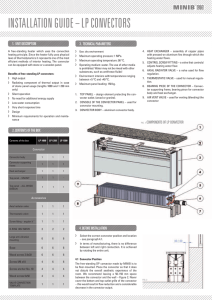

Tender text Möhlenhoff QSK without cover grille Trench heater as

advertisement

Tender text Möhlenhoff QSK without cover grille Trench heater as ready-to-install cross-flow fan-assisted System Convector QSK for installation in the floor area for installation in the screed or optionally for installation in raised floor. Working principle: Fan-assisted convection with cross-flow fan. System trough (floor trough) made of massive aluminium system profile (material: AlMg-Si 05), corrosion-protected by anodisation. Anodised shade C31, light bronze. Exterior adjustment blocks (optionally on the interior side) with buffers for acoustic decoupling, adjustable from 10 to 45 mm for fixing and for fine adjustment of the height. Heat exchanger made of round copper tubes and pressed-on, rigid aluminium fins, powder-coated in black and supported in stable, sound-absorbing system bulkheads. Heat exchanger installed in tilted position. PWW connection ¾“ on the front left side (in view direction towards the window) with Eurocone connection and venting. Covering of the tube feedthrough with gum mask. 105 °C media temperature, the medium is water according to VDI 2035. Internal unit consisting of completely removable heat exchanger and air guide. Hygiene compliant according to VDI 6022. Tightly coupled air rolls are driven by only one EC motor per QSK. Thus, the cross-flow fan is built in a way that an even and effective flow is ensured in parallel and over the entire length of the heat exchanger. The cross-flow fan with economic EC motor (24V) requires a maximum electrical power of 35 W. Cross-flow fan in sound absorbing, flow-optimised air baffle plate, perforated sheet cover and coarse filter mat avoid the penetration of small parts into air roll area. Fan control GS 2000 with sine-commuting motor controller integrated in the convector for lowest noise development, universal connection for external control systems including BMS, internal bus system for the interconnection of up to 15 convectors on control-technological basis, speed regulation via 0-10V signal or external 100k ohm potentiometer, input and output terminals for the through-connection for bus and supply voltage. Thermal output tested according to EN 442 or DIN 4704-4-5-1999-10. Hygiene compliant according to VDI 6022. Installation cover for the protection of the System Convector during the transport and construction phase. Installation instructions available in German, English, Russian, Italian and Danish. Constructive width of system trough (KB) Constructive height of system trough (KH) Constructive length of system trough (KL) 260 mm / 320 mm / 360 mm 110 mm 1250 to 3750 mm (increments of 250 mm) Heat exchanger with 2 tubes (260 mm) 3 tubes (320 mm) 4 tubes (360 mm) Hydraulic connection ¾” Eurocone one-sided, left side Electric connection On right side Continuous operating pressure 10 bar (optionally 16 bar) Speed __________ % Sound pressure level __________ dB(A) Sound power level __________ dB(A) System temperature PWW Room temperature Heating Heating power _____/____ Degree Celsius __________ Degree Celsius __________ Watts The Designer Roll-up Grille DR 15.KB or the Designer Linear Grille DL.15.KB must be ordered separately. Möhlenhoff make Type key: QSK KB-KH-KL Article No. __________