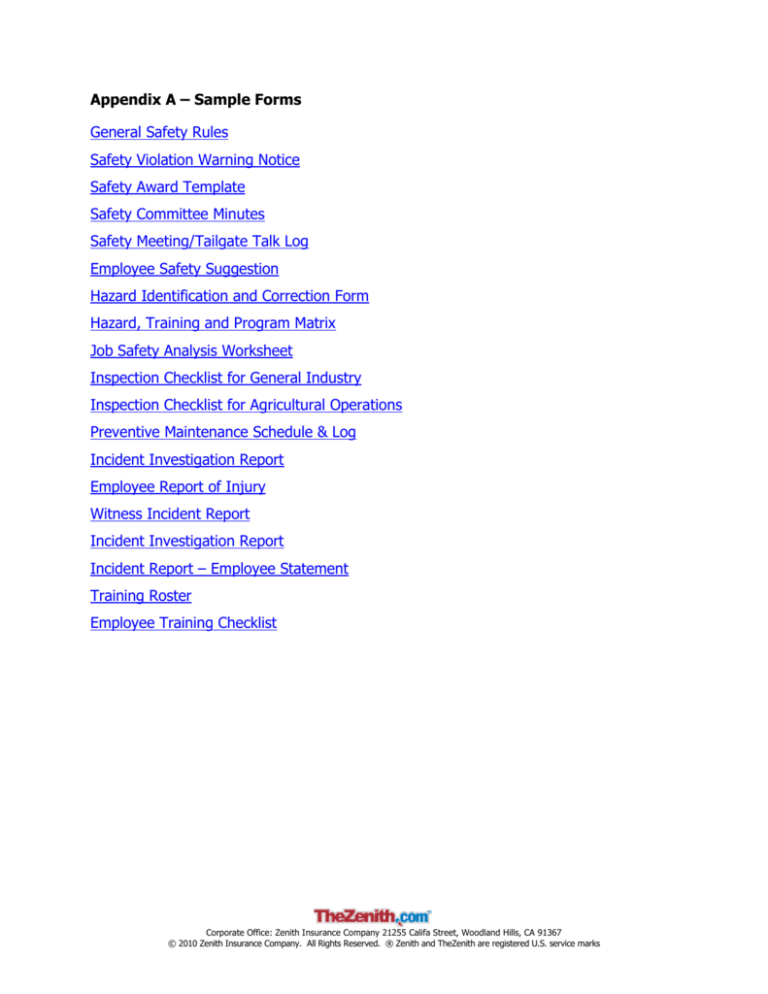

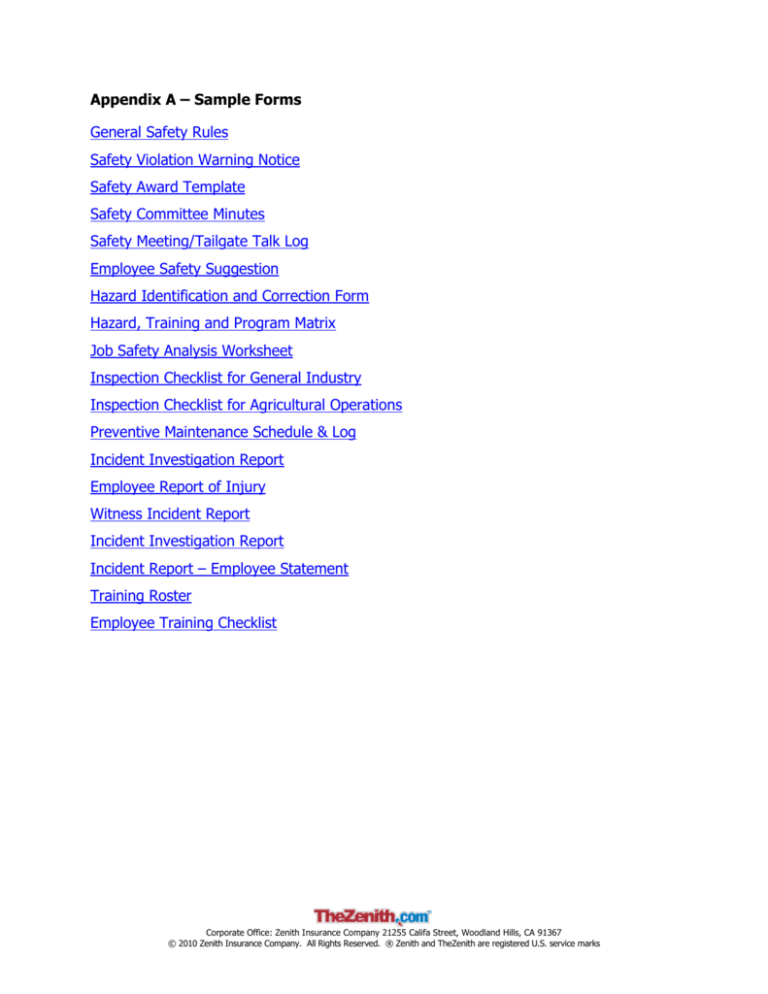

Appendix A – Sample Forms

General Safety Rules

Safety Violation Warning Notice

Safety Award Template

Safety Committee Minutes

Safety Meeting/Tailgate Talk Log

Employee Safety Suggestion

Hazard Identification and Correction Form

Hazard, Training and Program Matrix

Job Safety Analysis Worksheet

Inspection Checklist for General Industry

Inspection Checklist for Agricultural Operations

Preventive Maintenance Schedule & Log

Incident Investigation Report

Employee Report of Injury

Witness Incident Report

Incident Investigation Report

Incident Report – Employee Statement

Training Roster

Employee Training Checklist

Corporate Office: Zenith Insurance Company 21255 Califa Street, Woodland Hills, CA 91367

© 2010 Zenith Insurance Company. All Rights Reserved. ® Zenith and TheZenith are registered U.S. service marks

General Safety Rules

(Company Name) strives to provide a safe, healthful work environment. But safety

begins with YOU.

You are responsible for reporting any hazards to your supervisor immediately and

following safe work procedures. Any violation of safety rules will result in disciplinary

action. The following list of safety rules is not complete. Your manager will provide you

with additional information and training as necessary.

1. Report all accidents to your supervisor.

2. Report all unsafe or broken tools or equipment to your supervisor.

3. Don’t take chances.

4. Observe all warning signs, safety bulletins and posters.

5. Avoid ALL horseplay and never distract another worker.

6. Use protective clothing and equipment such as goggles, safety glasses, and guards.

It is mandatory that you use this equipment when required.

7. Report any safety hazard immediately to your supervisor.

