ChampionManorHouseRennovation

advertisement

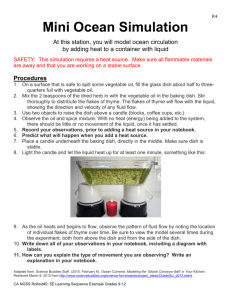

GETTING A FRESH START The Manor House, an ACTS Life retirement community in Seaford, Del., is surrounded by rich farmland and framed by the Atlantic Ocean and the Chesapeake Bay. The staff has been caring for senior residents in this picturesque atmosphere since the mid1960’s. The kitchen serves three meals a day everyday to 112 nursing home and assistedliving residents and serves dinner to an additional 120 independent-living residents in the dining room each night. All meals come from the main kitchen that, up until last year, relied on a dishroom original to the building that was “made to fit the space not the needs,” says Matt Carlisle, Director of Physical Plant of Methodist Manor House. Once the decision was made to renovate the dishroom, the overall goal of the project was to use the space more efficiently and upgrade the washing system to provide easy loading and scraping. Another goal was to relocate the dish machine to a more convenient location. The new location of the machine eliminated the need for 60 feet of drain pipe. The dishroom’s new design opens the space to an organized use of resources including an Energy Star Champion rack dish machine. Its unique single source closed-loop hot water system features an external gas booster and an automatic load Bi-Line EZ rack with rolling conveyors. The design team included corporate contact Linda Conti, director of purchasing services, (Matt Carlisle, Director of Physical Plant, Manor House, Michael Stempkowski, Principal, NEMA, (ask mike for NEFA names) Singer and Meech (sp?) Engineers, Kramer+Marks Architects and mechanical engineering from McHugh Engineering, Inc. “We spent a lot of time upfront planning the project so that everything would flow and fit into place during the actual installation,” says Carlisle. “We asked for the best and longest lasting equipment in the industry. Our company had used Champion and Bi-Line in several other locations. Knowing the amount of flexibility available in the design and knowing what we wanted, plus getting the right people involved, gave us the information and tools to get the job done.” The project planning began in 2010. The actual installation took place in six weeks and was completed in October 2012. Space constraints dictated that the new washroom would need to be kept within the existing kitchen footprint, which consisted of three distinct areas: the main area, a small room with several pieces of kitchen equipment and a small bake shop. The decision was made to redesign two adjacent small rooms into one highly functional dish washing area. The design also called for a new space for clean dish storage. The bake shop and remaining kitchen equipment that previously occupied the space were consolidated into the main area. Prior to the renovation, the foodservice staff manually scraped, rinsed and loaded dishes in separate areas of the kitchen which then had to be hand hauled to the dish loading station or the waste bins, causing excessive movement and traffic jams. Pots and pans did not have a dedicated area which meant staff needed to run them through the same dishmachine. The new kitchen features a dedicated pot and pan area and sink with a built-in built in agitator. With the flip of a switch, the agitator begins and clean pots emerge fifteen minutes later. The redesigned dishroom enables operators to receive trays, then scrap, sort, accumulate and load at one centralized location. In addition to easing kitchen traffic and eliminating hand-pushed racks, the new ergonomic setup keeps a steady flow to the dish machine. The centralized sorting table is equipped with two hang-down spray units. Now that staff can stay focused on scraping and stacking, dish racks are filled and then simply pushed onto the attached Bi-Line EZ slanted stainless steel roller conveyor. The conveyor consists of interlinked stainless steel rollers that turn in unison transporting dish racks directly into the dishwasher. The conveyor is gently sloped creating a gravity-induced advance of the filled dish racks from the work station to the Champion dish machine. Once the racks reach the machine, they are automatically loaded and washed. The new dish machine is a Champion 86 PW rack machine, capable of washing 277 racks per hour, more than doubling the old machine’s capacity. At the end of the wash cycle, a blower dries the dishes. The Energy Star rated Champion rack machine has additional energy saving features that reduce the overall costs of running and maintaining a dish machine. A gas booster is economical for heating water, but typically the high temperatures of the hot flame are destructive to the dish machine. Champion installed an external gas booster used to heat the metal coils inside the water tank. The coils, in turn, evenly heat the water to a certain temperature, saving the tank from exposure to an open flame. The old booster sat underneath the sorting table and was constantly splashed with water. The new booster sits one floor below the dish machine in the mechanical room where it is easy to access and the dish machine is still operable, even during routine maintenance of the booster. The new booster requires only one gas and one exhaust connection, eliminating the need for multiple connections. In addition to venting powerfully and silently to the outside, there is no longer steam rolling through the kitchen.” In the past, dish storage was decentralized and care had to be taken not to cross the clean dishes with incoming soiled dishes. The new set-up eliminates the possibility of cross over in two ways: first, by directing all soiled dishes into the central, enclosed location and second, by moving the loaded racks of soiled dishes in a sweeping curves that maximizes the available space and ends near the clean dishroom storage area. With the new system, the number of staff needed to operate the equipment and the number of times staff are required to touch the dishes has dropped. “We have probably cut restacking time by half,” says Carlisle. “One person can manage both ends of the wash system. The staff is definitely having a different and better experience.” At the West end of the new space is a dedicated pot and pan area that houses a new pot sink with a built-in agitator and multi garbage disposals. The electrical panel was upgraded and relocated to a new area. During the renovation, the new dish machine was added to an emergency generator so that operations can continue to run, even in the event of a power outage. Even the new drains were designed to travel a shorter length and are easily accessible. “We covered all the bases,” says Carlisle. “We got input from the staff and met with direct hands-on people as well and management within the culinary team and Michael Stempkowski at NEMA really helped us plan and build a good preventative maintenance program to keep our performance in place. We are very satisfied that we did it right the first time, plus all dishes look pretty and spotless. We freed up space, saved time and money and have no issues in the dishroom anymore.” Matt Carlisle Director of Physical Plant Methodist Manor House 302-628-5601 302-628-5647 fax mcarlisle@actslife.org my assistant Penny 302-628-5643