Edition: February 2011 CSTR: Part D025 Design – Earthworks for

advertisement

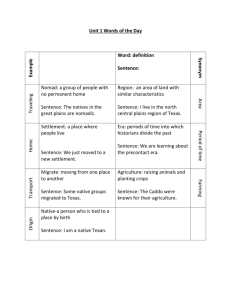

CSTR: Part D025 Design – Earthworks for Roads Edition: February 2011 PART D025 DESIGN – EARTHWORKS FOR ROADS CONTENTS 1. 2. 3. 4. 5. 6. 7. 8. 1. General References Design Requirements Dewatering Materials for Fill Settlement Acid Sulphate Soils Records GENERAL This Part specifies the requirements for the design of earthworks for roads and associated structures. This includes excavation, fills, verges, levees, sub-soil drainage, catch drains, side drains and open drains, spreading of topsoil and spreading of mulch. It excludes backfill of Reinforced Soil Structures (refer Part 420 "Reinforced Soil Structures"). The requirements of this Part are in addition to those specified in Part 210 "Construction of Earthworks". 2. REFERENCES Unless specified otherwise, all design shall be undertaken in accordance with the following: 3. 1) AS 3798 Guidelines on Earthworks for Commercial and Residential Developments. 2) AS 5100 Bridge Design. DESIGN REQUIREMENTS 3.1 Design Life The Contractor shall design assets for the following minimum design life: ELEMENT DESIGN LIFE (YEARS) Embankments, including reinforced embankments 100 Cut batters, including batter treatments 100 3.2 General The Contractor shall give due consideration to the following requirements in the design of the earthworks: (a) providing a safe run off area for errant vehicles; (b) providing a natural fit into the surrounding terrain; (c) minimising ongoing maintenance costs; (d) minimising the length of traffic barriers consistent with safety requirements; (e) limiting level changes and undulations in the finished pavement surface; and (f) limiting seasonal or permanent changes in the subsurface moisture regime. Earthworks shall be designed so that detrimental effects from water (e.g. concentrated flows, erosion, ponding of water) are kept to the minimum practicable. DPTI XXCxxx Page 1 CSTR: Part D025 Design – Earthworks for Roads Edition: February 2011 3.3 Stability and Surface Condition The earthworks shall be designed to achieve the following: (a) there is no detectable instability or evidence of impending loss of stability; (b) the surface is highly resistant to surface scour and erosion and will not suffer detrimental effects from a 1 in 10 year Average Recurrence Interval storm event; (c) in cuts, any material which becomes detached is prevented from reaching the road shoulder; and (d) there is no undermining or destabilisation of any existing batter slopes or structures. 3.4 Provision for Maintenance The Works shall be designed and constructed such that maintenance that would normally be required of the road and environs can be readily and economically undertaken. Plant and equipment access must be available to the final batter slope to allow ready installation of any treatment measures which may become necessary and to facilitate inspection and maintenance of the face of the batter. 4. DEWATERING Any existing groundwater table level must not be permanently affected by the Works. The Contractor shall make every reasonable endeavour to design structures and embankments to avoid temporarily lowering the existing groundwater table by dewatering. If dewatering cannot be avoided the Contractor shall: 5. (a) ensure that the extent and depth of the area to be dewatered is held to a practicable minimum; (b) ensure that the duration of any dewatering is held to a practicable minimum; (c) provide full details of any dewatering system, including the quantity and proposed method of disposal in the Quality Plan; and (d) ensure that dewatering water is disposed of in such a manner that it does not harm the environment and is in accordance with the Environmental Protection Act. MATERIALS FOR FILL Only Type A Material shall be used within 1.0 m of the finished surface of the pavement Fill material with a WPI greater than 1 200 shall not be used at any level directly below the pavement. The maximum allowable design modulus for fill materials is 100 MPa Design parameters for standard fill materials shall not exceed the following value unless the contractor can demonstrate higher values are appropriate: Material (Refer to Part 210 for definitions) Design Parameter Type A Fill E 70MPa, = 0.45 Type B Fill E 50MPa, = 0.45 E = Vertical Resilient Modulus, = Poisson Ratio of all sub-layers. DPTI XXCxxx Grading Sieve Size % Passing 106 100 75 90 - 100 0.075 0 - 35 Page 2 CSTR: Part D025 Design – Earthworks for Roads Edition: February 2011 4. Plasticity Index Max 20 Linear Shrinkage Max 7 Natural Subgrade Strengths The design CBR values of the natural subgrade shall not exceed the values in the following table: Section Description CBR of Natural Subgrade …. 1% 3% 6. SETTLEMENT Calculations Prior to the commencement of works, the Contractor shall provide calculations and details of estimated gross settlement, grade changes and creep at Practical Completion and at the Date of Final Completion. If methods for limiting or accelerating settlement are to be used, full details must be provided with the calculations. Settlement Limitations Level changes in the finished pavement surface shall comply with the following: (a) no increase in levels after completion of construction of the pavement; (b) maximum decrease in level of the pavement surface of 30 mm over any 12 month period following the construction of the pavement; (c) maximum differential settlement of 30 mm in a longitudinal direction, measured between Settlement Measurement Points spaced at 50 m, following construction of the pavement until the Date of Final Completion; (d) maximum differential settlement of 12 mm in a longitudinal direction, measured between Settlement Measurement Points spaced at 20 m, following construction of the pavement until the Date of Final Completion; (e) maximum differential settlement of 15 mm in a transverse direction, when measured between Settlement Measurement Points on opposite sides of each carriageway following construction of the pavement until the Date of Final Completion; Estimated settlement creep (extrapolated on a logarithmic time scale) at any point over this length shall not exceed 50 mm over the period of 10 years following the Date of Practical Completion. Monitoring The Contractor shall implement a monitoring program that records settlement for the period between completion of the embankment and expiry of the defects liability period. Settlement shall be recorded each fortnight for the first 6 months and monthly thereafter. A total of 4 settlement recording points is required, located 5 m and 15 m from each bridge abutment. Settlement shall be measured by a Surveyor meeting the requirements of Clause 130.1. Measurements shall be plotted graphically creep (on a logarithmic time scale) and forwarded to the Principal within 1 week. If calculations of predicted settlement have been prepared, these shall also be shown on the plot. If a Settlement Measurement Point is disturbed or lost it must be replaced as close as practicable to the original point before the next survey. Settlement must be determined by reference to a stable benchmark (eg a deep benchmark). DPTI XXCxxx Page 3 CSTR: Part D025 Design – Earthworks for Roads Edition: February 2011 7. ACID SULPHATE SOILS Potential acid sulphate soils may be present below the proposed route of the project, particularly in the northern section. In situ soil that is excavated from below the equilibrium groundwater level, or in situ soil below the natural equilibrium ground level that lies within the draw down zone of a groundwater dewatering system, has the potential to become actual acid sulphate soil. Potential acid sulphate soil that is excavated or dewatered shall be managed in accordance with the acid sulphate soils component of the Environmental Management Plan for the project and Part D020 – Design - Environmental. 8. RECORDS The following records shall be provided to the Principal: Drawings Construction drawings. Drawings of any temporary earthworks, including settlement limiting or accelerating methods or dewatering temporary works. Reports All relevant calculations and analysis, including those for settlement, slope stability, shrink – swell movement, the effect of any water table and any requirements for monitoring. Implementation Records Settlement records. ____________ DPTI XXCxxx Page 4