8. To lift heavy objects, squat down, keep your back straight and use the leg muscles

when lifting. Do not attempt to lift any object heavier than you can handle.

9. When using sharp-edged tools, cut away from your body.

10. Before starting work, tuck in loose clothing.

11. Keep the floors, aisles and passageways clear of stock, materials, scrap, tools, oil

and equipment. You are responsible for keeping your work area clean and

organized.

12. Do not undertake a job that appears to be unsafe.

13. Report any fire immediately to a manager or supervisor.

14. Do not block access to fire-fighting equipment, fire sprinklers or fire exits.

15. Learn the location of all fire exits and fire extinguishers. In case of fire, turn off all

electrical equipment and walk quietly to the nearest exit. Follow your manager’s

direction.

Safety Violation Warning Notice

Date: ____________

You have been observed violating the following company safety rules or practices:

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

Your violation may have been unintentional, or you may have not realized that you were

violating a safety rule or a safe practice. We are bringing this to your attention because of

management's sincere concern for your safety. We hope that you share this concern for

yourself and your fellow employees. Production, economy or convenience of either

management or our employee's shall not take precedence over safety in our operation.

Further violations of the above, or frequent violations of any safety rules, or safe practices,

will result in disciplinary action.

IF IN DOUBT, ASK YOUR SUPERVISOR, DON'T TAKE CHANCES!

______________________________________

Supervisor's Signature

I have read and understand the above warning notice. I agree that I will not commit this

violation again, and that I will try to increase the safety with which I work.

