separator Conductivity probe Thermometer Schematic diagram of the flow loop Figure 2. Hydrocal test section data obtained in the literature for moderate and high Reynolds numbers at power plant conditions can lead to significant errors. mm Figure 3. Surface measurments using FARO-Axis CMM with Laser Scanner III. FAC RATE AND MASS TRANSFER The FAC process in carbon steel piping is described by four steps. In the first process, metal oxidation occurs at metal/oxide interface in oxygen-free water and explained by the following reactions: Fe + 2H2O →Fe2+ + 2OH- + H2 Fe2++ 2OH-↔Fe(OH)2 3Fe + 4H2O →Fe3O4 + 4H2 A. Modeling Mass Transfer downstream an orifice Once the relationship between mass transfer and FAC wear rate is established, the computational model for MTC downstream of an orifice will be the objective of this section. Fully developed turbulent pipe flow is assumed in order to determine the mass transfer coefficients profiles downstream of the orifice. ANSI specifications of orifice were used to construct the geometrical model. Since the experimental condition in the present study is carried out for straight pipe section fabricated from hydrocal downstream of an orifice. The Solution is obtained for k-ε turbulent flow model in conjunction with the species transport equations using FLUENT CFD code. The velocity field of the incompressible viscous flow is obtained using the Reynolds averaged governing equations as follows: u i 0 xi u i 0 x i Momentum equation: The first process involves the solubility of the ferrous species through the porous oxide layer into the main water flow. This transport across the oxide layer is controlled by the concentration diffusion. The second step is described by the dissolution of magnetite at oxide/water interface as explained by the following reaction: 1/3Fe3O4 +(2-b)H+ +1/3H2↔Fe(OH)b(2-b)+ + (4/3-b)H2O) where Fe(OH)b(2-b)+ represents the different iron ferrous species b=(0,1,2,3) In the last step, a diffusion process takes place where the ferrous irons transfer into the bulk flowing water across the diffusion boundary layer. In this process, the species migrated from the metal/oxide interface and the species dissolved at the oxide/water interface diffuse rapidly into the flowing water. In this case, the concentration of ferrous iron in the bulk water is very low compared to the concentration at the oxide/water interface. It can be noticed that FAC mechanism involved convective mass transfer of the ferrous ions in the water. Over a limited length of piping component, FAC rate is considered as direct function of the mass flux of ferrous ions and can be calculated from the convective mass transfer coefficient (MTC) in the flowing water. Then, FAC rate is calculated from the MTC and the difference between the concentration of ferrous ions at the oxide/water interface (Cw) and the concentration of ferrous in the bulk of water (Cb) as: FAC rate = MTC( Cw – Cb) It should be also noted that most of the experimental studies and the correlations developed for MTC were carried out under low flow rates conditions compared with common operating conditions in power generation industry. Therefore, the MTC uj ui P 1 u i u i u j x j x i x j Re x j Species mass transport equation for a steady process with no chemical reaction is: .( vYi ) .J i S i where J i is the diffusion flux of species i, and arises due to concentration gradient and S i is the source term. The calculation of the local MTC is obtained similar to El-Gammal et al. [8] as: MTC ( z ) DSL c / n | w (cw cb ) where n is the normal vector to the wall surface and DSL is the diffusive coefficient of the solid species. Grid independence tests were performed by increasing the number of control volumes from 373,164 to 725,886. The effect of mesh refinement, on the variation of the velocity and mass transfer coefficient, found to be negligible beyond 725,886 grid points. The grid independence test resulted in a maximum difference of less than 1% in the mass transfer coefficient as the number of finite volumes increased from 725,886 to 853,240. Fully developed turbulent velocity profile is selected as the entrance condition for the inlet pipe. Assumption such as no-slip condition at the