______________________________________

Employee's Signature

Presented to:

Name

On DATE

for PURPOSE

Presenter’s Name

Presenter’s Title

Presenter’s Name

Presenter’s Title

Safety Committee Minutes

Date:

Members/Guests Present:

Absent:

Review/Approval of Minutes from (previous meeting date) Meeting:

Old Business: (record discussion concerning previous unresolved matters/recommendations):

Review of Incidents/Accidents: (record discussion regarding causes and committee recommendations for future

prevention):

Current Inspection Results/Recommendations: (assign numbers to current action items, establish person(s)

responsible and completion target dates)

New Business: (record discussion regarding safety education materials, contests, safety events, etc., which are

under consideration or are currently administered by committee)

(Secretary’s signature/date)

Safety Meeting/Tailgate Talk Log

Date

Name of Trainer

Subject(s) Covered

Work Location

____________

Attendees (Please print and sign your name legibly.) Use additional sheets as

necessary.)

Print

Signature

Safety Meeting/Tailgate Talk Log

Page 2

Print

Signature

Employee Safety Suggestion

This form may be used by employees to provide a safety suggestion or report an unsafe

workplace practice.

Description of Unsafe Acts of Conditions

Reasons for Unsafe Acts of Conditions

Suggestion for Improving Safety

Has This Subject Been Reported to Your Supervisor?

Employee Name (Optional)

Yes ____

No ____

Hazard Identification and Correction Form

Date

Hazard (1)

Identified

Dept

Corrective Action

Assigned to: (2)

(1) Hazards Identified, Incorporated from Inspection Checklists, etc.

(2) List who is responsible for corrective action

(3) Date corrective action required and that date which will be diaried and followed up on.

Date Req’d (3)

Date Comp.

Page ___ of ___

(1)

Hazards Identified

Hazard, Program and Training Matrix

.

.

.

.

.

.

.

.

.

l;

.

.

.

.

.

.

.

.

.

.

.

.

.

PROGRAMS

Training for

Department or

Functional Area

1) NOTE: This matrix is an example of commonly found workplace hazards that require special training. In addition, those noted most always require a specifically written program to support them.

Other hazard, training requirements and programs may exist for your operations. This is an example.

(2) Training Frequency: M=Monthly Q=Quarterly S=Semi Annually A=Annually N=As Needed N/A=Not Applicable (the assumption is that affected employees receive initial training upon hire)

R=Upon re-assignment

Job Safety Analysis Worksheet

Date of Analysis:

Reviewed By:

Company Name:

Job Title:

Analysis Done By:

Step 1: Sequence of Basic Job

Steps

Break the job into a sequence of steps. Each

of the steps should accompany some major

task. That task will consist of a series of

movements. Look at each series of

movements within that basic task.

New Job Safety Analysis

Department:

Step 2: Potential Hazards

To complete a JSA effectively, you must

identify the hazards or potential hazards

associated with each step. Every possible

source of energy must be identified. It is very

important to look at the entire environment to

determine every conceivable hazard that

might exist. Hazards contribute to accidents

and injuries.

Revised Job Safety Analysis

Step 3: Recommended Procedures

Using the Sequence of Basic Job Steps and

Potential Hazards, decide what actions are

necessary to eliminate, control, or minimize

hazards that could lead to accidents, injuries,

damage to the environment, or possible

occupational illness. Each safe job procedure

or action must correspond to the job steps and

identified hazards.

Job Safety Analysis Worksheet

Step 1: Sequence of Basic Job Steps

Step 2: Potential Hazards

Step 3: Recommended Procedures

CONTINUED…

CONTINUED…

CONTINUED…

Job Safety Analysis Worksheet

(Sample - For Reference Purposes Only)

Date of Analysis:

December 20, 2009

Reviewed By: Safety Manager

Company Name: ABC Company

Job Title: Machinist

Analysis Done By: Joe Safety

New Job Safety Analysis Revised Job Safety Analysis

Department / Task: Finishing / Grinding castings

Step 1: Sequence of Basic Job Steps

Step 2: Potential Hazards

Step 3: Recommended Procedures

Break the job into a sequence of steps. Each of

the steps should accompany some major task.

That task will consist of a series of movements.

Look at each series of movements within that

basic task.

To complete a JSA effectively, you must

identify the hazards or potential hazards

associated with each step. Every possible

source of energy must be identified. It is very

important to look at the entire environment to

determine every conceivable hazard that

might exist. Hazards contribute to accidents

and injuries.

Struck against edge of box or casting – cut

hand on burr.

Overexertion from lifting of heavy castings.

Struck by falling casting on foot.

Using the Sequence of Basic Job Steps and

Potential Hazards, decide what actions are

necessary to eliminate, control, or minimize

hazards that could lead to accidents, injuries,

damage to the environment, or possible

occupational illness. Each safe job procedure

or action must correspond to the job steps

and identified hazards.

1.

Right hand reaches into box, grasps

casting, carries it to wheel.

Wear gloves to protect against sharp

edges as required when handling raw

stock.

Use proper lifting procedures.

Get help if part is too large for one

person.

Wear steel toe footwear.

Job Safety Analysis Worksheet

(Sample - For Reference Purposes Only)

Step 1: Sequence of Basic Job Steps

Step 2: Potential Hazards

CONTINUED…

CONTINUED…

2.

Left hand grasps left side of casting, right

and left hands push casting against wheel.

Struck against burr on castings.

Struck against wheel.

Caught on rotating parts.

Flying sparks, dust, chips, or wheel

breakage.

Step 3: Recommended Procedures

CONTINUED…

3. Left hand places finished casting in box on

side of machine

Struck against box or castings.

Overexertion from lifting of heavy

castings.

Foot struck by castings.

Wear gloves to protect against sharp

edges of castings.

Keep hands clear of rotating parts.

Possible use of tool rest.

Do not wear loose clothing.

Do not wear gloves when grinding small

pieces.

Wear eye protection.

Ensure all required guards are in place;

i.e., side guards and tongue guards are

of proper size, tool rests and tongue

guards are properly adjusted.

Wear gloves to protect against sharp

edges of castings .

Use proper lifting techniques.

Provide for moving of finished stock.

Wear foot protection.

Inspection Checklist for General Industry

Note: The purpose of this report is to help you identify and correct unsafe work practices (acts) and conditions before an accident occurs. Begin

each inspection by making safety observations. Then, conduct a thorough inspection utilizing the checklist. Be sure to follow up on all items

needing action.

The items on this checklist should be made specific for your facility. To assist with development, (1) walk through each department with the

supervisor and identify specific hazards that should be addressed, (2) include previously hazards identified elsewhere in the Safety Program,

and/or (3) use OSHA checklists, such as OSHA Small Business Handbook or Cal OSHA Model Injury And Illness Prevention Program For High

Hazard Employers.

Use the space below for general safety observations. Look for unsafe behaviors and note them here. Remember, more than 80% of all accidents

are caused by unsafe acts of personnel. When unsafe acts are observed, the situation should be corrected immediately.

Notes:

Administrative:

OK

Action

Needed

Corrective

Action Taken

Housekeeping:

A. Walkways clear of obstructions

B. Employees clean up as they go

A. Required posters conspicuously

displayed

B. Recordkeeping requirements met

C. Workers trained prior to new or

unfamiliar tasks

Material Handling:

A. Employees trained in proper lifting

methods

B. Equipment provided for heavy or

awkward loads

C. Materials stored to prevent overreaching

Comments

Inspection Checklist for General Industry

Page 2

Floors:

A. Walking and working surfaces kept clear

Machinery and Equipment:

A. Moving parts guarded

B. Kept in safe operating condition

C. Operated and inspected per mfg.

instructions

Hand Tools:

A. Always inspected before using

B. Only used for intended purpose

C. Damaged tools repaired or replaced

promptly

Stairs:

A. Lighting adequate

B. Non slip surface

C. Handrails secure

Ladders:

A. Proper type for intended use

B. Maintained in good condition

C. Proper ladders used instead of chairs,

boxes, etc.

B. Spilled materials cleaned up

immediately

C. Holes in floor repaired or covered

First Aid:

Inspection Checklist for General Industry

Page 3

A. Fully stocked first aid kit

B. Emergency telephone numbers posted

C. At least one person trained in first aid

B. Communicated to all employees

C. Employees designated and trained to

implement plan.

A. Exits clearly marked

B. Exits accessible

C. Exit doors unlocked

A. All equipment either grounded or double

insulated

B. Extension cords in good repair

C. At least 30” clearance around control

panels

Emergency Action Plan:

A. Written; covers fire and other

emergencies

Fire Protection:

A. Fire fighting equipment is serviced and

accessible

B. Employees instructed in use of fire

fighting equipment

C. Employees instructed in fire protection

procedures

Egress:

Electrical:

Inspection Checklist for General Industry

Page 4

Personal Protective Equipment:

A. Proper equipment in use where needed

B. Properly maintained and stored

C. Employees trained in proper usage

Health Hazards:

A. Hazard communication program in

place.