walls, steady, viscous, incompressible liquid and fully turbulent with constant transport properties are also used in the present analysis. The mass concentration of the mixture species along the walls are adjusted to unity. Also, the solubility (Cw) of species in water is set to 0.275g/100g as specified by the manufacturer’s properties table for hydrocal-X21 [9]. RESULTS AND DISCUSSIONS Z/D≅ 2 Figure 5. Normalized Turbulent Kinetic Energy Distribution downstream the orifice 1.40E-09 B. Experimental and Simulation Results The surface wear morphology for the hydrocal test section after 60 min running time is shown in “Fig. 5”. The figure shows a maximum wear at approximately Z/D≅ 2 downstream the orifice. This is found to be consistent with the practical data shown in “Fig.4”. The axial distributions of the average mass transfer coefficient (MTC) and the wear rate are shown in “Fig. 6”. The distribution of the MTC is found to provide a strong indication of high FAC wear rate. This can be explained as the MTC relates the diffusive surface species flux and the concentration driving force given in “Eq. (5)”. “Fig. 6” clearly shows that MTC increases steeply downstream of the orifice reaching its maximum value at Z/D ≅ 2, which is located in the area with high circulation within the separating vortices. Measured Wear Rate (mm/year) x 10 [1] 1 [7] 0 0 1 2 3 4 5 6 7 8 L/D 8.00E-10 2 6.00E-10 1.5 4.00E-10 1 2.00E-10 0.5 0 2 4 6 8 10 12 REFERENCES [5] [6] 2 2.5 The authors appreciate the support of the Deanship of Scientific Research at KFUPM for their financial support under the (Grant No. IN090038) [4] 3 Experimental Data ACKNOWLEDGMENT Reheat Drain System 4 1.00E-09 Figure 6. Normalized Turbulent Kinetic Energy Distribution downstream the orifice [3] Reheat Supply System 3 Z/D Moisture Separator Drain System 5 CFD Data 0 Condensate System 6 1.20E-09 0.00E+00 [2] 7 3.5 Plaster Pipe Wear (mm) A. Power Plants inspection data Ultrasonic techniques (UT) measurements are commonly used to determine the wall thinning measurement in nearly all power plants and to provide more accurate data for measuring the remaining wall thickness in piping system. In the present study, 132 inspection data collected from 5 nuclear power plants and 3 fossil power plants for piping downstream an orifice were analyzed. The data of very high and low values of wear are compared to adjacent inspection readings in order to remove data outliers. Once the data set for each inspection location is verified, the wear is identified at each band along the pipe axis. The measured wear data at different location from the orifice were presented for different piping systems as shown in “Fig. 4”. Although, the data collected at different station show wide scatter in the measured wear, however, it is clearly indicating that the maximum wear for different piping system is located between 2-3 pipe diameters downstream of the orifice. MTC (m/s) IV. [8] Figure 4. Measured wear rate downstream orifces at different power plants [9] Kanster, W., Erve, M., Henzel, N., and Stellwag, B., “Calculation code for erosion corrosion induced wall thinning in piping system”, Nuclear Engineering and Design, Vol. 119, pp. 431-438, 1990. Yurmanov, V., Rakhmanov, A., 2009, “International Atomic Energy Agency, Workshop on Erosion-Corrosion, 21–23 April 2009, Moscow, Russian Federation. Moore, F.E., 2008. Welding and Repair Technology for Power Plants, 18th Int. EPRI Conference. Ahmed, W.H. " Evaluation of the Proximity Effect on Flow Accelerated Corrosion ", Annals of Nuclear Energy, Vol. 37, pp. 598-605, 2010. Poulson B. (1999) Wear 233-235, 497-504 Crawford, N.M., Cunningham, G., Spence, S.W.T. (2007) Proc. of the Institution of Mechanical Engineers, Part E, Journal of Process Mechanical Engineering, Vol. 221, no. 2, pp. 77-88 Poulson, B., “Mass Transfer from Rough Surfaces”, Corrosion Science, vol. 30, No. 6/7, pp. 743-746 1990. El-Gammal M., Mazhar H., Cotton J.S., Shefski C., Pietralik J., Ching C. Y., 2009. The hydrodynamic effects of single-phase flow on flow accelerated corrosion in a 90-degree elbow”, Nuclear Engineering and Design, vol. 240, 6, pp. 1589-159, 2010. USG Corporations, "Material Safety Data Sheet for Hydrocal X-21” MSDS#52-100-087, pp. 1 – 9.