B. Hazardous materials stored and used

properly

C. Warning and identification signs clearly

posted

Use this space to list additional items specific to your operations. Use an additional sheet to continue your list if you run out of

space.

Inspection Checklist for General Industry

Page 5

Conducted by:

Date:

Reviewed by:

Date:

Inspection Checklist for Agricultural Operations

GENERAL

1.

2.

3.

4.

5.

6.

All OSHA or workers compensation

notices posted in visible area

There is an established Safety

Program

Employees are instructed in proper

first aid and emergency procedures

Material safety data sheets readily

available

All work areas clean and orderly

Fire extinguishers are readily

available

FIELD

1.

2.

3.

4.

5.

6.

Ladders are free from weak,

damaged rails and loose or broken

rungs

Orchard ladders contain stable third

leg

Cutting, shearing and pruning hand

tools properly sharpened and stored

Grazing, hoeing, and raking tools

are rust free and stored adequately

Seatbelts on tractors with ROPS

fastened correctly and used

PTO guards on tractor or harvesting

implements secure

OK

Action

Needed

Corrective

Action Taken

OK

Action

Needed

Corrective

Action Taken

Comments

Comments

Inspection Checklist for Agricultural Operations

Page 2

FIELD

7.

8.

9.

10.

11.

12.

13.

Tractors and harvesting implements

are free from functioning or

mechanical defects

Tractors contain back wheel fenders

Vehicles have working head, signal,

and rear lights

Seatbelts on all vehicles fastened

adequately

Clean potable drinking water

available at all times

Hand washing and toileting stations

are properly maintained and

stocked

Designated areas for shade

14. Irrigation equipment and machines

in good working condition

15. Harvesting equipment and

machines in good working condition

16. Walkways clear from debris or

misplaced equipment

17. Moving parts on agricultural

equipment properly guarded

18. Hazardous substances properly

labeled and identified

19. First aid materials readily available

OK

Action

Needed

Corrective

Action Taken

Comments

Inspection Checklist for Agricultural Operations

Page 3

PACKING HOUSE

1.

2.

3.

4.

5.

6.

Walkway and floors are free of

trash, debris or misplaced

equipment

Machine guards in place

Packing equipment and tools

maintained, stored properly

First aid kits stocked and easily

accessible

Fire extinguishers easily accessible,

and in working condition

Platforms are stable

7.

Equipment and tools stored in

designated area

8. Signs posted for high voltage or

unsafe entry

9. Ventilation systems in proper

working condition

10. High voltage machines and

equipment grounded

11. Forklifts equipped with horn, brakes

and back up alert

12. No breaks or cracks on pallets

13. Hand and eye washing station in

operating condition

OK

Action

Needed

Corrective

Action Taken

Comments

Inspection Checklist for Agricultural Operations

Page 4

SHOP

1.

3.

Hazardous materials used, sorted,

labeled, and disposed of properly

Floors clean – no oil, radiator fluid,

etc.

All electrical cords in good condition

4.

Oily rags and paper are removed

5.

Eye protection is available and used

6.

Hand tools are in good condition

7.

Batteries are stored away from

ignition sources

Fire extinguishers are pressurized

2.

8.

9.

10.

11.

12.

13.

Compressed gas bottles are

restrained

Power tools are in good condition

and guarded

Flammable materials are stored in a

steel cabinet

Overhead hoists have hook safety

latches

Employees wear proper boots,

gloves, and other personal

protective equipment

OK

Action

Needed

Corrective

Action Taken

Conducted By: ________________________

Date: _________________________

Management Review: __________________

Date: _________________________

Comments

Preventive Maintenance Schedule & Log

Company:

Date Rev’d:

By:

Distribution: Orig:

Item/Machine/

Equipment

(1)

(2)

For Year:

Department:

Conducted by:

Copies to:

Frequency (1)

M, Q, S, A, O

Basic Instruction

Maintenance to

Perform

Comments

Frequency: M=Monthly, Q=Quarterly, S=Semi-Annually, A=Annually O=Other, Standard Annual Calendar

(3)

(5)

Initials

If Applicable (4) Include Required Follow Up Notes & Due Dates

Month Names Optional

(4)

Date

Completed.

By: (2)

Preventive Maintenance Schedule & Log

(Sample Only)

For Year:

Department:

Company:

Date Rev’d:

By:

Distribution: Orig:

Item/Machine/

Equipment

Cold water storage

tank

(3)

(4)

Conducted by:

Copies to:

Frequency (1)

M, Q, S, A, O

Q

March, June,

September,

December (5)

Basic Instruction

Exercise & lubricate

gate valves

Maintenance to

Perform

Exercise all cold water

valves; lubricate with

standard company

lubricant & submit

repair orders as needed

Comments (4)

All gate valves checked. All OK

except inlet water valve which

is sticking & needs to be

replaced. Work order

submitted & will confirm

Repair NLT 4-15-10

Frequency: M=Monthly, Q=Quarterly, S=Semi-Annually, A=Annually O=Other, Standard Annual Calendar

(3)

(5)

Initials

If Applicable (4) Include Required Follow Up Notes & Due Dates

Month Names Optional

Date

Completed.

3/15/10

By: (2)

ABC

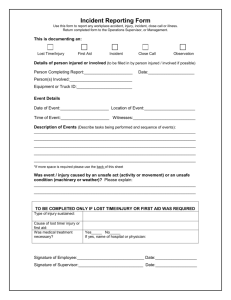

Incident Investigation Report

The purpose of this report is to help prevent similar incidents from recurring. Make this report as accurate and

thorough as possible. Remember, always follow-up with the appropriate corrective action(s).

Incident:

Near Miss

Minor Injury

Incident Date:

Minor Illness

Major Injury

Time:

Major Illness

AM/PM

Injured Employee:

Occupation:

Months on this job:

Incident Description

Where did the incident occur?

Witness(es)

How did the incident occur? (What was the employee doing when injured?)

Describe the injury(s) or damage

Circle Affected

Body Part

What unsafe act(s) or condition(s) contributed to the incident?

Corrective Actions

What do you recommend be done (or have you done) to prevent this type of incident from recurring?

What corrective action(s) has (have) been taken?

Date:

If you suspect that this claim is fraudulent, call Zenith’s Fraud Hotline: 1-866-296-4748

Investigation conducted by:

Date:

Report reviewed by:

Date:

Employee Report of Injury

The purpose of this report is to prevent similar incidents from occurring. It should be completed and signed by the

injured worker.

Incident:

Near Miss

Minor Injury

Incident Date:

Minor Illness

Major Injury

Time:

Major Illness

AM/PM

Injured Employee:

Occupation:

Months on this job:

Incident Description

When did you report the incident and to who?

Did you require medical attention?

Yes:

No:

Location of incident (entrance, loading dock, bathroom, etc.)

Witness(es)

Describe in detail how the incident occurred and what you were doing when it occurred?

Circle Affected

Body Part

What body part(s) were affected?

What unsafe act(s) or condition(s) contributed to the incident?

What is at least one thing that can be done to prevent this type of incident from recurring?

Employee Signature:

Date:

Witness Incident Report

The purpose of this report is to prevent similar incidents from occurring. Remember, we are fact finding, not

fault finding. Please make this report as accurate and thorough as possible.

Witness Name:

Time:

Job Title/Occupation:

Incident:

Near Miss

AM/PM

Work Phone:

Minor Injury

Incident Date:

Minor Illness

Major Injury

Time:

Major Illness

AM/PM

Injured Employee:

Incident Description

Location of incident (entrance, loading dock, bathroom, etc.)

Describe in detail how the incident occurred and what the employee was doing

when it occurred.

What unsafe act(s) or condition(s) contributed to the incident?

What body part(s) were affected?

What is at least one thing that can be done to prevent this type of incident from

happening again?

Witness Signature:

Date:

Circle Affected

Body Part

Incident Investigation Report

First show concern and respond to the immediate needs of injured employee(s) (emotional, medical, notification of relatives, transportation,

etc.). Once assured, complete your review at the incident scene as soon as possible. Show to all that the purpose of this review is not to

assign blame, rather to ultimately prevent future incidents via a thorough review. Safely secure the scene. Be prepared as necessary to

take photos, measure, sketch, gather evidence, refer to written standards, have witnesses complete written statements, etc. Determine:

who, what, where, when, how, and why?

Conduct interviews individually at the incident scene and in a non-threatening environment. Ask open-ended questions such as “What did

you observe?” and then do not interrupt respondents. To prompt responses, say, “Then what happened?” Wait until respondent has

finished talking and only then ask clarifying questions to fill in information gaps. Always ask their opinion about corrective action.

Name of Injured Employee

Job Title

If other than HQ, Branch/Jobsite Location of Injury

Task Performed when Injured

Date & Time Injury Occurred

Date and Time Reported to Supervisor

Injured Employee’s

Department

Injured Employees Experience in

Was Task (Check One)

How Long Employed?

Job Task (Check One)

Routine Infrequent

New

Novice

Competent

New Experience

Expert Unauthorized

When Did Injury Occur In Shift

Occurred on Company Premises?

Exact Location Where Injury Occurred

(Check One) Early Mid

Near Break

Late,

Yes

No

Overtime

When was On-Scene

Observation of

Incident Site made by

Supervisor?

Photos/Sketches Attached?

Yes

No

Was Post-Incident Drug Testing

Administered?

Yes

No

Any Witnesses? If “Yes,”

attach Statements

Yes

No

Evidence Secured?

Yes

No

Who is the management person responsible for

coordination of return to work and for maintaining

regular contact with concern for injured worker?

Additional Comments:

If Drug Test Performed, Where, Date,

Time

Have the injured worker and medical provider been

informed that transitional work will be offered for

immediate return to work within medical restrictions?

Yes

No

Nature of Injury and Body Parts Affected: (e.g., cut left thumb, broken right arm, strained lower back, etc.)

Severity of Injury/Illness

“Near-Miss” Incident (no injury)

First-Aid (in house treatment only)

Minor Medical (initial doctor treatment, then release)

Serious (partial disability, continuing medical care)

Catastrophic (critical condition, severe disability, fatality)

Work Status Following Initial Medical Treatment

Full Duty Returned to work on next shift

Transitional’ Duty Returned to work on next shift

Lost Time (did not return to work on next shift)

Mechanism of Injury

Slip/Trip/Fall onto same level

Chemical, Heat/Cold, Blade)

Fall from above level (ledge, platform, ladder, stairs)

Caught In/On/Between (pinched, snagged, grabbed)

blood)

Overexertion (strain from force, exhaustion)

Respiratory Exposure

Struck-Against (hit on, bumped into)

Contact With (Electrical,

Struck By (hit by something)

Repetitive Motion Condition

Airborne Material in Eye

Bio-hazard Exposure (needle stick,

Vehicle Incident Other:______________________________________

Describe in Detail How the Incident Occurred

Comment on equipment/tools, materials, people, vehicles, or environmental factors (such as noise, lighting, heat, cold etc.) that may have

contributed.

Protective Gear Used by Injured Employee (when incident occurred)

Comment on equipment/tools, materials, people, vehicles, or environmental factors (such as noise, lighting, heat, cold etc.) that may have

contributed.

Immediate Causes of Incident (identify both behavior(s) and condition(s). Check as many as applicable.

Behaviors/Work Practices

Physical Conditions

Using Improper Equipment (wrong type/damaged)

Abuse or Misuse of Equipment

Removing Safety Devices or making them inoperable

Failing to Use PPE or Seatbelts

Improper Placement/Arrangement (unstable)

Improper Handling Technique (help, grip, reach, posture)

Failure to Use Handling Equipment (carts, lifts, etc.)

Improper Body Position or Overreach (in harms way)

Working on Equipment in Motion

Performing at Unsafe Speed or Pace

Not Authorized or Qualified to Perform

Failure to Isolate/Secure/Lockout

Horseplay

Inadequate Ventilation

Other/Comments:

Inadequate Guards/Barriers/Safety Devices

Inadequate or Improper Protective Equipment

Defective/Worn Tools or Equipment in Service

Congested/Restricted Area/No Separation

Fire or Explosion Hazard

Working Surface Unsafe (slippery, sloped)

Poor Housekeeping/Disorder/Traffic Flow

Noise/Vibration

Temperature Extremes

Visibility Inadequate (dark, glare, obscured)

Heavy Work Uncontrolled

Production Pace Unsafe

Emergency Systems/Provisions Inadequate

Root Causes of Incident (identify both personal factor(s) and management practice factor(s). Check as many as

applicable.

Possible Personal Factors

Possible Management Practice Lacking

Knowledge Insufficient

Skill Insufficient

Experience Insufficient

Motivation Lacking

Fatigue (mental or physical

Personal Issues

Other: ____________________________

Leadership/Supervision/Enforcement

Engineering/Design/Capacity/Containment

Process/Work Methods

Maintenance/Inspection program

Staffing/Manpower/Hiring Practices

Tools/Equipment Provided

Hazardous Materials Alternatives/Controls

Training/Development

Hazard Identification/Evaluation

Other/Comments:

Preventive Measures to be Considered. Check as many as applicable.

General Enforcement

Improvement

Housekeeping/Disposal

Improvement

Repair/Replace

Equipment

P.P.E. improvement

Training or Re-Training

of Employees

Substitute Safer Alternative

Material

Congestion/Traffic

Improvement

Individual Corrective

Counseling

Guards/Safety Devices

Improved

Supply/Purchasing

Improvement

Formal Procedure

Development/ Revision

Engineering/Process

Improvements

Inspection/Maintenance

Improvement

Ventilation improvement

Staffing/Hiring Stds /

Development

Visibility / Illumination

Improved

Noise/Vibration

Improvement

Discontinue/Eliminate

Task

Rotation of Employees

Storage / Arrangement

Improvement

Emergency

Systems/Provisions

Remove / Eliminate

Hazard

Employee Awareness/

Communication

Provide Employee Incentive

Safety Efforts

Effectiveness

Conduct Hazard

Analysis

Job Re-Assignment of

Employee(s)

Remove Employee

Disincentive

Work Method

improvement

Workstation Re-Design

Temperature

improvement

Warning System

Provided

Other/Comments:

Specific Corrective

Action(s) Taken

Person(s)

Responsible

Report Completed by (Supervisor):

Target Date

Date Completed

Date:

Routed for Review to:

Manager:

Executive:

Safety Committee:

Comments:

Comments:

Comments:

Incident Report – Employee Statement

Note: The purpose of this form is to assist management with determining the facts surrounding an

incident, and to prevent future similar incidents in consideration of all contributing factors.

Event:

Approximate Date/Time of Event:

Name of Employee Providing This Statement:

Date/Time of Statement:

Please be as detailed as possible and take whatever time is necessary to thoroughly contribute to this

incident review. Use additional pages as needed. You will be assisted with any writing difficulties as

needed.

WHEN precisely did these events occur? (During break, during an installation or delivery, during

overtime etc.)

WHEN

WHO all was involved? (Any injured parties, other witnesses, a vendor or contractor, or anyone that can

provide important information?)

WHO

WHERE exactly did the events occur?

WHERE

WHAT happened? Explain in detail all you know about the incident

WHAT

HOW did the event occur?

HOW

WHY in your opinion did the event occur?

WHY

RECOMMENDATIONS: HOW in your opinion could the incident have been prevented and WHAT is

needed to be done to prevent future incidents?

RECOMMEND

My signature below acknowledges that I have been completely truthful with all I know about this

incident at this time. I will immediately forward additional information to management as it may

further appear to me.

Signature of Employee : _______________________________

Date: ______________

Training Roster

Name of Trainer

Date

Name of Training

Location of Training

Training Aids Used

____________

Attendees (Please print and sign your name legibly.) Use additional sheets as necessary.)

Print

Signature

Training Roster

Page 2

Print

Signature

Employee Training Checklist

Employee Name:

All of the rules indicated below were explained to me, I fully understand them, and agree to

abide by them while working for (Company Name). (Note: Have the employee and supervisor

sign his/her initials in the blank next to the safety rules covered with them.)

(Note: The following are examples of common training topics. It should be tailored for your

company with your specific training needs. It may be adapted from your Training Matrix.)

Employee

Initials

General Safety Rules

Reporting Injuries and Illnesses

Equipment and Vehicle Safety

Ladder Safety

Electrical Safety

Hazard Communication

Fire Prevention

Back Safety

Machine and Tool Safety

Personal Protective Equipment

Heat Illness Prevention

Supervisor

Initials

Date